The functionality of a hedge trimming tool relies heavily on its various components working together harmoniously. Each piece plays a vital role in ensuring optimal performance, making it essential for users to familiarize themselves with the intricacies of these elements. Gaining insight into how these parts interact can greatly enhance the user experience and maintenance practices.

By exploring the configuration and roles of each segment, one can appreciate the craftsmanship involved in creating efficient gardening tools. A thorough comprehension of these elements not only aids in troubleshooting but also empowers users to make informed decisions regarding repairs and replacements. Whether you are a seasoned gardener or a novice, understanding these components will enhance your overall gardening experience.

Furthermore, recognizing the importance of each part encourages better care and handling of the equipment, leading to increased longevity and performance. In this discussion, we will delve into the specifics of each element, offering a detailed overview that aids users in maximizing their equipment’s capabilities.

Overview of Stihl HS 56 C

The HS 56 C is a highly efficient tool designed for maintaining and shaping hedges with precision. This device combines power and ease of use, making it an essential addition to any gardener’s collection. Its ergonomic design ensures comfort during operation, allowing for extended use without fatigue.

Key Features

This machine is equipped with a powerful engine that provides excellent cutting performance. The cutting blades are specifically engineered to deliver clean cuts, promoting healthy growth in plants. Additionally, the lightweight construction enhances maneuverability, making it easy to reach even the most challenging areas.

Maintenance and Care

Regular maintenance is crucial for optimal performance. It is recommended to keep the cutting blades sharp and to check the fuel levels before each use. Proper care not only extends the lifespan of the tool but also ensures safety during operation. Always refer to the user manual for detailed maintenance guidelines and troubleshooting tips.

