The structure and arrangement of various elements in complex machinery play a critical role in its efficiency and maintenance. Understanding how these components interact with each other is key to ensuring smooth operation and prolonging the lifespan of the equipment.

When dealing with advanced machinery, it is crucial to have a clear reference to the layout of each element. This not only simplifies the process of maintenance but also assists in identifying potential issues before they become major problems. A well-organized schematic can save significant time and effort during troubleshooting.

Having access to a detailed breakdown of

Stihl FS450 Overview

The machine is a powerful tool designed for demanding outdoor tasks, commonly used for clearing, trimming, and cutting thick vegetation. Its high-performance engine ensures reliable operation even in tough conditions, making it a popular choice for professionals.

Durability and efficiency are key characteristics of this model, allowing it to handle both small-scale and large-scale projects with ease. The device’s ergonomic design provides user comfort during extended use, minimizing fatigue and enhancing productivity.

Thanks to its versatile capabilities, the tool is adaptable to various environments, providing excellent performance whether used in dense undergrowth or for general landscaping. Its advanced features make it suitable for professionals who require a reliable and robust machine for heavy-duty applications.

Key Features of Stihl FS450

This powerful brushcutter is designed to handle demanding tasks in various environments. It offers a range of capabilities that ensure efficiency and reliability, making it a top choice for users requiring high performance in tough conditions.

- Engine Power: Equipped with a robust engine that delivers exceptional cutting power, allowing it to handle thick vegetation with ease.

- Durability: Built with high-quality materials, it withstands extensive use and tough environmental conditions, ensuring long-lasting performance.

- Ergonomic Design: The machine is designed with user comfort in mind, featuring adjustable handles and a harness for reducing strain during prolonged usage.

- Versatility: Suitable for various applications, from clearing dense undergrowth to maintaining large areas of land.

- Easy Maintenance:

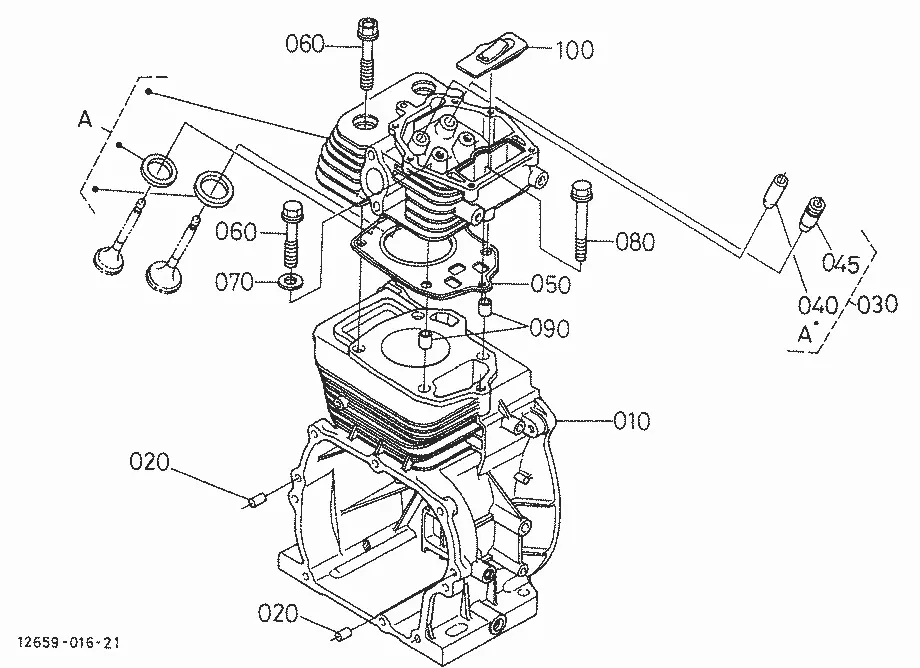

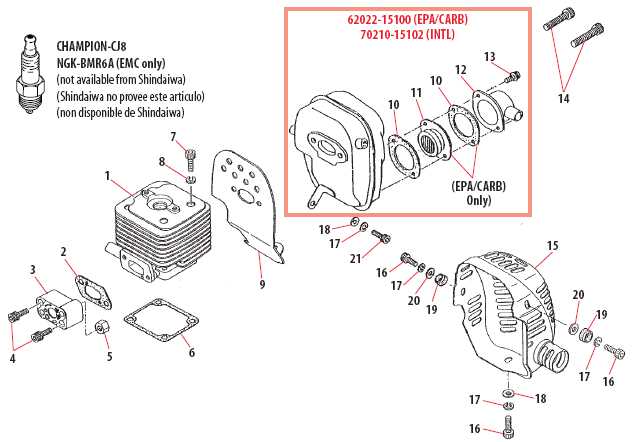

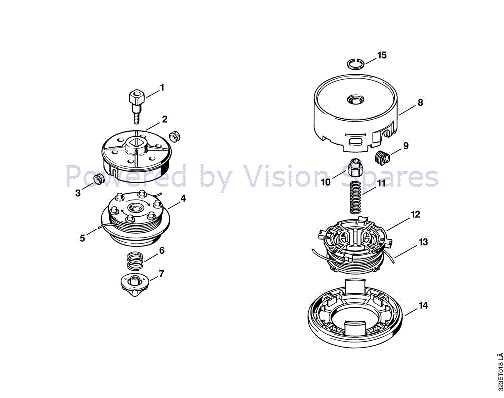

Understanding Parts and Components

To ensure efficient operation, it’s crucial to understand the various elements that make up the equipment. Each component plays a key role in ensuring optimal functionality, and recognizing how they interact can prevent breakdowns and prolong the machine’s lifespan. Regular maintenance and awareness of the structure will also help identify potential issues early.

Engine Assembly: This core section powers the device and includes several interconnected mechanisms. Proper upkeep of the engine ensures continuous and reliable operation.

Cutting Mechanism: The system responsible for cutting relies on precise parts working together seamlessly. Ensuring that each section is well-maintained guarantees a clean and efficient cutting process.

Handle and Controls: The operator’s ability to control the machine depends heavily on the ergonomic design and functionality of the control elements. Keeping these in good condition ensures safety and ease of use during operation

Importance of Using Genuine Parts

When it comes to maintaining equipment, the quality of the components used is crucial for performance and durability. Using authentic components ensures the machinery operates efficiently, preventing unnecessary wear and extending the lifespan of the tool. It is vital to rely on original elements specifically designed for the device to maintain safety and optimal function.

Benefits of Authentic Components

By choosing genuine components, users can expect better compatibility and overall efficiency. These elements are tailored to meet the exact specifications of the equipment, reducing the risk of breakdowns and ensuring smoother operation.

Advantages Description Longevity Original components are built to last longer and reduce the need for frequent replacements. Common Issues with FS450 Model

The machine often encounters certain problems that may affect its performance and reliability over time. Regular usage and environmental factors contribute to the occurrence of these issues. Proper maintenance can help mitigate some of the more frequent concerns.

Engine Overheating: One of the more typical issues is the motor running too hot, which can be caused by inadequate cooling or blocked air filters. Regularly checking and cleaning the air intake can prevent this.

Fuel System Problems: Inefficient fuel delivery or contamination in the fuel can lead to poor engine performance. Ensure that fuel lines and the fuel filter are inspected regularly to avoid clogging.

Vibration: Excessive shaking during operation may indicate worn-out components, such as the clutch or drive shaft. Addressing this promptly by replacing faulty parts can

Maintaining Your Stihl FS450

Regular upkeep of your equipment ensures longevity and efficient operation. By following a consistent maintenance schedule, you can prevent common issues, extend the life of your tool, and maintain its top performance.

Key Maintenance Tasks

- Check and clean the air filter to ensure proper airflow and prevent engine strain.

- Inspect the spark plug for wear and replace it as necessary to maintain smooth ignition.

- Examine the fuel system for leaks or blockages, ensuring consistent fuel delivery.

- Regularly lubricate moving parts to prevent friction and reduce wear over time.

Blade and Cutting Head Care

- Sharpen the cutting blades periodically to maintain optimal cutting efficiency.

- Ensure the cutting head is free of debris and secure to prevent imbalance during operation.

- Replace worn blades or strings to avoid reduced

Step-by-Step Repair Guide

This section provides detailed instructions for resolving common issues with a heavy-duty cutting tool. The guide is structured to help you identify malfunctioning components, replace worn-out elements, and perform basic maintenance tasks to ensure optimal performance.

1. Inspect the Components

Start by examining all essential parts. Look for signs of wear, damage, or debris that may affect functionality. Clean the components to remove any buildup that could hinder operation.2. Disassemble the Unit

Carefully take apart the necessary sections, ensuring each piece is handled with care to avoid further damage. Keep track of small components, such as screws or fasteners, by organizing them properly.3. Replace Worn Elements

Identify which elements need to be replaced. Use compatible spare parts for the best results. Ensure all connections are secure before proceeding toTools Needed for Repairs

When working on outdoor machinery, having the right set of equipment is crucial for efficient and safe repairs. Without the appropriate instruments, even minor fixes can become more complicated and time-consuming.

