For anyone engaged in the maintenance or repair of a chainsaw, a thorough grasp of its individual elements is essential. Recognizing how these components fit together can significantly enhance the efficiency of your equipment. This section will delve into the intricate assembly of a specific model, offering insights that cater to both seasoned users and newcomers.

Exploring the intricate layout of a chainsaw is vital for troubleshooting issues and ensuring optimal performance. Each segment, from the power source to the cutting mechanisms, plays a crucial role in the overall functionality. By examining how these parts interact, users can better appreciate their significance in the machinery.

Additionally, understanding the various components allows for more informed decisions when it comes to replacements or upgrades. Whether seeking to enhance performance or resolve a malfunction, knowledge of the equipment’s structure empowers users to act confidently. This exploration serves as a valuable resource for anyone looking to optimize their chainsaw experience.

This section provides a comprehensive understanding of a popular cutting tool designed for various applications. Its robust design and user-friendly features make it a preferred choice for both professionals and DIY enthusiasts.

The tool is known for its reliability and efficiency in handling different types of woodwork tasks. Below are some key highlights:

- Powerful Engine: Equipped with a strong motor that ensures optimal performance.

- Lightweight Design: Easy to maneuver, reducing fatigue during extended use.

- Safety Features: Incorporates mechanisms to enhance user safety during operation.

- Versatile Use: Suitable for various tasks, from cutting firewood to pruning trees.

Understanding the components and functionality of this chainsaw will aid users in achieving the best results while ensuring longevity and performance. Regular maintenance and familiarity with the tool’s features contribute significantly to its effectiveness.

Key Features of the MS211 Model

This model stands out due to its remarkable design and functionality, catering to both novice and experienced users. With an emphasis on efficiency and reliability, it has become a popular choice among outdoor enthusiasts and professionals alike.

Powerful Engine Performance

The engine delivers impressive power, ensuring optimal cutting efficiency. Its robust design minimizes vibrations, allowing for smoother operation during extended use.

Lightweight and Ergonomic Design

Featuring a lightweight structure, this model is easy to handle and maneuver, reducing user fatigue. The ergonomic grip enhances comfort, making it suitable for prolonged tasks without compromising performance.

