In the world of power tools, having a clear understanding of the intricate layout of each element is essential for effective maintenance and repairs. Every component plays a crucial role in the overall functionality, ensuring optimal performance and longevity of the machine. Knowing how these elements interact can greatly enhance the user experience.

For enthusiasts and professionals alike, delving into the specifics of each section provides valuable insights. Recognizing the placement and purpose of various items not only aids in troubleshooting but also facilitates a smoother repair process. This knowledge empowers users to tackle challenges confidently.

Ultimately, grasping the comprehensive structure of your equipment will enhance your skills and efficiency. This guide aims to illuminate the details, helping you navigate through the essential components with ease and precision.

Understanding Stihl MS390 Components

This section aims to provide insight into the essential elements of a specific model of power equipment, exploring their functions and interrelationships. By grasping these components, users can enhance their operational efficiency and maintenance practices.

Main Elements

- Engine: The heart of the machine, responsible for power generation.

- Fuel System: Ensures proper mixture and delivery of fuel.

- Ignition System: Initiates combustion for optimal performance.

- Chain System: Transmits power to the cutting mechanism.

- Bar: Guides and supports the chain during operation.

Maintenance Tips

- Regularly check the fuel mixture for efficiency.

- Inspect the chain for wear and proper tension.

- Clean the air filter to ensure optimal airflow.

- Keep the spark plug in good condition for reliable ignition.

Importance of Parts Diagrams

Understanding the structure and components of machinery is crucial for effective maintenance and repairs. Visual representations serve as valuable resources, helping users identify individual elements and their relationships within the overall system. This clarity can significantly enhance the efficiency of troubleshooting and assembly processes.

Benefits of Visual Guides

Utilizing visual guides offers several advantages:

| Benefit | Description |

|---|---|

| Improved Clarity | Illustrations provide a clear view of how components fit together, reducing confusion during repairs. |

| Enhanced Accuracy | Visual aids help in ensuring the correct parts are used, minimizing the risk of errors. |

| Time Efficiency | Quick reference to illustrations can significantly speed up the repair process. |

| Better Communication | Illustrations facilitate discussions among technicians, making it easier to convey complex ideas. |

Conclusion

In summary, visual representations of machine components are essential tools for anyone involved in maintenance and repair. They foster understanding, enhance precision, and streamline the entire process, ultimately contributing to improved performance and longevity of the equipment.

Key Features of Stihl MS390

This model is designed for both professional and amateur users, offering a blend of power and usability. Its construction emphasizes durability and efficiency, making it a reliable choice for various tasks in forestry and landscaping.

Powerful Engine

The unit boasts a robust engine that delivers exceptional cutting performance. With high torque and optimal fuel efficiency, it ensures prolonged usage without frequent refueling.

User-Friendly Design

Featuring an ergonomic handle and lightweight structure, this tool is easy to maneuver. The quick-access air filter and simplified starting mechanism enhance the overall user experience, allowing for seamless operation.