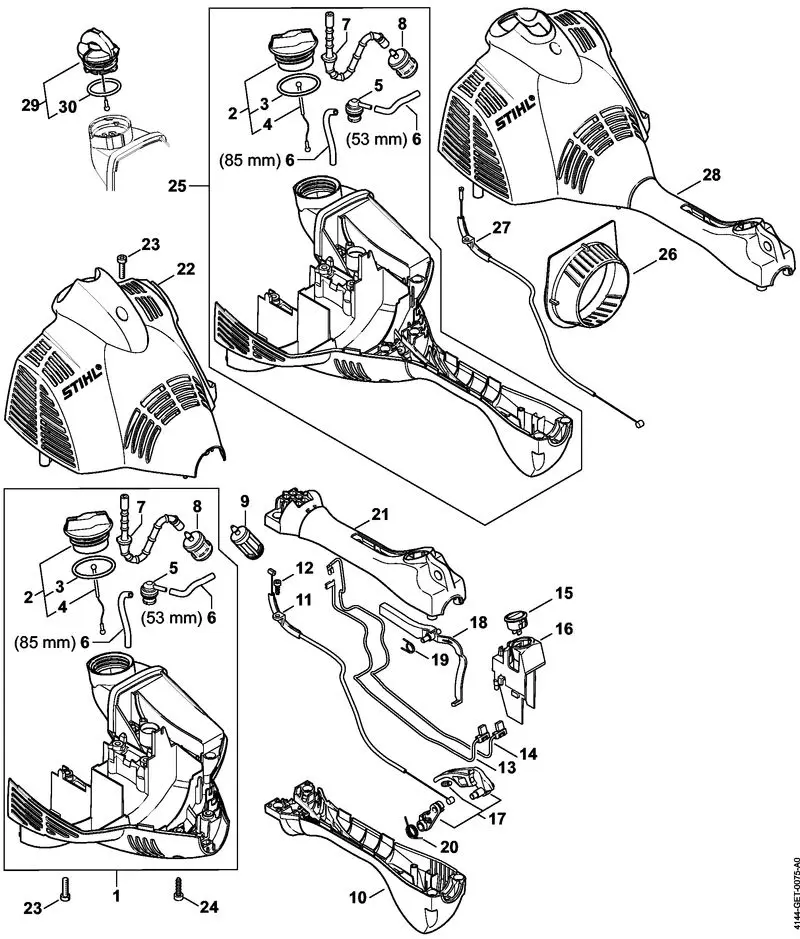

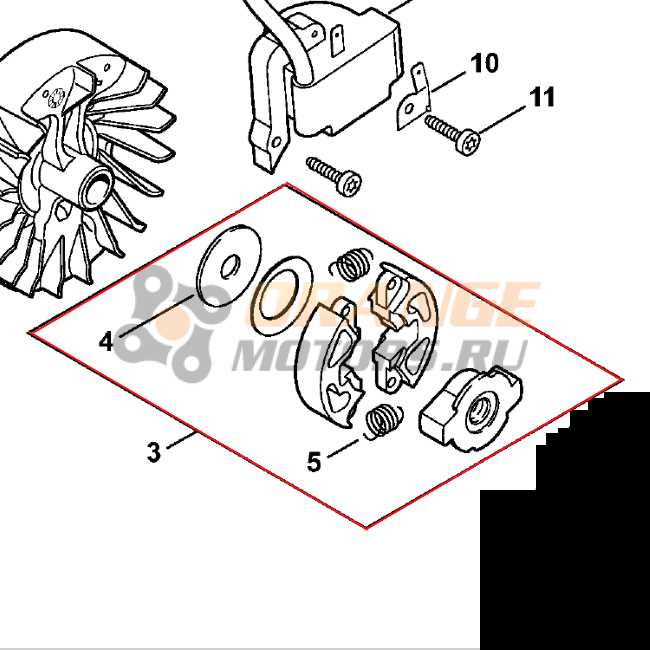

Importance of Parts Diagrams

Understanding the assembly of machinery and equipment is essential for effective maintenance and repair. Visual representations of components serve as valuable resources, providing users with a clear overview of how different elements fit together. These illustrations enhance comprehension, making it easier to identify and locate specific items within a complex structure.

Accurate visuals can significantly streamline the troubleshooting process. When issues arise, having access to a detailed depiction allows technicians to quickly pinpoint problematic areas and determine necessary interventions. This efficiency not only saves time but also reduces the risk of errors during repairs.

Moreover, these representations facilitate better communication among team members. When discussing repairs or modifications, referring to a common visual aid helps ensure everyone is on the same page, minimizing misunderstandings. Ultimately, the availability of comprehensive visual guides contributes to enhanced operational efficiency and longevity of the equipment.

Key Components of the Machine

This section focuses on the essential elements that make up the equipment, highlighting their significance in ensuring optimal performance. Understanding these components is crucial for effective operation and maintenance, allowing users to appreciate the design and functionality behind the tool.

Major Elements

- Engine: The power source that drives the entire unit, providing the necessary energy for operation.

- Blades: Sharp instruments designed for cutting, essential for achieving precise results.

- Handle: The part that allows users to grip the machine comfortably while ensuring control during use.

- Gearbox: This component transmits power from the engine to the blades, allowing for efficient cutting action.

- Fuel System: Includes the tank and lines, responsible for delivering fuel to the engine for combustion.

Supportive Features

- Safety Guard: A protective element that minimizes the risk of injury by shielding users from moving parts.

- Throttle Control: Allows users to adjust the speed of the blades, providing flexibility for different tasks.

- Vibration Dampening System: Reduces the impact of vibrations on the operator, enhancing comfort during prolonged use.

How to Read a Parts Diagram

Understanding an assembly illustration is essential for effective maintenance and repair tasks. This visual guide provides a comprehensive overview of components, showcasing their arrangement and relationships within a machine. By familiarizing oneself with this representation, one can enhance their ability to identify individual elements and comprehend how they interact with each other.

To begin, note the reference numbers or labels that correspond to each item. These identifiers allow users to easily locate specific components within the accompanying documentation or inventory lists. Additionally, pay attention to the visual representation of each part; the drawings often depict various angles and orientations, which can clarify how pieces fit together.

