The inner workings of a chainsaw consist of various elements that together create a powerful and efficient tool. Each component plays a critical role in ensuring the machine operates smoothly, contributing to performance, safety, and longevity. For anyone involved in repair or maintenance, a clear understanding of how these parts function is essential.

By recognizing the individual pieces and their connections, users can better troubleshoot issues and maintain the device effectively. This guide aims to provide a detailed look at these elements, allowing for a deeper comprehension of the machine’s operation and its key features.

Whether you’re performing regular upkeep or addressing a specific issue, having a comprehensive view of these essential parts will help ensure the tool remains in optimal condition. Knowing how these mechanisms interact can save time and prevent costly repairs in the long run.

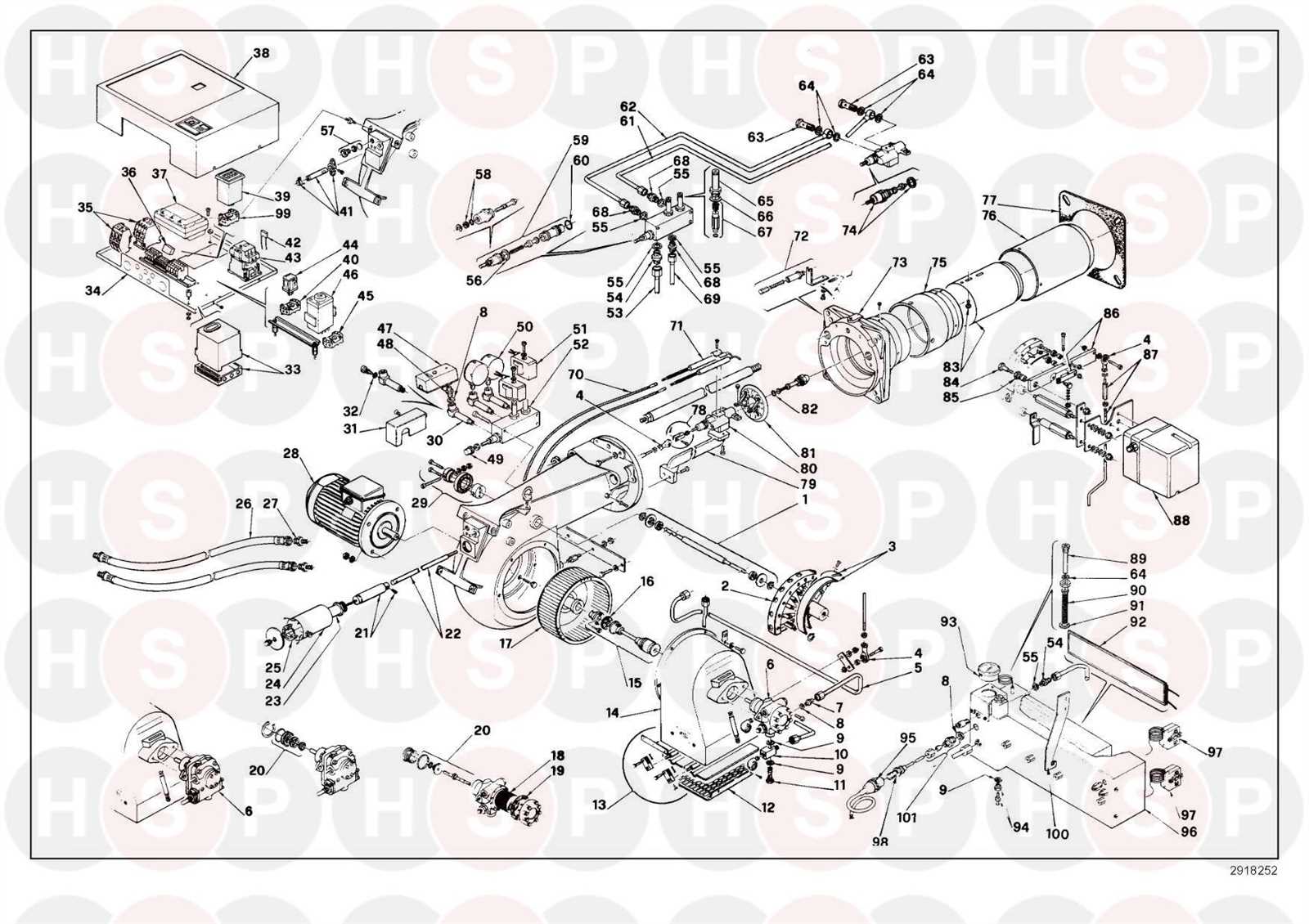

Component Overview

The model features a range of vital elements designed to ensure smooth operation and durability. Each component plays a specific role in maintaining efficient functionality, from the engine to the cutting mechanism, with a focus on precision and reliability.

