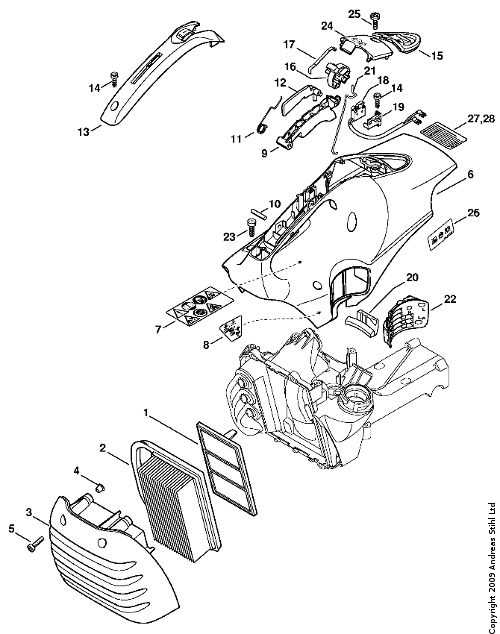

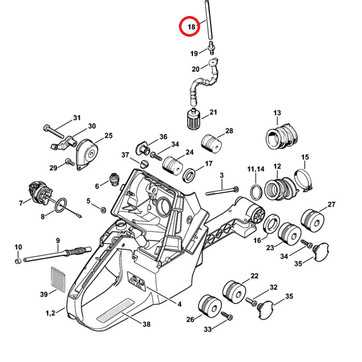

When working with machinery, having a comprehensive overview of its elements is crucial for efficient maintenance and repair. This knowledge empowers users to troubleshoot issues effectively and ensures optimal performance. A clear representation of the various components enhances understanding and aids in identifying parts that may need attention.