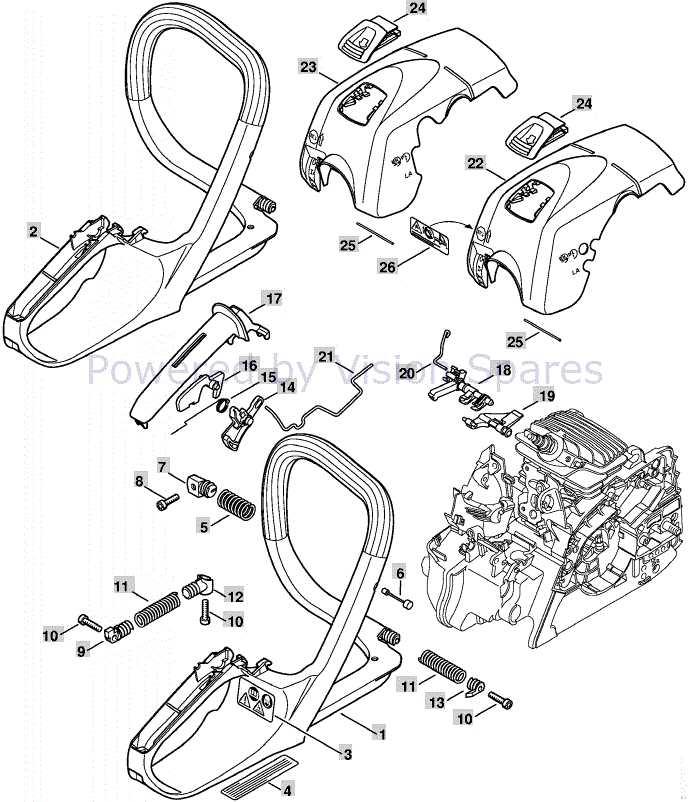

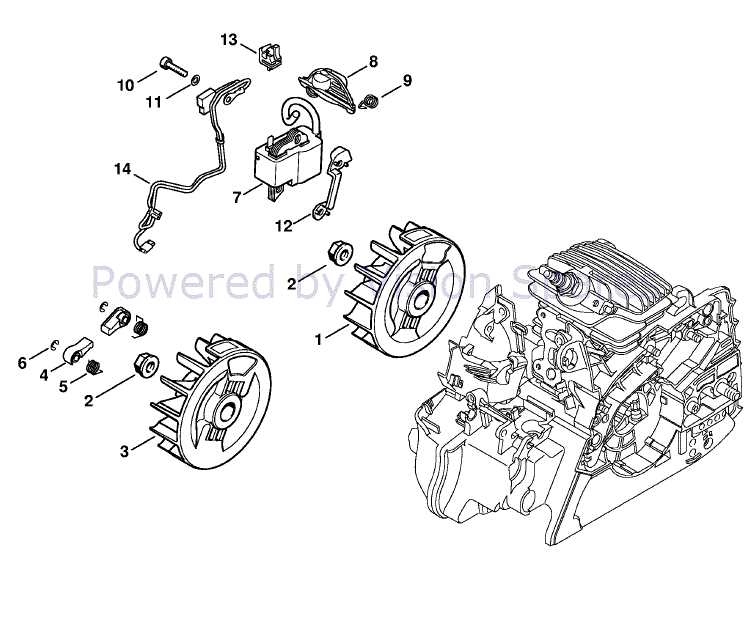

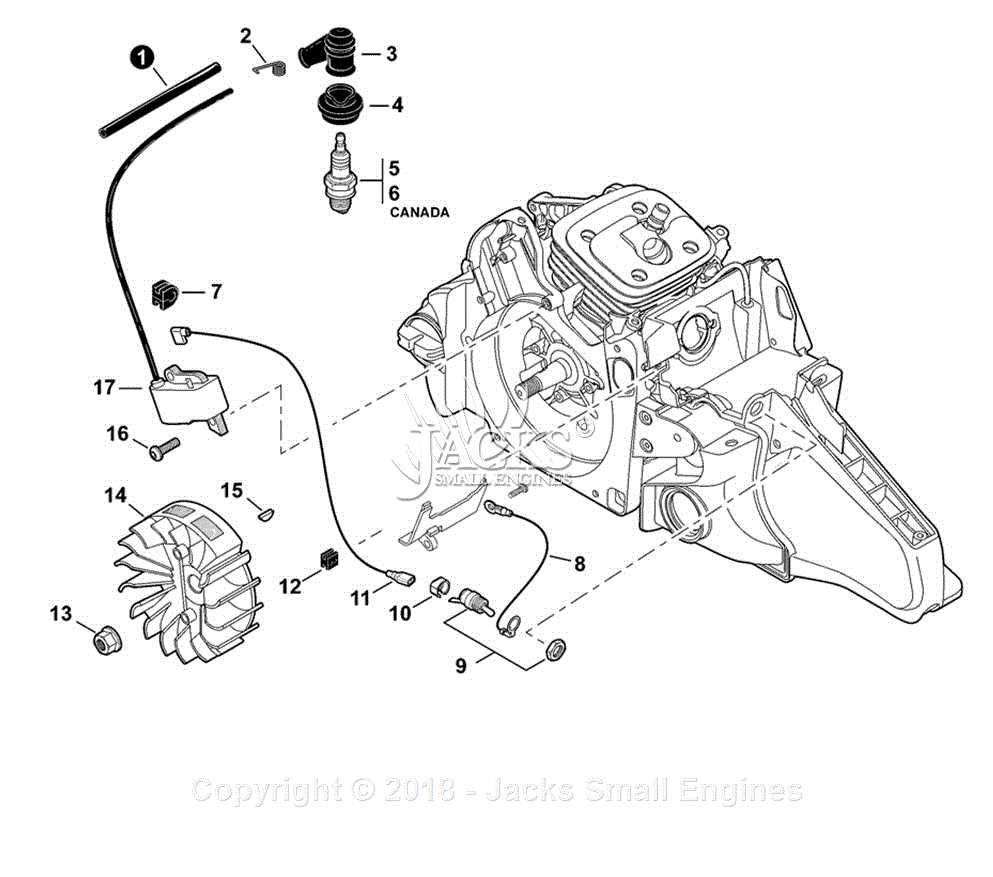

Importance of Parts Diagram

Understanding the layout of a machine’s components is crucial for maintenance and repair. A visual representation of these elements provides users with the necessary information to identify and locate each part efficiently. This knowledge can significantly enhance the overall performance and longevity of the equipment.