Engine and Powertrain

The core of this machine lies in its powerful engine, which drives the entire system. It provides the necessary force to power the cutting blade while ensuring fuel efficiency and reduced emissions. The powertrain is specifically calibrated to deliver optimal performance during intensive use.

Cutting Mechanism

The cutting system is designed for precision and ease of use, allowing for effective wood cutting with minimal effort. The chain and bar work in harmony to achieve smooth cuts, supported by an advanced lubrication system that prolongs the lifespan of the blade and ensures consistent results over time.

Engine Assembly Breakdown

The engine is a crucial component, consisting of multiple interconnected elements that work together to ensure smooth operation. Understanding its structure allows for easier maintenance and troubleshooting, which helps in prolonging the machine’s life and improving performance.

Main Components

The engine assembly consists of several primary elements that are essential for its function. These parts fit together in a precise manner to convert fuel into mechanical energy.

- Cylinder: The chamber where the fuel mixture ignites and creates power.

- Piston: Moves inside the cylinder, driven by the combustion of the fuel, transferring energy to the crankshaft.

- Crankshaft: Converts the linear motion of the piston into rotational energy used to drive the machinery.

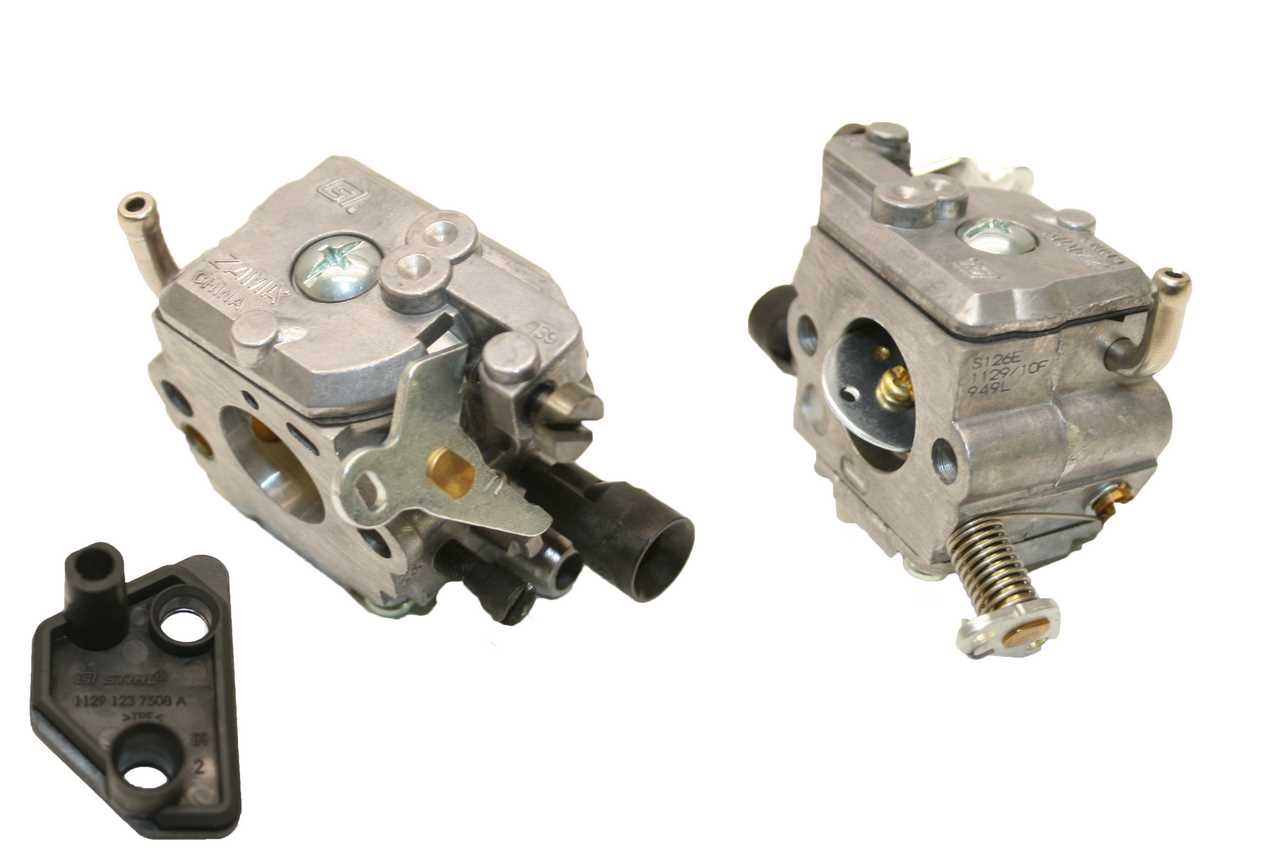

- Carburetor: Responsible for mixing air and fuel in the correct proportion for combustion.

Supporting Mechanisms

In addition to the main parts, there are several mechanisms that support the engine’s efficiency and stability.

- Ign

Fuel System Components

The fuel system plays a critical role in the engine’s performance, ensuring that the right mixture of fuel and air reaches the combustion chamber. Each part of this system is designed to work together to deliver fuel efficiently and maintain optimal operation. Understanding how these components interact can help in maintaining and troubleshooting the system.

Main Components Overview

The system includes several key elements that contribute to the delivery and regulation of fuel. These components work in harmony to ensure smooth functionality and prevent any interruptions in fuel flow. Below is a table summarizing the essential parts involved.

