Maintaining and repairing a chainsaw requires a clear understanding of how its various components fit together. By having a detailed visual reference, you can ensure that every element is correctly placed, minimizing potential issues during assembly or disassembly. This guide aims to provide an organized look at essential mechanisms, offering clarity for both beginners and experienced users.

Understanding the internal and external mechanisms of your cutting tool allows for more efficient repairs and adjustments. Whether you are troubleshooting a problem or simply performing routine upkeep, this resource helps you identify key parts and their respective functions, ensuring your tool operates smoothly and safely.

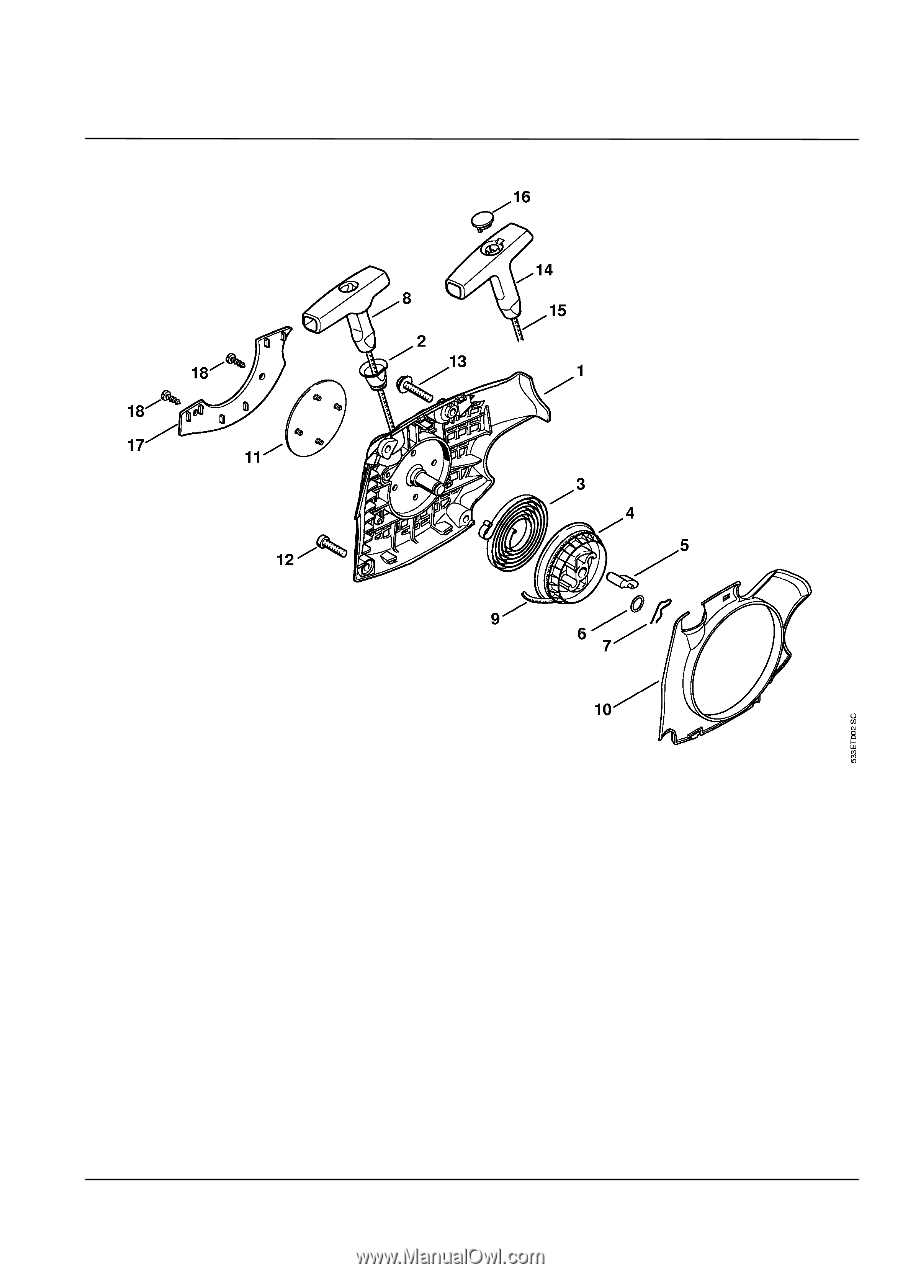

Stihl MS211C Parts Overview

This section introduces the key components that make up the structure and functionality of the well-known chainsaw model. Understanding these elements is crucial for proper maintenance and efficient performance, as each element contributes to the overall operation. We will explore the essential elements, providing a clear understanding of their roles in ensuring smooth operation.

