When maintaining outdoor machinery, a thorough understanding of its elements is essential for optimal performance and longevity. This section explores the intricate structure of a particular model, offering insights into its individual components and their functions. By familiarizing yourself with these parts, you can ensure better care and efficient operation.

Identifying each element not only aids in repairs but also enhances your overall grasp of how the equipment operates. Knowing the various sections will empower users to tackle any issues that may arise during usage. Additionally, it can facilitate smoother maintenance procedures, allowing for a more seamless experience.

In summary, exploring the various sections of your machinery equips you with the necessary knowledge to handle challenges effectively. By understanding how each component works together, you can enhance your skills and extend the lifespan of your equipment.

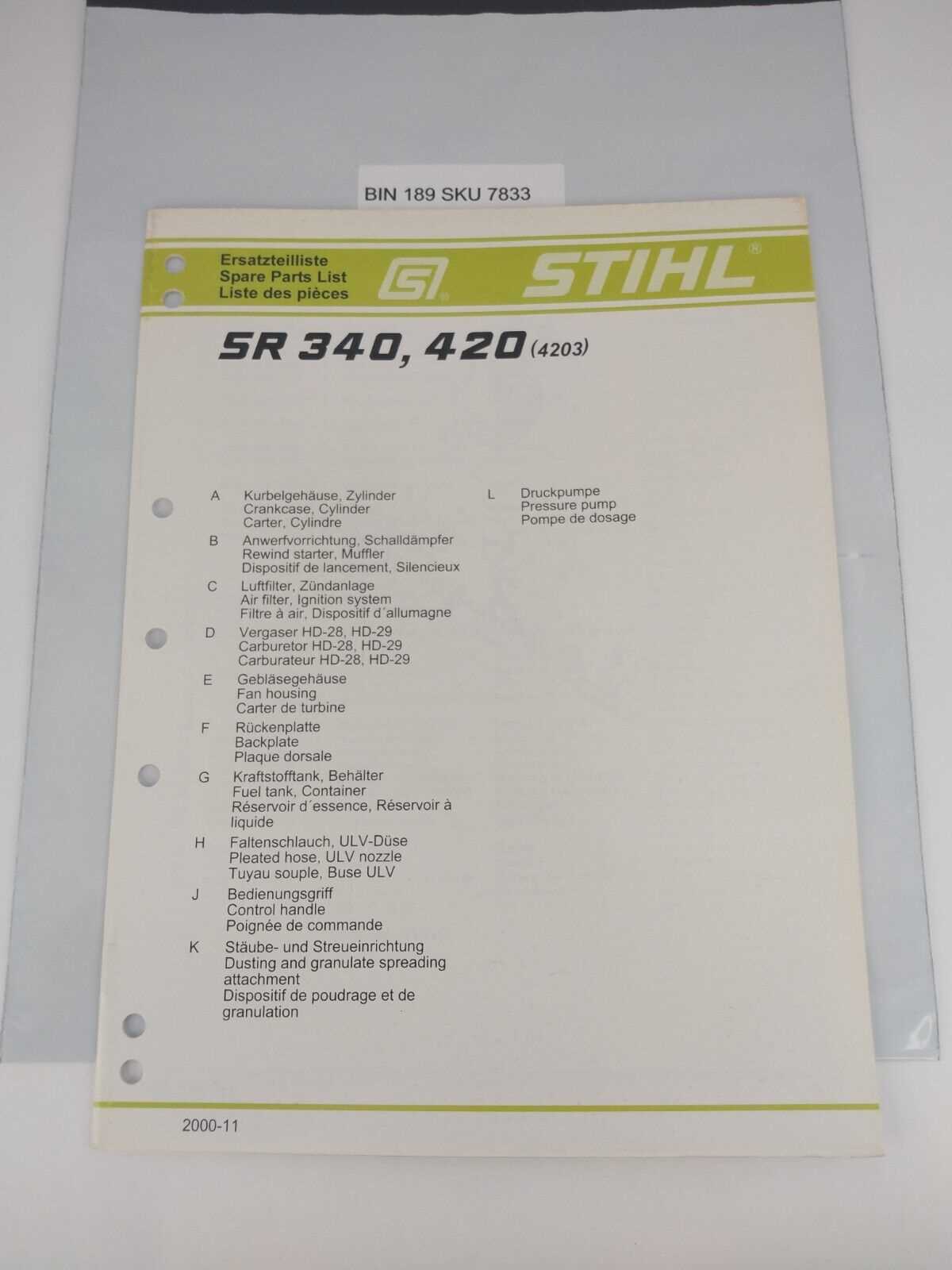

This section provides a comprehensive look at a specific model of outdoor equipment. Understanding its components is essential for effective maintenance and repair. Familiarity with the various parts can enhance the user experience and ensure optimal performance.

Key Features

- Robust engine for efficient operation

- Lightweight design for easy handling

- Versatile attachments for diverse tasks

Maintenance Tips

- Regularly check and clean the air filter.

- Inspect the cutting head for wear and replace if necessary.

- Ensure proper fuel mix to maintain engine health.

