Understanding the internal structure and key elements of pressure washers is crucial for ensuring optimal performance and longevity. Whether you’re a professional technician or a DIY enthusiast, becoming familiar with the different elements that make up these machines helps in both maintenance and troubleshooting.

When examining the internal layout, you’ll find that various connectors, hoses, and mechanisms work together to generate the desired output. Each component plays a specific role, and recognizing these elements will allow you to address potential issues more efficiently.

In this section, we will explore the most important mechanical and electrical elements, providing you with a comprehensive view of how everything operates together. By focusing

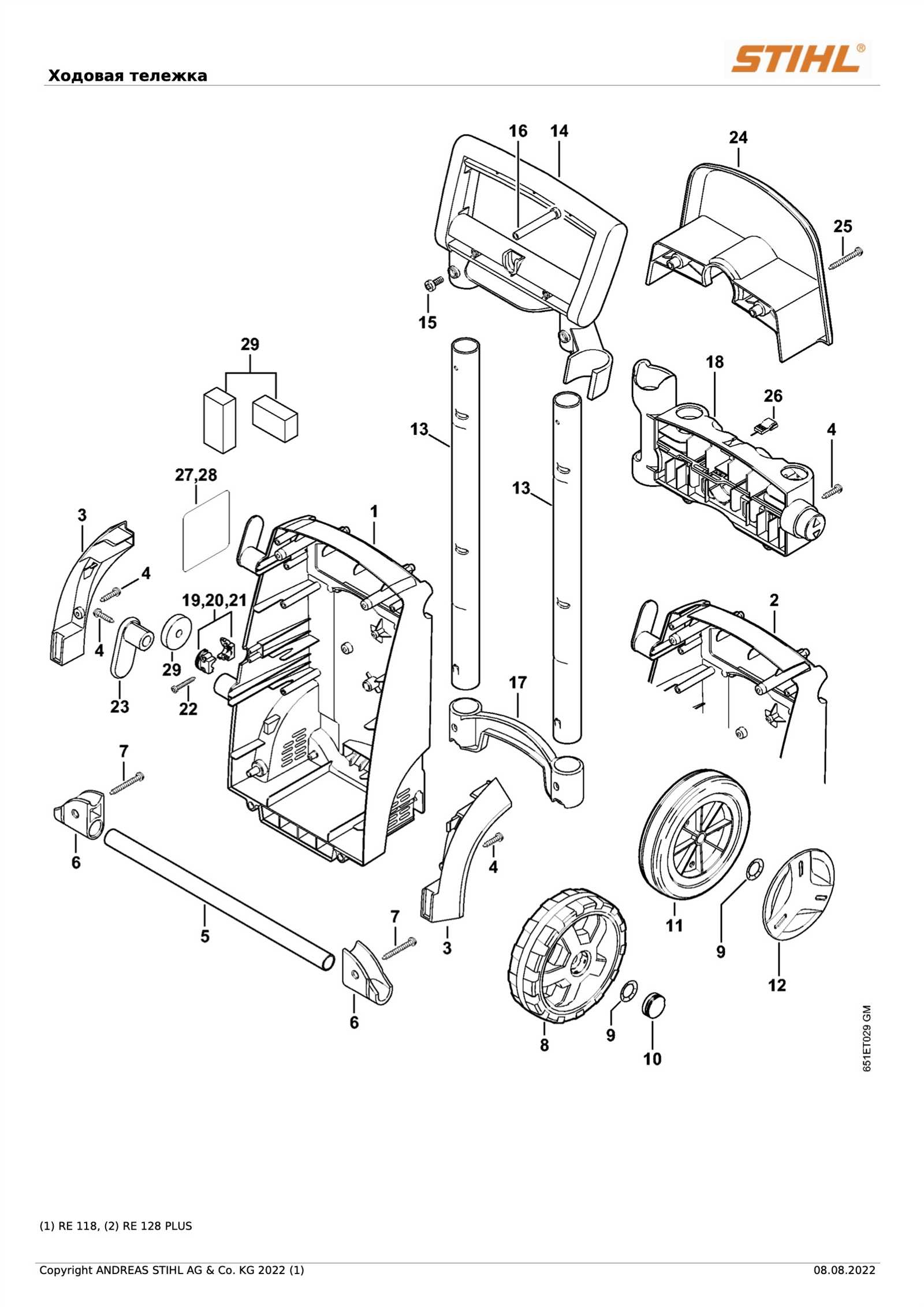

Key Components of Stihl RE 130 Plus

The efficiency and reliability of this high-pressure cleaning tool depend on several crucial elements working together seamlessly. Each component is designed to ensure optimal performance, delivering powerful water flow and durability. Understanding the main elements can help users maintain and troubleshoot their equipment effectively.

Motor and Pump

The heart of the cleaning machine lies in its motor and pump, which generate the necessary power to create high-pressure water output. These parts are engineered to withstand prolonged use, offering consistent and strong performance during demanding cleaning tasks.

