The intricate assembly of a gardening tool can significantly influence its performance and durability. Understanding the various elements that comprise this equipment allows users to optimize its functionality and ensure efficient operation.

In this section, we will delve into the essential components, highlighting their roles and interactions within the device. By familiarizing yourself with these integral parts, you can enhance your maintenance practices and troubleshoot effectively when issues arise.

Whether you are a seasoned user or a newcomer, gaining insight into the structure of this tool will empower you to make informed decisions regarding repairs and upgrades. A comprehensive grasp of the inner workings paves the way for a more productive gardening experience.

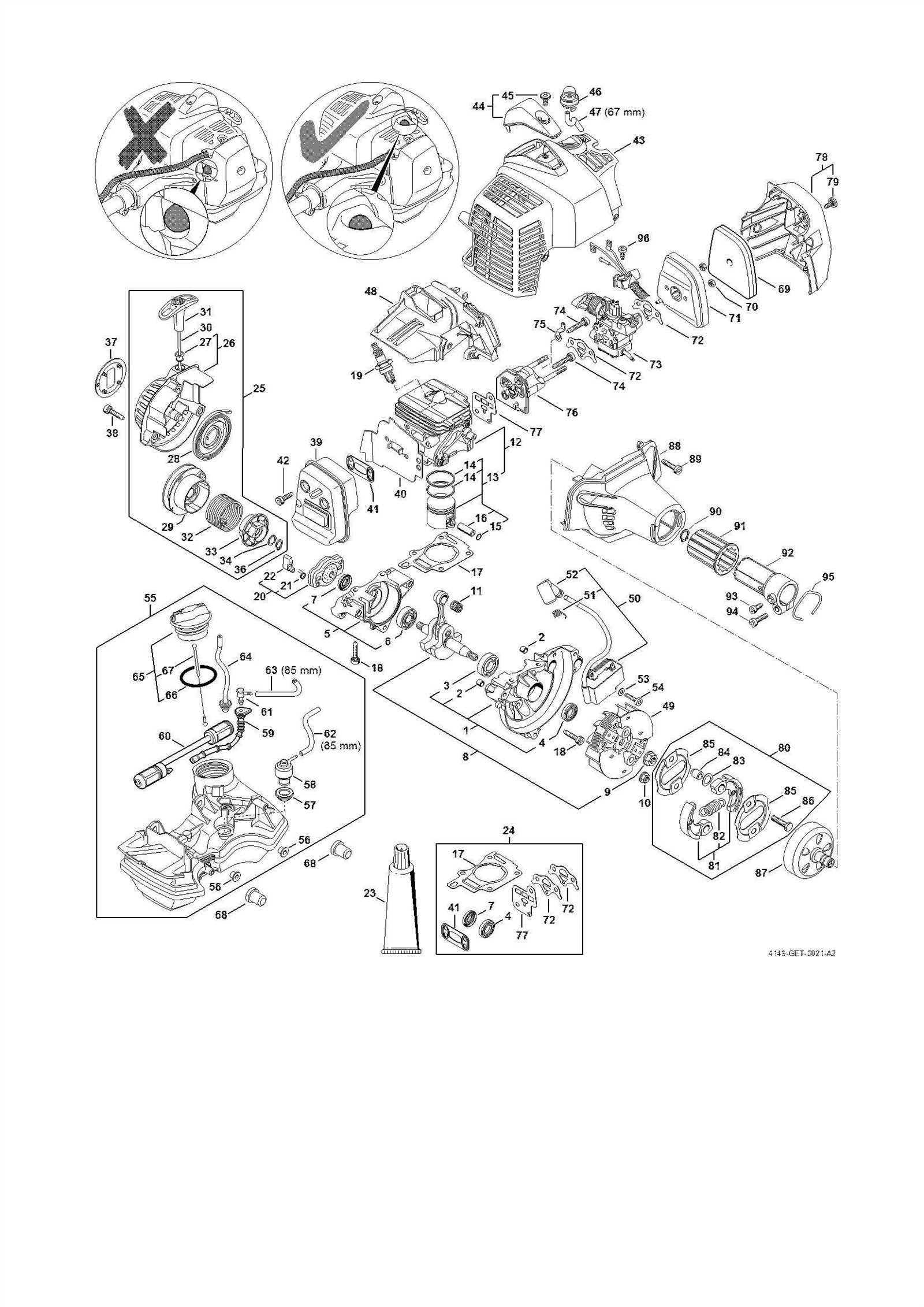

Understanding Stihl MM 56 C Components

This section aims to provide an in-depth look at the various elements that contribute to the functionality of the MM 56 C model. Each component plays a critical role in ensuring the efficiency and performance of the equipment, making it essential to comprehend their individual functions and interactions.

Core Elements and Their Functions

The primary elements of this model include the engine, transmission, and attachments, each serving a specific purpose. The engine is responsible for powering the machine, while the transmission ensures that energy is effectively transferred to the working attachments. Understanding how these core components work together can enhance maintenance practices and overall performance.

Maintenance and Replacement Considerations

Regular inspection and timely replacement of worn or damaged elements are vital for optimal operation. Familiarity with each part’s role can assist in identifying potential issues early. Prioritizing maintenance not only extends the lifespan of the equipment but also improves its effectiveness in various tasks.

Key Features of the Equipment

This section highlights the essential characteristics that make the tool effective and user-friendly. Understanding these elements enhances the overall experience and efficiency during operation.

- Robust Construction: Designed to withstand various outdoor conditions, ensuring longevity and reliability.

- Ergonomic Design: Features a comfortable grip and intuitive controls, reducing user fatigue during extended use.

- Powerful Engine: Equipped with a high-performance engine that delivers consistent power for various tasks.

- Versatile Attachments: Supports multiple accessories, allowing for a range of applications from tilling to cultivating.