Component Function Fuel Tank Stores fuel for the engine and supplies it as needed. Fuel Filter Removes impurities from the fuel before it reaches the engine. Fuel Line Ignition Parts and Wiring Understanding the components responsible for powering the ignition system is crucial for maintaining proper engine function. This section provides an overview of the key elements involved in ensuring smooth starting and reliable operation. The ignition system consists of several interconnected elements that work together to produce a spark, necessary for the combustion process.

Key Components

The ignition system is built around a few critical components, including the coil, spark plug, and wires. The coil generates the necessary voltage, the spark plug delivers it to the combustion chamber, and the wiring connects these parts efficiently, ensuring consistent communication between the engine’s electrical and mechanical systems.

Wiring and Connections

The wiring in the ignition system must be properly insulated and free of damage. Any corrosion or wear on the connectors can lead to misfires or failure to start. Ensuring the wires are correctly attached and regularly inspected helps prevent common ignition issues.

Component Function Ign Air Filter and Intake System

The efficiency of the engine relies heavily on a clean and well-maintained air intake system. This component ensures that only purified air reaches the combustion chamber, significantly contributing to the overall performance of the machinery. A well-functioning air filtration system not only improves fuel efficiency but also extends the engine’s lifespan by preventing dirt and debris from entering critical components.

Components of the Intake System

The intake system consists of several crucial parts designed to work together to ensure optimal airflow. These include the air filter, intake manifold, and related seals and clamps that help maintain airtight connections. Each element plays a specific role in filtering air and directing it to the engine in the right quantities.

Maintenance and Replacement

Regular maintenance of the intake system is key to preserving its functionality. Periodic cleaning or replacement of the air filter prevents blockages that can restrict airflow. Additionally, inspecting the intake system for any cracks or leaks in seals ensures that unfiltered air does not bypass the system, which could cause engine damage.