Hose and Nozzle

The hose

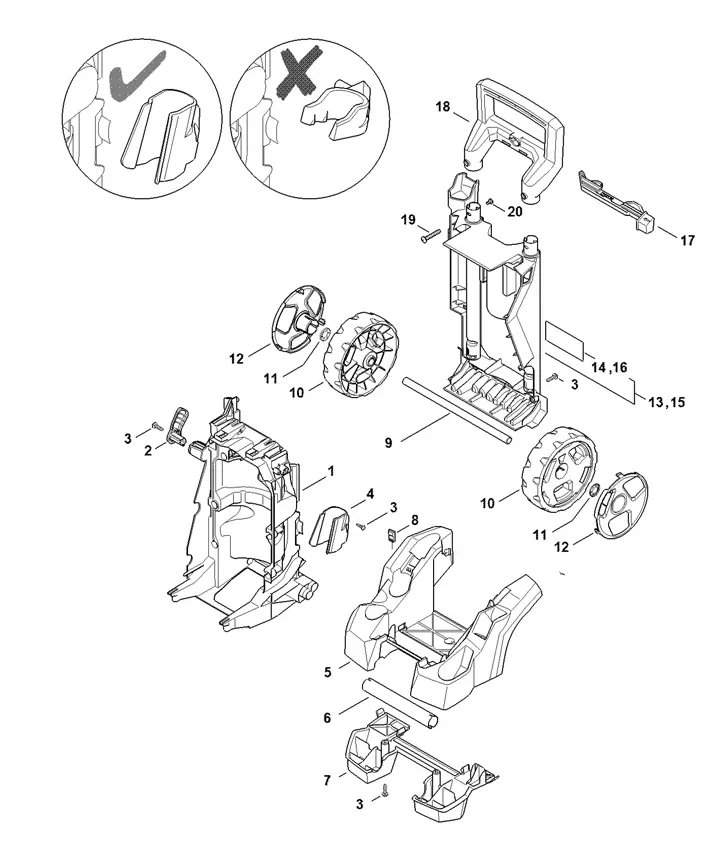

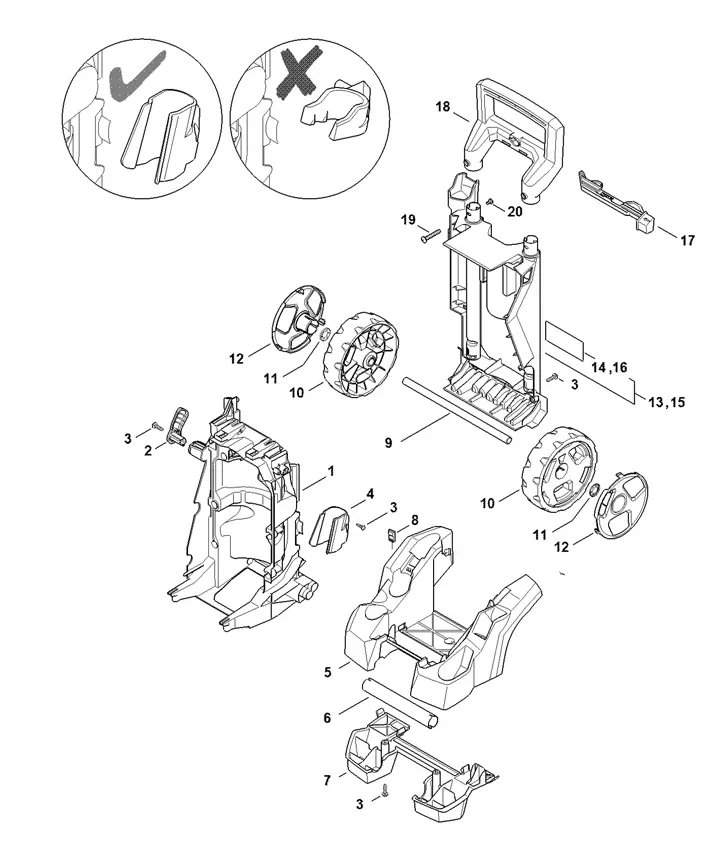

Understanding the Pressure Washer Structure

The internal design of a high-pressure cleaning device is built around several key components that work together to generate and control water flow at elevated pressures. These elements ensure the efficient functioning of the equipment, allowing users to perform tasks like cleaning surfaces with precision and power.

| Component |

Function |

| Pump |

Responsible for increasing water pressure to the necessary level for effective cleaning. |

| Motor |

Provides the mechanical power required to drive the pump and maintain continuous water pressure. |