- Easy Maintenance: Simplified access to components facilitates quick maintenance and servicing.

These features collectively contribute to the tool’s effectiveness, making it a valuable addition for users seeking efficiency in their gardening and landscaping tasks.

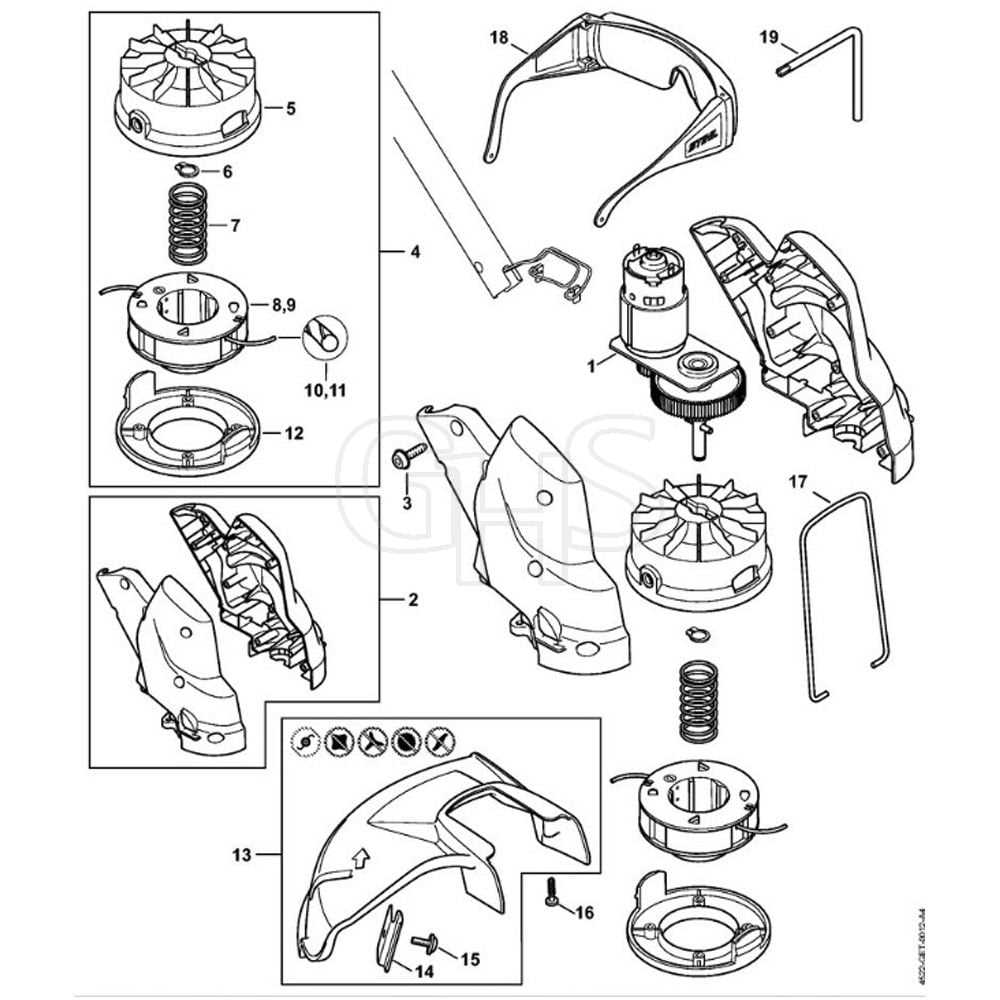

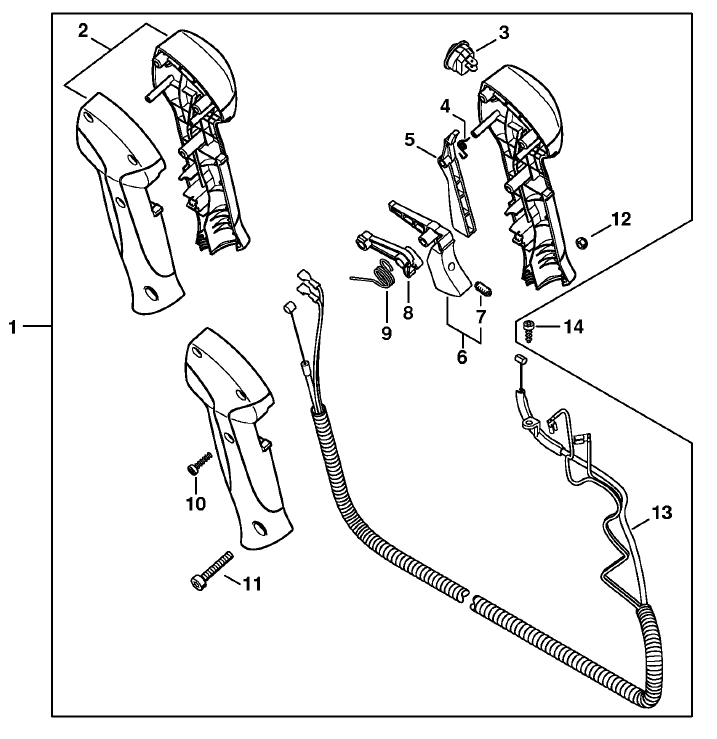

Parts Identification and Functions

Understanding the various components of the machine is essential for effective maintenance and operation. Each element plays a critical role in ensuring optimal performance, and knowing their specific functions can greatly enhance user experience.