Key Components Breakdown

The main body contains several critical units that work together to deliver power and precision. These units are designed for durability and ease of use, ensuring the tool operates effectively. Each segment plays a distinct role, from powering the engine to controlling the cutting mechanism.

| Component | Description | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Engine Unit | The power source that drives the cutting process, providing the necessary force for operation. |

| Component | Function |

|---|---|

| Clutch Drum | Houses the friction pads and engages with the drive belts to transfer power. |

| Friction Pads | Provide the necessary grip to engage the clutch, allowing for power transmission. |

| Springs | Control the engagement force of the clutch, ensuring smooth operation. |

| Drive Belts | Connect the engine to the clutch drum, transmitting power to the cutting tool. |

Proper maintenance of the clutch mechanism is essential for preventing wear and ensuring efficient operation. Regular inspection and replacement of worn components can enhance performance and prolong the life of the equipment.

Recoil Starter Functionality

The recoil starter is a critical component in many handheld power tools, serving as the mechanism to initiate the engine’s operation. It allows users to easily start the engine by providing a reliable and straightforward way to engage the ignition system. This essential feature ensures that the equipment is ready for use with minimal effort, making it a vital aspect of user experience.

How It Works

When the operator pulls the starter cord, it activates a spring-loaded device that spins the engine’s flywheel. This action creates the necessary momentum for the ignition process to begin. The recoil system typically consists of a series of pulleys and a spring mechanism that efficiently translates the pulling motion into rotational energy. Once the engine fires, the system retracts the cord back into its housing, ready for the next start.

Importance of Maintenance

Regular upkeep of the recoil starter is essential for ensuring reliable performance. Dirt and debris can accumulate, affecting the smooth operation of the mechanism. Additionally, wear and tear on the cord or spring may lead to starting difficulties. Routine inspections and timely replacements of worn parts can significantly enhance the longevity and efficiency of this crucial starting system.

Oil Pump and Lubrication System

The oil pump and lubrication system play a vital role in ensuring the longevity and efficient operation of a chainsaw. Proper lubrication minimizes friction between moving parts, reduces wear, and enhances overall performance. Understanding the components and functionality of this system is essential for effective maintenance and optimal performance.

Key components of the lubrication system include:

- Oil Pump: This device is responsible for delivering oil to critical areas of the engine, ensuring that all moving parts are adequately lubricated.

- Oil Reservoir: A storage tank that holds the lubricating oil, from which the pump draws the necessary fluid.

- Oil Lines: Tubes that transport the oil from the reservoir to the pump and then to the engine components.

- Nozzles: These direct the flow of oil precisely where it is needed, allowing for efficient lubrication.

When considering the functionality of the lubrication system, several aspects should be noted:

- The oil pump typically operates automatically, adjusting the flow based on the engine’s RPM.

- Regularly checking the oil level in the reservoir is crucial to prevent the pump from running dry, which could lead to serious damage.

- It is important to use the correct type of oil for the system to ensure optimal lubrication and performance.

- Periodic inspection of the oil lines and nozzles is necessary to identify any blockages or leaks that could impede oil flow.

By understanding and maintaining the oil pump and lubrication system, users can enhance the durability and efficiency of their chainsaw, ensuring it operates smoothly for years to come.

Handle Assembly and Vibration Control

The handle assembly plays a crucial role in the overall functionality and comfort of power tools. Proper design and construction not only enhance user experience but also ensure safe operation during extended use. A well-engineered handle can significantly reduce fatigue and improve control, especially in high-performance applications.

Vibration control is an essential feature in the handle assembly, as excessive vibrations can lead to discomfort and long-term health issues. Effective vibration dampening systems help minimize the impact of vibrations on the user’s hands and arms. This section discusses the key components and mechanisms that contribute to effective handle assembly and vibration management.

- Handle Design: Ergonomic shapes and materials contribute to a comfortable grip, reducing strain during operation.

- Damping Mechanisms: Various technologies, such as rubber mounts or springs, can absorb vibrations before they reach the user.

- Weight Distribution: A balanced design helps maintain control and stability, minimizing the effects of vibration.

- Maintenance Considerations: Regular checks on the handle assembly and its components ensure optimal performance and user safety.

Understanding the importance of handle assembly and vibration control is essential for users seeking to enhance their experience and maintain their tools effectively. By focusing on these aspects, operators can achieve better results while ensuring their safety and comfort.