The efficient operation of a small engine relies on the seamless integration of its various elements. This section will delve into the essential components that make up a typical 5 HP engine, providing insights into their functionality and significance. By exploring these key parts, readers will gain a deeper appreciation for the intricate design and engineering involved in these machines.

Each component plays a vital role in ensuring optimal performance, from the ignition system to the fuel delivery mechanism. Understanding the relationship between these elements can enhance troubleshooting skills and maintenance practices. As we break down the structure, readers will find a wealth of information to assist in both repairs and upgrades, making this knowledge invaluable for enthusiasts and professionals alike.

In addition, we will highlight common issues associated with these components, offering practical advice for addressing potential problems. By familiarizing oneself with the inner workings, individuals can empower themselves to make informed decisions when it comes to servicing their machinery.

Overview of 5 HP Engines

Five horsepower engines are widely recognized for their compact design and reliable performance, making them suitable for a variety of applications. These power units are commonly utilized in lawn equipment, generators, and small machinery. Their efficiency and durability make them a popular choice among users seeking dependable solutions for both residential and commercial tasks.

Typically, these engines feature a simple yet effective construction that allows for easy maintenance and servicing. Understanding the essential components and their functions can enhance operational efficiency and prolong the lifespan of the engine.

| Component | Description |

|---|---|

| Cylinder | The chamber where combustion occurs, driving the piston. |

| Piston | Moves up and down within the cylinder, converting fuel energy into mechanical motion. |

| Crankshaft | Transforms the linear motion of the piston into rotational motion to drive the output shaft. |

| Fuel System | Delivers the appropriate mixture of air and fuel for combustion. |

| Ignition System | Creates a spark to ignite the fuel-air mixture within the cylinder. |

| Cooling System | Regulates engine temperature to prevent overheating, ensuring optimal performance. |

Key Components of Briggs & Stratton

The efficiency and performance of small engines rely on several vital elements that work in harmony. Understanding these essential components is crucial for proper maintenance and effective operation. This section outlines the primary features that contribute to the overall functionality of these engines.

Essential Engine Elements

- Power Source: This is the heart of the engine, converting fuel into mechanical energy.

- Fuel System: Comprising the tank and carburetor, this system ensures the correct mixture of air and fuel.

- Ignition System: Responsible for initiating combustion, this system includes spark plugs and ignition coils.

- Cooling Mechanism: Prevents overheating by circulating air or liquid around the engine.

- Exhaust System: Directs waste gases away from the engine and reduces noise levels.

Additional Functional Components

- Crankshaft: Converts linear motion from the piston into rotational motion.

- Piston: Moves up and down within the cylinder, creating pressure for combustion.

- Valves: Regulate the flow of air and fuel into the cylinder and the exit of exhaust gases.

- Gaskets: Ensure airtight seals between various components, preventing leaks.

These fundamental elements form the backbone of the engine, influencing its performance and longevity. Regular inspections and timely replacements of these components are essential for optimal operation.