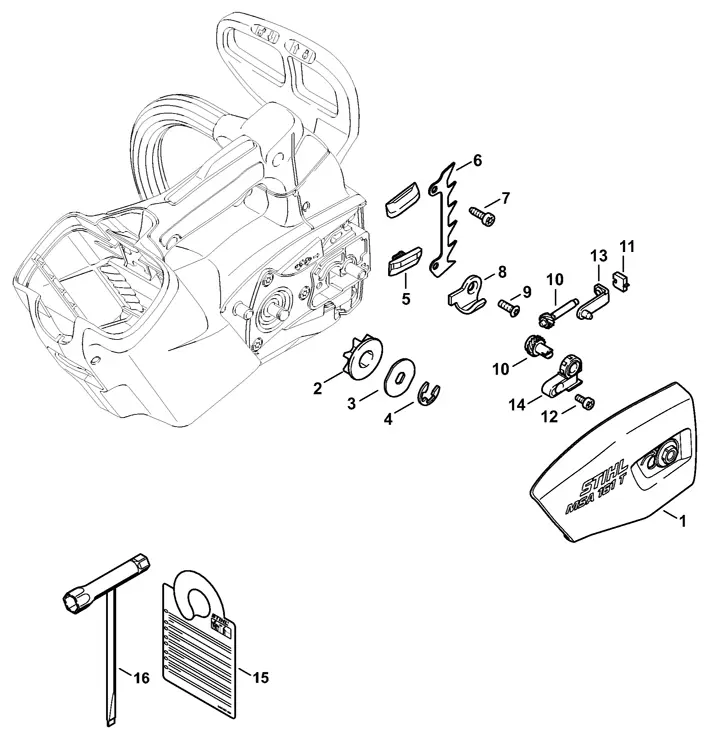

Component Function Air Filter Traps dust and debris from the air before it enters the engine Intake Manifold Distributes filtered air to the engine’s combustion chamber Chain Tensioner and Adjustments

The chain tensioning mechanism plays a vital role in ensuring optimal performance and safety during operation. Proper adjustments are necessary to maintain the ideal tightness of the cutting chain, which can affect both efficiency and longevity of the equipment.

Importance of Proper Tensioning

Maintaining the correct tension is crucial for several reasons:

- Prevents the chain from slipping off during use.

- Reduces the risk of chain breakage.

- Enhances cutting performance by allowing for smooth operation.

- Minimizes wear on the guide bar and chain, prolonging their lifespan.

Adjustment Procedure

To achieve the right tension, follow these steps:

- Ensure the equipment is turned off and cooled down.

- Locate the tensioning mechanism, typically found on the side of the bar.

- Loosen the tensioning screw using a suitable tool.

- Adjust the chain tension by turning the screw until the chain is snug against the guide bar.

- Re-tighten the screw securely to hold the adjustment in place.

- Check the tension again by pulling on the chain; it should move freely but not sag.

Regular inspection and adjustment of the chain tension will ensure safe and efficient operation, helping to prevent potential issues during use.

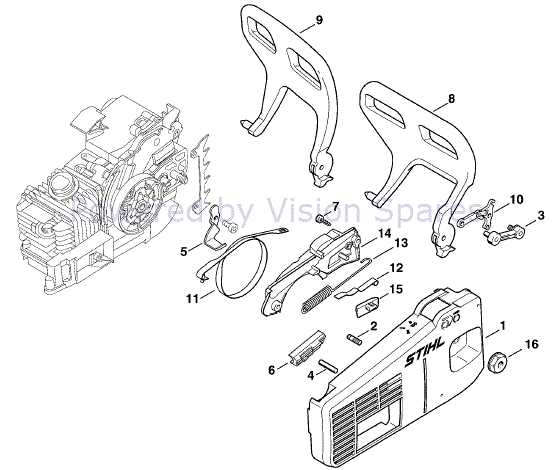

Starter Mechanism and Recoil Spring

The starter mechanism is a crucial component that facilitates the initial operation of a small engine. It enables the user to ignite the engine by manually engaging a system that generates the necessary torque. A well-functioning starter ensures smooth and reliable starts, allowing the equipment to perform efficiently.

The recoil spring plays an essential role in this system. It is designed to retract the starter cord after it has been pulled, ensuring that the mechanism resets quickly for the next attempt. This spring must maintain the right tension to ensure proper retraction, preventing the cord from becoming jammed or tangled. Regular inspection and maintenance of both the starter mechanism and recoil spring are vital for optimal performance and longevity of the equipment.

In summary, understanding the relationship between the starter mechanism and recoil spring enhances the user’s ability to troubleshoot and maintain their equipment effectively, ensuring reliable operation in various tasks.

Exhaust System Layout

The exhaust system of a chainsaw plays a crucial role in the overall performance and efficiency of the machine. It is designed to direct exhaust gases away from the engine, minimizing back pressure and enhancing combustion efficiency. Understanding the layout of this system helps in maintaining optimal engine function and prolonging the tool’s lifespan.