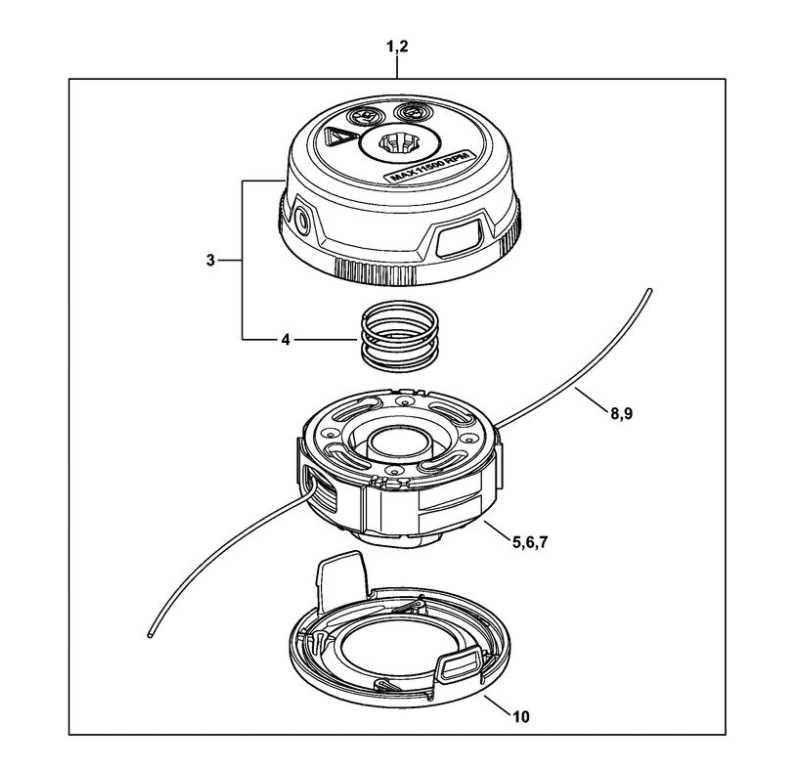

Importance of Parts Diagram

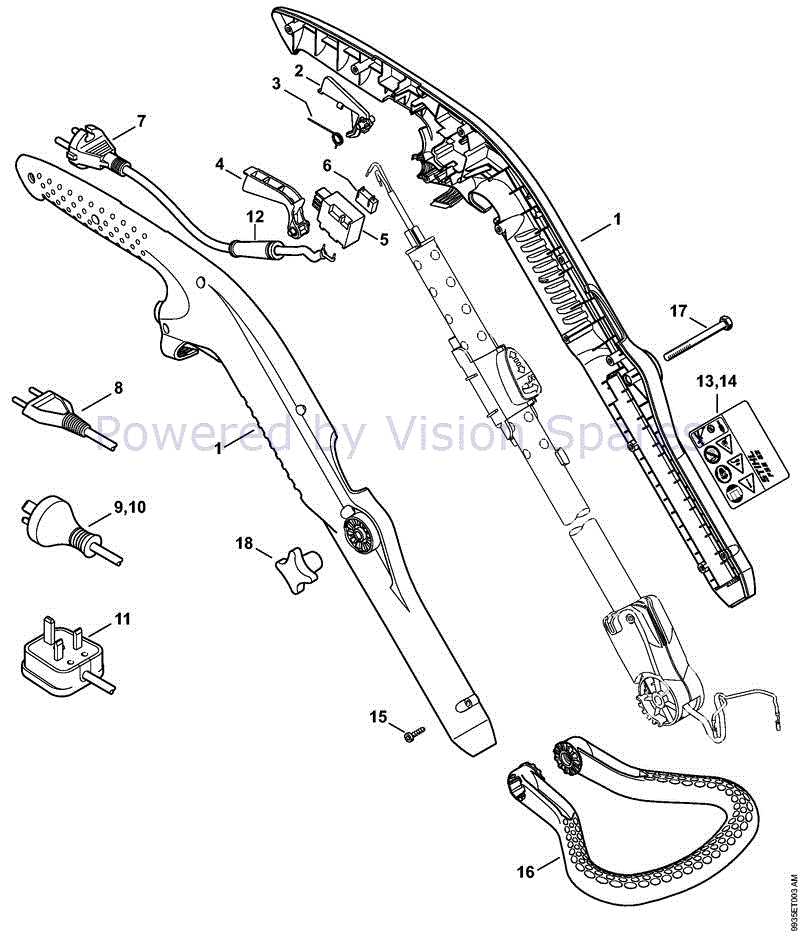

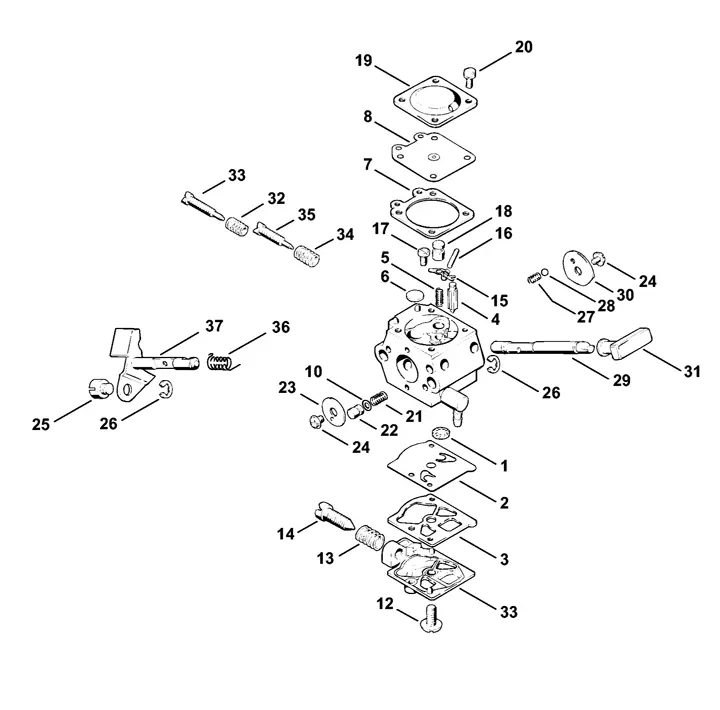

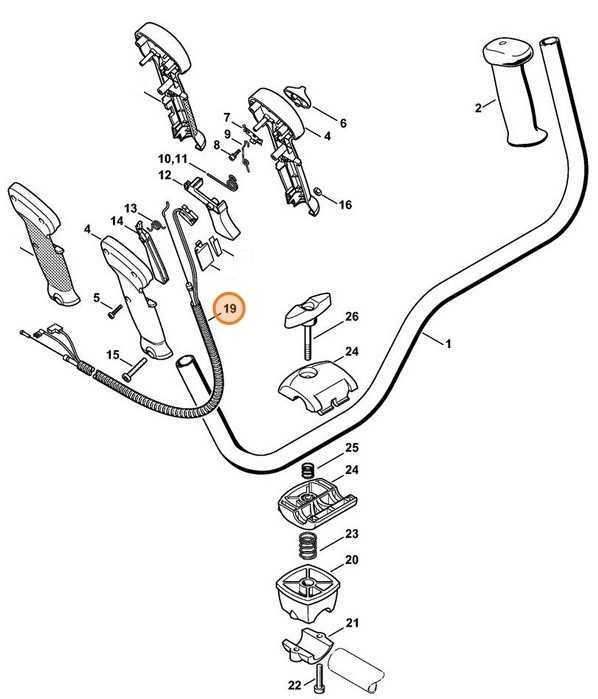

Understanding the layout and function of various components in machinery is crucial for effective maintenance and repair. A visual representation helps users identify each element’s role, facilitating smoother troubleshooting and assembly processes.

Enhancing Efficiency

Utilizing a visual reference can significantly improve repair efficiency. Users can:

- Quickly locate specific components.

- Reduce the risk of errors during reassembly.

- Save time in the maintenance process.

Facilitating Learning

A clear visual guide aids in the learning process for both novices and experienced operators. Benefits include:

- Better comprehension of machinery operation.

- Increased confidence in performing repairs.

- Empowerment to tackle complex issues independently.

Main Components of FS52

This section explores the essential elements that contribute to the functionality and performance of a particular outdoor power tool. Understanding these key components is crucial for effective maintenance and operation.