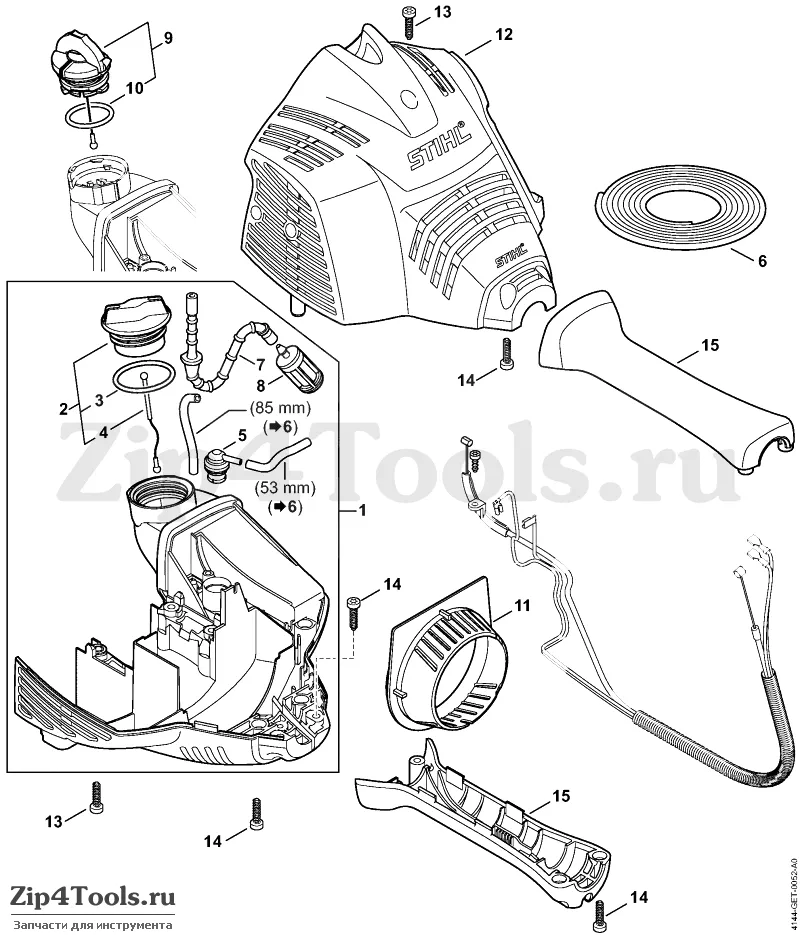

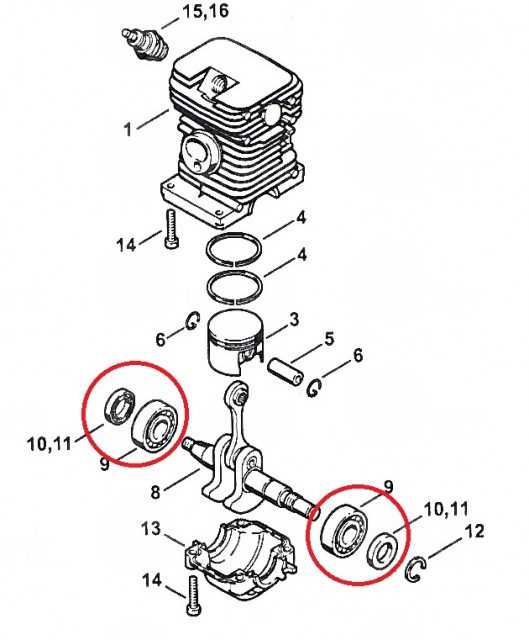

Engine Assembly: This is the powerhouse of the equipment, responsible for converting fuel into mechanical energy. A well-functioning engine ensures reliable operation.

Transmission System: This mechanism transfers power from the engine to the working tools. Its efficiency affects the overall effectiveness of the device during operation.

Cutting Blade: A vital element that performs the actual work. Its sharpness and design determine how effectively the machine can handle various tasks.

