Understanding the essential components of outdoor power tools is crucial for effective maintenance and operation. This section aims to provide a comprehensive overview of the various elements that constitute the FS 56 RC model, which is known for its reliability and performance in lawn care tasks. Familiarity with these components can enhance users’ experience and ensure the longevity of the equipment.

Identifying each component plays a vital role in troubleshooting and repair. By recognizing how these parts interact, operators can quickly address any issues that may arise during use. Furthermore, being well-informed about the specific functions of each piece allows for better decision-making when it comes to replacements or upgrades.

In this exploration, we will delve into the intricate details of the individual elements that make up this efficient machine. By breaking down each part’s purpose and relevance, users will gain valuable insights into how to maintain their equipment effectively. An informed operator is an empowered operator, and understanding these components is the first step toward achieving optimal performance.

This section aims to provide a comprehensive overview of the various elements that make up the device, facilitating better understanding and maintenance. Knowing the different components will aid users in troubleshooting and enhancing the performance of their equipment.

Key Elements of the Device

Each component plays a crucial role in the overall functionality, ensuring optimal operation during use. Familiarity with these parts can lead to more efficient repairs and modifications.

Component Overview Table

| Component Name | Description |

|---|---|

| Engine | The core element responsible for power generation. |

| Fuel Tank | Holds the necessary fuel for operation. |

| Handle | Provides grip and control during usage. |

| Trimmer Head | Where the cutting line is attached for trimming. |

| Cutting Blade | Used for more heavy-duty cutting tasks. |

| Starter Mechanism | Initiates the engine for operation. |

| Throttle Trigger | Controls the engine speed and power. |

| Choke | Helps in starting the engine in cold conditions. |

| Air Filter | Prevents debris from entering the engine. |

| Exhaust System | Directs harmful gases away from the operator. |

| Protection Guard | Ensures safety during operation by shielding the user. |

| Vibration Dampeners | Reduces vibrations to enhance user comfort. |

Overview of Key Parts

This section provides an overview of the essential components that contribute to the functionality and performance of the equipment. Understanding these elements is crucial for effective maintenance and operation, ensuring longevity and efficiency in use.

Main Components

- Engine: The heart of the machine, responsible for power generation.

- Fuel System: Facilitates the delivery of the necessary fuel to the engine.

- Cutting Head: Engages in the primary task of trimming or cutting vegetation.

- Handle: Provides a grip for maneuvering and controlling the device.

Supportive Elements

- Throttle Control: Allows for the regulation of engine speed and power output.

- Starting Mechanism: Initiates engine operation, enabling the tool to begin functioning.

- Guard: Ensures safety by protecting the user from debris and potential hazards.