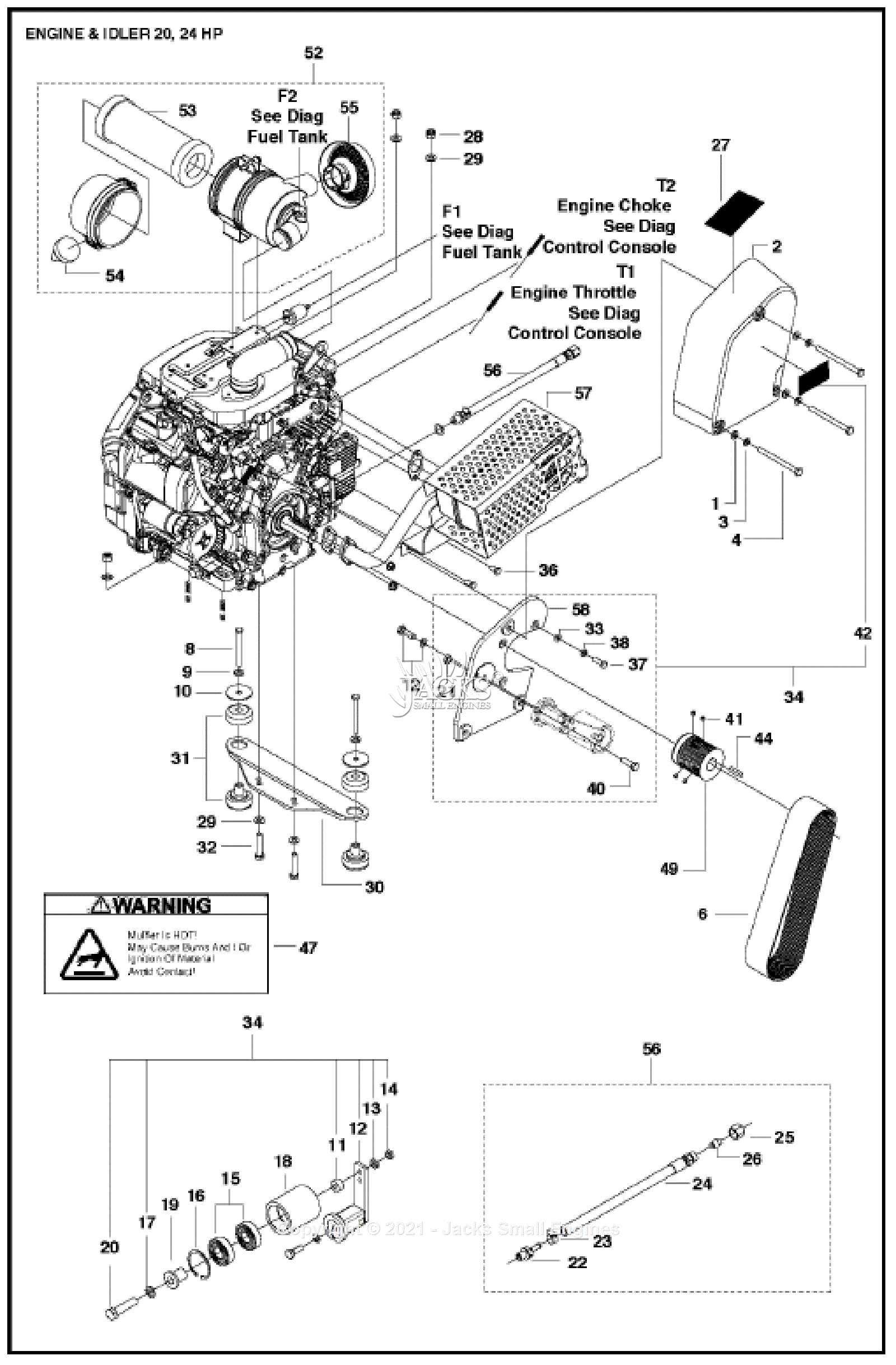

Engine Assembly

The engine assembly is the heart of the tool, providing the necessary power for cutting tasks. It consists of various parts that work together to ensure optimal performance.

Cutting Head

The cutting head is vital for executing the primary function. It houses the blades or trimmer lines that engage with the vegetation, enabling precise cutting and trimming.

How to Read the Diagram

Understanding a schematic representation is crucial for effective maintenance and repair. It provides a visual guide that helps users identify components and their relationships within a device.

Here are some key points to consider when interpreting such representations:

- Familiarize Yourself with Symbols: Different symbols represent various parts. Knowing what each symbol means is essential.

- Follow the Lines: Lines indicate connections between elements. Tracing these can clarify how parts interact.

- Use a Legend: Many diagrams include a legend or key that explains symbols and color coding.

Taking time to study these aspects will enhance your understanding and allow for more efficient troubleshooting and assembly.

Common Replacement Parts

Maintaining outdoor equipment often requires attention to various components that may wear out over time. Identifying and replacing these essential elements can enhance performance and prolong the lifespan of your machinery.

Key Components to Consider

- Blades and Cutting Tools

- Fuel Filters

- Air Filters

- Spark Plugs

- Drive Shafts

Benefits of Regular Replacement

- Improved Efficiency

- Enhanced Safety

- Reduced Downtime

- Lower Operating Costs