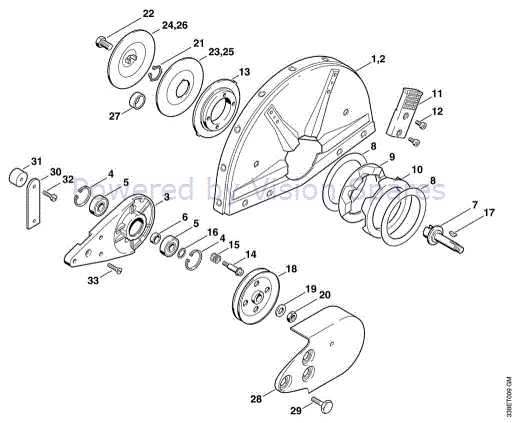

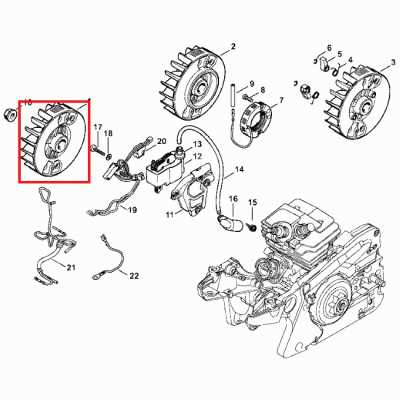

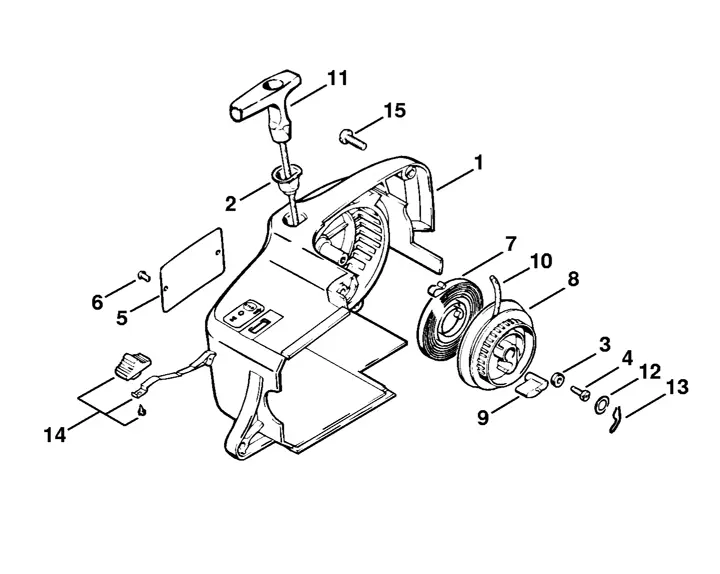

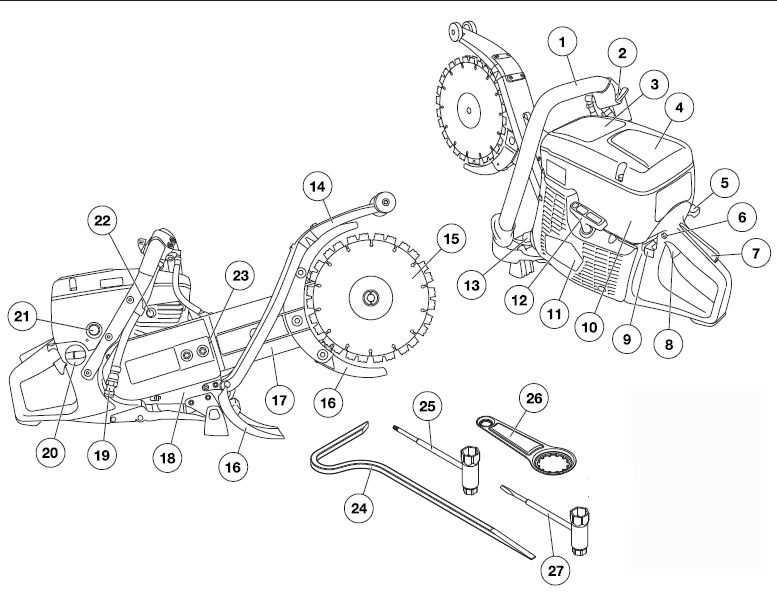

Illustrations that showcase the intricate assembly of a cutting device serve as valuable references. They provide insight into how each segment interacts with others, allowing for better decision-making when performing repairs or upgrades. This clarity can significantly reduce the time spent on maintenance tasks.

Moreover, a detailed reference guide can be instrumental for both novice and experienced users. By familiarizing oneself with the layout and functions of individual elements, one can approach repairs with greater confidence. This ultimately leads to more effective management of the equipment and a longer lifespan.

This section aims to provide clarity on the components that make up a specific model of equipment, detailing each element’s function and interaction within the overall assembly. A thorough comprehension of these elements is essential for effective maintenance and repair, ensuring optimal performance and longevity of the machine.

Key Components Overview

- Engine Assembly: The heart of the machine, responsible for power generation.

- Fuel System: Includes the tank, filter, and lines that deliver the necessary fuel for operation.

- Cooling System: Essential for maintaining optimal operating temperatures, preventing overheating.

- Cutting Mechanism: Comprises the blades and related components that execute the cutting tasks.

- Starter Assembly: Facilitates the initial ignition process to get the machine running.

Importance of Understanding Each Element

Recognizing the significance of every component allows users to diagnose issues more effectively. For instance, if the engine does not start, one can focus on the fuel delivery or starter assembly. Familiarity with the overall structure enables better troubleshooting, reduces downtime, and enhances safety during operation.

- Check the fuel system for blockages or leaks.

- Inspect the cutting mechanism for any signs of wear or damage.

- Ensure the cooling system is functioning properly to avoid overheating.

- Review the starter assembly to confirm it is in good working condition.

Common Issues and Repairs

Proper maintenance and timely troubleshooting are essential for keeping outdoor cutting equipment functioning smoothly. Understanding frequent challenges that can arise and knowing how to address them ensures both efficiency and longevity of the tool. This section highlights typical malfunctions and methods to address them effectively.