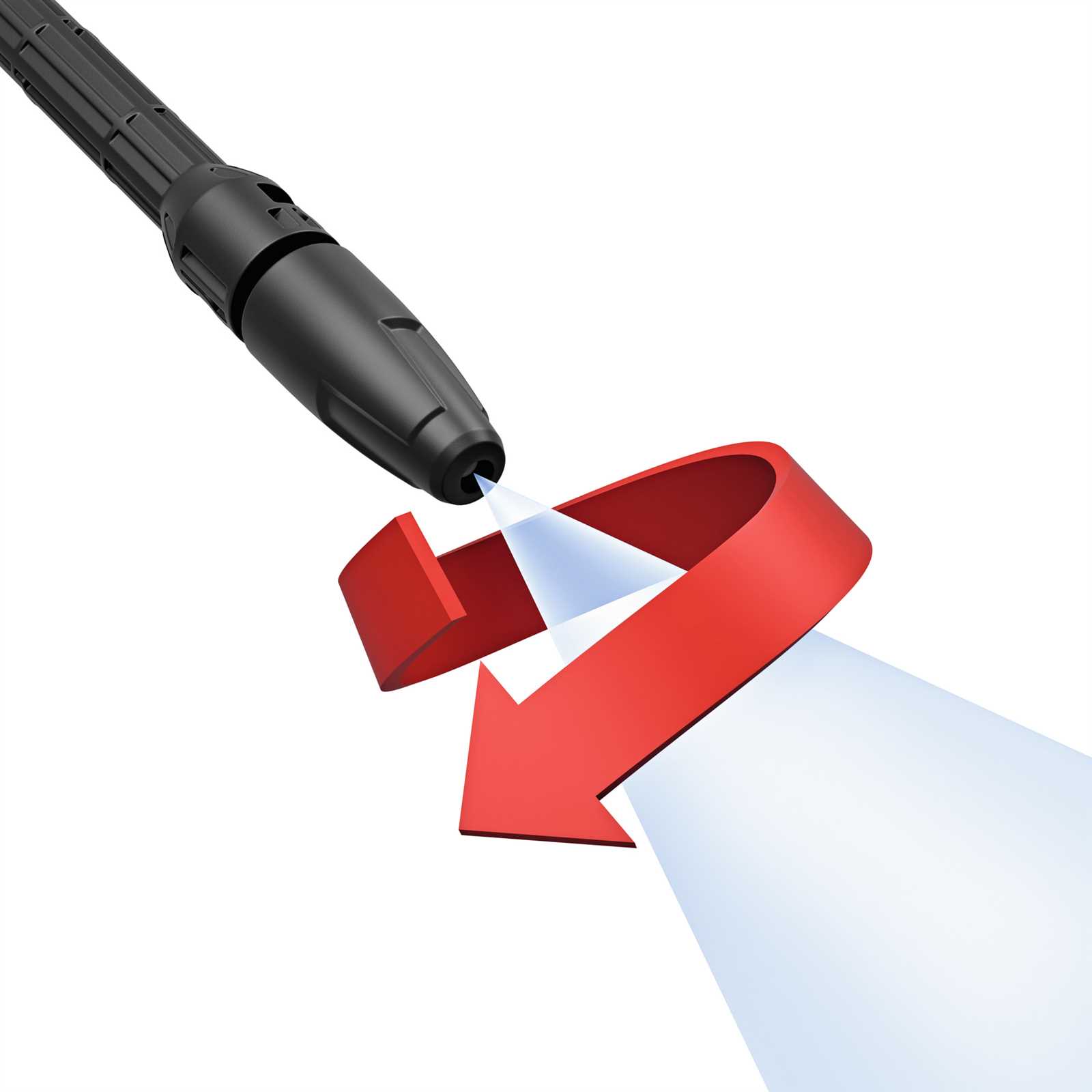

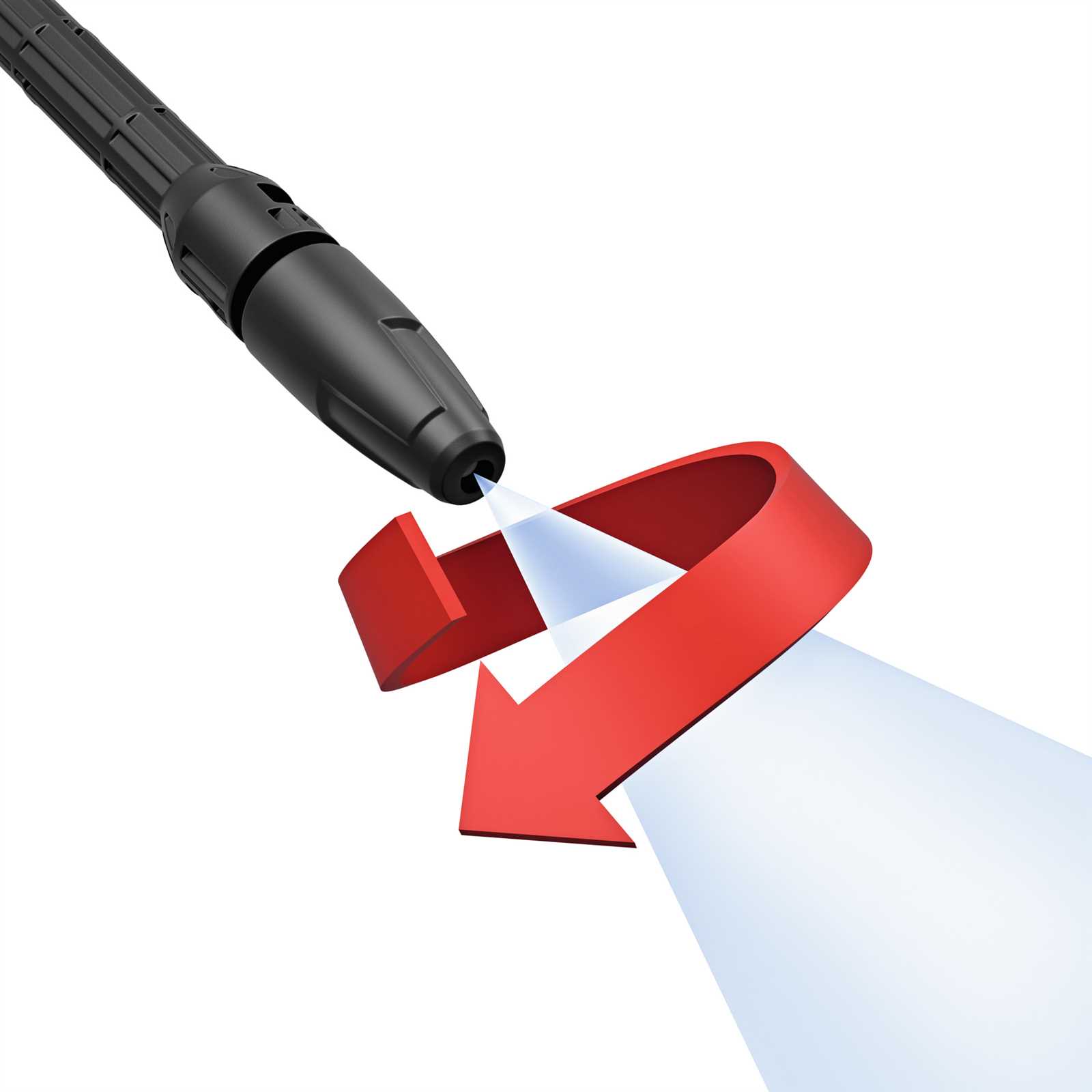

Exploring Hose and Nozzle Features

Understanding the components related to water flow and spray adjustment is essential for efficient use. These elements directly influence how effectively you can clean various surfaces and adapt to different cleaning tasks. A well-designed system enhances ease of use and precision, ensuring optimal results across a range of applications.