Components of the Exhaust System

- Muffler: This component reduces noise produced by the engine and directs exhaust gases away.

- Exhaust Port: The outlet through which gases exit the engine, ensuring proper flow and pressure.

- Exhaust Manifold: A passage that connects the exhaust port to the muffler, facilitating the movement of gases.

Maintenance Tips

- Regularly inspect the muffler for any signs of damage or blockage.

- Ensure that all connections are secure to prevent leaks.

- Clean the exhaust port to maintain proper airflow and prevent buildup.

Bar and Chain Mechanism

The bar and chain assembly plays a crucial role in the functionality of cutting equipment, enabling efficient and precise operations. This mechanism consists of interconnected components that work together to facilitate the cutting process, ensuring that the tool performs effectively under various conditions. Understanding the elements and their interactions is essential for maintaining optimal performance and longevity of the device.

Components of the System

This mechanism typically includes a guide bar, a cutting chain, and a tensioning system. The guide bar provides a stable track for the chain, allowing it to rotate smoothly during operation. The cutting chain is equipped with sharp teeth designed for slicing through wood and other materials. A tensioning system ensures that the chain remains adequately tight, preventing slippage and ensuring efficient cutting action.

Maintenance and Care

Regular maintenance of the bar and chain assembly is vital to prolong its lifespan and enhance performance. Keeping the cutting teeth sharp, adjusting the tension appropriately, and lubricating the system can prevent wear and ensure smooth operation. Additionally, inspecting the guide bar for signs of damage or wear is essential to avoid complications during use.

Clutch Assembly and Operation

The clutch system in a chainsaw plays a crucial role in the machine’s functionality, enabling efficient power transfer from the engine to the cutting mechanism. This assembly consists of various components that work together to engage and disengage the power based on the operational requirements.

At the heart of this system is the clutch drum, which is connected to the engine’s crankshaft. When the engine runs, centrifugal force acts on the clutch shoes, pushing them outward. This action engages the clutch, allowing power to flow to the chain for cutting. Conversely, when the engine speed decreases, the shoes retract, disengaging the power transfer and allowing the chain to stop, enhancing safety and control during operation.

Regular inspection and maintenance of the clutch assembly are essential to ensure optimal performance. Worn-out components can lead to slippage or inefficient engagement, negatively affecting cutting efficiency. Replacing damaged parts promptly can significantly extend the lifespan of the equipment and maintain its cutting performance.

Oil Pump and Lubrication System

The oil pump and lubrication system play a vital role in maintaining the performance and longevity of any power tool. Proper lubrication ensures that moving parts function smoothly, reducing friction and wear. A well-designed system is essential for optimizing the efficiency of the engine while preventing overheating and damage to internal components.

Functionality of the Lubrication Mechanism

This mechanism typically operates by circulating oil through various parts of the engine. The pump draws oil from a reservoir and delivers it to key areas, such as the chain and guide bar. This continuous flow is crucial for keeping the machinery running efficiently and for prolonging its operational lifespan.

Importance of Regular Maintenance

Maintaining the lubrication system is essential for optimal performance. Regular checks of the oil level, along with timely replacements of the oil filter, can prevent potential issues. Ignoring these aspects can lead to increased wear and tear, ultimately resulting in costly repairs and reduced efficiency.

Handle and Anti-Vibration Mounts

The handle assembly and anti-vibration components play a crucial role in the operation and comfort of handheld power equipment. These elements are designed to enhance user experience by providing stability and reducing the impact of vibrations generated during use. Proper integration of these features can lead to improved control and decreased fatigue over extended periods of operation.

Handles are typically crafted from durable materials, ensuring a secure grip while also being lightweight to facilitate ease of maneuverability. Anti-vibration mounts, on the other hand, serve to isolate the user from excessive oscillations that may arise during operation. This not only protects the user’s hands and arms but also contributes to the longevity of the equipment.

Incorporating effective vibration dampening solutions is essential for maintaining optimal performance and safety. Regular inspection of the handle and mounts is recommended to ensure they remain in good condition, as any wear or damage can adversely affect the functionality and comfort of the tool.