Maintenance Tips for Longevity

Regular upkeep is essential for ensuring the prolonged performance of your outdoor equipment. By following a few simple guidelines, you can enhance its efficiency and extend its lifespan.

1. Clean After Each Use: Make it a habit to remove debris and dirt after every session. This prevents buildup that can lead to operational issues.

2. Inspect Components Regularly: Periodic checks of essential parts can help identify wear and tear early. Replace any damaged elements promptly to avoid further complications.

3. Use Quality Fuel: Always opt for high-grade fuel to optimize performance and reduce the risk of engine problems. Mixing the right oil can also make a significant difference.

4. Store Properly: During off-seasons, ensure that your equipment is stored in a dry, cool place. Covering it can protect it from dust and moisture, which can cause rust.

5. Follow Manufacturer Guidelines: Always refer to the recommended maintenance schedule provided by the manufacturer. Adhering to these instructions can significantly enhance durability.

By implementing these practices, you can ensure that your equipment remains in top condition for years to come.

Troubleshooting Common Issues

Identifying and resolving frequent problems can enhance the performance and longevity of your equipment. This section outlines typical challenges users may face and offers effective solutions.

-

Engine Won’t Start:

- Check fuel levels and ensure it’s fresh.

- Inspect the spark plug for wear or damage.

- Examine the air filter for clogs.

-

Power Loss:

- Ensure the correct fuel-to-oil ratio is used.

- Clean or replace the air filter.