Durability and Flexibility

The material and construction of the water conduit are crucial for long-lasting performance. A flexible but sturdy design allows for better maneuverability, reducing strain during extended use. In contrast

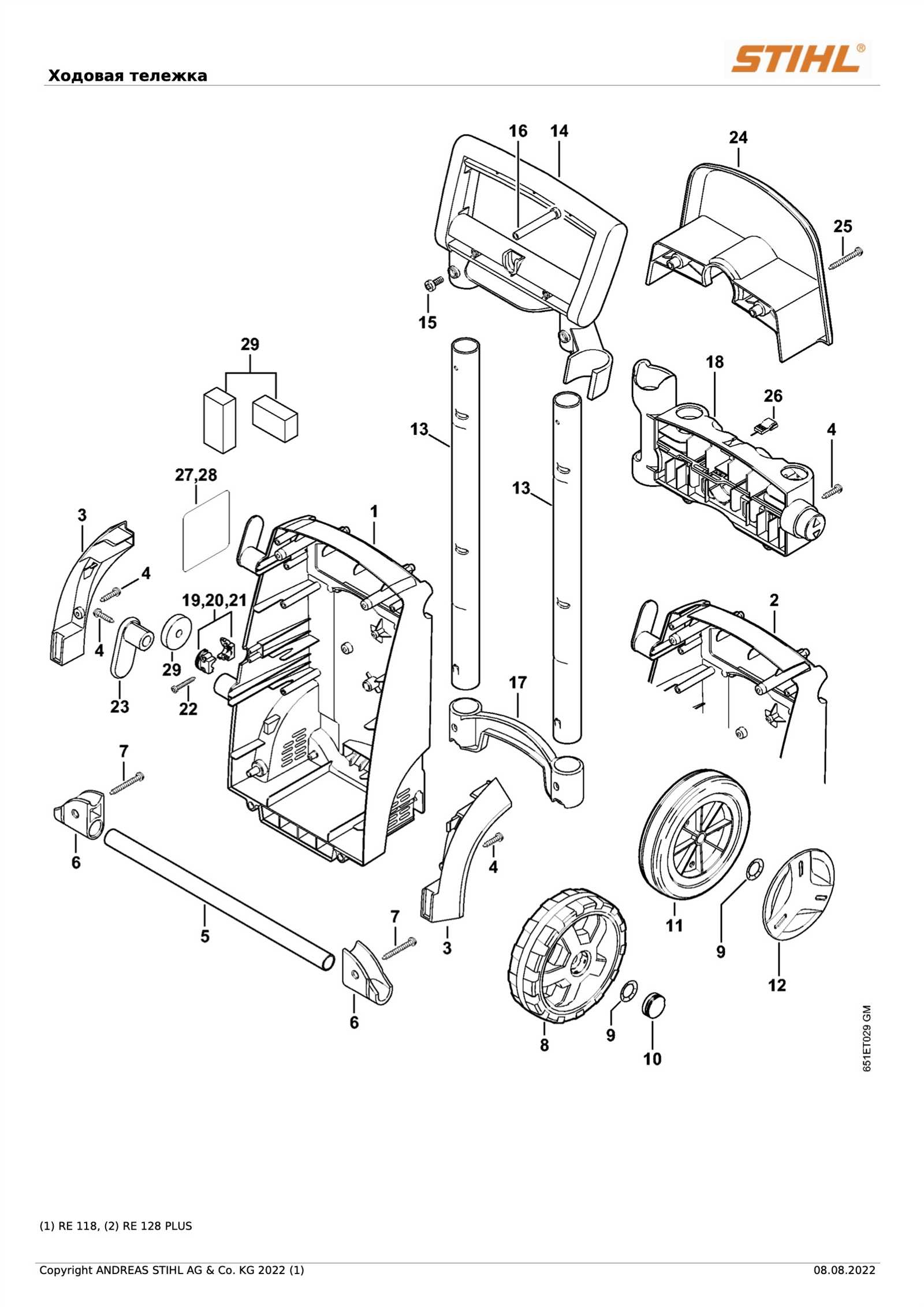

Internal Parts Breakdown of Stihl RE 130

The inner workings of this high-pressure cleaning system are designed for both efficiency and durability. Each component plays a critical role in maintaining the overall performance of the equipment, ensuring optimal power and function during usage. Understanding the arrangement of these elements is key to proper maintenance and repairs, as it provides a detailed view of how everything fits together.

Core components of the cleaning device include essential mechanisms responsible for generating water pressure, regulating flow, and ensuring long-lasting operation. By knowing the internal configuration and how these pieces interconnect, users can address any technical issues more effectively, reducing downtime