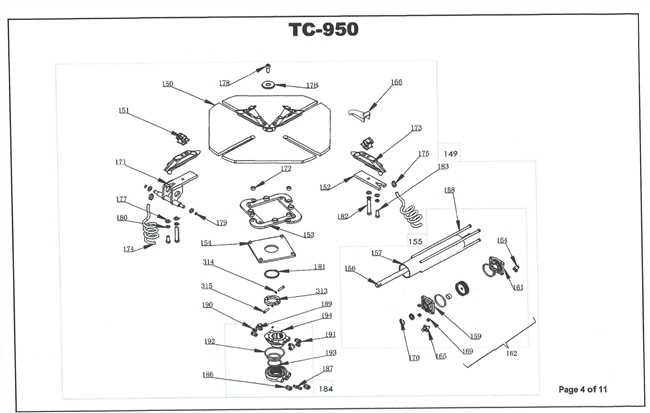

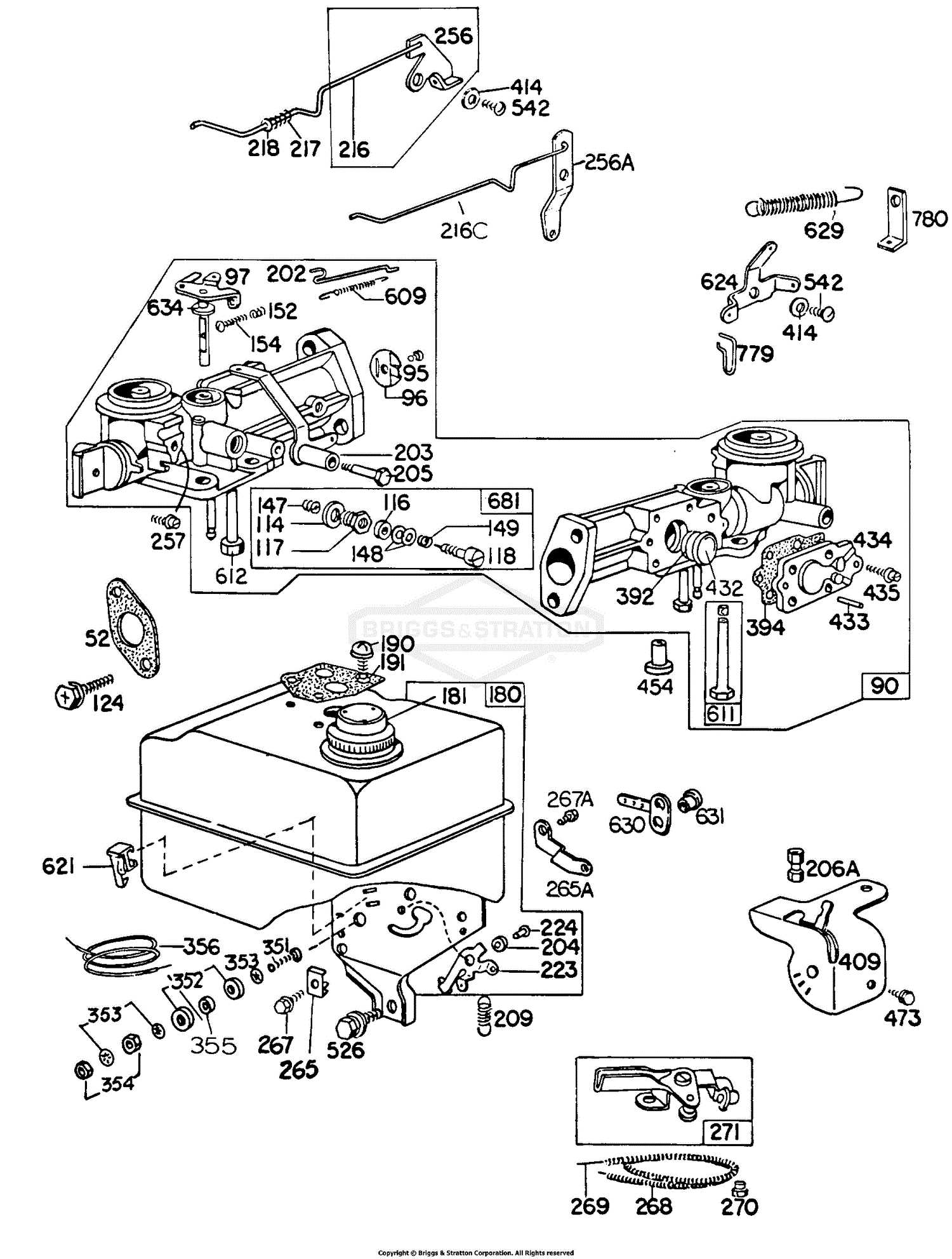

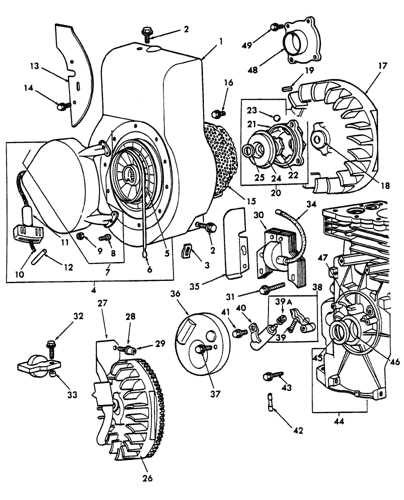

