In the realm of outdoor power equipment, familiarity with the various components of a brushcutter is essential for effective maintenance and troubleshooting. This understanding not only enhances operational efficiency but also contributes to the longevity of the machine. By exploring the key elements involved, users can gain insights into their functionality and interrelationships.

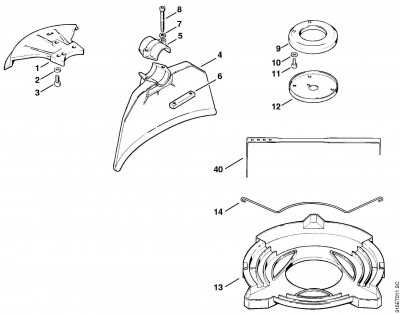

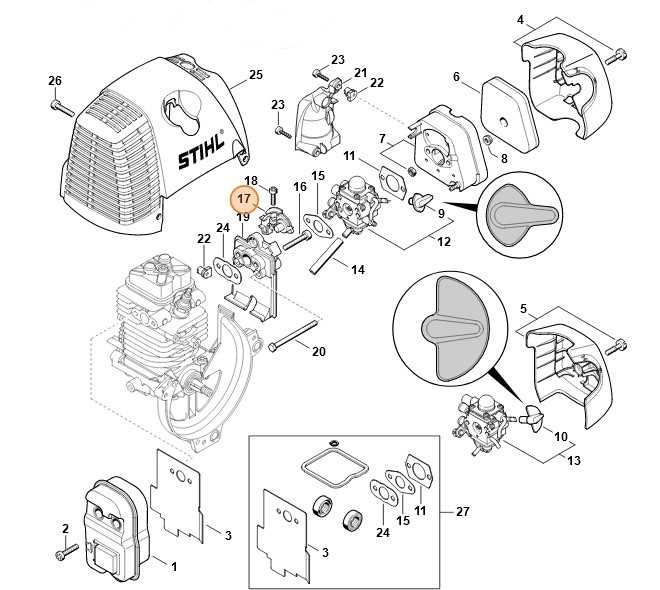

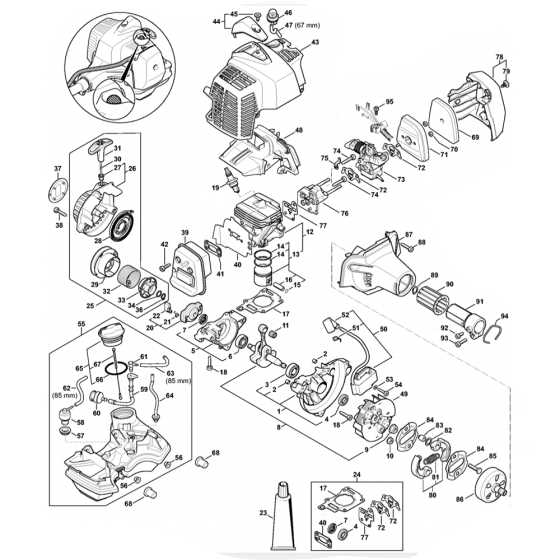

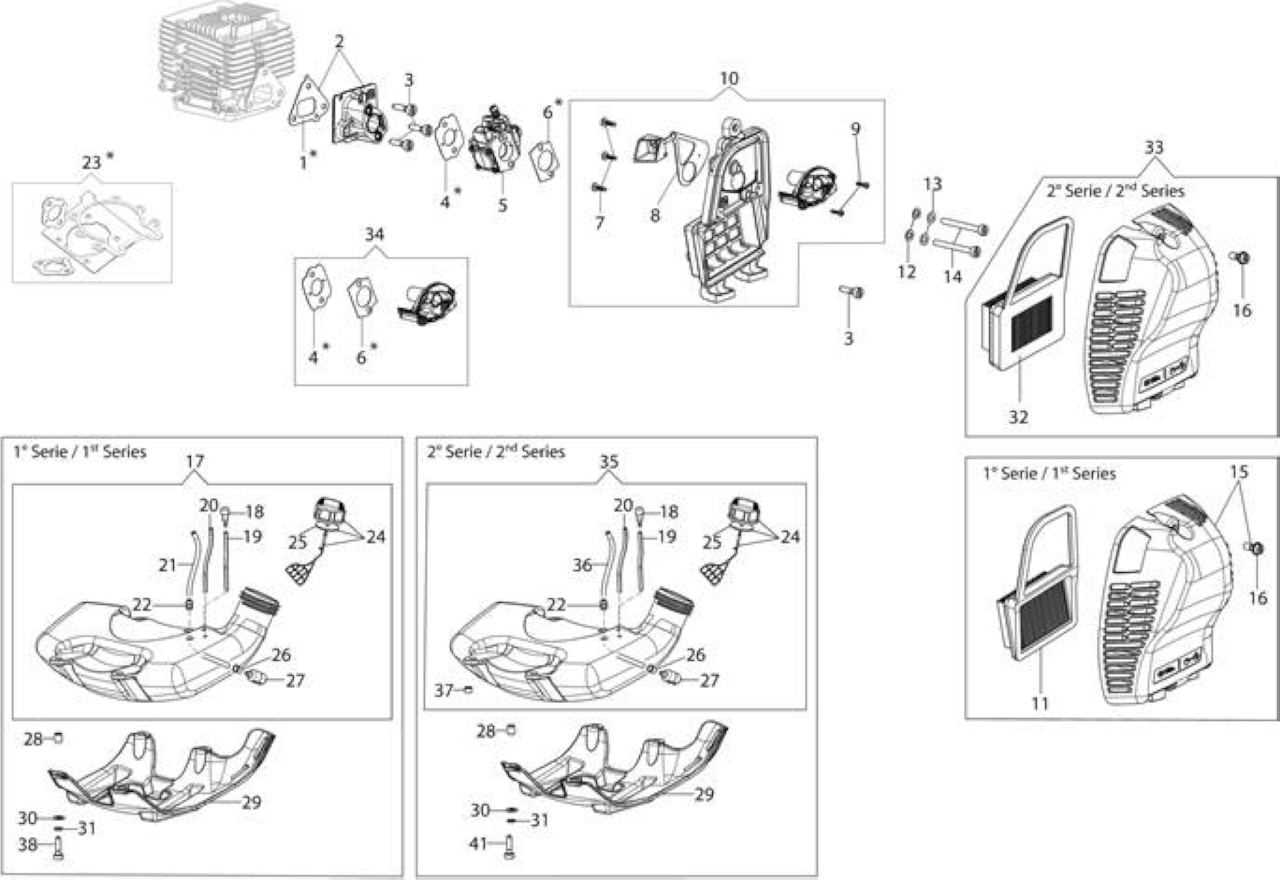

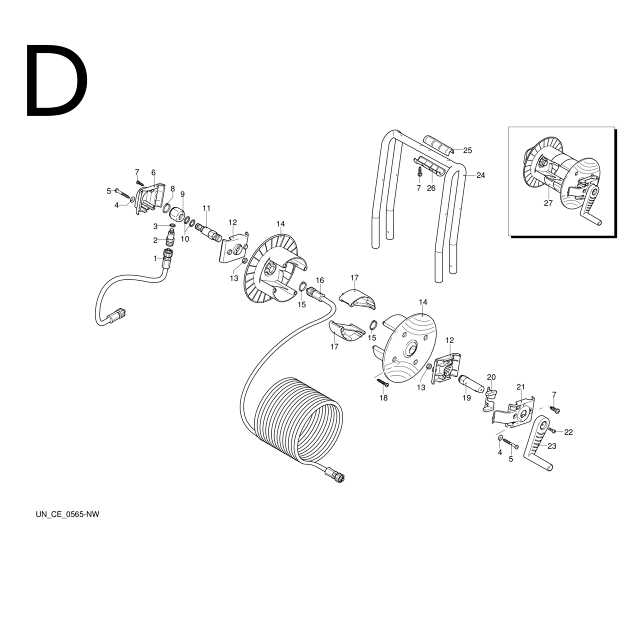

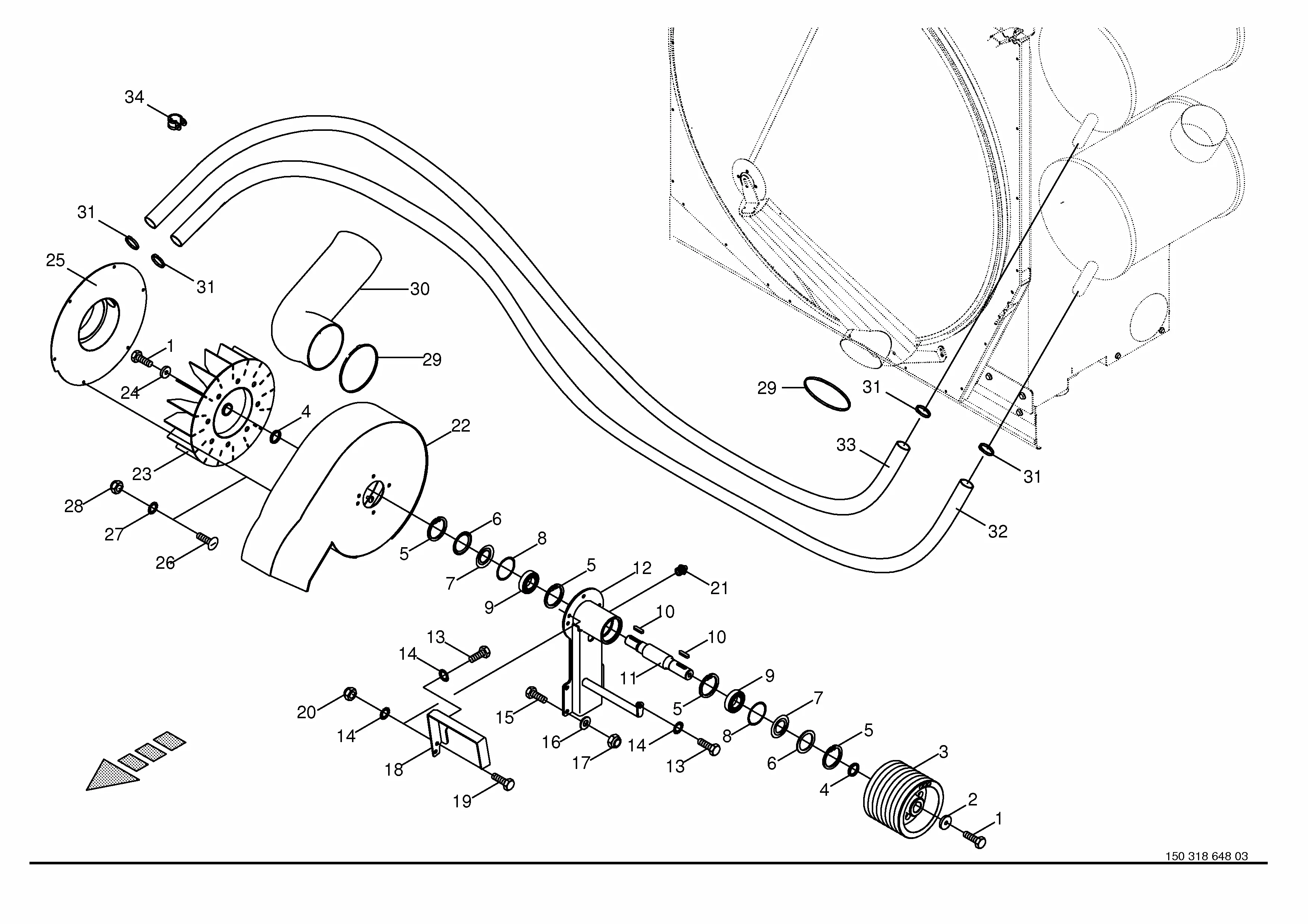