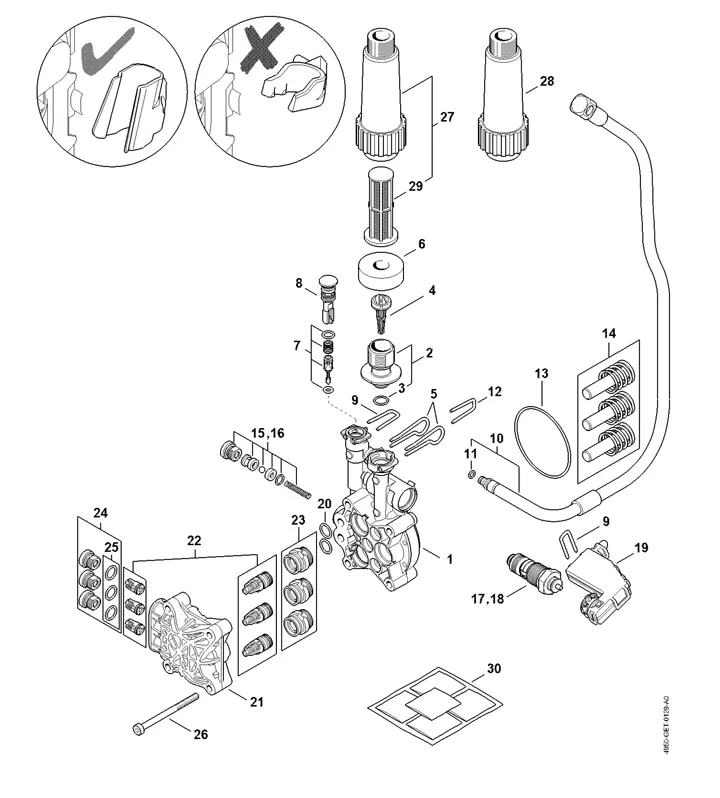

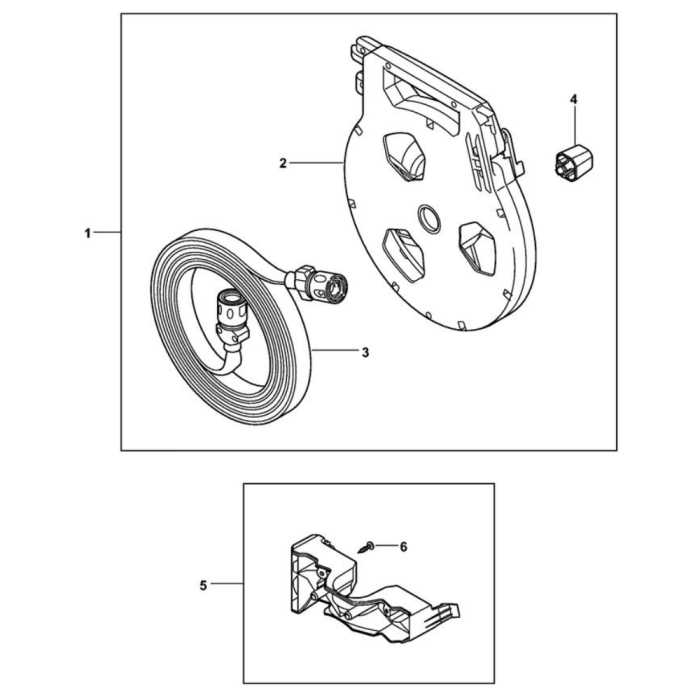

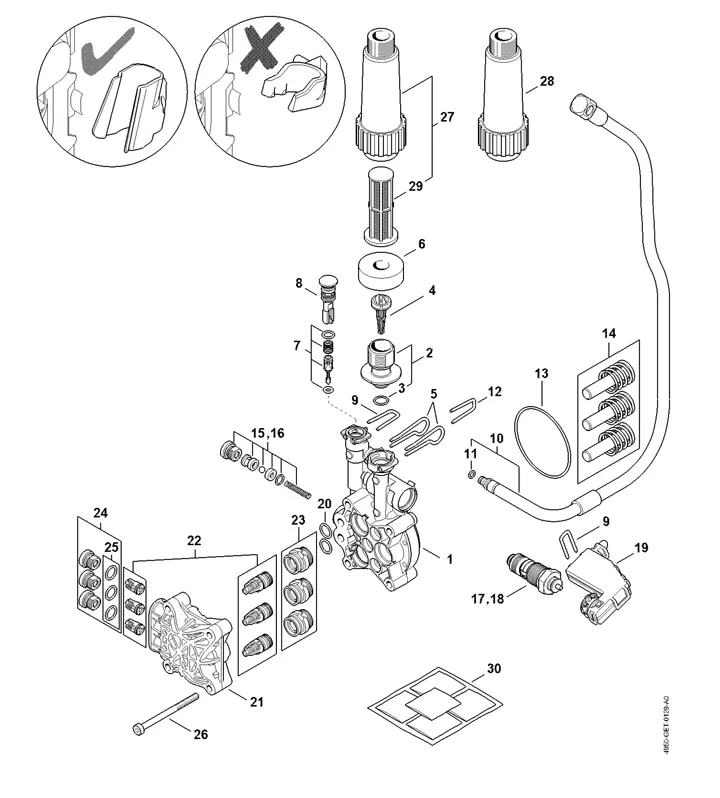

Water Inlet and Outlet Overview

The water entry and exit points play a critical role in ensuring efficient fluid flow through the system. Understanding their configuration and operation helps maintain optimal performance and prevent issues related to blockages or leaks.

Both the input and output points are designed to facilitate smooth transitions of water during the cleaning process. Below is an outline of key components and their functions:

- Inlet connection: Allows water to enter the device, often fitted with a filter to prevent debris from entering the system.

- Outlet valve: Ensures proper water flow out of the

Important Seals and Gaskets in Stihl

In any mechanical system, the integrity of connections is crucial for optimal performance. Seals and gaskets play a significant role in preventing leaks and maintaining pressure within various components. Their quality and condition can greatly impact the functionality and longevity of the equipment.

Types of Seals can vary widely, from O-rings to flat gaskets, each designed for specific applications. Ensuring that the right type is used in the correct location is essential for effective operation. Maintaining these components is vital to prevent wear and tear, which can lead to costly repairs or diminished efficiency.

