In the realm of outdoor machinery, a thorough comprehension of the various components that make up your device is crucial for optimal performance and longevity. Familiarity with these elements not only enhances maintenance practices but also aids in identifying potential issues before they escalate. By gaining insight into the intricate layout and functionality of each segment, users can ensure their equipment operates at its best.

Exploring the layout of these essential elements reveals a structured approach to understanding how each part interacts with one another. This knowledge empowers users to make informed decisions when it comes to repairs and upgrades. A detailed overview helps in visualizing how the device operates, enabling efficient troubleshooting and problem-solving.

Moreover, having access to a comprehensive representation of these components can significantly simplify the process of reassembly or replacement. Whether you are a novice or a seasoned user, being aware of the arrangement and purpose of each part can enhance your confidence and proficiency when working with your machinery. Embracing this understanding ultimately contributes to a more effective and satisfying user experience.

Understanding the Key Components of Stihl FS88

This section aims to delve into the essential elements of a certain cutting tool, shedding light on its fundamental parts and their functions. Familiarizing oneself with these crucial components can enhance the understanding of how the device operates, leading to more effective use and maintenance.

Main Parts Overview

The primary elements of this cutting equipment include various integral components that work in harmony to achieve optimal performance. Each part plays a vital role in ensuring efficiency and longevity, contributing to the overall functionality of the device.

| Component | Description |

|---|---|

| Engine | Drives the cutting mechanism, providing necessary power for operation. |

| Cutting Head | Contains the cutting line or blades that perform the trimming action. |

| Throttle Control | Allows the operator to regulate the speed and power of the engine. |

| Fuel Tank | Holds the fuel needed for the engine to function effectively. |

| Handle | Provides a grip for the operator, ensuring comfort and control during use. |

Importance of Regular Maintenance

To ensure the longevity and efficiency of this cutting tool, regular maintenance of its key components is essential. Keeping the elements clean and well-lubricated not only enhances performance but also reduces the likelihood of malfunctions during operation.

Exploring the Engine Parts of Stihl FS88

The heart of any outdoor power equipment lies within its engine, a complex assembly of components that work in harmony to deliver performance and reliability. Understanding the various elements that contribute to the functionality of the engine is crucial for maintenance and optimal operation.

| Component | Description |

|---|---|

| Cylinder | This is the chamber where combustion occurs, playing a vital role in converting fuel into mechanical energy. |

| Piston | The piston moves up and down within the cylinder, compressing the fuel-air mixture and transferring force to the crankshaft. |

| Crankshaft | This component translates the linear motion of the piston into rotational motion, driving the output shaft. |

| Carburetor | The carburetor mixes air and fuel in the correct proportions to ensure efficient combustion within the engine. |

| Ignition System | This system generates a spark that ignites the fuel-air mixture, initiating the combustion process. |

| Exhaust System | The exhaust system expels combustion gases from the engine, helping to maintain optimal performance and reduce emissions. |

Guide to the Cutting System Elements

This section provides an overview of the essential components involved in the cutting mechanism of a trimmer. Understanding these elements is crucial for efficient operation and maintenance, ensuring optimal performance during usage.

Key Components of the Cutting System

The cutting system is comprised of various parts that work together to facilitate effective grass trimming. Each element plays a significant role in achieving precise cuts and overall efficiency.

| Component | Description |

|---|---|

| Cutter Head | The part that houses the cutting line and is responsible for trimming grass and weeds. |

| Cutting Line | A flexible cord that extends from the cutter head, designed to slice through vegetation. |

| Gearbox | Converts the rotational motion from the engine to the cutting head, providing the necessary torque. |

| Spool | Holds the cutting line and releases it as needed during operation. |

| Protection Guard | Safeguards the user from debris and helps maintain the proper length of the cutting line. |

Maintenance Tips

Regular upkeep of the cutting system components is vital for maintaining performance. Ensure the cutting line is replaced as needed, and the cutter head is cleaned to prevent clogging and enhance efficiency.

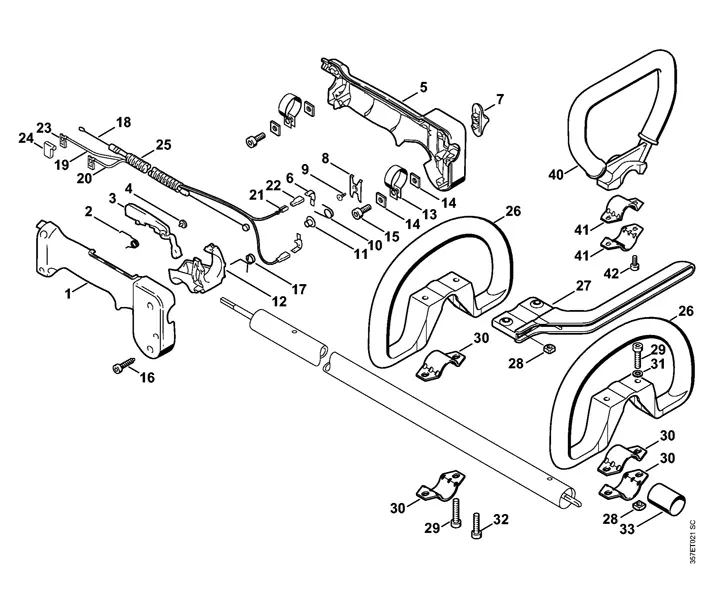

Replacing the Handle Assembly Efficiently

Swapping out the handle assembly can greatly enhance the usability and comfort of your equipment. This procedure not only improves control but also ensures a better user experience during operation. Knowing the proper steps to follow is essential for a successful replacement.