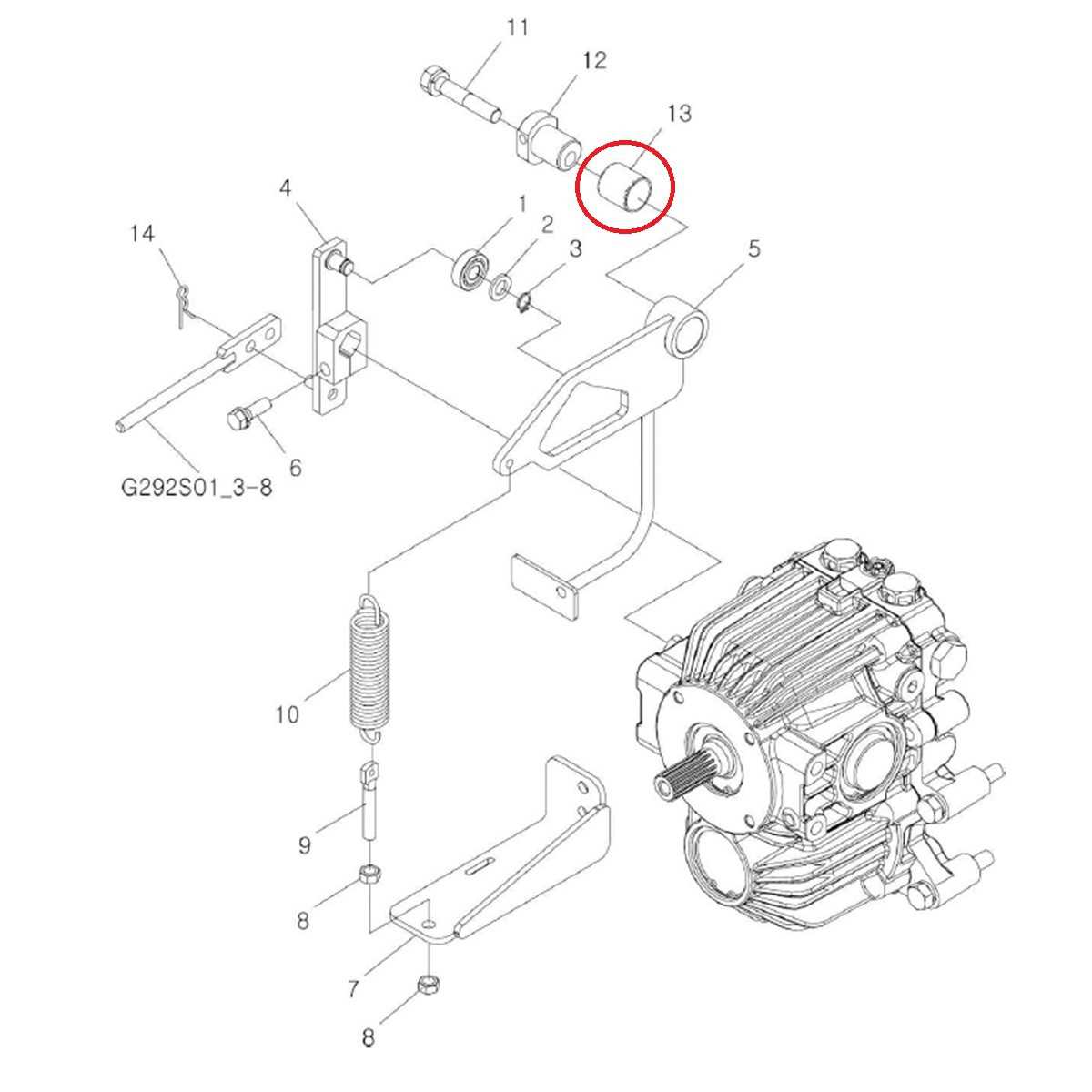

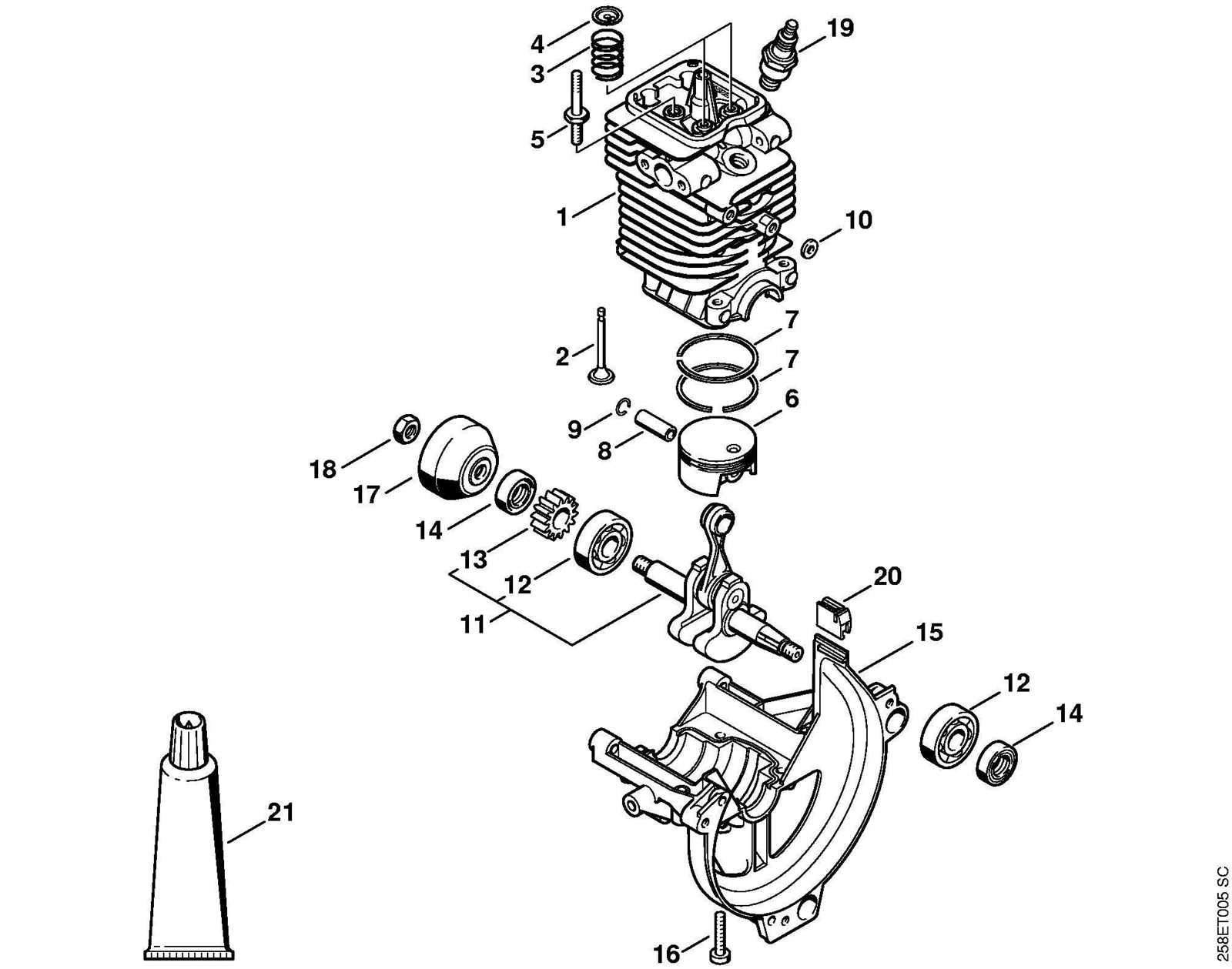

Visual aids play a crucial role in comprehending the assembly and arrangement of these elements. They provide a clear representation of how different parts work together, enabling users to identify specific components quickly. This knowledge can be invaluable when seeking replacements or performing repairs, ensuring that the equipment remains in optimal condition.