Common Issues associated with damaged seals and gaskets include fluid leaks and decreased performance. Regular inspection and timely replacement are key practices to avoid potential breakdowns. Investing in high-quality replacements ensures the durability and reliability of the entire system.

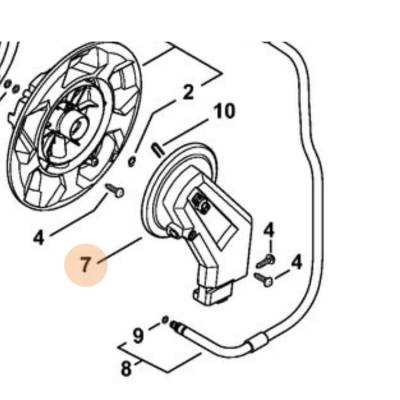

Motor and Pump Assembly Guide

This section provides essential information on the assembly of the motor and pump unit, highlighting critical components and their functions. Proper assembly is vital for ensuring optimal performance and longevity of the equipment.

Key Components

Understanding the main elements involved in the motor and pump assembly is crucial. Here are the key parts you should be familiar with:

- Electric Motor

- Pump Housing

- Impeller

- Drive Shaft

- Sealing Gaskets

Assembly Steps

Follow these steps to effectively assemble the motor and pump:

- Begin by securing the electric motor in the designated position.

- Attach the pump housing to the motor using the provided fasteners.

- Insert the impeller into the pump housing, ensuring it fits snugly.

- Connect the drive shaft to the motor, aligning it with the impeller.

- Install sealing gaskets to prevent leaks.

- Perform a final inspection to ensure all components are securely fastened.

Following this guide will help in achieving a successful assembly, ultimately leading to improved functionality of the system.