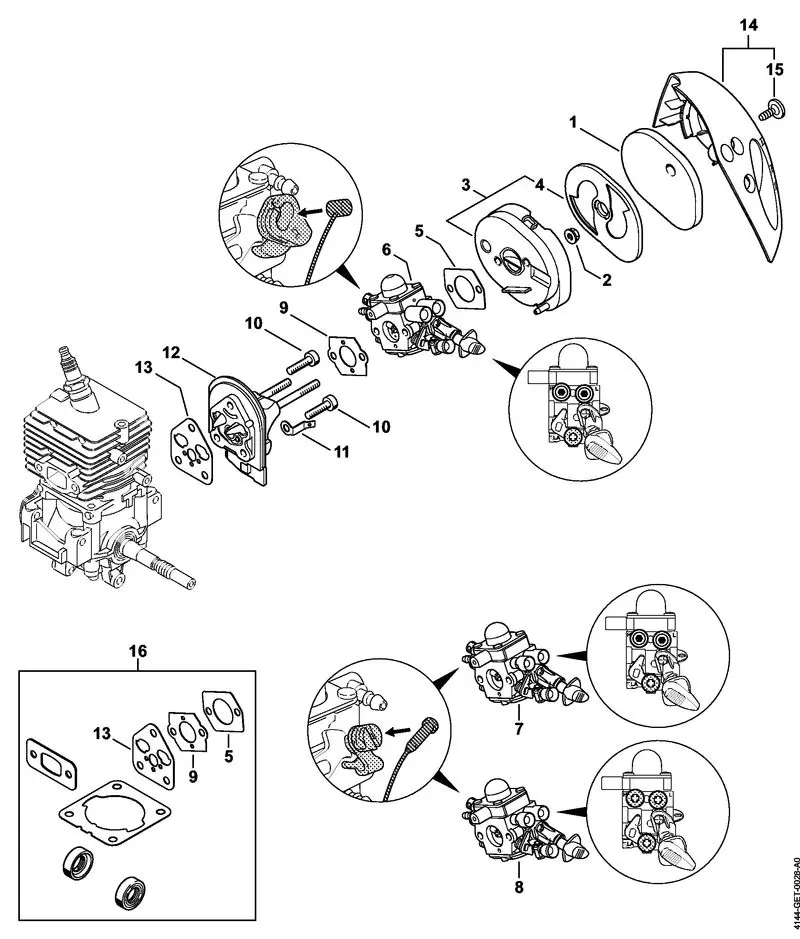

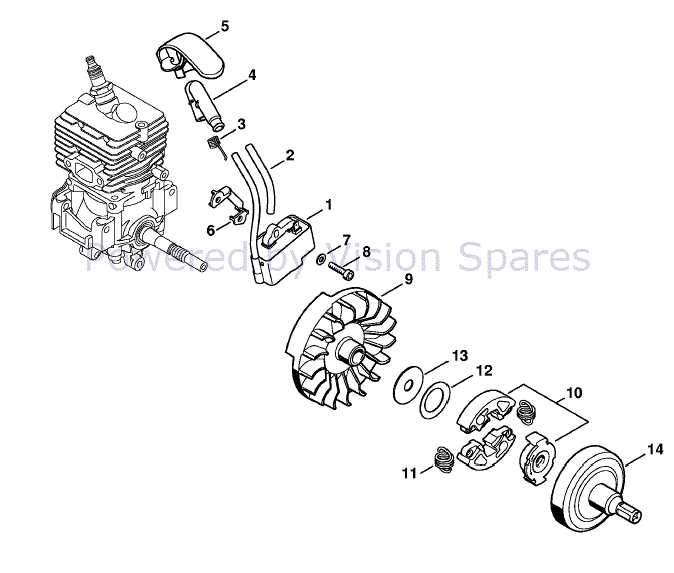

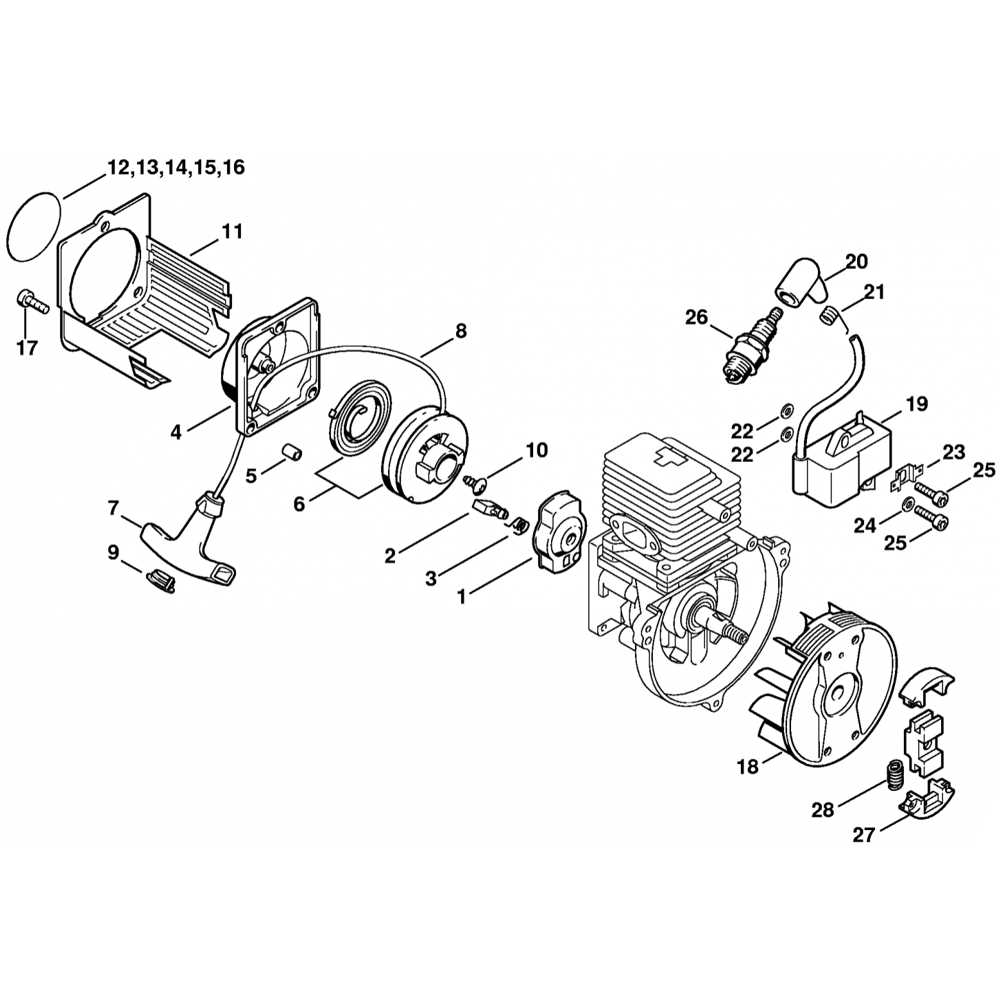

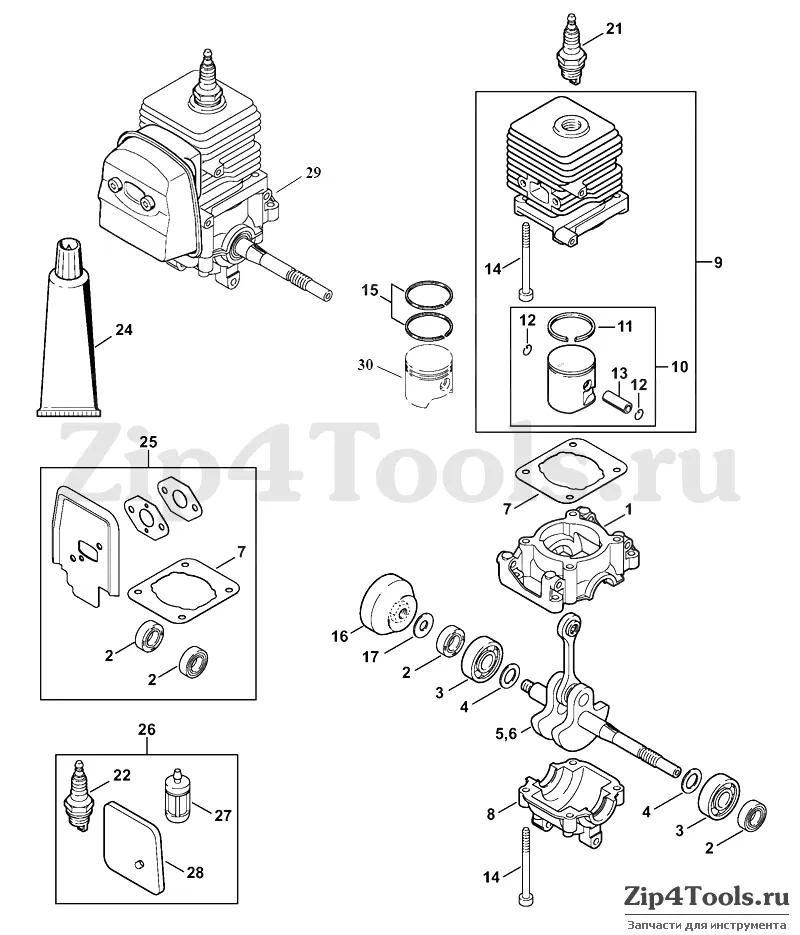

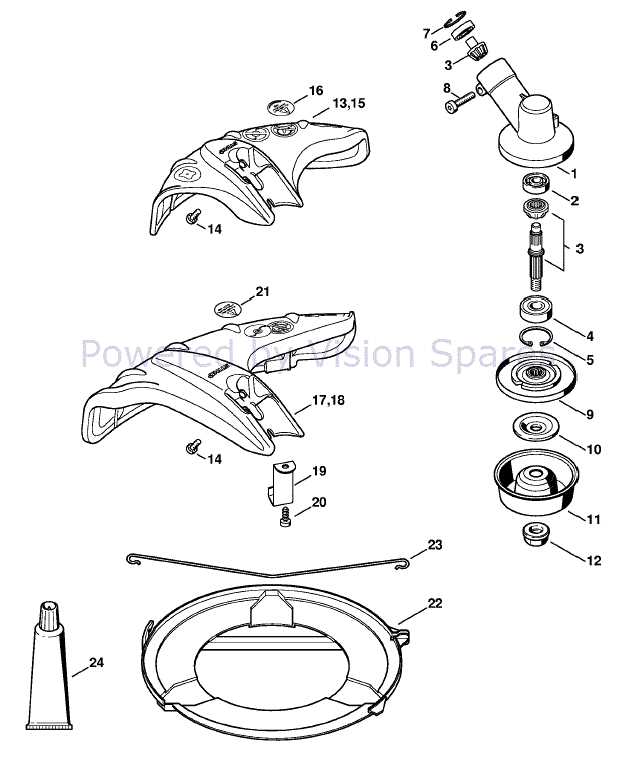

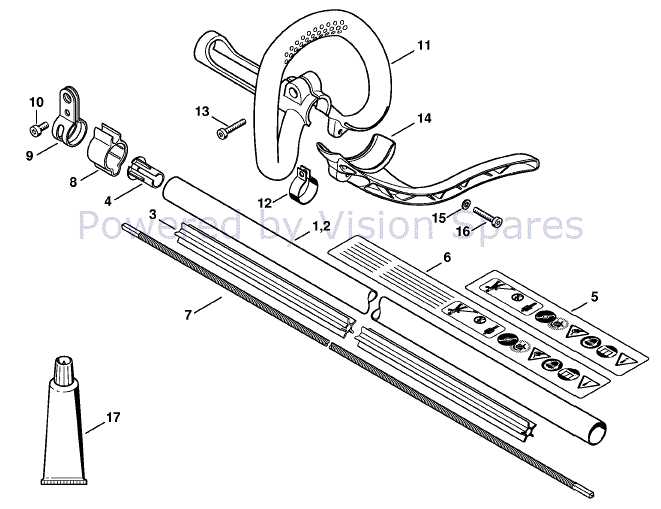

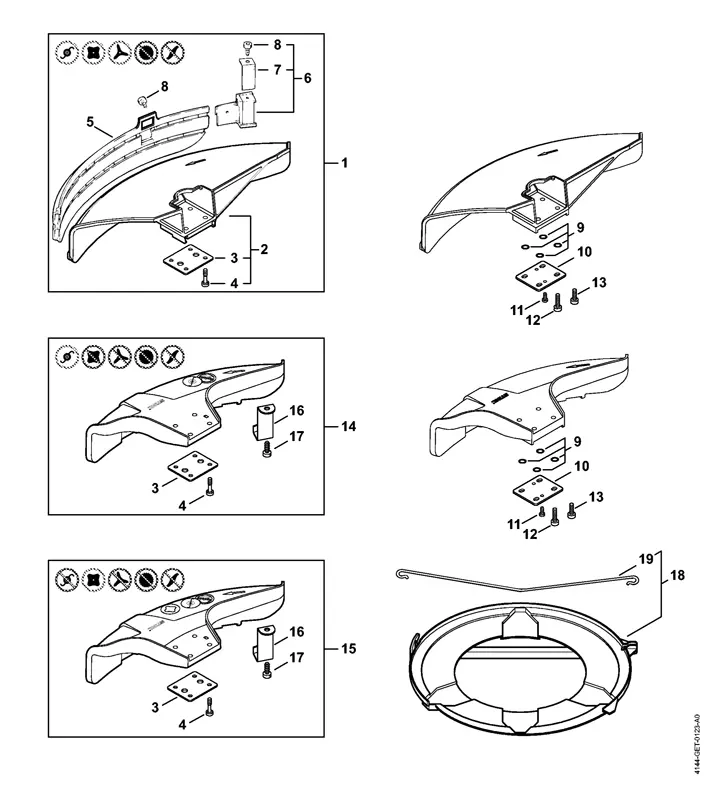

Importance of a Parts Diagram

A visual representation of components within a machine plays a crucial role in maintenance and repair processes. Understanding how each element fits together can significantly simplify troubleshooting and enhance the efficiency of repairs.

Benefits of Understanding Component Layout

- Facilitates quick identification of individual elements.

- Improves the accuracy of reassembly after repairs.

- Assists in recognizing missing or damaged components.

- Streamlines communication between technicians and users.

Enhancing Repair Skills

- Encourages a systematic approach to maintenance tasks.

- Fosters a deeper understanding of machine operation.

- Promotes confidence in performing repairs independently.

Incorporating a visual guide into the maintenance routine not only simplifies the process but also empowers users to take charge of their equipment’s longevity.

