When it comes to the maintenance and operation of your cutting tool, having a clear visual representation of its various elements is essential. This resource aims to provide an overview of how each part fits together, ensuring optimal performance and longevity. A well-maintained machine not only enhances efficiency but also guarantees safety during use.

By exploring the intricate relationships among different components, you can better appreciate the engineering behind your equipment. Identifying key sections will empower you to make informed decisions regarding repairs and upgrades, ultimately prolonging the life of your tool.

Whether you are a seasoned user or a novice, familiarizing yourself with the inner workings of your chainsaw can significantly improve your experience. This guide is designed to delve into the ultimate layout of the tool, facilitating a deeper understanding of its construction and functionality.

Understanding Stihl MS 362 C-M

This section aims to provide a comprehensive overview of a popular model in the world of power tools, particularly focusing on its key features, functionality, and components. Knowing the essential parts and their roles can significantly enhance user experience and maintenance practices.

The tool is designed for both professional and recreational use, making it versatile for various tasks. Understanding the mechanics behind it can aid users in troubleshooting and optimizing performance. Below is a simplified breakdown of the main components and their purposes.

| Component | Function |

|---|---|

| Engine | Drives the cutting mechanism, providing power and efficiency. |

| Guide Bar | Supports the cutting chain and determines the cutting length. |

| Chain | Enables cutting by rotating around the guide bar. |

| Air Filter | Prevents debris from entering the engine, ensuring optimal performance. |

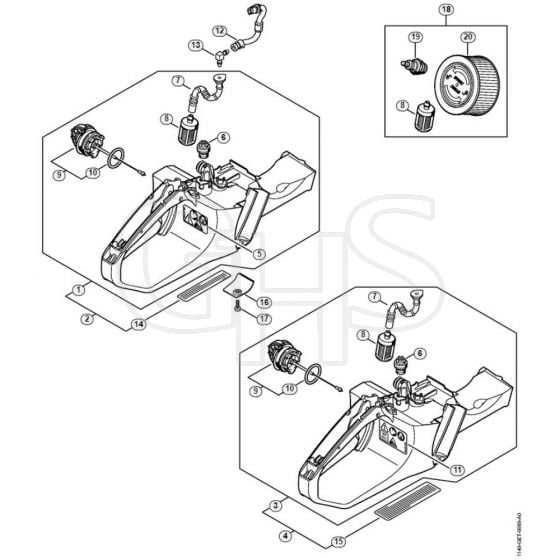

| Fuel System | Supplies the engine with the necessary fuel for operation. |

| Safety Features | Includes mechanisms like chain brakes to enhance user safety. |

By familiarizing oneself with these essential elements, users can maximize the effectiveness and longevity of their equipment. Regular maintenance and understanding of each component’s function are key to achieving the best results.

Importance of Parts Diagrams

Understanding the intricate components of machinery is essential for effective maintenance and repair. Visual representations serve as invaluable tools, enabling users to identify and locate each element within the device. This clarity enhances the repair process, minimizes errors, and fosters greater confidence among users.

Moreover, these visual aids facilitate communication between technicians and manufacturers, ensuring everyone is on the same page regarding specifications and requirements. A detailed representation helps streamline the ordering of replacements, reducing downtime and increasing efficiency. Overall, such illustrations are fundamental in achieving optimal performance and longevity of equipment.

Key Components Overview

This section provides an insight into the essential elements of a high-performance cutting tool. Understanding these critical parts is vital for effective maintenance and optimal operation. Each component plays a unique role in ensuring reliability and efficiency during use.

Power Unit

The power unit is the heart of the machine, responsible for generating the necessary energy to drive the cutting mechanism. It typically features a robust engine designed for durability and performance, ensuring that the tool can handle demanding tasks with ease. Proper maintenance of this unit is crucial for longevity and efficiency.

Cutting Assembly

The cutting assembly includes the chain and bar, which work together to deliver precision cuts. The quality and design of these elements greatly influence the effectiveness of the tool. Regular inspection and timely replacement of the chain and bar are recommended to maintain optimal performance.

Regular upkeep of these key components not only enhances the functionality of the tool but also ensures safety during operation. Familiarity with each part allows users to troubleshoot issues effectively and prolong the lifespan of their equipment.