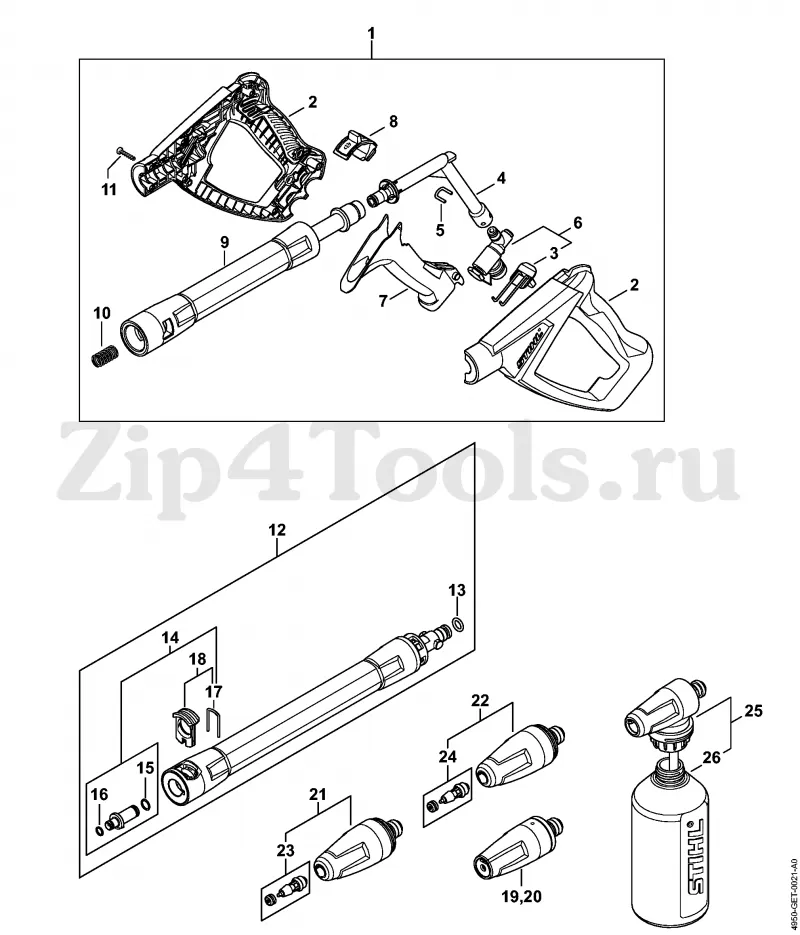

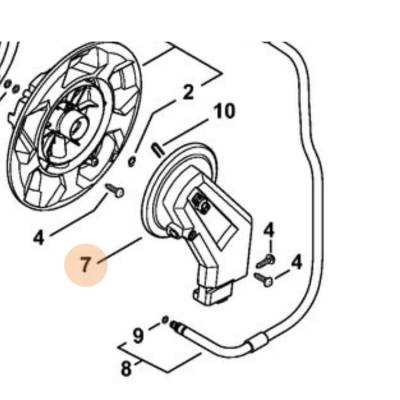

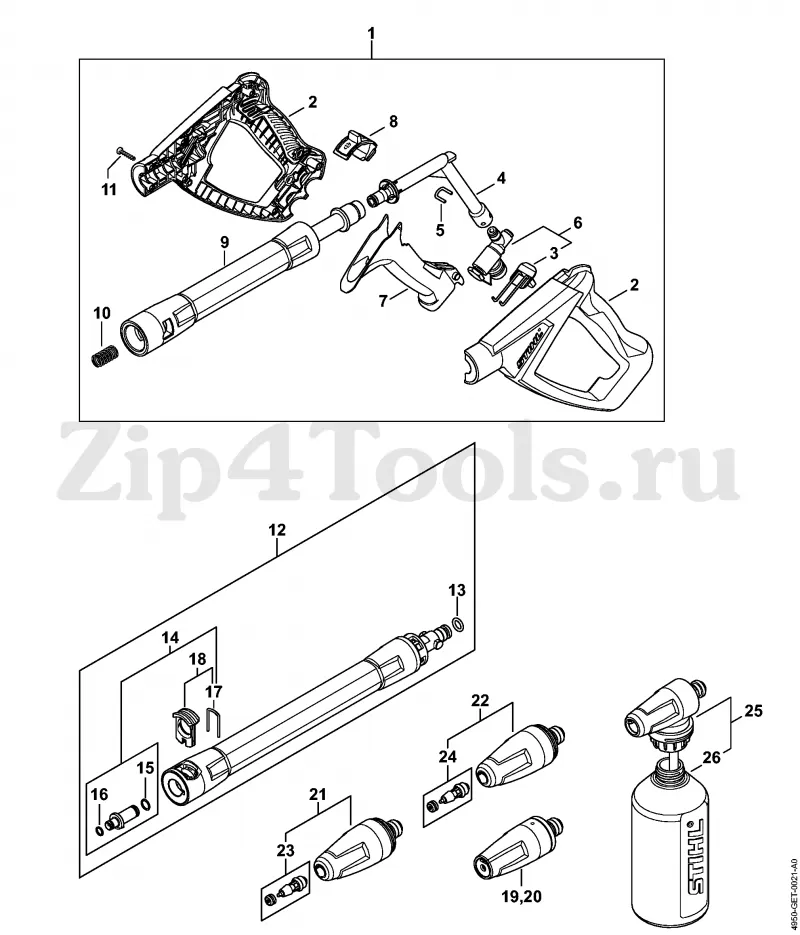

Spray Lance and Trigger Gun Parts

The spray lance and trigger mechanism are crucial components of high-pressure cleaning equipment. These elements work together to deliver a precise stream of water, enabling effective cleaning in various applications. Understanding the configuration and functionality of these parts can enhance the overall efficiency of the cleaning process.

| Component |

Description |

| Spray Lance |

A long, tubular structure that directs the flow of water and can vary in length for different tasks. |

| Trigger Gun |

A handheld device that controls water flow, allowing the operator to start or stop the spray with ease. |

| Nozzle |

Interchangeable attachment at the end of the lance that determines the spray pattern and pressure. |

| Safety Lock |

A feature that prevents accidental activation of the trigger, enhancing user safety. |

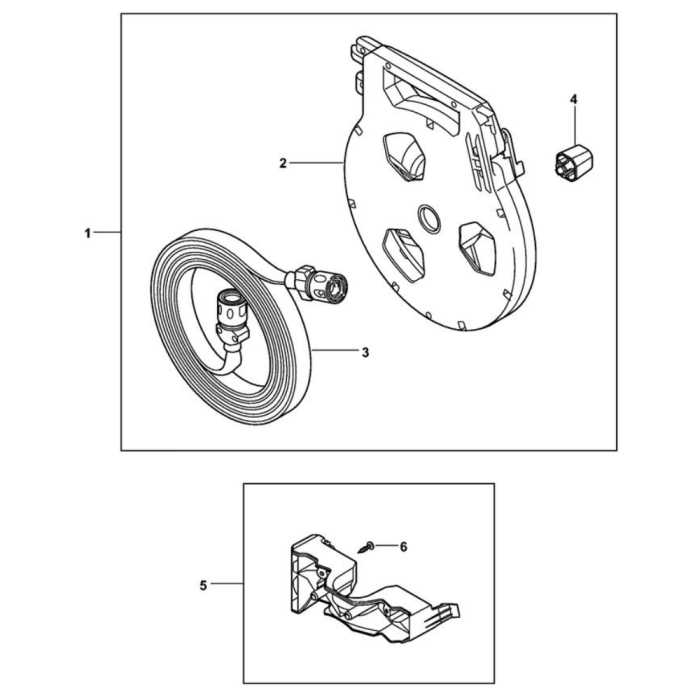

| Hose Connector |

Joint that connects the hose to the lance or gun, ensuring a secure and leak-free fit. |