Enhances Maintenance Efficiency

Having a clear illustration of the components allows for quicker diagnostics and repairs. When users can easily see where each element is located, they can:

- Identify worn or damaged pieces swiftly.

- Reduce the time spent on maintenance tasks.

- Ensure that all components are correctly reassembled after servicing.

Facilitates Accurate Replacements

When replacing worn or damaged items, knowing the exact specifications and placements is vital. A comprehensive representation aids in:

- Selecting the right replacements from suppliers.

- Avoiding errors that could lead to improper installations.

- Ensuring optimal functioning by matching parts accurately.

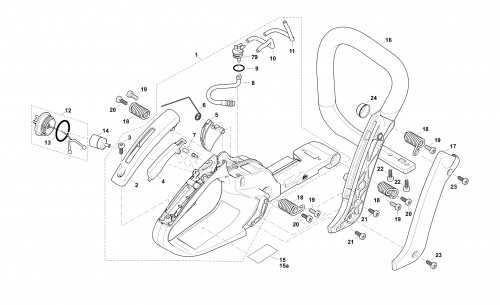

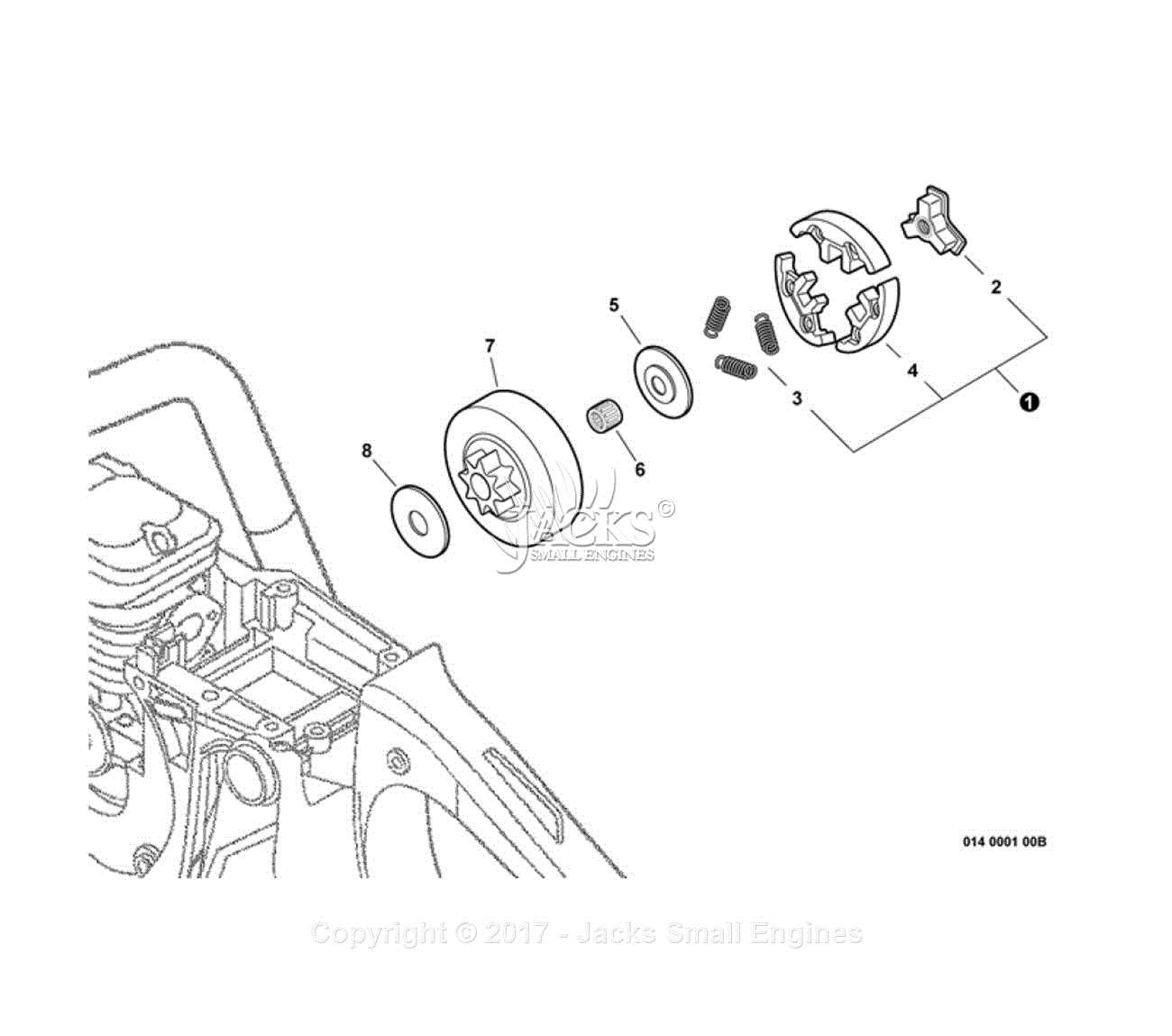

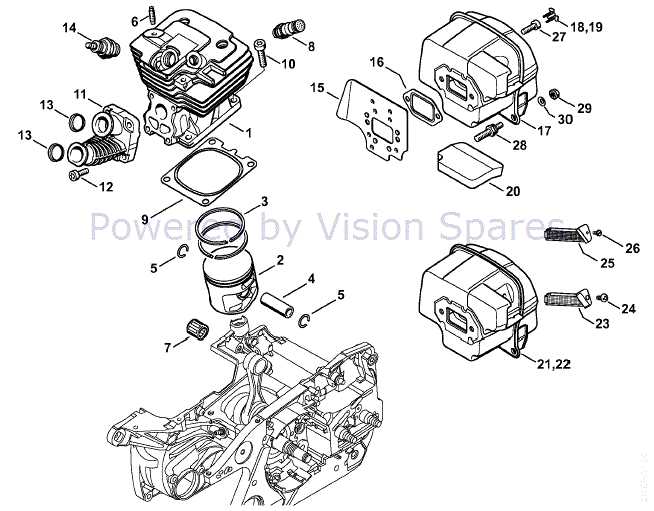

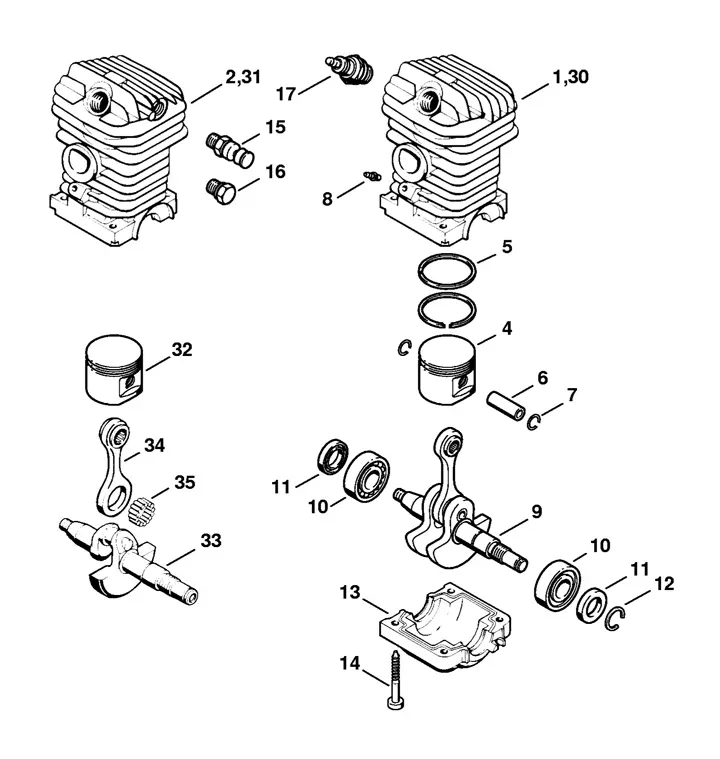

Main Components of MS211

The core elements of this cutting tool play a crucial role in its performance and functionality. Understanding these key parts can enhance user experience and maintenance, ensuring efficient operation.

Engine: The power unit serves as the heart of the equipment, converting fuel into mechanical energy. Its performance directly impacts cutting efficiency and overall capability.