How to Read the Diagram

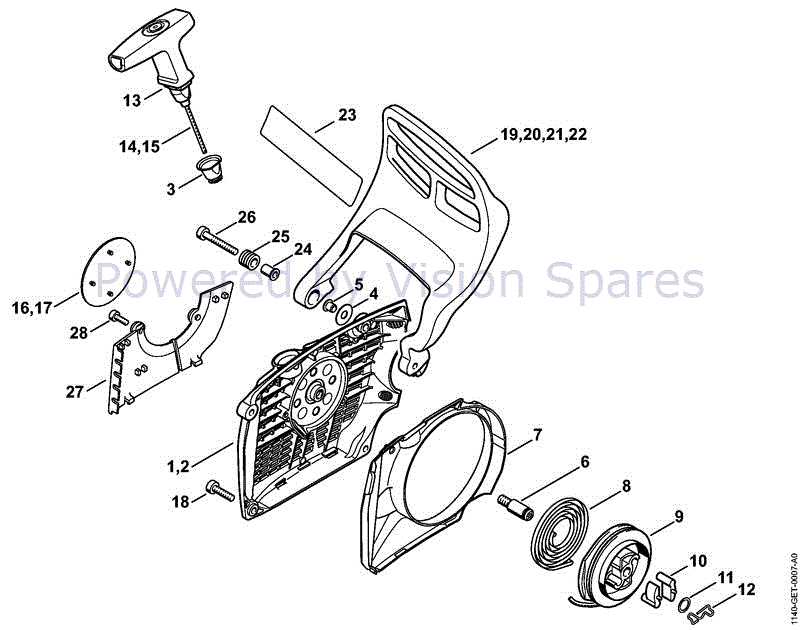

Understanding a schematic representation is essential for anyone looking to maintain or repair their equipment effectively. A visual breakdown provides clarity on how components interact and their specific locations within the assembly. By familiarizing yourself with this format, you can streamline troubleshooting and parts replacement.

Begin by identifying the key components highlighted in the illustration. Each element is typically labeled with a unique identifier, allowing for easy reference. Take note of the various sections, as they often correspond to specific functions or areas within the machine.

Next, pay attention to the connections and pathways indicated by lines or arrows. These will guide you in understanding how different parts fit together and work in unison. Analyzing these connections is crucial for comprehending the overall functionality and for diagnosing any issues that may arise.

Additionally, look for any notes or legends that accompany the visual. These annotations often provide further insights, including maintenance tips or specific part numbers, which can be invaluable when sourcing replacements. Familiarity with these details will enhance your repair experience and ensure that you are well-equipped for any task.

Common Replacement Parts

When maintaining a chainsaw, certain components may require frequent substitution to ensure optimal performance and longevity. Understanding which elements are most susceptible to wear can help users manage their equipment effectively.

Essential Components

Regular maintenance often involves replacing specific pieces that endure the most stress during operation. These components include items like the guide bar, chain, and air filter.

Replacement Guide

| Component | Frequency of Replacement | Purpose |

|---|---|---|

| Guide Bar | Every 3-5 uses | Supports the chain and aids in cutting |

| Chain | Every 5-10 uses | Facilitates cutting through wood |

| Air Filter | Monthly | Prevents debris from entering the engine |

Maintenance Tips for Longevity

Ensuring the durability and efficiency of your equipment requires consistent care and attention. Regular maintenance not only extends the life of your tool but also enhances its performance, making it a reliable companion for all your tasks.

| Tip | Description |

|---|---|

| Regular Cleaning | Remove debris and dirt after each use to prevent wear and tear. |

| Check Fuel and Oil Levels | Maintain proper levels to ensure optimal engine performance and lubrication. |

| Inspect Components | Regularly examine parts for damage or wear, replacing them as needed. |

| Sharpen Blades | Keep cutting edges sharp for efficient operation and reduced strain on the engine. |

| Follow Manufacturer Guidelines | Adhere to recommended service intervals and procedures for best results. |

Identifying Compatible Accessories

When it comes to enhancing your outdoor equipment, selecting the right attachments and components is essential for optimal performance and longevity. Understanding compatibility ensures that your machine operates smoothly while maximizing efficiency.

Researching Compatibility

Start by consulting the manufacturer’s guidelines and specifications. This will provide a solid foundation for identifying which accessories are suitable for your model. Always look for detailed information regarding dimensions, fitting mechanisms, and performance ratings.

Evaluating Aftermarket Options

While original parts are often the safest choice, there are numerous aftermarket options available. Ensure these alternatives meet quality standards and are designed to function seamlessly with your equipment. Reading reviews and seeking recommendations can also help you make informed decisions.

Assembly Instructions for Components

Proper assembly of machine elements is crucial for optimal performance and longevity. Following a systematic approach ensures that each part fits correctly and functions as intended. This section provides detailed guidelines for assembling various components, enhancing your understanding of the process.

Begin by gathering all necessary components and tools. Organize them to streamline the assembly process and minimize errors. Referencing a detailed schematic can also help visualize the correct configuration.

| Step | Description |

|---|---|

| 1 | Inspect each component for damage or wear before beginning assembly. |

| 2 | Align the primary unit with the corresponding mounting brackets securely. |

| 3 | Attach the secondary components, ensuring proper orientation to avoid misalignment. |

| 4 | Use appropriate fasteners and tighten them according to specified torque settings. |

| 5 | Perform a final inspection to confirm that all parts are securely attached and functioning smoothly. |

Following these steps will lead to a successful assembly, contributing to the efficiency and reliability of the machine. Always consult the specific manuals for any additional requirements or special considerations.