Next, observe any accompanying notes or legends that provide further information about each element. These annotations can include details such as material specifications, assembly instructions, or maintenance tips. By taking the time to study these details, users can gain a deeper understanding of their equipment and make informed decisions during repairs or replacements.

Lastly, practicing with these illustrations over time will improve one’s ability to interpret them quickly and accurately. Regular engagement with these visual aids will build confidence and efficiency in handling maintenance tasks, ultimately leading to better performance and longevity of the equipment.

Common Replacement Parts Explained

Understanding the components that may require replacement is essential for maintaining optimal performance in your equipment. Regular wear and tear can lead to decreased efficiency, making it important to identify and address these issues promptly. Below are some commonly replaced components and their functions.

- Blades: Sharp blades are crucial for achieving clean cuts. Over time, they can become dull or damaged, necessitating replacement for effective operation.

- Filters: Air and fuel filters play a vital role in maintaining engine performance. Clogged filters can hinder airflow and fuel delivery, affecting overall functionality.

- Spark Plugs: These components ignite the fuel-air mixture in the engine. Worn or fouled spark plugs can lead to starting issues and reduced power.

- Fuel Lines: Flexible hoses that transport fuel to the engine. Cracks or leaks in fuel lines can cause performance problems and safety hazards.

- Drive Belts: These belts connect the engine to the cutting mechanism. A worn or broken belt can disrupt the cutting action, leading to ineffective operation.

Regular inspection and timely replacement of these components can enhance the longevity and efficiency of your equipment, ensuring it operates smoothly for years to come.

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the durability and efficiency of your equipment. Regular attention to maintenance can prevent premature wear and tear, ultimately extending the lifespan of your device. By following some straightforward guidelines, you can keep your tool running smoothly and effectively for years to come.

Regular Cleaning

Cleaning your equipment after each use is crucial. Debris, dirt, and residues can accumulate and cause damage over time. Use a soft brush or cloth to remove any buildup, paying particular attention to hard-to-reach areas. This simple practice not only enhances performance but also prevents rust and corrosion.

Routine Inspections

Conducting routine checks is vital to identify any potential issues before they escalate. Look for signs of wear on components, ensure all parts are securely attached, and check for any unusual noises during operation. Addressing minor problems early can save you time and money in the long run. Additionally, refer to the manufacturer’s guidelines for recommended service intervals to maintain optimal performance.

Identifying Parts by Number

Understanding the various components of your equipment is essential for effective maintenance and repairs. Each element is typically assigned a unique identification code, allowing for easy reference and procurement when necessary. This system simplifies the process of locating specific components and ensures that you can quickly find the right item without confusion.

When searching for a particular element, begin by consulting the identification list provided by the manufacturer. This list will usually contain numbers alongside descriptions, enabling you to match your needs with the correct item. By using these identification numbers, you can avoid potential mistakes and ensure that replacements or repairs are executed with precision.

In case of any difficulties in locating the required element, consider reaching out to authorized dealers or service centers. They can provide expert assistance in identifying and sourcing the necessary components, ensuring that your equipment remains in optimal condition.

Where to Purchase Genuine Parts

Finding authentic components for your equipment is essential for maintaining optimal performance and longevity. Genuine items ensure compatibility and reliability, which can significantly affect the functionality of your tools. There are several avenues available for acquiring these high-quality replacements, each with its own advantages.

Authorized Dealers

One of the most reliable sources for obtaining original components is through authorized dealers. These retailers have direct access to the manufacturer’s inventory, guaranteeing that you receive genuine merchandise. Consider the following benefits:

- Expert assistance from knowledgeable staff.

- Access to the latest models and updates.

- Assurance of product authenticity and warranty coverage.

Online Retailers

Another convenient option is to shop through reputable online platforms. Many well-known websites offer a wide selection of authentic merchandise. When purchasing online, keep these tips in mind:

- Verify the retailer’s reputation through customer reviews.