Moreover, being well-versed in the configuration of these tools empowers users to tackle any challenges that may arise during usage. Whether it involves routine maintenance or addressing unexpected issues, a comprehensive grasp of the brushcutter’s layout allows for more informed decisions and efficient problem-solving.

Understanding the primary components of a tool is essential for effective maintenance and repair. Each section plays a crucial role in the overall functionality, and recognizing these areas can greatly enhance the user’s ability to troubleshoot and service the equipment.

Essential Components Overview

- Engine Assembly: This section houses the motor, which is the heart of the equipment.

- Transmission System: Responsible for transferring power from the engine to the working parts.

- Cutter Head: The area where the cutting mechanism is located, critical for performance.

Exploring Individual Assemblies

- Ignition System: Facilitates the start-up process by igniting the fuel-air mixture.

- Fuel System: Includes components that store and deliver fuel to the engine efficiently.

- Handle and Control System: Provides the user with the means to operate and maneuver the tool.

By familiarizing oneself with these key sections, users can not only maintain their equipment more effectively but also extend its lifespan through informed care and attention.

Common Issues with Components

When using a power tool, various elements may encounter challenges that can affect performance and efficiency. Recognizing these common problems can help in timely maintenance and ensure smooth operation. Below are some frequent issues associated with essential components and their potential solutions.

Fuel System Concerns

- Fuel Contamination: Impurities in fuel can lead to clogged filters, affecting the tool’s ability to start and run smoothly.

- Incorrect Fuel Mixture: Using the wrong fuel-to-oil ratio can result in poor performance and possible damage to the engine.

- Blocked Fuel Lines: Debris or sediment can obstruct fuel flow, causing stalling or failure to start.

Ignition System Issues

- Faulty Spark Plug: Worn or dirty spark plugs can lead to misfires or difficulty in starting.

- Ignition Coil Failure: A malfunctioning ignition coil can prevent the engine from firing, resulting in no start conditions.

- Wiring Problems: Damaged or loose connections can disrupt electrical flow, causing inconsistent performance.

Maintenance Tips for Longevity

Regular upkeep is essential for ensuring the durability and optimal performance of your equipment. Implementing effective maintenance practices can significantly extend the lifespan of your tools while maintaining their efficiency. Below are some key recommendations to consider.

Routine Checks

- Inspect the device before each use to identify any signs of wear or damage.

- Ensure that all components are securely attached and functioning properly.

- Clean the exterior and any accessible parts to prevent debris buildup.

Lubrication and Storage

- Regularly apply suitable lubricants to moving parts to reduce friction.

- Store the equipment in a dry and sheltered location to protect it from environmental factors.

- Remove fuel and fluids if the equipment will not be used for an extended period.

Ordering Replacement Parts Efficiently

When it comes to maintaining your equipment, acquiring necessary components in a timely manner is crucial. Ensuring a smooth replacement process not only enhances the functionality of your tools but also extends their lifespan. Understanding how to streamline this process can save you both time and resources.

Identify the Required Components

Before making a purchase, it is essential to determine exactly which components are needed. Reviewing the user manual or consulting reliable sources can help clarify the specifications. This preparation prevents errors and ensures that you select the right items for your machinery.

Utilize Online Resources

Taking advantage of online platforms can significantly enhance the efficiency of your ordering process. Many websites offer detailed catalogs and allow users to search by model or type. Additionally, reading reviews and checking ratings can guide you in choosing reputable suppliers, ensuring the quality of the components you receive.

Tools Needed for Repairs

When undertaking maintenance or fixing equipment, having the right tools at your disposal is essential for achieving efficient and effective results. Proper preparation not only simplifies the repair process but also ensures that all components are handled correctly, minimizing the risk of damage.

Basic Hand Tools are the foundation for any repair task. A set of screwdrivers, pliers, and wrenches will help in disassembling and reassembling various parts. Having a variety of sizes ensures that you can tackle any fastener that may be encountered during the process.

Safety Equipment should never be overlooked. Gloves and protective eyewear are vital to shield yourself from potential hazards. This precaution helps maintain safety while working with sharp or moving components.