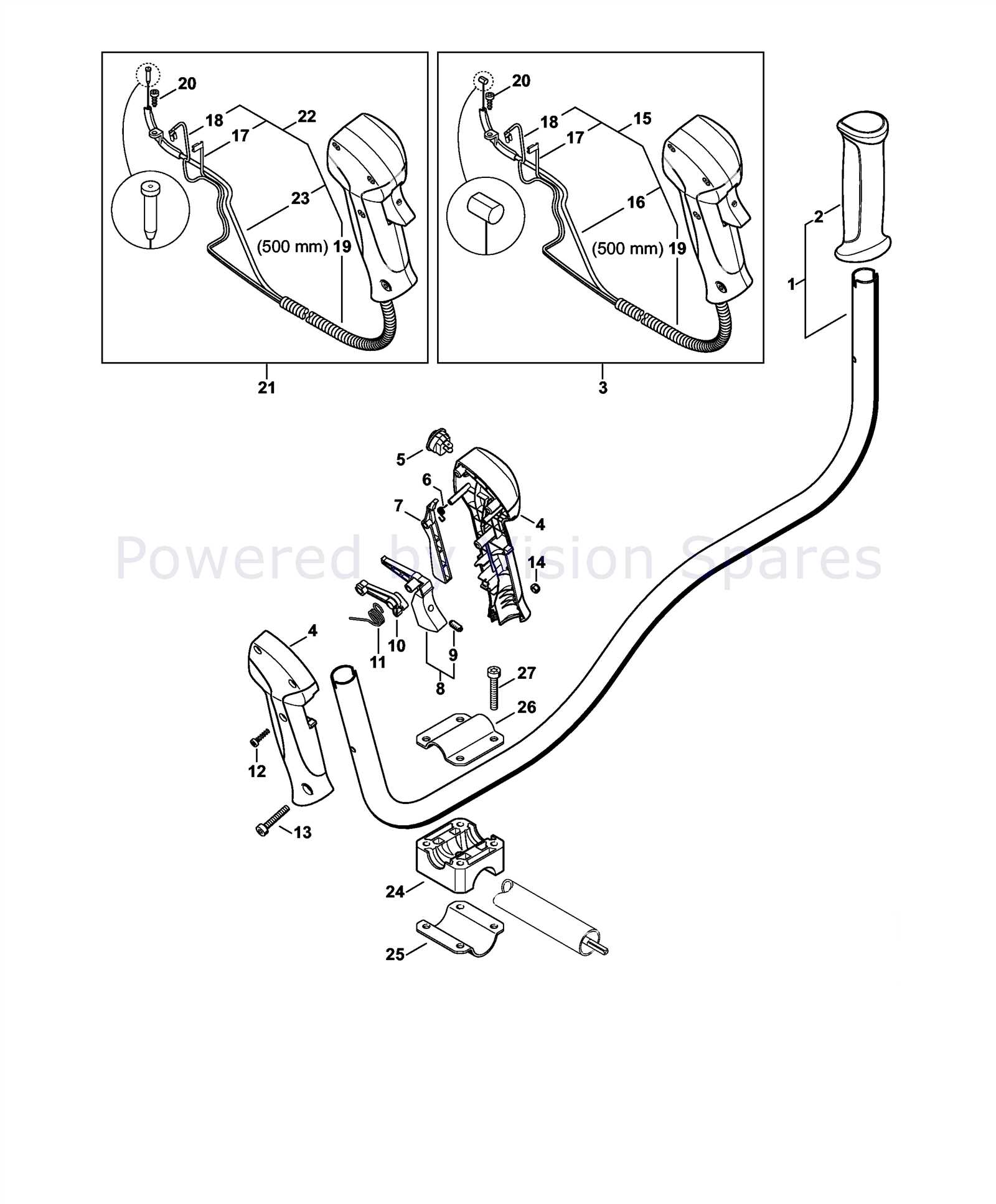

Handle and Control Mechanisms: These components provide the user with the ability to maneuver the machine. Ergonomic design enhances comfort and reduces fatigue during extended use.

Fuel System: This system delivers the necessary fuel to the engine. Proper maintenance ensures consistent performance and longevity of the equipment.

Safety Features: Integrated systems designed to protect the user and equipment from potential hazards. Understanding these features is crucial for safe operation.

Maintenance Tips for Longevity

Ensuring the extended lifespan of your equipment involves regular upkeep and mindful practices. By adhering to essential maintenance routines, you can enhance performance and reduce the likelihood of breakdowns.

Regular Cleaning

Keeping the exterior and internal components clean is vital. Accumulated dirt and debris can lead to operational inefficiencies. Use a soft brush or cloth to remove buildup, ensuring air vents and moving parts are unobstructed.

Routine Inspections

Conduct frequent checks on essential elements such as filters, blades, and belts. Look for signs of wear or damage, and address any issues promptly. This proactive approach can prevent minor problems from escalating into costly repairs.

Investing time in maintenance not only boosts functionality but also contributes to safety, making your equipment reliable for all tasks ahead. Remember, a well-maintained machine is a productive machine.

Common Issues and Solutions

When working with gardening equipment, users often encounter various challenges that can affect performance and efficiency. Understanding these common problems and their corresponding remedies can help ensure smoother operation and prolonged lifespan of the machinery.

Frequent Problems

| Issue | Description | Possible Solution |

|---|---|---|

| Engine Won’t Start | The engine fails to ignite or run properly. | Check the fuel supply and ensure the spark plug is clean and properly connected. |

| Overheating | The machine becomes excessively hot during use. | Inspect air filters for clogs and ensure adequate airflow around the engine. |

| Loss of Power | Reduced performance during operation. | Examine the fuel filter and replace it if necessary; check for blockages in the exhaust. |

Maintenance Tips

Regular maintenance is essential for preventing common issues. Cleaning air filters, checking fuel lines, and ensuring all connections are secure can help maintain optimal performance. Additionally, following the manufacturer’s guidelines for servicing can extend the life of the equipment.

How to Replace Worn Parts

Replacing worn components is essential for maintaining the efficiency and longevity of your equipment. By addressing these issues promptly, you can ensure optimal performance and reduce the risk of further damage.

- Identify the Components

- Inspect the equipment thoroughly to determine which elements are degraded.

- Look for signs of wear, such as cracks, fraying, or reduced functionality.

cssCopy code

- Prepare all tools needed for the replacement process.

- Common tools may include screwdrivers, wrenches, and pliers.

- Follow the manufacturer’s guidelines for safely detaching the damaged components.

- Keep track of any screws or fasteners to avoid losing them.

- Carefully fit the new elements in place, ensuring proper alignment.

- Secure everything tightly, checking for any loose fittings.

- Once everything is reassembled, power on the equipment to verify functionality.

- Monitor for any unusual noises or performance issues during initial use.

Regular maintenance and timely replacements will enhance the performance of your machinery and extend its lifespan.

