Maintaining outdoor equipment often requires a clear understanding of its individual elements and how they come together. Knowing the layout and structure of different pieces is essential for effective upkeep and repairs. In this section, we will explore the key components and their role in ensuring smooth operation.

Whether it’s routine maintenance or fixing specific issues, understanding the positioning and connection of various parts is crucial. By reviewing the configuration, you’ll be better prepared to handle both minor adjustments and more complex fixes, ensuring your equipment continues to perform reliably.

Familiarity with the inner workings of your tool allows you to address potential problems quickly. This knowledge not only saves time but also ensures that any replacements or adjustments are done correctly, minimizing the risk of future issues.

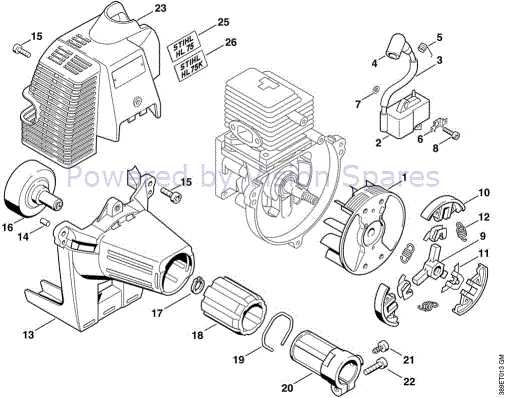

Comprehensive Guide to HL75K Parts

In this guide, we will explore the various components and mechanisms that make up a versatile cutting tool. Understanding each piece and its role can help with maintenance, repairs, and overall efficiency. Whether you’re performing routine upkeep or troubleshooting an issue, knowing how each element interacts is essential for optimal performance.

| Component | Description | ||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

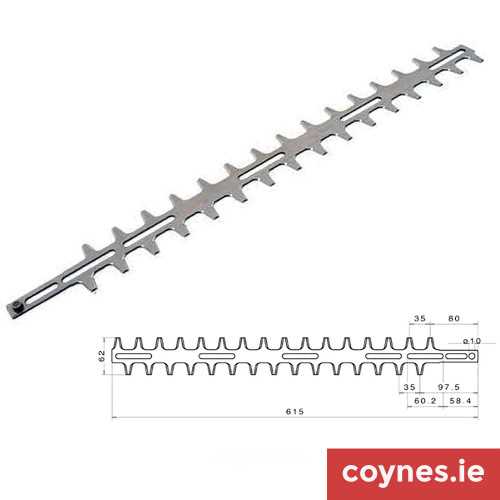

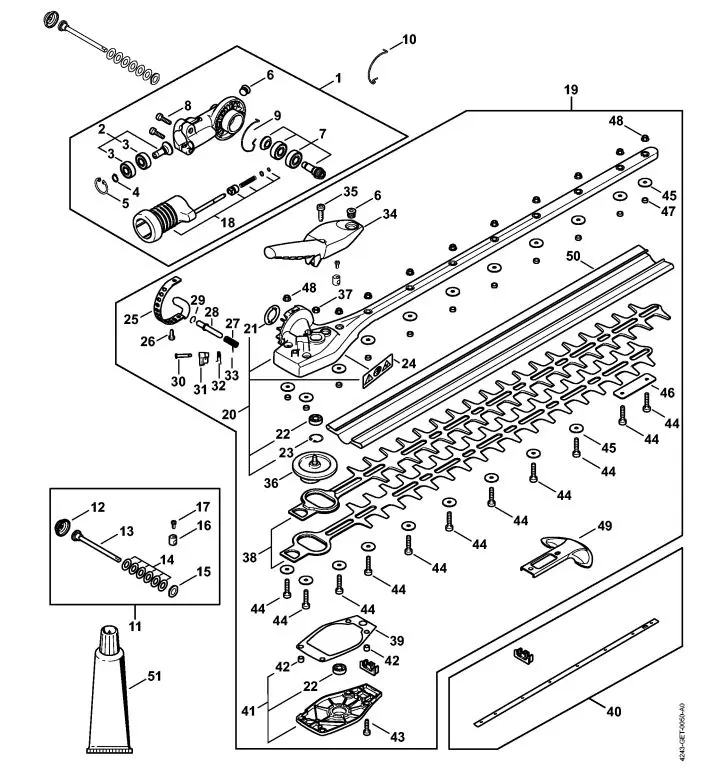

| Cutter Head | The section responsible for performing the main trimming action, featuring sharp blades that handle thick vegetation with ease. | ||||||||||||||||||||||||