Identifying Replacement Components

When maintaining outdoor power equipment, understanding how to recognize and source essential components is crucial for optimal performance. This process involves familiarizing oneself with various elements that contribute to the machine’s functionality. Being knowledgeable about these parts can ensure seamless operation and longevity of the equipment.

Common Component Types

Replacement items typically fall into several categories, including those related to the engine, cutting apparatus, and control mechanisms. Engine components often include filters, spark plugs, and gaskets, while the cutting apparatus may involve blades, trimmers, and other attachments. Control mechanisms can consist of throttle controls and ignition switches, all of which are vital for smooth operation.

Sourcing Quality Components

Acquiring high-quality replacement items is essential for maintaining equipment efficiency. Consider purchasing from authorized dealers or reputable online platforms to ensure compatibility and reliability. Checking product reviews and consulting with professionals can also aid in making informed choices when selecting components.

Common Issues with Each Part

Every component of a machine can encounter specific challenges that may affect its performance. Understanding these common issues can help in troubleshooting and maintaining the equipment effectively.

Engine and Fuel System

- Starting Difficulties: The engine may fail to start due to a clogged fuel filter or stale fuel.

- Overheating: Insufficient cooling due to debris blocking the air intake can cause overheating.

- Fuel Leaks: Damaged fuel lines can lead to leaks, posing safety hazards.

Cutting Head and Blades

- Worn Blades: Dull or damaged blades can reduce cutting efficiency and require frequent replacements.

- Line Feed Problems: The line may not feed correctly if the spool is incorrectly loaded or the tension is off.

- Vibration Issues: Excessive vibrations during operation may indicate imbalanced or loose components.

How to Access the Diagram

Obtaining a visual representation of the assembly can be essential for effective maintenance and repair. This section provides guidance on where to locate the necessary illustrations that can aid in understanding the components and their arrangement.

Online Resources

Various online platforms offer comprehensive resources, including user manuals and detailed illustrations. Websites dedicated to equipment maintenance often feature downloadable guides that include clear visuals, making it easier to comprehend the layout of the system.

Local Dealers

Your local dealer or service center is another reliable source for accessing visual aids. These professionals can provide printed materials or direct you to online portals where you can find the required resources tailored to your specific model.

Maintenance Tips for Longevity

Proper upkeep is essential for extending the lifespan of your outdoor equipment. By following a few simple guidelines, you can ensure optimal performance and reliability for years to come.

- Regular Cleaning: After each use, clean the exterior to remove dirt and debris. Pay special attention to the air filter and cooling fins.

- Check Fuel Quality: Use fresh fuel to prevent engine issues. Stale fuel can lead to poor performance and potential damage.

- Inspect Blades and Cutting Tools: Ensure that blades are sharp and in good condition. Dull blades can strain the engine and reduce efficiency.

In addition to these practices, consider the following recommendations:

- Routine Inspections: Periodically check all components for wear and tear. Replace any damaged parts promptly to avoid further issues.

- Proper Storage: Store your equipment in a dry, protected area when not in use. This helps prevent rust and other environmental damage.

- Follow Manufacturer Guidelines: Adhere to the maintenance schedule provided in the user manual to keep your equipment running smoothly.

By implementing these maintenance strategies, you can enhance the durability and efficiency of your equipment, ensuring it remains a reliable tool for your outdoor tasks.

Tools Needed for Repairs

When undertaking maintenance tasks, having the right tools is essential for ensuring effective repairs. Proper equipment not only enhances efficiency but also helps prevent potential damage during the process. Below is a list of recommended tools that can assist in performing various repair activities.

| Tool | Description |

|---|---|

| Wrench Set | Essential for loosening and tightening nuts and bolts. |

| Screwdriver Set | Useful for removing and securing screws in various components. |

| Plier | Great for gripping and manipulating small parts. |

| Socket Set | Facilitates quick adjustments in tight spaces. |

| Torque Wrench | Helps ensure that screws and bolts are tightened to the specified tension. |

| Multimeter | Essential for diagnosing electrical issues and ensuring proper functionality. |

Step-by-Step Assembly Instructions

Assembling your equipment correctly is crucial for optimal performance and safety. Following a systematic approach will ensure that every component fits together seamlessly, allowing for efficient operation. This guide provides clear, detailed steps to help you through the assembly process with ease.

Preparation Before Assembly

Before starting, gather all necessary tools and components. Ensure that your workspace is clean and organized to avoid any missing parts. Review the components to familiarize yourself with each piece and its function. Having a checklist can be beneficial for tracking progress.