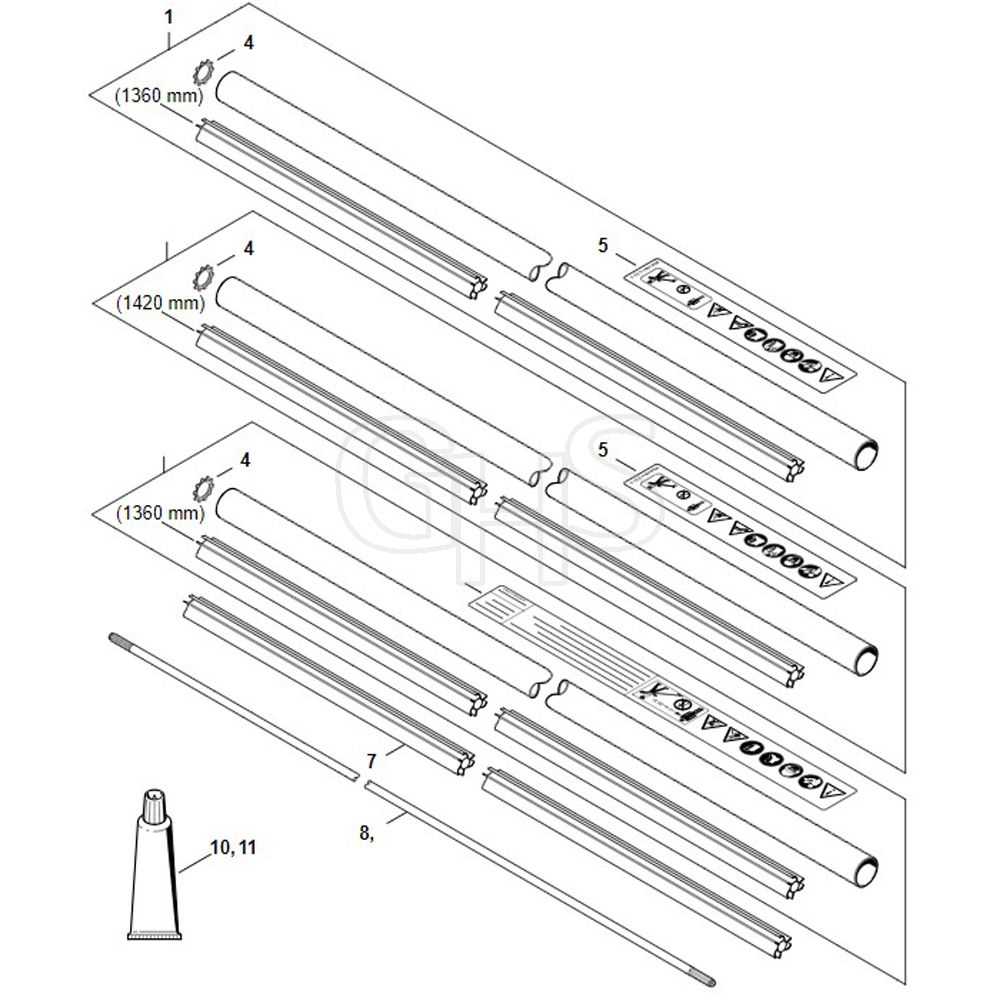

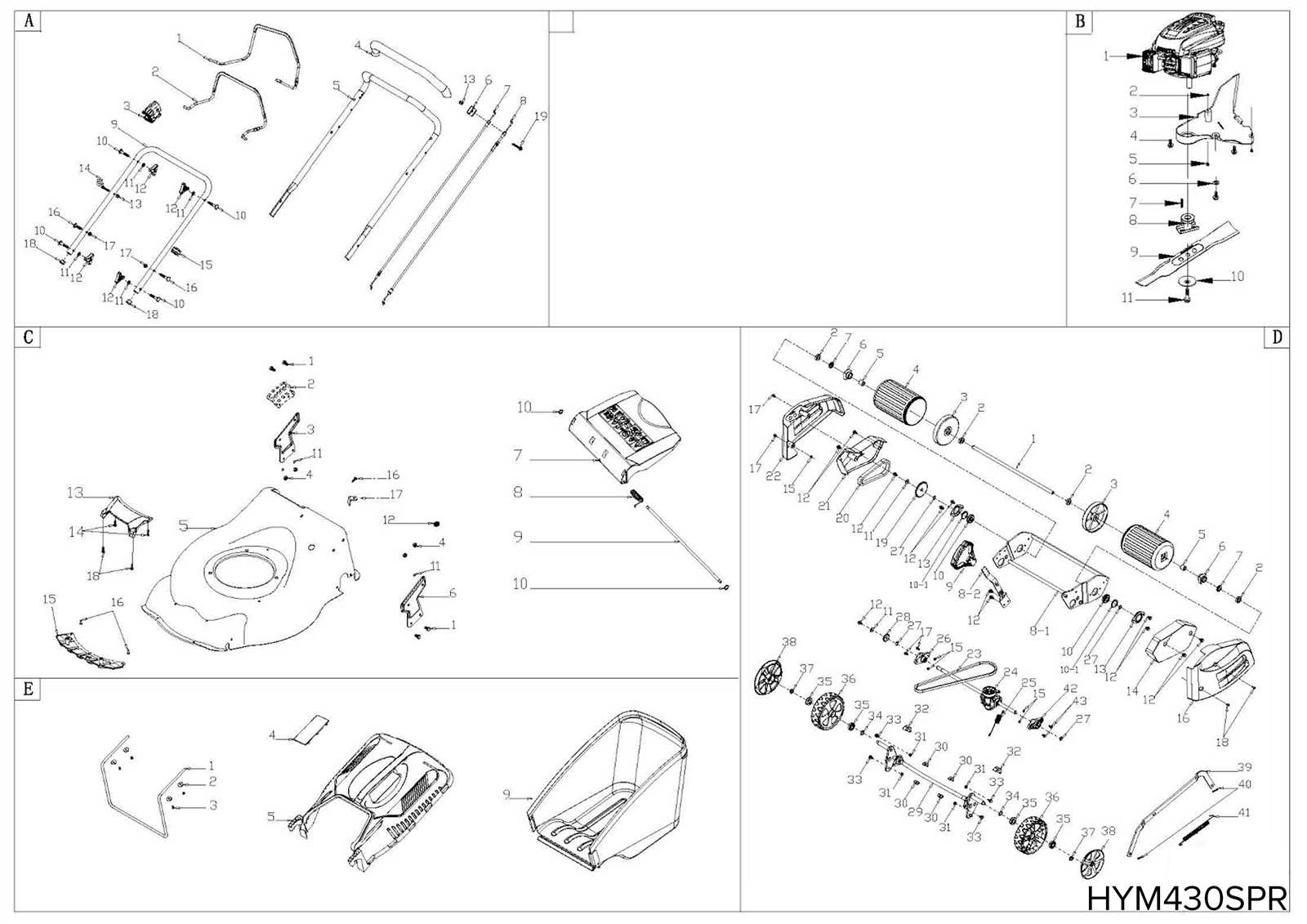

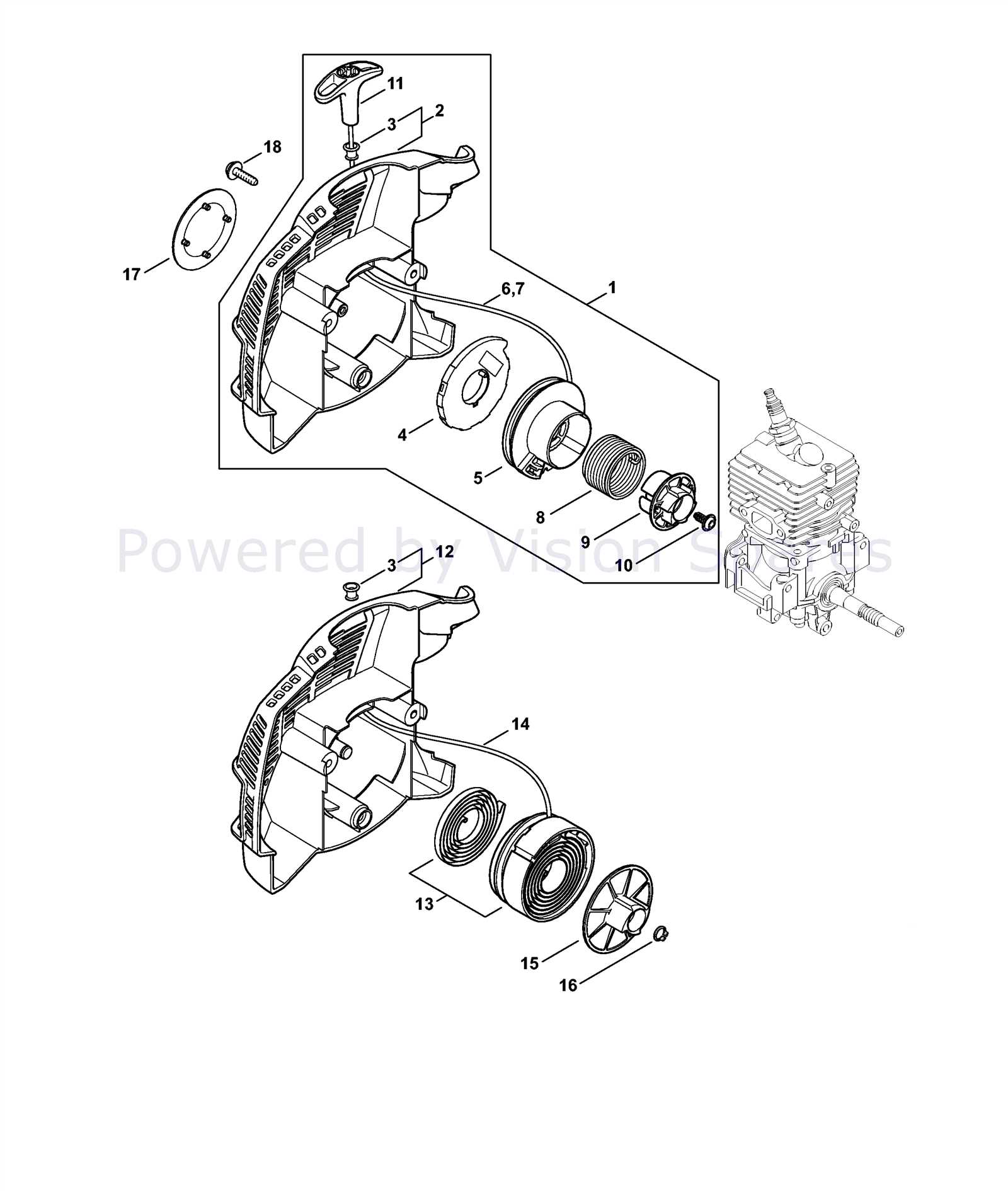

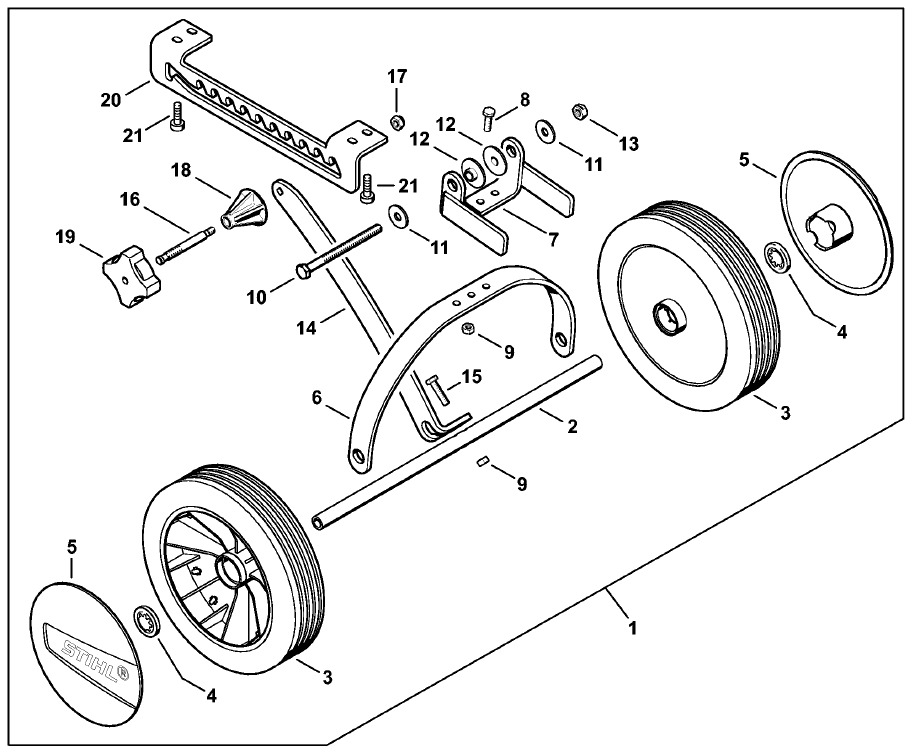

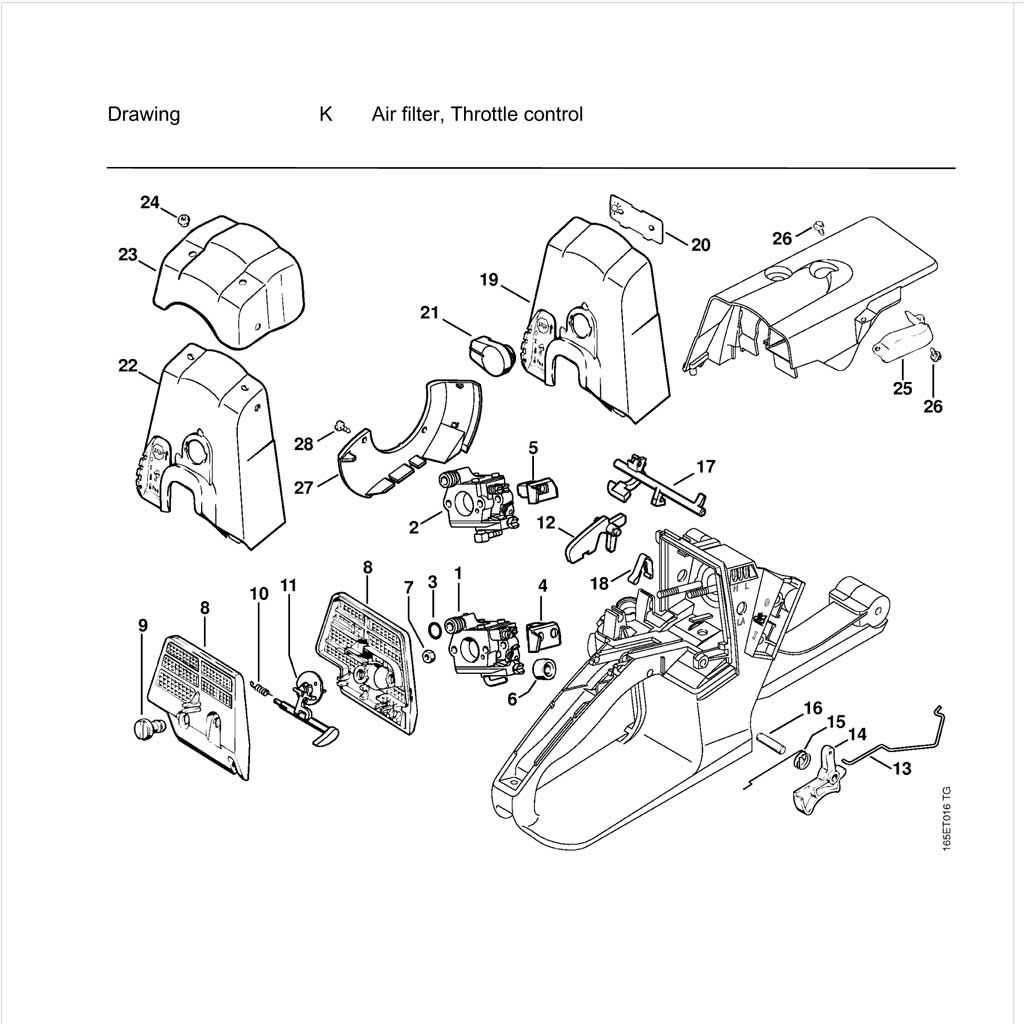

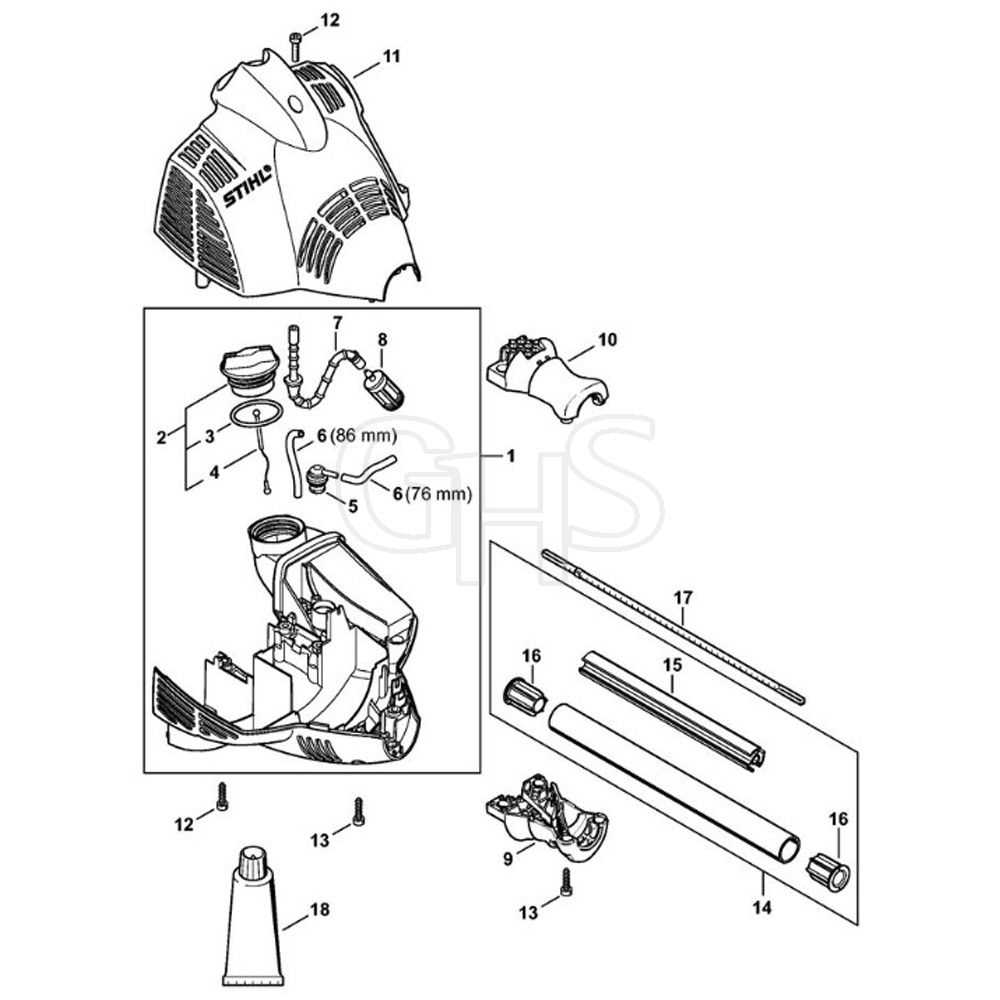

Diagram Overview: Visual Aid

This section provides a comprehensive visual reference, enhancing understanding of component layout and functionality. By utilizing a structured illustration, users can easily identify key elements and their relationships within the assembly.

| Component | Description |

|---|---|

| Housing | Protective outer shell that encases internal mechanisms. |

| Engine | Power source that drives the entire system. |

| Handle | Control interface allowing for maneuverability and operation. |

| Blades | Cutting elements responsible for performing the primary function. |

| Fuel Tank | Reservoir for storing the energy source necessary for operation. |

Assembly Instructions for Efficiency

To achieve optimal performance during the assembly process, following a systematic approach is essential. Ensuring that all components are organized and easily accessible can significantly reduce assembly time and enhance productivity.

Begin by reviewing the assembly sequence carefully. Familiarize yourself with each part and its corresponding position. Group similar components together to streamline the workflow and minimize confusion during the process.