Bar and Chain: These components work together to create the cutting action. The bar provides the support, while the chain, equipped with sharp teeth, facilitates the actual cutting process.

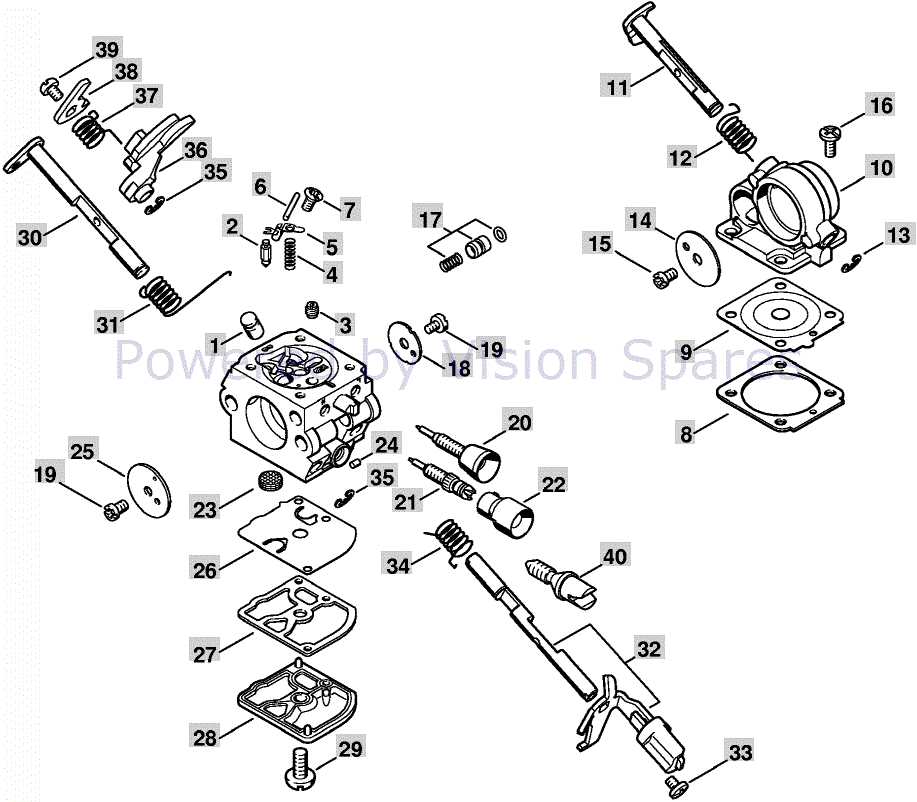

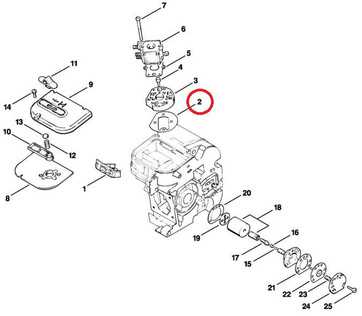

Fuel System: This system is essential for delivering the necessary fuel mixture to the engine, ensuring optimal combustion and power generation. Proper maintenance of this system is vital for reliable operation.

Ignition System: Responsible for starting the engine, this system initiates the combustion process. A well-functioning ignition system is critical for the tool’s responsiveness and efficiency.

Air Filter: This component protects the engine from dust and debris, ensuring clean air intake. Regular checks and replacements can prolong the engine’s lifespan and maintain its performance.

How to Read the Parts Diagram

Understanding a technical illustration is essential for effective maintenance and repair. These visual guides provide an overview of components and their relationships within a machine, facilitating a smoother workflow. Familiarity with the layout enhances the ability to locate and identify each element accurately.

Identifying Key Components

Begin by familiarizing yourself with the major sections of the illustration. Each group often represents a specific area of the equipment, highlighting various elements such as:

- Engines and power sources

- Cutting tools and blades

- Housing and protective covers

- Control mechanisms

Understanding Symbols and Labels

Technical illustrations utilize various symbols and labels to convey information efficiently. Pay attention to the following:

- Numbers: Corresponding to a parts list for easy reference.

- Arrows: Indicate the direction of assembly or movement.

- Color coding: Helps differentiate between various types of components.