Assembly Process

Begin the assembly by attaching the main body to the handle. Secure all screws tightly but avoid over-tightening, which may cause damage. Next, connect the cutting head to the main shaft, ensuring a snug fit. If applicable, install any safety guards and check their placement for proper protection during operation. Finally, conduct a thorough inspection of the assembled unit, confirming that all parts are secure and positioned correctly.

Tip: Always refer to the manufacturer’s guidelines for specific instructions regarding your model, as each unit may have unique features.

Where to Find Authentic Parts

Locating genuine components for your equipment is essential to ensure optimal performance and longevity. Whether you are a professional or a casual user, sourcing high-quality replacements can significantly impact the effectiveness of your tool. It is crucial to choose reputable sources that guarantee the authenticity and reliability of the items you purchase.

One of the most reliable options is to visit authorized dealers who specialize in your brand. These dealers typically carry a comprehensive inventory of original components and can offer expert advice on the best options for your specific model. Additionally, many manufacturers have online stores where you can browse and order the necessary items directly from the source.

Another avenue to explore is local repair shops that focus on maintenance and servicing of equipment. These establishments often stock authentic components and can provide installation services, ensuring everything fits and functions correctly. Furthermore, online marketplaces can be a valuable resource, but it is essential to verify the seller’s credibility and ensure that the items listed are original and not replicas.

Comparing OEM and Aftermarket Options

When it comes to selecting components for your equipment, understanding the differences between original and alternative options is essential. This section explores the advantages and disadvantages of both categories, providing insights to help you make an informed choice.

Quality and Performance

Original components are typically manufactured by the brand itself, ensuring compatibility and reliability. In contrast, alternative options may vary significantly in quality, with some offering comparable performance while others might fall short. Evaluating the specific requirements of your equipment can guide you in selecting the best choice.

Cost Considerations

While original components often come with a higher price tag, they usually guarantee longevity and efficiency. Alternative options tend to be more affordable, but the trade-off may include reduced durability or performance. Analyzing your budget and the long-term benefits can influence your decision effectively.

| Aspect | OEM | Aftermarket |

|---|---|---|

| Quality | High reliability and compatibility | Varies, some can be high quality |

| Cost | Generally more expensive | Typically lower cost |

| Availability | Readily available through authorized dealers | Widely available, but quality can vary |

| Warranty | Often comes with a warranty | Warranty may vary or be absent |

Expert Advice for Troubleshooting

When facing issues with your outdoor equipment, understanding the common problems and their solutions can greatly enhance your experience. By applying systematic approaches to identify and resolve malfunctions, you can ensure efficient operation and prolong the life of your device.

Here are some key troubleshooting tips:

- Identify the Symptoms: Start by observing the specific issues your equipment exhibits. This could include unusual noises, vibrations, or performance lags.

- Check the Fuel System: Ensure that the fuel used is fresh and clean. Stale or contaminated fuel can lead to starting difficulties and operational inefficiencies.

- Inspect the Air Filter: A clogged air filter restricts airflow and can affect performance. Regular cleaning or replacement is crucial for optimal functionality.

- Examine the Spark Plug: A worn or dirty spark plug can hinder ignition. Regular inspection and replacement can resolve starting problems.

- Look for Loose Connections: Ensure that all connections, including electrical components and fittings, are secure to avoid intermittent faults.

By following these guidelines and maintaining a proactive approach, you can troubleshoot effectively and keep your equipment running smoothly.

Frequently Asked Questions

This section aims to address common inquiries regarding maintenance and assembly for various outdoor equipment models. Here, we provide clarity on essential components, troubleshooting, and operational guidance to enhance user experience.

| Question | Answer |

|---|---|

| How do I identify the correct components for my equipment? | Refer to the manufacturer’s guidelines or product manual, which typically includes specifications for all necessary items. |

| What should I do if a part is missing? | Contact your local dealer or authorized service center for assistance in acquiring the necessary replacement. |

| How can I ensure proper installation of components? | Follow the assembly instructions provided in the manual carefully and use the recommended tools for optimal results. |

| Is there a way to troubleshoot common issues? | Yes, consulting the troubleshooting section of the user manual can help identify and resolve frequent problems. |

| Where can I find detailed operational guidance? | The user manual contains comprehensive operational instructions tailored for various tasks and conditions. |