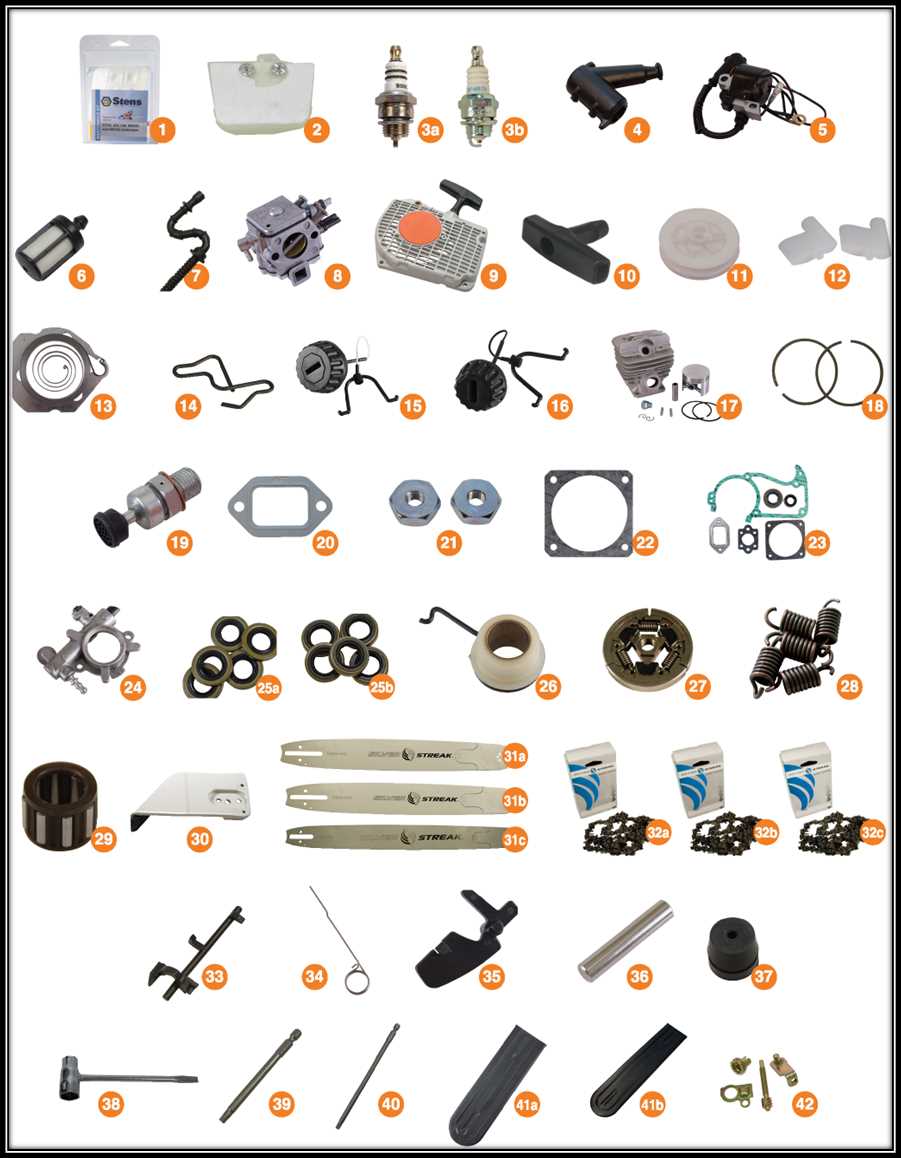

Identifying Essential Replacement Parts

Understanding the key components of your equipment is crucial for maintaining optimal performance. Regular assessment of these elements ensures that your machine operates efficiently and minimizes the risk of unexpected failures. Knowing which components may require replacement can significantly enhance the longevity and effectiveness of your tool.

Key Components to Monitor

Several essential elements should be regularly inspected for wear and tear. Keeping an eye on these parts can prevent costly repairs and ensure seamless operation.

| Component | Function |

|---|---|

| Cylinder | Houses the piston and creates compression for the engine. |

| Piston | Converts fuel energy into mechanical energy. |

| Chain | Transfers power from the engine to the cutting mechanism. |

| Air Filter | Prevents dirt and debris from entering the engine. |

Signs of Wear and When to Replace

Recognizing the signs of deterioration in these components is essential. Unusual noises, decreased performance, or visible damage indicate the need for immediate attention and potential replacement to maintain the machine’s efficiency.

Common Repairs for MS390 Chainsaw

Owning a powerful cutting tool requires understanding some of the most frequent issues that may arise during its operation. Familiarity with common malfunctions can significantly enhance the longevity and efficiency of your equipment. This section will cover typical repairs, helping you maintain peak performance and avoid unnecessary downtime.

Engine Troubles

One of the most prevalent concerns is engine performance. Issues such as difficulty starting, stalling, or reduced power can stem from various factors. Clogged fuel filters and dirty air filters are common culprits that can impede airflow and fuel delivery. Regular cleaning and timely replacements of these components are essential for optimal function.

Chain and Bar Maintenance

The cutting elements require special attention to ensure effective operation. Worn chains can lead to poor cutting performance and increased strain on the engine. Additionally, a damaged guide bar can affect alignment and efficiency. Periodic inspection and timely replacement of these parts are crucial for maintaining smooth and safe cutting action.

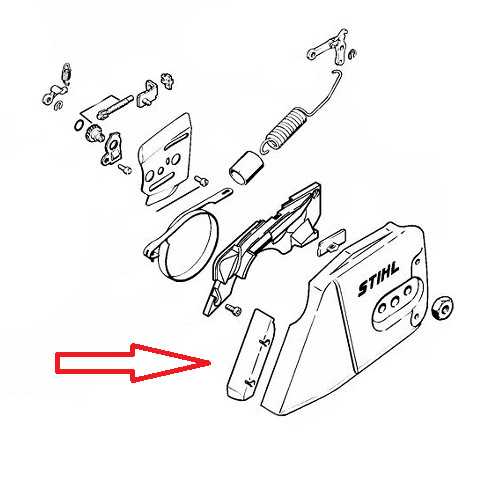

How to Read Parts Diagrams

Understanding visual representations of components is essential for efficient maintenance and repair. These illustrations provide a clear layout of each element, making it easier to identify necessary pieces for replacement or servicing.

| Step | Description |

|---|---|

| 1 | Begin by locating the key or legend, which explains symbols and numbering used in the visual guide. |

| 2 | Identify the main assembly or system being represented to understand its overall structure. |

| 3 | Focus on individual components; note how they fit together and their specific roles within the assembly. |

| 4 | Cross-reference with your manual or parts list to ensure you are looking at the correct elements. |

Where to Find Authentic Parts

Locating genuine components for your outdoor power equipment is essential for optimal performance and longevity. Various sources provide reliable options, ensuring you acquire the right elements that meet quality standards. Whether you’re seeking replacements or upgrades, knowing where to look can save time and enhance your experience.

Official dealerships are the most dependable source, offering products that meet manufacturer specifications. These retailers often have knowledgeable staff who can assist with your specific needs. Additionally, authorized service centers can provide both parts and expert installation, ensuring everything functions correctly.