Troubleshooting Common Issues

Addressing problems with outdoor power equipment can be straightforward with the right approach. Understanding common malfunctions and their symptoms allows for effective diagnosis and timely repairs. This section will guide you through frequently encountered issues and provide insights into their potential causes and solutions.

One prevalent concern is difficulty starting the machine. If the engine refuses to ignite, it may indicate issues with the fuel supply, such as stale gasoline or a clogged filter. Ensuring the fuel is fresh and the filter is clean can often resolve this problem. Additionally, check the spark plug for wear or damage, as a faulty spark plug can prevent ignition.

Another common issue is irregular engine performance, which may manifest as stalling or a lack of power during operation. This can be attributed to several factors, including an improperly adjusted carburetor or air filter obstructions. Regular maintenance, including cleaning or replacing the air filter and tuning the carburetor, is essential for optimal functionality.

Excessive vibrations while operating the equipment can also signal underlying issues. This may result from loose or damaged components, such as the chainsaw bar or blade. Inspecting these parts and ensuring they are securely fastened can help minimize vibrations and enhance safety.

Lastly, if the tool emits unusual noises or shows signs of overheating, it may indicate lubrication problems or mechanical wear. Regularly checking the oil levels and using the appropriate lubricant can prevent these issues. If problems persist, consulting a professional technician may be necessary to avoid further damage.

Tools Required for Repairs

When undertaking maintenance or fixing equipment, having the right instruments is essential for a successful outcome. Proper tools not only streamline the process but also ensure safety and efficiency during repairs.

Essential items include wrenches, screwdrivers, and pliers, which facilitate the assembly and disassembly of various components. Additionally, a torque wrench may be necessary to apply the correct amount of force when tightening screws and bolts.

Specialized tools, such as chain sharpeners and cleaning brushes, help maintain performance and longevity. Lastly, protective gear like gloves and goggles is crucial for personal safety throughout the repair process.

Where to Find Genuine Parts

Locating authentic components for your machinery is essential for optimal performance and longevity. Ensuring that you use quality replacements can prevent issues and maintain efficiency. Here are some trusted sources to consider when searching for these items.

Authorized Dealers

- Visit local retailers that specialize in power equipment.

- Check the manufacturer’s website for a list of certified distributors.

- Inquire about warranty services that may include replacement options.

Online Platforms

- Explore e-commerce sites that focus on outdoor equipment.

- Look for forums and communities dedicated to machinery where users share recommendations.

- Verify the credibility of sellers by checking reviews and ratings.

Understanding Warranty Coverage

Warranty coverage is an essential aspect of purchasing power tools, ensuring that customers receive support and protection for their investment. Understanding the terms and conditions associated with a warranty can help users make informed decisions and maintain their equipment effectively.

Key Components of Warranty Coverage

When evaluating warranty options, consider the following elements:

- Duration: Most warranties specify a timeframe during which claims can be made, typically ranging from one to three years.

- Scope: Warranties usually cover defects in materials and workmanship but may exclude normal wear and tear or misuse.

- Claim Process: Understanding the steps to file a warranty claim is crucial. This often includes providing proof of purchase and a detailed description of the issue.

Importance of Keeping Documentation

Maintaining accurate records is vital for a smooth warranty experience:

- Keep receipts and invoices as proof of purchase.

- Document maintenance activities and repairs performed.

- Familiarize yourself with warranty terms to avoid misunderstandings.

By comprehending the nuances of warranty coverage, users can enhance their ownership experience and ensure their equipment remains in optimal condition for years to come.

Upgrading Components for Performance

Enhancing the efficiency and power of your equipment often involves the strategic modification of its internal elements. By carefully selecting and upgrading specific parts, users can achieve improved functionality and longevity. This section explores various enhancements that can elevate overall performance, making tools more effective for demanding tasks.

One of the primary areas for improvement is the air intake system. Upgrading to a high-flow air filter can increase airflow, resulting in better combustion and, ultimately, higher power output. Pairing this with a tuned exhaust system can further optimize performance by reducing back pressure and enhancing exhaust flow.

Additionally, considering the ignition system is crucial. An advanced ignition module can provide a stronger spark and more precise timing, leading to improved acceleration and responsiveness. This can be particularly beneficial in demanding applications where every bit of power counts.

Another aspect to consider is the fuel system. Implementing a performance carburetor can allow for more precise fuel delivery, which can enhance the efficiency of the combustion process. This results in better throttle response and increased overall power.

Lastly, upgrading the cutting components, such as chains and bars, can significantly affect performance. Choosing lighter materials or specialized designs can reduce drag and improve cutting speed, making tasks more efficient and less labor-intensive.