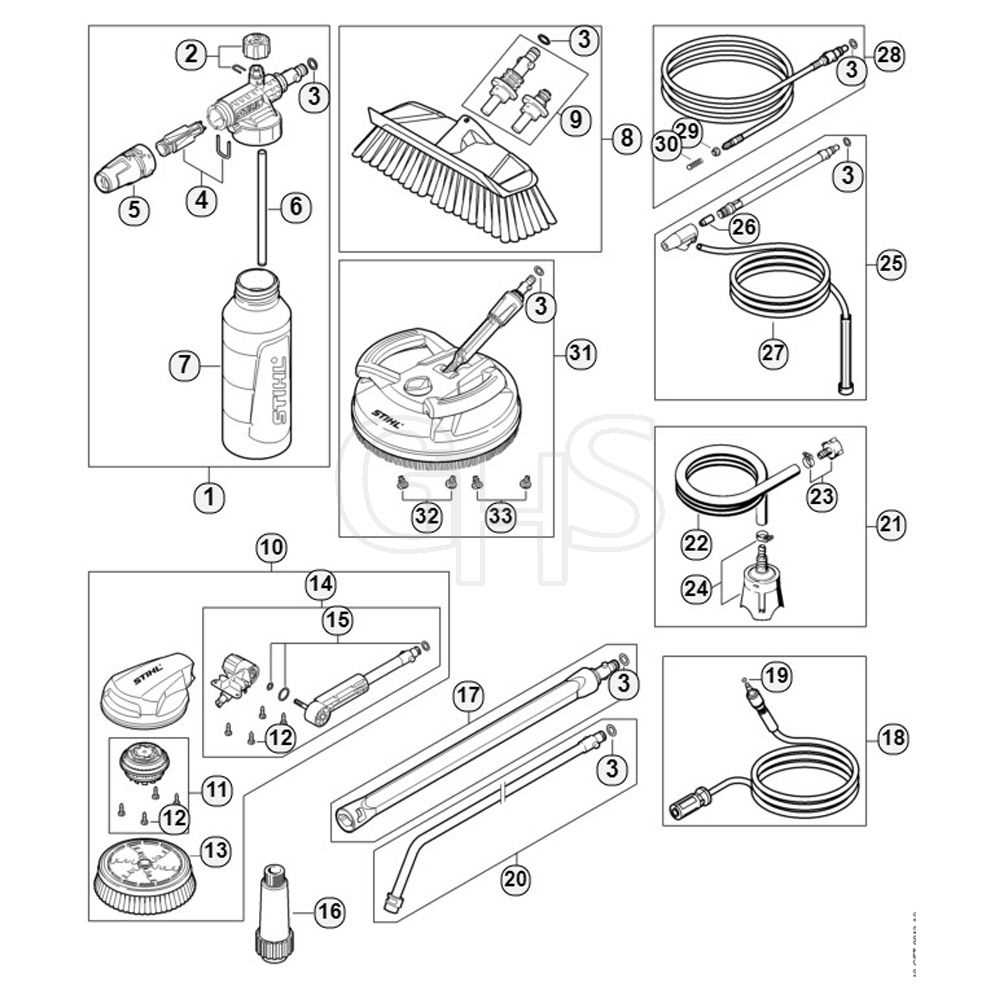

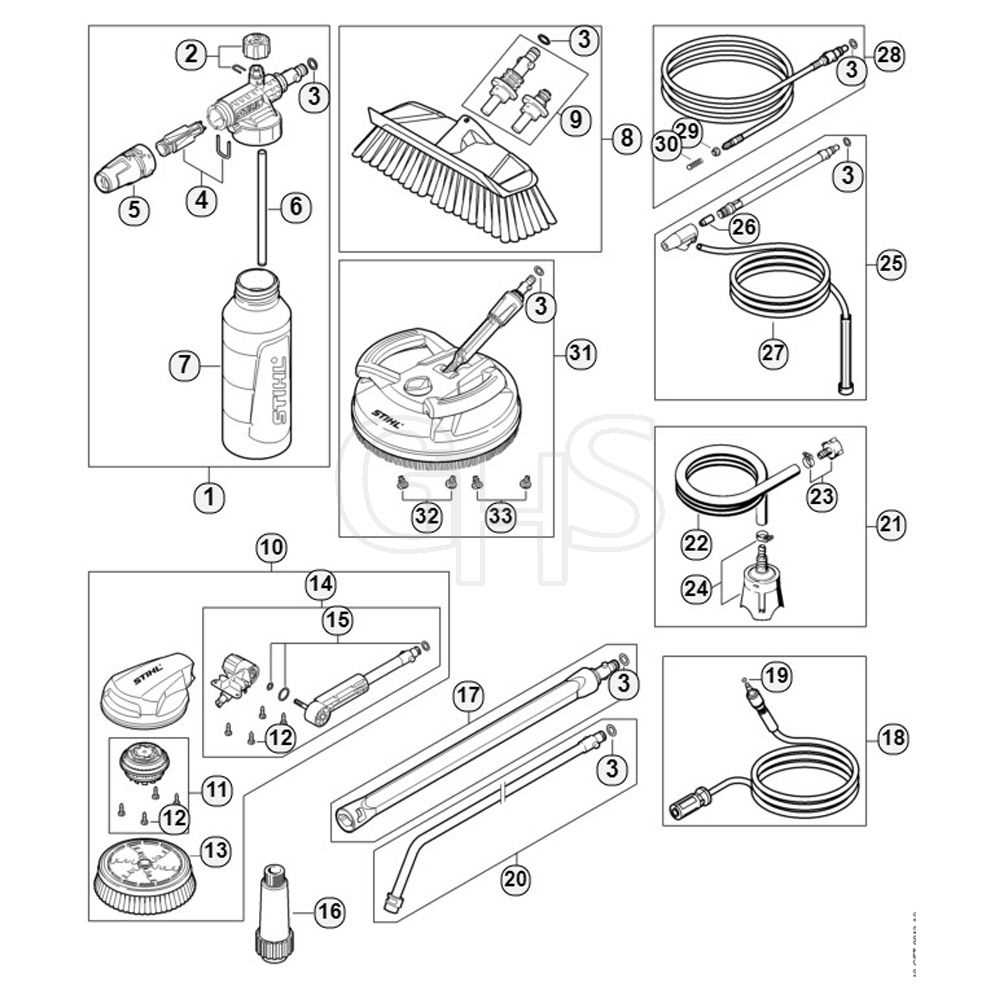

Accessories and Attachments for Stihl RE 130

When enhancing the functionality of your high-pressure cleaning equipment, various add-ons can significantly improve performance and efficiency. These accessories are designed to provide versatile solutions for a range of cleaning tasks, enabling users to tailor their experience according to specific needs.

Below is a list of popular accessories that complement the functionality of this pressure washer:

| Accessory Type |

Description |

| Surface Cleaner |

Ideal for cleaning large flat surfaces like driveways and patios quickly and evenly. |

| Extension Wand |

Allows users to reach higher areas without the need for ladders, making cleaning safer and easier. |

| Turbo Nozzle |

Provides a powerful rotating spray for tough stains, increasing cleaning efficiency. |

| Detergent Injector |

Enables the application of soap or cleaning solutions for more effective cleaning on various surfaces. |

| Replacement Hoses |

Various lengths and diameters available to extend reach and adaptability for different cleaning tasks. |