| Drive Shaft | This connects the power source to the cutting mechanism,

Understanding Key Components of HL75K

The functionality of this tool relies on the interaction of several essential mechanisms that contribute to its overall performance. Each part plays a role in ensuring efficient operation and durability, allowing for smooth and consistent usage over time. One of the most important elements is the cutting mechanism, which ensures precision and effectiveness. This component needs to be well-maintained to avoid any decrease in performance. Another significant section is the drive system, which powers the tool, allowing it to perform under various conditions. Proper care of these systems can enhance the tool’s lifespan and efficiency. Additionally, attention should be paid to smaller components such as the protective casing and handles, which ensure both user safety and comfort. These parts are crucial in creating a safe operating environment, while also providing ease of use during long periods of work. Understanding the role of these key elements can help in maintaining optimal performance and avoiding unnecessary wear and tear. How to Maintain Your HL75K PartsRegular upkeep of your equipment is essential to ensure smooth performance and extend its lifespan. Proper care prevents breakdowns and helps keep all components working efficiently. By following basic maintenance practices, you can avoid costly repairs and downtime. Cleaning the individual components after each use is crucial. Dirt, debris, and plant material can accumulate and affect how the tool operates. Use a brush or compressed air to remove any build-up, especially from moving mechanisms. Lubrication is another key step. Keeping moving parts well-oiled minimizes friction and wear. Be sure to use the correct type of lubricant and apply it as recommended for optimal functioning. In addition to regular cleaning and lubrication, inspecting all parts for wear or damage is vital. Look for any signs of cracks, rust, or loose connections. Replacing worn-out elements early can prevent more serious issues down Identifying Wear and Tear in HL75KRecognizing signs of deterioration in equipment over time is crucial for maintaining performance. Regular inspection helps identify which components may need attention, preventing more significant issues in the future. Some of the most common areas that show aging include the cutting edges and mechanical joints. These parts experience the most strain during operation, and visible damage such as nicks, dullness, or loose connections often signal a need for maintenance. Pay attention to vibrations and unusual sounds, as these can indicate worn-out internal elements. Additionally, check for excessive heat buildup during use, as it can point to increased friction or failing lubrication systems. Frequent upkeep and early detection of wear ensure that the tool continues to function efficiently and extends its overall lifespan. Replacing Worn-Out Blades on HL75K

Over time, cutting tools can become less efficient due to wear and tear. Replacing dull or damaged components is essential for maintaining optimal performance and ensuring clean, precise trimming results. Regular inspection and timely replacement of these parts help keep the equipment running smoothly. Signs of Dull or Damaged Blades

Recognizing when blades are no longer performing well is key to avoiding further issues. Here are some common indicators that it’s time to replace them:

Steps for Replacing the Blades

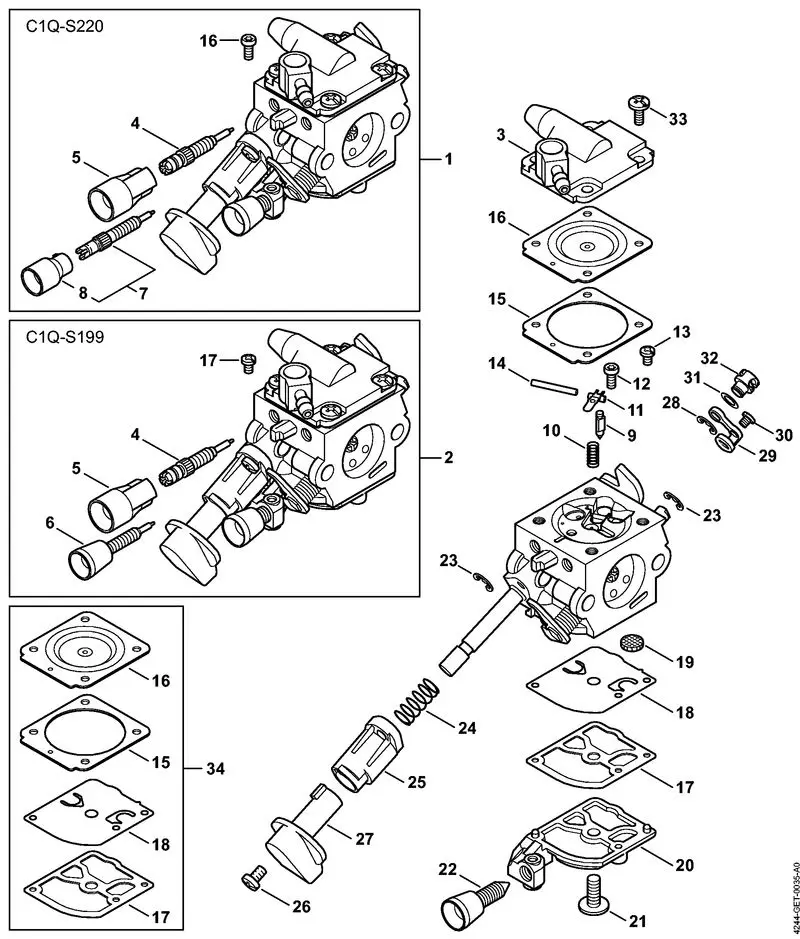

When the cutting edges are no longer functioning Exploring HL75K Engine Mechanisms

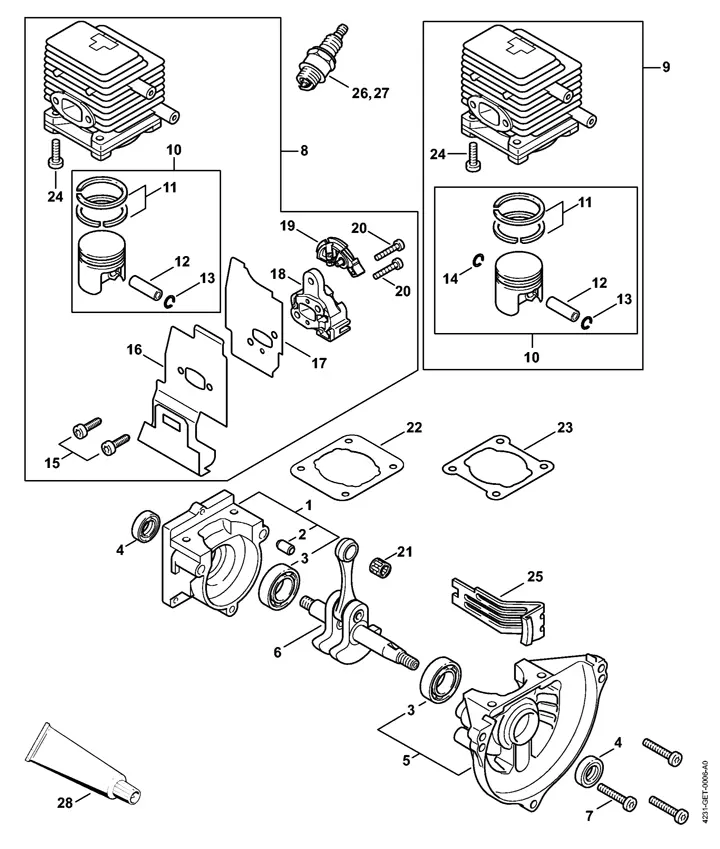

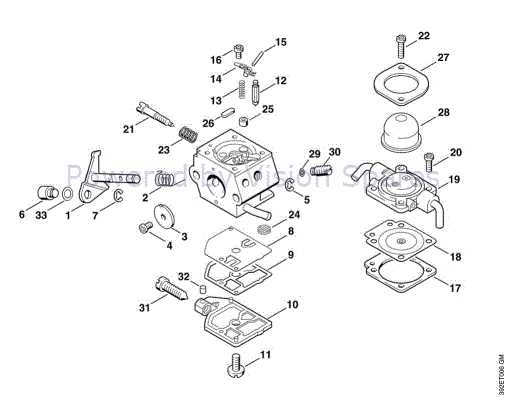

The examination of engine components reveals intricate systems that drive performance and efficiency. Understanding the various mechanisms at play provides valuable insights into how these machines operate and the roles each part plays in the overall functionality. Key aspects of engine mechanisms include:

Additionally, attention to the following components can further improve understanding:

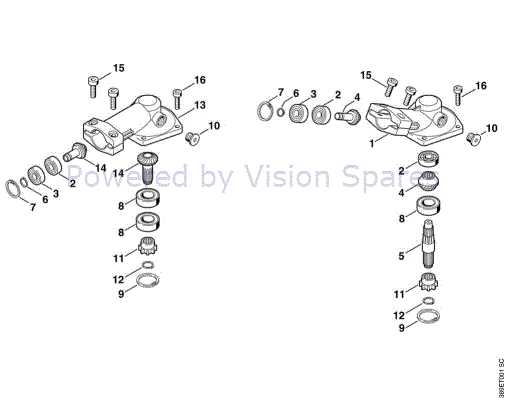

By exploring these elements, one gains a comprehensive view of the complexities involved in engine design and operation. HL75K Gearbox Assembly Breakdown

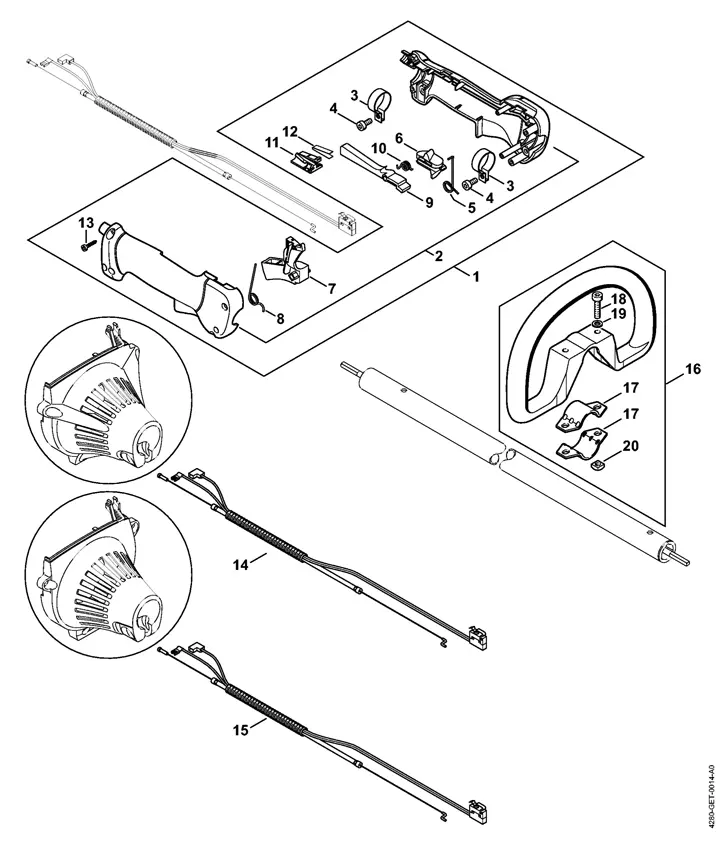

The gearbox assembly plays a crucial role in the efficient functioning of various machinery. It is responsible for transmitting power from the engine to the working components, allowing for effective operation. Understanding the components and their arrangement within the gearbox can help in maintenance and troubleshooting. This assembly typically consists of several key elements, including gears, shafts, and housing. Each part is designed to work in harmony with the others, ensuring smooth operation. Proper lubrication and alignment of these components are essential to prevent wear and tear, which can lead to reduced performance or failure. When examining the gearbox, it’s important to identify the arrangement of gears and their specific functions. Each gear has a unique role in adjusting the speed and torque delivered to the machinery. Regular inspection and servicing can prolong the life of these components and enhance overall efficiency. Choosing the Right HL75K PartsSelecting the appropriate components for your equipment is crucial for maintaining optimal performance and longevity. Understanding the various elements involved will help ensure that your machine operates efficiently and effectively. Each part plays a significant role, and making informed decisions can lead to better outcomes and reduced maintenance costs. Understanding Component Functionality

Each component serves a unique purpose, contributing to the overall functionality of your device. Familiarizing yourself with these functions can aid in identifying which replacements or upgrades are necessary. Components can vary significantly in design and material, impacting their performance and durability. Factors to Consider When Selecting ComponentsWhen choosing replacements, consider the following aspects:

Cleaning Tips for HL75K Components

Regular maintenance of your equipment is essential for optimal performance and longevity. Proper cleaning of various components ensures they function efficiently and reduces the risk of damage. This section provides effective cleaning techniques to keep your tools in excellent condition, enhancing their reliability and extending their lifespan. Essential Cleaning Supplies

To achieve the best results, gather the necessary cleaning supplies before starting the process. Common items include:

Step-by-Step Cleaning ProcessFollow these steps to effectively clean your equipment:

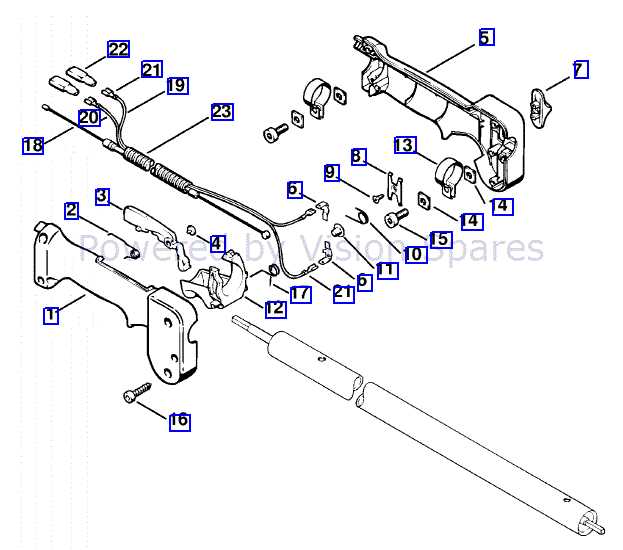

By following these cleaning tips, you can maintain the efficiency and reliability of your equipment, ensuring it operates smoothly for years to come. HL75K Handle and Grip ReplacementReplacing the handle and grip of your tool can significantly enhance comfort and control during operation. Over time, wear and tear can lead to a decline in performance and user experience. By replacing these components, you not only restore functionality but also improve safety and efficiency. Choosing the Right ComponentsWhen selecting new handles and grips, it’s important to consider the material and ergonomics. A good grip will provide better control and reduce fatigue during extended use. Look for durable materials that can withstand outdoor conditions. Installation Process

Follow these steps for a successful replacement:

By following these guidelines, you can ensure that your tool remains effective and comfortable, allowing for improved performance in your tasks. Best Practices for HL75K Lubrication

Proper lubrication is essential for maintaining the efficiency and longevity of any equipment. Ensuring that moving parts receive adequate lubrication reduces friction, minimizes wear, and enhances overall performance. By following specific guidelines, users can significantly improve the operational life of their tools while ensuring they function optimally. Regularly check the lubrication levels and apply the appropriate type of lubricant recommended for the equipment. It is crucial to use high-quality oils or greases that are compatible with the materials of the components. When applying lubricant, focus on critical areas such as joints, bearings, and other high-friction points. Over-lubrication can be as detrimental as under-lubrication, so adhering to manufacturer specifications is important. Clean the surfaces around lubrication points before applying any product. This prevents contamination and ensures that the lubricant can penetrate effectively. Additionally, it is advisable to perform maintenance checks after extended use to identify any signs of wear or damage, which may indicate the need for more frequent lubrication or other interventions. Keeping a maintenance log can help track usage and lubrication schedules, promoting a proactive approach to equipment care. Common HL75K Problems and Solutions

In any tool designed for outdoor tasks, various challenges may arise that can hinder performance and efficiency. Understanding these issues and their solutions can help users maintain their equipment effectively. Here are some frequent complications and their respective remedies:

Regular maintenance and timely interventions can significantly enhance the longevity and performance of your outdoor equipment. Where to Find HL75K Replacement PartsFinding the right components for your gardening equipment is essential for maintaining optimal performance. When your tool requires replacements, there are various avenues to explore. Each option may offer different advantages, so understanding where to look can simplify the process. Online RetailersThe internet is a convenient resource for sourcing essential items. Here are some popular platforms to consider:

Local Stores

Visiting physical shops can be beneficial as well. Consider these types of establishments:

Regardless of your choice, ensuring that you purchase high-quality components will enhance the longevity and efficiency of your gardening tools. |