Basic maintenance often requires simple tools such as screwdrivers, pliers, and wrenches. For more advanced tasks, a torque wrench and specific socket sets might be necessary to handle fasteners properly.

Additionally, specialized devices like a spark plug wrench, an air filter cleaner, and a fuel line remover

Finding Replacement Parts Online

When it’s time to replace specific components of your equipment, the internet can be a valuable resource. Many platforms provide access to a wide range of products suited for your needs, offering both original and compatible options. By knowing what you need and how to search effectively, you can quickly find the correct solutions for your equipment.

Search by Model Number

The most effective way to locate the correct item is by using the model number of your machine. This ensures you are presented with options tailored specifically to the version of your equipment. Inputting this number in search engines or on trusted online stores can yield the most accurate results.

Check Reviews and Compatibility

Before making a purchase, it’s important to verify compatibility with your machine. Reading reviews from other users can provide valuable insights into the performance and reliability of the replacement options. This will help you make an informed decision

Comparing FS450 with Other Models

This section explores the differences and similarities between a specific model of brush cutter and its counterparts in the market. By examining various aspects such as performance, features, and usability, users can make informed decisions about which model best suits their needs.

When comparing this model to others, it becomes evident that there are notable distinctions in engine power and efficiency. Some alternatives may offer lighter weights, making them more suitable for prolonged use without fatigue, while others may emphasize additional features that enhance functionality for specific tasks.

Furthermore, the ease of maintenance varies among different models. Some designs incorporate user-friendly mechanisms that simplify repairs and part replacements, while others might require more technical know-how. Understanding these factors can significantly impact the long-term satisfaction and productivity of users.

Lastly, considering the overall cost-effectiveness is crucial. While one model may have a higher initial price, its durability and performance could lead to lower operational costs over time compared to cheaper alternatives that may not withstand heavy use.

User Reviews and Feedback

This section highlights the experiences and opinions of users regarding a specific model of outdoor equipment. By examining various reviews, potential buyers can gain insight into performance, durability, and overall satisfaction.

Many users have shared their thoughts on the functionality and reliability of this equipment. Here are some common themes from their feedback:

- Performance: Users often praise the efficiency and power of the tool, noting how well it handles tough tasks.

- Ease of Use: Feedback frequently mentions the user-friendly design, making it accessible for both beginners and experienced users.

- Durability: Several reviewers emphasize the sturdy construction and long-lasting components, which contribute to a worthwhile investment.

- Maintenance: Users appreciate the straightforward maintenance process, which helps in prolonging the equipment’s lifespan.

Overall, the reviews indicate a strong satisfaction among users, highlighting the balance between performance and usability. This feedback serves as a valuable resource for anyone considering this model for their outdoor projects.

Safety Precautions When Using FS450

When operating machinery, it is essential to prioritize safety to prevent accidents and injuries. Proper handling and understanding of the equipment can significantly reduce the risk associated with its use. Familiarizing oneself with safety guidelines and recommended practices is crucial for a secure working environment.

Personal Protective Equipment

Wearing appropriate personal protective gear is vital when engaging with outdoor equipment. This includes helmets, gloves, eye protection, and sturdy footwear. These items help safeguard against potential hazards such as flying debris and accidental contact with moving parts.

Operational Guidelines

Before starting the machine, ensure that all safety features are functioning correctly. Always read the user manual to understand the specific requirements and instructions. Maintain a clear workspace, and be aware of your surroundings to avoid potential accidents while operating the equipment.

Resources for Further Learning

Exploring additional materials can significantly enhance your understanding and proficiency in using various outdoor equipment. By engaging with diverse resources, you can gain insights into maintenance, troubleshooting, and operational techniques that will ensure optimal performance.

Online Forums and Communities

Participating in online discussions and communities dedicated to outdoor machinery allows users to share experiences, tips, and solutions to common challenges. These platforms can provide valuable knowledge and foster connections with fellow enthusiasts.

Instructional Videos and Tutorials

Visual learning through video tutorials can be particularly effective. Many experts and enthusiasts create content demonstrating specific tasks, from basic maintenance to advanced repairs. Watching these videos can help reinforce your skills and provide practical demonstrations.