By mastering these elements, you can effectively navigate the illustration, leading to improved repair and maintenance practices.

Identifying Replacement Parts

When maintaining outdoor power equipment, recognizing the correct components is crucial for optimal performance. Proper identification ensures that the machine operates smoothly and efficiently. Understanding the various elements involved can significantly simplify the repair process and enhance the longevity of the device.

Common Components to Consider

- Engine assembly

- Bar and chain

- Fuel system parts

- Ignition components

- Air filtration system

Steps to Identify Necessary Components

- Consult the equipment manual for specifications.

- Inspect the existing components for any markings or numbers.

- Research online databases or retailer catalogs for compatibility.

- Seek assistance from professionals if uncertain about any parts.

By following these guidelines, users can confidently identify the components required for their machinery, ensuring efficient repairs and replacements.

Maintenance Tips for MS211

Proper upkeep of your cutting equipment is essential for optimal performance and longevity. Regular maintenance ensures that the machine operates smoothly, reducing the risk of breakdowns and enhancing safety during use. Below are key practices to keep your equipment in top condition.

1. Clean the Equipment Regularly: After each use, it is crucial to remove any debris, sawdust, or residue that may have accumulated. A clean exterior prevents overheating and promotes better airflow.

2. Check the Chain Tension: Ensure that the chain is correctly tensioned. A loose chain can lead to inefficient cutting and potential accidents, while an overly tight chain can cause excessive wear and tear on both the chain and the bar.

3. Sharpen the Chain: Regularly sharpening the chain enhances cutting efficiency and reduces strain on the motor. Dull blades not only make cutting more difficult but also increase the likelihood of accidents.

4. Inspect and Replace Worn Parts: Periodically check for signs of wear on components such as the chain, bar, and air filter. Timely replacement of these parts is essential to maintain optimal functionality.

5. Store Properly: When not in use, ensure the equipment is stored in a dry, secure location. Proper storage helps prevent damage from environmental factors and extends the lifespan of the machinery.

By following these maintenance tips, you can ensure that your cutting equipment remains reliable and effective throughout its life. Consistent care not only improves performance but also promotes safety for the user.

Common Issues and Solutions

In the realm of outdoor power tools, encountering problems is not uncommon. Understanding typical challenges can help users troubleshoot effectively and maintain optimal performance. This section explores frequent complications faced by users and offers practical solutions to enhance tool longevity.

| Issue | Description | Solution |

|---|---|---|

| Engine Won’t Start | The machine fails to ignite, often due to fuel or ignition issues. | Check fuel levels, ensure fresh fuel is used, and inspect the spark plug for damage. |

| Chain Doesn’t Move | The cutting chain remains stationary, hindering operation. | Examine the chain tension and adjust as necessary; ensure the chain brake is disengaged. |

| Overheating | The tool becomes excessively hot during use, which can lead to damage. | Allow the engine to cool down; check for blocked air vents and clean as needed. |

| Vibrations | Excessive vibrations can affect control and comfort during operation. | Ensure all screws and components are securely tightened; consider using vibration-dampening gloves. |

Ordering Genuine Stihl Parts

When it comes to maintaining your equipment, ensuring you have access to authentic components is crucial. These original replacements guarantee compatibility and durability, enhancing the overall performance of your machinery. Knowing where and how to acquire these items can make a significant difference in the longevity and efficiency of your tools.

Finding Authorized Dealers

Locate certified retailers that specialize in authentic components. These vendors are equipped with knowledgeable staff who can assist in identifying the correct items needed for your specific model. Always check their credentials to confirm they offer genuine products.

Utilizing Online Resources

The internet provides various platforms where you can browse and order original replacements. Many official websites feature extensive catalogs and diagrams, allowing you to select the exact components required. Take advantage of customer support services to clarify any doubts regarding compatibility.