Online marketplaces also present a vast selection of genuine components. Reputable websites often feature customer reviews, allowing you to gauge the reliability of the seller. Always verify that the components come with proper documentation to ensure authenticity.

Finally, community forums and local enthusiast groups can be valuable resources. Fellow users often share insights on where to find authentic products and may even sell or trade components. Engaging with such communities can provide tips and leads on hard-to-find items.

Maintaining Your Stihl MS390

Proper upkeep of your power tool is essential for optimal performance and longevity. Regular attention ensures that it operates efficiently and safely, preventing potential breakdowns that can hinder your work.

Routine Inspections: Make it a habit to inspect the equipment regularly. Check for wear and tear, especially on the cutting components, and address any issues promptly to avoid further damage.

Cleaning: After each use, clean the exterior and the air filter. A clean machine runs more efficiently and reduces the risk of overheating.

Lubrication: Keep moving parts well-lubricated. This practice minimizes friction, prolongs the life of the equipment, and enhances performance during operation.

Fuel Quality: Use high-quality fuel and maintain proper fuel mixtures. This prevents engine issues and ensures smooth operation.

Storage: When not in use, store the tool in a dry, sheltered place. This protects it from environmental factors that can cause rust and degradation.

By adhering to these maintenance tips, you will enhance the efficiency and durability of your tool, ultimately ensuring it remains a reliable companion in your tasks.

Upgrading Components for Better Performance

Enhancing the functionality of your machinery can lead to significant improvements in efficiency and longevity. By focusing on key elements of the system, you can achieve optimal performance that meets or exceeds your expectations. Upgrading various components not only maximizes output but also ensures a smoother operation over time.

Key Components to Consider for Upgrades

- Fuel System: Upgrading the fuel filter and lines can lead to better fuel flow and efficiency.

- Air Filter: A high-performance air filter allows for improved airflow, enhancing combustion.

- Ignition System: Installing a premium spark plug can provide more reliable ignition and increased power.

- Chain and Bar: Opting for a high-quality cutting chain can improve cutting speed and reduce wear.

Benefits of Component Upgrades

- Improved Efficiency: Upgrading parts can lead to less energy consumption and more effective operation.

- Enhanced Durability: Higher-quality components often resist wear and tear better, extending the life of the machinery.

- Increased Power: Better components can contribute to a noticeable boost in overall power and performance.

- Smoother Operation: Upgraded systems reduce vibrations and operational noise, leading to a more enjoyable user experience.

Comparing MS390 with Other Models

When evaluating a specific model of chainsaw, it’s essential to consider how it stacks up against its peers. Each variant has unique features, performance capabilities, and intended uses, making direct comparisons valuable for users seeking the best fit for their needs. This analysis focuses on various aspects, such as power output, weight, ergonomics, and maintenance requirements, to highlight key differences and similarities.

Power and Performance

In terms of power, some models may offer higher engine output, making them suitable for heavier cutting tasks, while others are designed for lighter, more precise work. Comparing torque and chain speed can reveal which options are better for specific applications, from felling trees to pruning branches.

Design and Usability

Ergonomics play a crucial role in user experience. Variations in weight and balance can significantly impact handling, especially during extended use. Additionally, ease of maintenance and accessibility of components can differ, influencing long-term ownership satisfaction. Analyzing these factors helps users determine which model aligns with their operational preferences.

Safety Considerations for Repairs

When engaging in maintenance tasks, prioritizing safety is essential to prevent accidents and injuries. Understanding the proper precautions and using appropriate protective gear can significantly reduce risks during any repair process.

Firstly, ensure that the workspace is clear and well-lit. Clutter can lead to distractions or accidents, while adequate lighting helps to see the components clearly. Always work on a stable surface to avoid unnecessary movement of tools or equipment.

Secondly, it’s crucial to wear the right personal protective equipment (PPE). This includes gloves to protect your hands from sharp edges, goggles to shield your eyes from debris, and hearing protection if you are using loud tools. By being equipped properly, you enhance your safety during the entire process.

Additionally, disconnecting the power source before starting any repairs is a fundamental step. This prevents accidental activation of the equipment, which could result in severe injuries. Taking this precaution is vital for a safe working environment.

Finally, familiarize yourself with the specific equipment you are working on. Understanding its components and operation can help you identify potential hazards. Being informed empowers you to handle repairs confidently and safely.

FAQs About Stihl MS390 Parts

This section addresses common inquiries related to components of a popular chainsaw model. Understanding these queries can help users maintain their equipment efficiently and enhance its performance.

| Question | Answer |

|---|---|

| What are the most frequently replaced components? | The air filter, spark plug, and chain are often replaced to ensure optimal operation. |

| Where can I find replacement components? | Authorized dealers, online retailers, and specialized shops offer various replacements. |

| How can I identify a faulty part? | Look for unusual noises, leaks, or performance drops to diagnose issues effectively. |

| Are there any maintenance tips? | Regularly clean the air filter, check the oil level, and sharpen the chain for best results. |