Cleaning Tools are also crucial for maintaining the longevity of the equipment. Brushes and cleaning solvents will assist in removing dirt and debris, allowing for a clearer view of the components that need attention.

Lastly, consider having a workbench or sturdy surface to facilitate a comfortable working environment. This will provide ample space for organizing tools and components, enabling a smoother workflow.

How to Read the Parts Diagram

Understanding a technical illustration is crucial for effective maintenance and repair of equipment. These visuals provide essential information about individual components, their arrangement, and how they interact within the system. Grasping this information can significantly enhance your ability to troubleshoot and service the machinery efficiently.

When interpreting these illustrations, consider the following points:

- Familiarize Yourself with Symbols: Each representation may use specific symbols to denote various parts. Understanding these can prevent confusion.

- Identify Component Groups: Often, parts are organized into groups based on their function. Recognizing these clusters can help you locate items quickly.

- Check Reference Numbers: Each element typically has a reference number that corresponds to a list or index. This can aid in identifying what each part is and its specifications.

- Observe Orientation: Pay attention to how components are oriented in the image. This can provide insights into how they fit together and their operational positions.

- Use a Legend: Many illustrations include a legend or key. Refer to this to clarify any uncertainties regarding symbols or reference numbers.

By following these guidelines, you can enhance your understanding of the technical illustration, allowing for more effective maintenance and repairs.

Frequently Asked Questions

This section addresses common inquiries related to the assembly and maintenance of outdoor power tools, aiming to provide clarity on various aspects users often ponder. Whether you are a novice or experienced operator, these questions will help enhance your understanding and ease your usage of equipment.

Common Inquiries

- What should I do if my tool does not start?

- How often should I perform maintenance checks?

- Where can I find suitable replacement components?

- What are the recommended safety precautions during operation?

Maintenance and Care

- Regularly clean the machine to prevent debris buildup.

- Inspect the fuel and oil levels before each use.

- Replace any worn or damaged components promptly to ensure optimal performance.

- Consult the user manual for specific maintenance schedules and guidelines.

Comparing Models in the Series

When exploring various models within a specific range, it is essential to recognize the differences and similarities that define their functionality and performance. Each variant is designed with unique features that cater to different user needs, making comparisons crucial for informed decision-making. This section highlights key aspects that set each model apart while emphasizing their common purpose.

Performance and Efficiency

One of the most significant factors to consider is the performance level of each model. Variations in engine capacity and power output can greatly affect operational efficiency. While some models may excel in handling tougher terrains, others are better suited for lighter tasks. Evaluating these aspects helps users select the most appropriate option for their intended applications.

Features and Usability

Different models may offer a range of features that enhance usability, such as weight, handle design, and ease of maintenance. Some options might incorporate advanced technologies aimed at improving user comfort and reducing fatigue during prolonged use. Understanding these features enables potential buyers to choose a model that aligns with their preferences and operational requirements.

Best Practices for Safe Use

When operating any type of outdoor power equipment, adhering to safety guidelines is crucial to prevent accidents and injuries. Proper preparation, equipment handling, and awareness of surroundings can significantly enhance user safety.

Before starting the equipment, always inspect it for any signs of damage or wear. Ensure that all components are functioning correctly and securely attached. This preliminary check can prevent malfunctions during use.

Wearing appropriate personal protective equipment (PPE) is essential. Items such as safety goggles, gloves, ear protection, and sturdy footwear can safeguard against potential hazards like debris or loud noise.

Maintain a clear work area free of obstacles, bystanders, and pets. This practice reduces the risk of distractions and ensures that the operator can focus entirely on the task at hand.

During operation, maintain a firm grip on the equipment and use both hands whenever possible. Stay alert to the surroundings and be aware of any changes in terrain or weather conditions that might affect safety.

Finally, always follow the manufacturer’s guidelines for usage and maintenance. Understanding the recommended practices and limitations of the equipment enhances safety and performance, ensuring a smooth and efficient operation.