When assembling, utilize appropriate tools to secure each part firmly. This not only guarantees stability but also prevents any potential issues arising from loose connections. Regularly check for alignment and fitment as you progress to ensure that the final assembly meets the required standards.

Lastly, conduct a thorough inspection upon completion. This step is crucial to identify any overlooked discrepancies and confirm that everything is functioning as intended. Implementing these practices will enhance efficiency and lead to a successful assembly outcome.

Tools Required for Repairs

When undertaking maintenance or repairs on your gardening equipment, having the right tools is essential for achieving efficient and effective results. A well-equipped workspace can significantly simplify the process and ensure that all tasks are completed safely.

Basic Hand Tools

Start with a selection of basic hand tools. Screwdrivers in various sizes, including flathead and Phillips, are crucial for removing and securing components. Additionally, a good set of wrenches will help you tackle bolts and nuts. Don’t forget pliers for gripping and manipulating smaller parts, as well as a hammer for gently persuading stubborn components.

Specialized Equipment

For more intricate repairs, specialized tools may be necessary. A multimeter is invaluable for diagnosing electrical issues, while a torque wrench ensures that fasteners are tightened to the manufacturer’s specifications. Consider investing in a toolbox or organizer to keep everything readily accessible, making your repair efforts more efficient.

Where to Purchase Replacement Parts

Finding the right components for your equipment is essential for maintaining its performance and longevity. Numerous options are available to ensure you acquire the necessary items effectively and efficiently.

Here are some reliable sources to consider:

- Authorized Dealers: Visit local dealers who specialize in equipment servicing. They often carry genuine items and can provide expert advice.

- Online Retailers: Websites dedicated to outdoor tools and machinery frequently stock a wide selection of components. Make sure to verify their credibility through customer reviews.

- Manufacturer’s Website: Check the official website for a dedicated section on purchasing replacements. This ensures you receive quality items that match your equipment.

- Second-Hand Markets: Explore platforms for used items. This can be a cost-effective option, but be sure to check the condition before purchasing.

By exploring these avenues, you can ensure that you find the right components to keep your equipment running smoothly.

Safety Precautions During Use

Ensuring safety while operating any equipment is crucial to prevent accidents and injuries. Proper precautions not only protect the user but also enhance the overall performance of the tool. Adhering to guidelines can significantly reduce risks associated with handling machinery.

Personal Protective Equipment

