Maintaining a well-functioning garden tool requires knowledge of its essential elements. When you understand how each component works together, it becomes easier to troubleshoot issues and ensure optimal performance. This guide provides an overview of the primary elements that make up one of the most commonly used grass-cutting devices.

In this article, we’ll explore the various sections and parts that contribute to the efficiency and reliability of the device. Whether you’re looking to replace a damaged element or simply gain a deeper understanding of the tool’s structure, this breakdown will offer valuable insights. By familiarizing yourself with these components, you can enhance the longevity and functionality of your equipment.

Essential Guide to FS45 Weed Eater Components

The machinery we use for maintaining outdoor areas is composed of various critical elements that ensure smooth and efficient operation. Each component plays a vital role in the functionality of the device, contributing to both its performance and durability. Understanding these elements will help you keep the equipment in prime condition, maximizing its lifespan and effectiveness.

Engine and Power Unit

The heart of the equipment is its motor, which provides the power necessary for operation. This unit is designed to convert fuel into mechanical energy, driving the mechanism that enables effective trimming. Regular maintenance of the motor, including cleaning and tuning, ensures optimal performance.

Trimmer Head and Cutting Line

The cutting assembly is the part responsible for actually performing the trimming. It consists of a rotating head that houses the line, which spins rapidly to cut through grass and light brush. Keeping the cutting line in good condition and replacing it as needed is essential for achieving precise and efficient results.

Understanding the Mechanics of FS45 Trimmer

The inner workings of this trimming tool are designed to offer both efficiency and precision. By examining the core components and how they interact, you can gain a deeper appreciation of its performance. Understanding the basic mechanics allows for better maintenance and troubleshooting, ensuring long-term reliability.

Key Mechanical Features

The structure of the trimmer consists of several essential parts that function together to deliver smooth operation. Here are some of the main elements:

- Engine System: The power source responsible for driving the cutting mechanism, allowing the trimmer to operate efficiently.

- Drive Shaft: This component transfers the engine’s power to the cutting head, ensuring the necessary rotation for trimming.

- Cutting Head: The rotating head where the line or blade is attached. It performs the

Key Parts of a Sturdy Trimmer Engine

The internal mechanism of this versatile tool is composed of essential elements that ensure smooth operation and efficiency. Understanding the main components of its engine can help with maintenance and troubleshooting, leading to a longer lifespan and optimal performance.

Main Engine Components

- Carburetor: This component mixes fuel and air in the right proportion to enable combustion. Proper adjustments are critical for engine efficiency.

- Ignition Coil: Generates the necessary spark to ignite the fuel mixture, ensuring the engine starts and runs smoothly.

- Crankshaft: Converts the linear motion from the piston into rotational force, driving the cutting head.

- Piston: Moves up and down within the cylinder, creating the force needed to turn the crankshaft.

- Muffler: Reduces noise from exhaust gases and helps in controlling

How to Maintain FS45 Weed Eater Blades

Proper care of the cutting blades ensures efficient performance and extends the life of your trimming tool. Regular maintenance is essential to keep the blades sharp, clean, and free from debris. By following a few simple steps, you can ensure your equipment stays in optimal condition, ready to handle any task with ease.

Cleaning the Blades

After each use, it’s important to remove grass clippings and dirt from the blades. Use a soft brush or cloth to clean off debris, ensuring the blades are free from any build-up that could hinder performance. For tougher grime, applying a mild detergent can help dissolve it. Dry the blades thoroughly after cleaning to prevent rust or corrosion.

Sharpening and Lubrication

Blades should be inspected regularly for dullness. If they appear worn, sharpen them with a file or sharpening tool to restore their edge. Once sharpen