- Ensure they provide detailed descriptions and images of the items.

- Check return policies and warranty information.

Common Issues and Solutions

When working with gardening tools, users may encounter various challenges that can affect performance and efficiency. Understanding these common problems and their solutions can help ensure smooth operation and prolong the lifespan of the equipment.

Engine Won’t Start

If the engine fails to start, it may be due to several factors. First, check the fuel level and ensure that it is fresh. Stale fuel can lead to starting issues. Additionally, inspect the spark plug for wear and tear; a dirty or faulty spark plug can prevent ignition. Regular maintenance of these components is crucial for optimal performance.

Excessive Vibration

Experiencing excessive vibration during operation can be concerning. This issue is often caused by loose or damaged components. Check all screws and bolts to ensure they are tightened properly. Moreover, inspect the blades for any signs of damage or imbalance. Replacing worn or damaged parts can significantly reduce vibration and improve the overall functioning of the tool.

Tools Required for Repairs

When it comes to maintaining and fixing outdoor equipment, having the right tools is essential for ensuring effective and safe repairs. Proper tools not only facilitate the repair process but also help to prevent damage to the equipment and enhance overall performance.

Here is a list of essential tools that you may need for repairs:

- Wrenches: Useful for loosening and tightening nuts and bolts.

- Screwdrivers: Various sizes and types, including flathead and Phillips, are necessary for different screws.

- Pliers: Ideal for gripping, twisting, and cutting wires.

- Socket Set: Provides a range of socket sizes for working with various fasteners.

- Torque Wrench: Ensures that fasteners are tightened to the manufacturer’s specifications.

- Replacement Blades: Necessary for any cutting equipment maintenance.

- Lubricants: To reduce friction and wear on moving parts.

- Cleaning Supplies: Brushes and cloths for maintaining cleanliness and removing debris.

- Safety Gear: Goggles, gloves, and masks to protect yourself during repairs.

Having these tools on hand will make the repair process smoother and more efficient, allowing you to keep your equipment in optimal condition.

Safety Precautions During Maintenance

Proper maintenance is essential for ensuring the longevity and safe operation of your equipment. Adhering to safety measures during this process minimizes risks and protects both the user and the device. Below are key guidelines to follow while performing maintenance tasks.

- Always wear appropriate personal protective equipment (PPE), including gloves, safety goggles, and ear protection.

- Ensure the equipment is turned off and disconnected from any power source before beginning maintenance.

- Work in a well-ventilated area to avoid inhaling harmful fumes or dust particles.

- Keep the work area clean and organized to prevent accidents and injuries.

In addition to the basic precautions, consider the following steps:

- Read the user manual thoroughly before starting any maintenance procedures.

- Inspect tools and equipment for damage before use, replacing any faulty items immediately.

- Never bypass safety features or remove guards while working on the machinery.

- Dispose of waste materials, such as oil or filters, in accordance with local regulations.

By following these safety precautions, you can ensure a safe and effective maintenance process, prolonging the lifespan of your equipment while protecting yourself from potential hazards.

Comparing with Other Models

When evaluating different models within a particular category, it is essential to consider various aspects such as performance, durability, and user-friendliness. Each model has its unique features that cater to specific needs, making it crucial to analyze how they stack up against one another.

Performance Metrics

In terms of performance, several alternatives showcase varying levels of efficiency and power. Some models might offer enhanced cutting capabilities, while others excel in fuel efficiency. This comparison allows users to identify which tool best meets their requirements based on their intended use.

User Experience

Moreover, the user experience can significantly differ between models. Factors such as weight, balance, and ease of operation play a vital role in overall satisfaction. Users often prefer tools that provide comfort during extended use, highlighting the importance of ergonomics in the design of these devices.

Ultimately, a thorough comparison reveals valuable insights that can guide potential buyers in making an informed decision based on their specific preferences and operational needs.