Engine Starting Problems

Difficulty in starting the motor is a prevalent issue, often caused by a lack of fuel flow or a blocked air filter. To address this, check the condition of the spark plug and clean or replace the air filter if it appears dirty. A clogged fuel line may also be to blame, requiring careful inspection and potential replacement to restore proper operation

Tools Needed for Disassembly

Efficient and safe dismantling of machinery requires specific equipment. Using the correct instruments ensures a smoother process, minimizing risks and potential damage to components. This guide outlines the essential tools that facilitate the breakdown process.

Essential Hand Tools

Manual equipment forms the foundation for any disassembly task. A set of various screwdrivers, including both flathead and Phillips, allows for precision work on small fasteners. A wrench set, adjustable and standard, is vital for loosening or tightening bolts and nuts of varying sizes. Pliers and a hammer are useful for removing stubborn parts, while a utility knife assists with cutting any tied or taped components.

Specialized Instruments

Tips for Replacing Components

Changing certain elements of a machine can enhance its lifespan and restore its performance. Understanding the process and taking the right precautions ensures that each replacement is both effective and safe. Below are some key guidelines and strategies to help make the process smoother.

Prepare the Necessary Tools

Before beginning, gather the appropriate tools and equipment to ensure a seamless process. Having the right items on hand will save time and prevent potential damage during disassembly or reassembly.

- Use a set of wrenches and screwdrivers suitable for different fasteners.

- Keep safety gear like gloves and goggles ready to avoid injuries.

- Have a clean workspace with good lighting to clearly see each component.

Step-by-Step Approach

Following

Locating Original Parts Online

Finding authentic components for machinery can be crucial for maintaining optimal performance and extending the lifespan of the equipment. With numerous sources available on the internet, identifying reliable options requires careful consideration of quality and compatibility. The following tips can guide users in the search for trusted supplies and ensure that they acquire items that match their needs.

Choosing Reputable Vendors

When searching for replacement items, selecting well-established retailers is essential. Look for businesses with positive reviews and a proven track record of customer satisfaction. Many specialized websites also offer detailed product descriptions and technical specifications, making it easier to confirm the suitability of an item. Opting for authorized sellers can further guarantee the authenticity of the purchased elements.

Comparing Online Catalogs

To ensure the best match for your equipment, it’s helpful

Comparison of Aftermarket Options

Exploring alternative replacement components can be a practical choice for those looking to balance quality and cost. These substitutes often provide a range of compatibility and performance levels, catering to varied needs. Understanding the strengths and limitations of different alternatives can help in making a well-informed decision.

Quality Versus Affordability

One of the primary considerations when selecting a substitute is the balance between durability and price. Some options prioritize robust construction and materials, aiming to match or even surpass the original specifications. Others may offer more budget-friendly alternatives, though they might compromise slightly in terms of longevity or precision. It is crucial to weigh these factors based on usage requirements and budget constraints.

Availability and Compatibility

Another aspect to consider is the availability of alternatives and their compatibility with existing equipment. Some options are readily available from multiple suppliers, offering a quick solution

Assembly Instructions for TS400

This section provides a step-by-step guide to putting together the equipment. These instructions will help ensure each component is correctly aligned and secured, allowing for smooth operation and long-lasting performance.

Preparation Before Assembly

Before starting the process, ensure all elements are available and organized. It’s crucial to work in a clean area with the right tools to prevent any misplaced elements. Read through the entire guide to familiarize yourself with the sequence of actions.

- Check that all bolts, screws, and nuts are present.

- Organize the various components to streamline the process.

- Have safety gloves and goggles ready for protection.

Main Steps to Follow

Maintenance Schedule for Longevity

Regular upkeep is crucial for ensuring optimal performance and extending the life of equipment. A well-structured routine can prevent unexpected breakdowns, maintain efficiency, and reduce repair costs over time.

- Daily Checks:

- Inspect all fluid levels and top up if necessary.

- Examine the exterior for any visible damage or wear.

- Verify the functionality of all safety features before use.

- Weekly Care:

- Clean air filters to ensure proper airflow and reduce the strain on the engine.

- Tighten loose fasteners to prevent vibrations and wear.

- Lubricate moving components for smooth operation and minimal friction.