To begin, gather all necessary tools and materials to streamline the process. A well-organized workspace will help you avoid interruptions and make the task more efficient. Carefully detach the existing handle by following the manufacturer’s guidelines, paying attention to any securing fasteners that need removal.

Once the old handle is removed, inspect the attachment points and surrounding areas for any signs of wear or damage. This will help ensure that the new assembly will fit properly and function effectively. When installing the new handle, align it carefully and secure it firmly to prevent any looseness during use.

Finally, test the newly installed handle by performing a brief operation check. This will confirm that everything is functioning correctly and that you can operate the device with ease and confidence. Regular maintenance and timely replacements contribute to the longevity and efficiency of your equipment.

Fuel System Overview for Stihl FS88

The fuel mechanism plays a crucial role in the efficient operation of handheld outdoor equipment. It is responsible for delivering the necessary energy to power the engine while ensuring optimal performance and minimal emissions. Understanding the components and functioning of this system can greatly enhance maintenance practices and troubleshooting efforts.

Key Components of the Fuel Mechanism

This system typically consists of several essential parts, including a fuel tank, fuel lines, a filter, and a carburetor. Each component contributes to the overall functionality by ensuring that the engine receives a clean and consistent fuel supply.

Functionality and Maintenance Tips

Regular inspection and maintenance of the fuel system are vital for longevity and efficiency. It is advisable to check for leaks, replace clogged filters, and ensure that the fuel is fresh and appropriate for the equipment. Keeping the system clean will prevent performance issues and prolong the lifespan of the equipment.

Understanding the Ignition Mechanism

The ignition system plays a crucial role in the operation of outdoor power equipment, ensuring that the engine starts and runs efficiently. This mechanism is responsible for generating the spark needed to ignite the fuel-air mixture, enabling the engine to function effectively. A well-understood ignition system can lead to improved performance and easier troubleshooting when issues arise.

Components of the Ignition System

The ignition assembly typically includes several key elements, each serving a specific function. The coil generates voltage, while the spark plug ignites the fuel. Additionally, the flywheel plays a vital role in creating the necessary magnetism to trigger the ignition process.

Maintaining the Ignition System

Regular maintenance of the ignition system is essential for optimal performance. This includes checking the spark plug for wear and ensuring that the coil is functioning correctly. By addressing these components, users can prevent potential failures and ensure reliable operation of their equipment.

Drive Shaft Parts and Their Functions

The drive shaft is a crucial component in a machine, responsible for transferring rotational energy from the engine to various parts. Understanding the individual elements that constitute this assembly is essential for effective maintenance and operation. Each component plays a distinct role in ensuring smooth performance and durability.

Key Components of the Drive Shaft

Several vital elements work together within the drive shaft assembly. These include the main shaft, couplings, and bearings, each serving specific functions. The main shaft acts as the primary conduit for power transmission, while couplings connect different sections securely. Bearings facilitate smooth rotation, reducing friction and wear.

Functions of Each Element

Each part of the drive shaft has a unique purpose that contributes to overall efficiency. The main shaft is engineered to withstand high torque and stress, ensuring consistent power delivery. Couplings allow for flexible alignment and compensate for misalignments, enhancing the assembly’s resilience. Meanwhile, bearings minimize friction, which helps prolong the lifespan of the entire system.

Maintenance of the Gearbox Assembly

Regular upkeep of the gearbox unit is essential for ensuring optimal performance and longevity. This component plays a crucial role in transferring power, and its proper functioning directly impacts the efficiency of the equipment. Neglecting maintenance can lead to reduced effectiveness and potential damage.

Inspection and Cleaning

Routine inspection of the gearbox assembly should involve checking for any signs of wear or damage. It is important to clean the exterior and interior components to prevent the buildup of dirt and debris, which can hinder performance. Use a soft brush and a suitable cleaning agent to remove any contaminants.

Lubrication and Adjustment

Proper lubrication is vital for the smooth operation of the gearbox. Apply high-quality grease to all moving parts, ensuring even distribution. Additionally, periodic adjustments may be necessary to maintain correct tension and alignment. Follow the manufacturer’s guidelines for specific lubrication intervals and adjustment procedures.

Air Filter Housing and Its Importance

The air filter housing plays a crucial role in the overall performance and longevity of outdoor power equipment. It serves as a protective enclosure for the air filter, ensuring that only clean air enters the engine. This component is vital for maintaining optimal air flow and preventing contaminants from affecting the engine’s operation.

Functionality of the Air Filter Housing

The primary functions of the air filter housing include:

- Shielding the air filter from dirt and debris.

- Facilitating proper air intake for efficient combustion.

- Helping to maintain the correct air-fuel ratio for optimal engine performance.

Maintenance and Care

Proper maintenance of the air filter housing is essential for ensuring its effectiveness. Key maintenance practices include:

- Regularly inspecting the housing for cracks or damage.

- Cleaning or replacing the air filter as needed to ensure maximum airflow.

- Checking for any blockages in the intake system.

By prioritizing the upkeep of the air filter housing, users can significantly enhance the efficiency and durability of their equipment.

Troubleshooting Common Part Failures

Addressing frequent component malfunctions is essential for maintaining optimal performance and ensuring longevity. Understanding potential issues and their remedies can significantly enhance functionality and user experience.

Below are some common problems and suggested solutions that may arise:

| Issue | Possible Cause | Recommended Solution |

|---|---|---|

| Engine not starting | Faulty ignition system | Check spark plug condition and replace if necessary. |

| Overheating | Insufficient lubrication | Ensure proper oil levels and quality; refill or change oil as needed. |

| Unusual vibrations | Loose or damaged components | Tighten bolts and inspect for wear; replace damaged parts. |

| Poor cutting performance | Dull or worn cutting tool | Sharpen or replace the cutting tool to restore efficiency. |