Wearing appropriate personal protective gear is essential. This includes safety goggles to shield your eyes from debris, ear protection to minimize noise exposure, and sturdy gloves to safeguard your hands. Additionally, wearing long pants and sturdy boots can provide further protection from potential hazards.

Operational Guidelines

Before using the equipment, familiarize yourself with its controls and safety features. Always inspect the machine for any signs of wear or damage. Maintain a safe distance from others while operating, and never bypass safety mechanisms. Following the manufacturer’s instructions and guidelines will ensure a safer working environment.

Comparing with Other Models

When evaluating different gardening equipment, it’s essential to analyze various models and their specifications to identify unique features and performance capabilities. This comparison enables users to make informed decisions based on their specific needs and preferences.

Key Differences

- Engine Power: Various models may offer different engine outputs, impacting efficiency and effectiveness.

- Weight and Portability: Some units are designed to be lighter, enhancing ease of use and maneuverability.

- Attachment Compatibility: A selection of tools may provide compatibility with various attachments, broadening functionality.

Performance and Usability

- Cutting Width: The size of the cutting area can vary, affecting the time needed for tasks.

- Ergonomics: User comfort can differ significantly, with some designs prioritizing ease of handling.

- Fuel Efficiency: Models may exhibit varying levels of fuel consumption, influencing long-term operational costs.