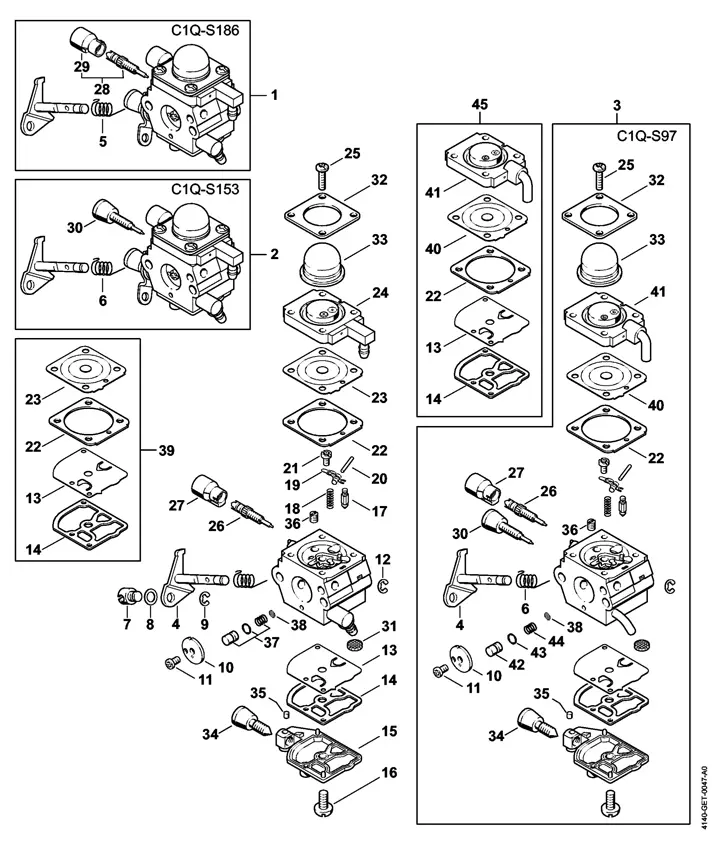

Common FS45 Carburetor Issues and Fixes

The carburetor is a crucial component in small engine machinery, and its performance directly affects the engine’s overall efficiency. Over time, issues can arise that hinder proper fuel delivery, leading to operational problems. Recognizing these common symptoms and addressing them promptly can ensure smooth performance.

Difficulty Starting: One of the frequent signs of a malfunctioning carburetor is trouble starting the engine. This can result from clogged jets or an incorrect fuel-air mixture. Cleaning the carburetor and adjusting the mixture screw can often solve this problem.

Rough Idle: If the engine struggles to maintain a stable idle, it may indicate a dirty or blocked carburetor. In such cases, a thorough cleaning and inspection of the idle jet is necessary to restore proper function.

Engine Stalling: When the engine stalls unexpectedly during operation, it might be due to fuel starvation caused by a restricted fuel flow. Regular maintenance, including

Replacing the Fuel Line on FS45

Maintaining the fuel line is crucial for ensuring optimal performance of your outdoor power equipment. A deteriorated or blocked line can lead to poor fuel flow, affecting the engine’s efficiency. This guide will walk you through the necessary steps to successfully replace the fuel conduit, enhancing the overall functionality of your machine.

Tools and Materials Needed

Before starting the replacement process, gather the following items:

- Replacement fuel line – Ensure it is compatible with your model.

- Fuel line cutter – A sharp tool for clean cuts.

- Screwdriver – For loosening and tightening connections.

- Safety gloves – To protect your hands during the process.

Step-by-Step Replacement Process

1. Turn off the equipment and disconnect the spark plug to prevent accidental starts.

2. Remove the housing covering the fuel line, using a screwdriver to access the area.

3. Carefully detach the old line from the fuel tank and the carburetor, noting the connection points.

4. Measure and cut the new fuel line to the appropriate length, ensuring it matches the original configuration.

5. Attach the new line securely to both the tank and the carburetor, making sure there are no leaks.

6. Reassemble the housing and reconnect the spark plug. Your equipment is now ready for use.

FS45 Ignition System: Components and Function

The ignition mechanism of small engines plays a crucial role in their performance and reliability. Understanding its various elements and how they work together can significantly enhance maintenance and troubleshooting efforts.

Key Components: The primary elements of this system include the ignition coil, spark plug, flywheel, and various wiring connections. Each component has a specific function that contributes to the overall ignition process.

Functionality: The ignition coil generates high voltage, which is necessary for the spark plug to ignite the fuel-air mixture within the combustion chamber. The flywheel, often integrated with magnets, helps create the electrical energy required for the coil’s operation. Proper interaction among these parts ensures efficient engine start-up and optimal running conditions.