- Inspect the exhaust for blockages.

-

Excessive Vibration:

- Check for loose screws or fasteners.

- Inspect the cutting attachment for damage.

- Ensure the shaft is properly aligned.

By addressing these common issues, users can maintain optimal functionality and prevent further complications.

Where to Buy Parts

Finding the right components for your equipment can enhance its performance and longevity. There are various sources available, each offering unique advantages and options.

- Authorized Dealers: Visiting an authorized distributor ensures that you receive genuine items specifically designed for your model. They often provide expert advice and support.

- Online Retailers: Numerous e-commerce platforms specialize in outdoor equipment accessories. They typically offer a wide selection at competitive prices, along with customer reviews for better decision-making.

- Local Hardware Stores: Many neighborhood stores carry essential accessories. This option allows you to inspect items before purchasing, ensuring compatibility.

- Second-Hand Market: Websites and local classifieds often have pre-owned components at reduced prices. However, exercise caution to confirm their condition and compatibility.

Consider the convenience and reliability of each option when making your purchase decision. Quality components are essential for maintaining efficiency and safety.

Assembly Instructions

This section provides guidance on how to properly assemble the components of your equipment. Following these instructions will ensure optimal performance and longevity.

| Step | Description |

|---|---|

| 1 | Begin by organizing all necessary components for easy access during assembly. |

| 2 | Refer to the manual for specific assembly sequences to avoid errors. |

| 3 | Secure all parts tightly, ensuring no loose connections that could lead to malfunction. |

| 4 | Once assembled, conduct a thorough check to confirm all components are fitted correctly. |

Safety Precautions to Consider

When operating any outdoor power equipment, it is essential to prioritize safety to prevent accidents and injuries. Understanding and adhering to safety guidelines can significantly reduce risks while ensuring effective usage.

Before starting any task, ensure that you are wearing appropriate protective gear, such as gloves, goggles, and sturdy footwear. Familiarize yourself with the equipment’s features and functions, as well as the manufacturer’s instructions.

| Safety Gear | Purpose |

|---|---|

| Gloves | Protects hands from cuts and abrasions |

| Goggles | Prevents debris from entering the eyes |

| Ear Protection | Reduces noise exposure |

| Sturdy Footwear | Provides support and protection |

Always inspect the equipment for any signs of wear or damage before use. Ensure that the work area is clear of obstacles and bystanders to maintain a safe environment. Regular maintenance is crucial for the longevity and safe operation of the machinery.

Upgrading FS52 Components

Enhancing the performance of your outdoor power equipment can significantly improve its efficiency and longevity. By focusing on specific elements, you can tailor the machine to better meet your needs, whether for professional use or personal projects.

Evaluating Key Elements: Start by assessing the primary components that may benefit from an upgrade. Consider aspects such as the cutting mechanism, power source, and ergonomic features. Upgrading these areas can lead to better performance and ease of use.

Choosing Quality Replacements: When selecting new parts, prioritize high-quality alternatives. Durable materials and reliable brands can make a substantial difference in the overall performance and lifespan of your equipment.

Implementing upgrades not only enhances functionality but also allows for a more customized user experience. Stay informed about the latest innovations to keep your equipment at peak performance.

Frequently Asked Questions

This section addresses common inquiries related to maintenance and repair components for outdoor power equipment. Understanding these aspects can help users ensure their devices operate efficiently and effectively.

What should I do if my machine is not starting?

Several factors could contribute to starting issues, such as fuel problems, spark plug condition, or air filter blockage. It is advisable to check these elements systematically to identify the root cause.

How often should I replace worn parts?

Replacement frequency depends on usage and specific components. Regular inspections are crucial; parts that show signs of wear should be replaced promptly to maintain performance.

Where can I find quality replacement components?

Reliable sources include authorized dealers, reputable online retailers, or local hardware stores. Always ensure that the components match the specifications of your equipment for optimal results.

Can I perform repairs myself?

Many repairs can be done by individuals with basic mechanical skills. However, for complex issues, seeking professional assistance may be more prudent to avoid further complications.