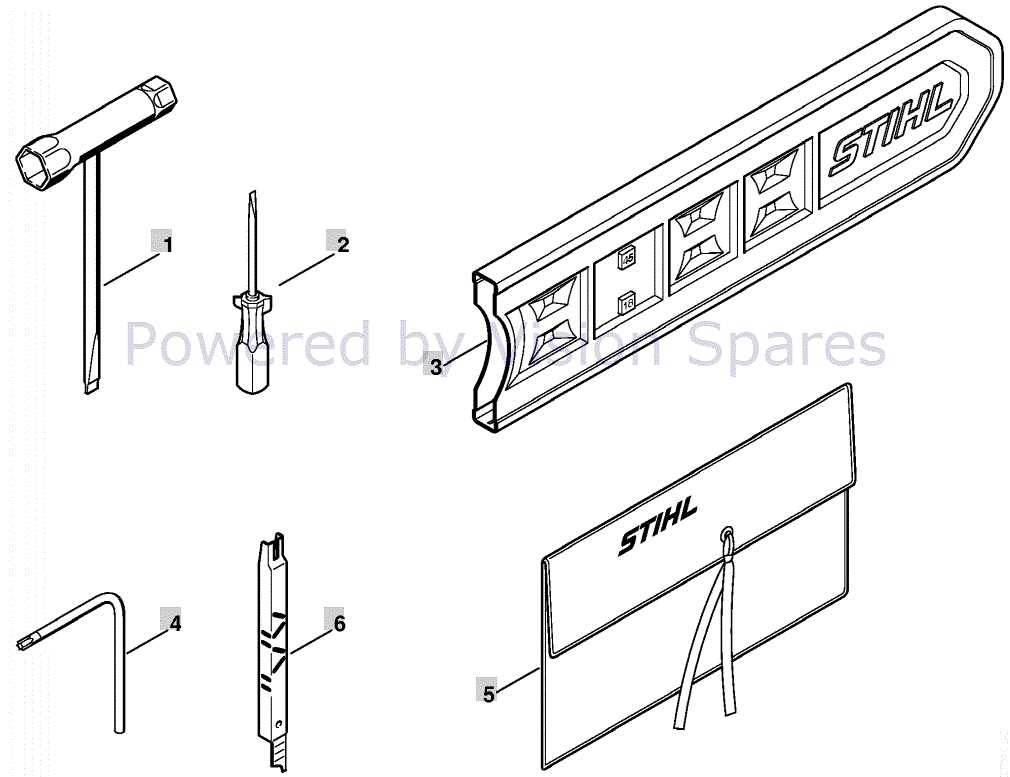

Assembly and Disassembly Guidelines

Proper techniques for assembling and disassembling equipment are essential for maintaining functionality and ensuring safety. Understanding each component’s role will help streamline the process and prevent damage during handling. This section provides valuable insights into effective methods and best practices for reassembling machinery.

Before beginning the assembly or disassembly process, it is crucial to have the right tools at hand. Ensure a clean, organized workspace to facilitate an efficient workflow. Below is a table outlining the necessary tools and their purposes:

| Tool | Purpose |

|---|---|

| Wrench Set | For loosening and tightening bolts and nuts. |

| Screwdriver Set | For removing and securing screws of various types. |

| Pliers | For gripping and bending components as needed. |

| Safety Gloves | To protect hands during handling of sharp or heavy parts. |

| Cleaning Cloth | For wiping down surfaces and removing debris. |

Follow these steps for efficient assembly:

- Identify each component and its corresponding location.

- Start with the base and gradually build upwards, ensuring secure fits.

- Use the appropriate tools to avoid stripping screws or damaging parts.

During disassembly, remember to document each step. This practice aids in reassembly and minimizes confusion. Reversing the assembly steps is generally effective, but always refer to the specific requirements of each component. Proper handling and organization of parts will significantly enhance the reassembly process.

Where to Find Parts Diagrams

Finding visual representations of components for your equipment is essential for maintenance and repairs. These illustrations provide a clear overview of each element and how they fit together, facilitating a more efficient repair process. Here are some reliable resources to help you locate these valuable references.

Online Resources

- Manufacturer’s Website: Official sites often have detailed visuals for their products, making them a primary source for accurate information.

- Online Retailers: Many online shops specialize in equipment supplies and provide visuals alongside their listings, aiding in identification.

- Forums and Community Groups: Enthusiasts and professionals often share resources, including illustrations, on dedicated platforms.

Printed Manuals and Guides

- Owner’s Manual: Always check the owner’s manual, as it frequently includes detailed images and breakdowns of components.

- Service Manuals: These comprehensive guides usually provide extensive visual references and are invaluable for in-depth repairs.