Maintenance Tips: Regular inspection of the spark plug and connections, along with periodic cleaning of the coil, can help maintain the system’s effectiveness and prevent potential issues.

Detailed Breakdown of the FS45 Air Filter

The air filtration system plays a crucial role in the performance and longevity of small engine tools. Proper maintenance and understanding of this component can significantly impact the overall efficiency of the device. This section focuses on the air filter specific to the model in question, detailing its structure, function, and maintenance practices.

Key aspects of the air filtration system include:

- Design: The filter is typically designed to trap dust and debris, ensuring that clean air enters the engine.

- Material: Most filters are made from foam or paper, providing a balance between filtration and airflow.

- Location: It is usually situated in a designated housing, making it accessible for maintenance.

Regular upkeep is essential to maintain optimal functionality. Consider the following maintenance tips:

- Inspection: Regularly check the filter for dirt accumulation and damage.

- Cleaning: Foam filters can be washed with soapy water, while paper filters should be gently tapped to remove debris.

- Replacement: If the filter shows signs of wear or is too dirty, replacement is necessary to ensure efficient engine performance.

Understanding these components can help users maintain their equipment effectively, leading to better performance and extended service life.

Troubleshooting FS45 Weed Eater Spark Plug Problems

Identifying and resolving issues related to the ignition component is crucial for optimal performance. This section will guide you through common problems, symptoms, and solutions that may arise, ensuring a smoother operation of your equipment.

Common Symptoms of Ignition Issues

- Difficulty starting the engine

- Intermittent engine performance

- Excessive smoke during operation

- Engine misfiring or stalling

Steps to Diagnose and Fix Problems

- Inspect the ignition component for damage or wear.

- Check for proper electrode gap and clean any carbon buildup.

- Ensure connections are tight and free of corrosion.

- Replace the ignition component if it appears faulty.

Following these troubleshooting steps can help you delve into the core of the issue, leading to the ultimate resolution of your ignition concerns.

Exploring the Role of the FS45 Throttle

The throttle mechanism in outdoor power equipment plays a critical role in regulating engine performance and responsiveness. It serves as a crucial interface between the user and the machine, allowing for precise control over speed and power output. Understanding how this component functions can enhance the overall efficiency and handling of the device during operation.

Functionality of the Throttle System

The throttle system is designed to modulate airflow to the engine, which directly affects combustion and, consequently, the power produced. When the user adjusts the throttle, they control the amount of fuel and air mixture entering the engine, enabling variations in speed and torque. This ability to finely tune the performance is essential for achieving optimal results in various tasks, from light trimming to more demanding cutting applications.

Importance of Proper Maintenance

FS45 Gearbox Assembly: A Step-by-Step Guide

This section provides a comprehensive approach to assembling the gearbox of a specific model. Understanding the assembly process is crucial for ensuring optimal performance and longevity of the equipment. Follow the detailed steps outlined below to achieve a successful assembly.

-

Gather Necessary Tools and Components:

- Wrench set

- Screwdriver set

- New seals and gaskets

- Grease or lubricant

-

Prepare the Workspace: Ensure that you have a clean, well-lit area to work. Lay out all tools and parts for easy access.

-

Remove Old Gearbox: Disconnect any attachments and carefully unscrew the old gearbox. Keep track of screws and small parts.

-

Inspect Components: Examine the gearbox and surrounding areas for wear or damage. Replace any worn parts before proceeding.

-

Install New Gaskets: Apply new seals and gaskets to ensure a tight fit and prevent leaks.

-

Assemble the Gearbox: Follow the specific order of assembly for the gearbox components. Refer to the manufacturer’s guide if available.

-

Secure with Fasteners: Use the appropriate screws and bolts to secure all parts. Ensure they are tightened according to specifications.

-

Reconnect Attachments: Once the gearbox is securely in place, reconnect any components that were previously removed.

-

Test Functionality: Before full operation, test the assembly to ensure everything is working smoothly. Listen for any unusual sounds and check for leaks.

By following these steps carefully, you can effectively assemble the gearbox, ensuring that your equipment operates efficiently and reliably.