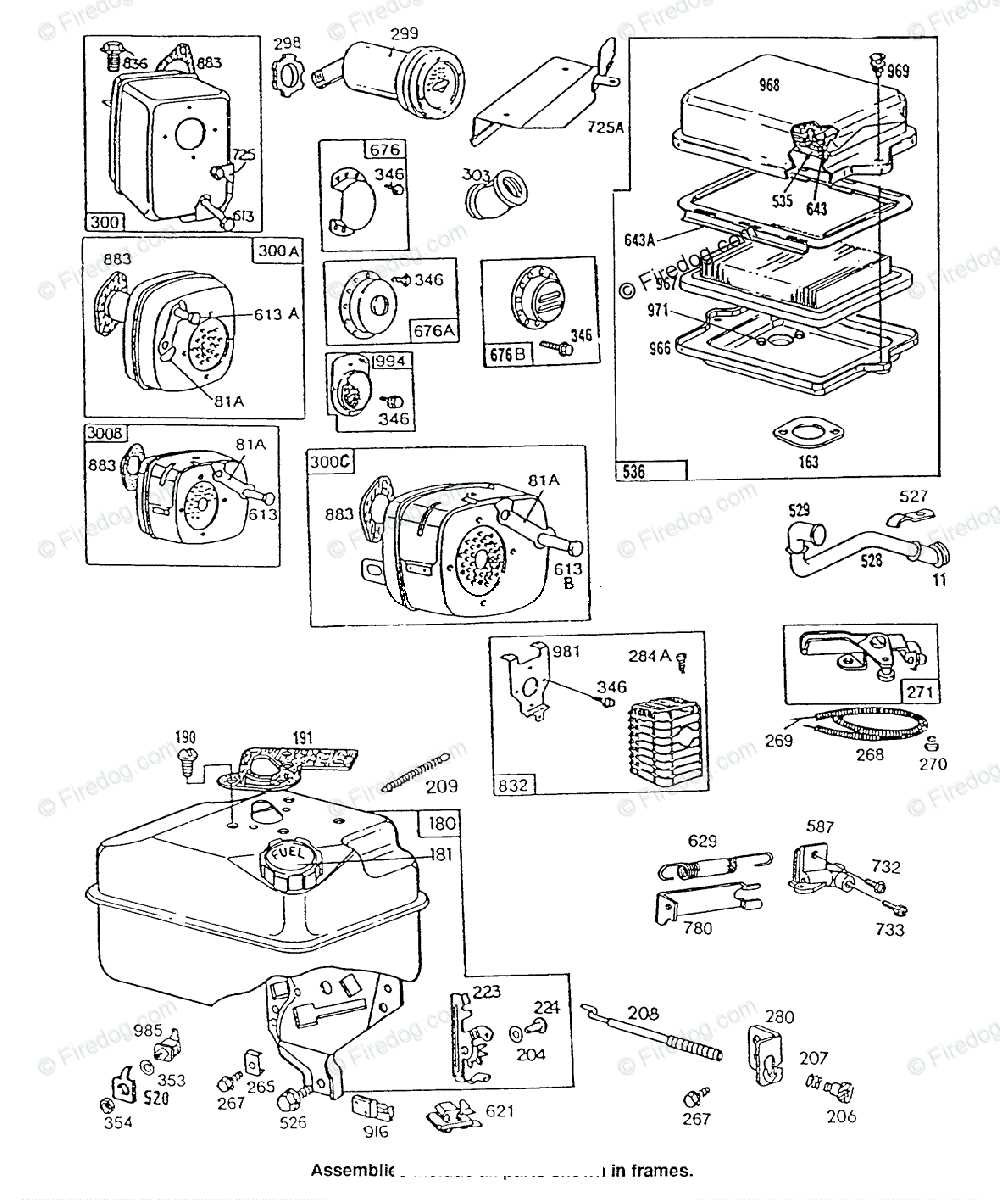

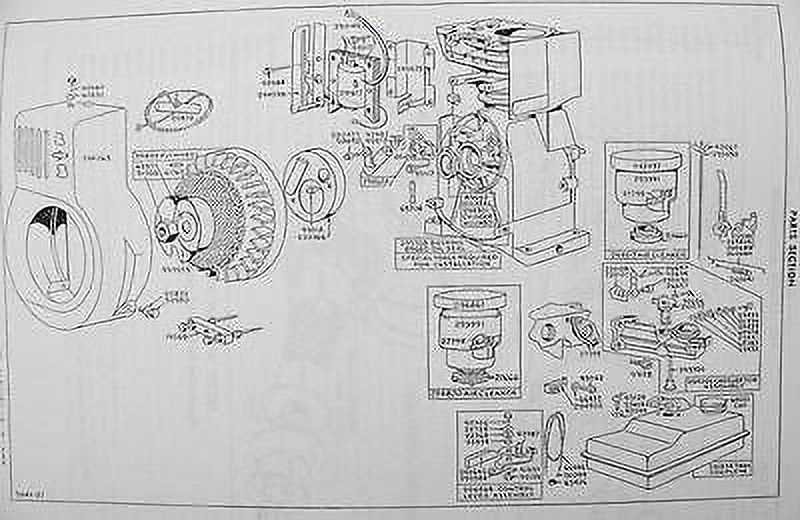

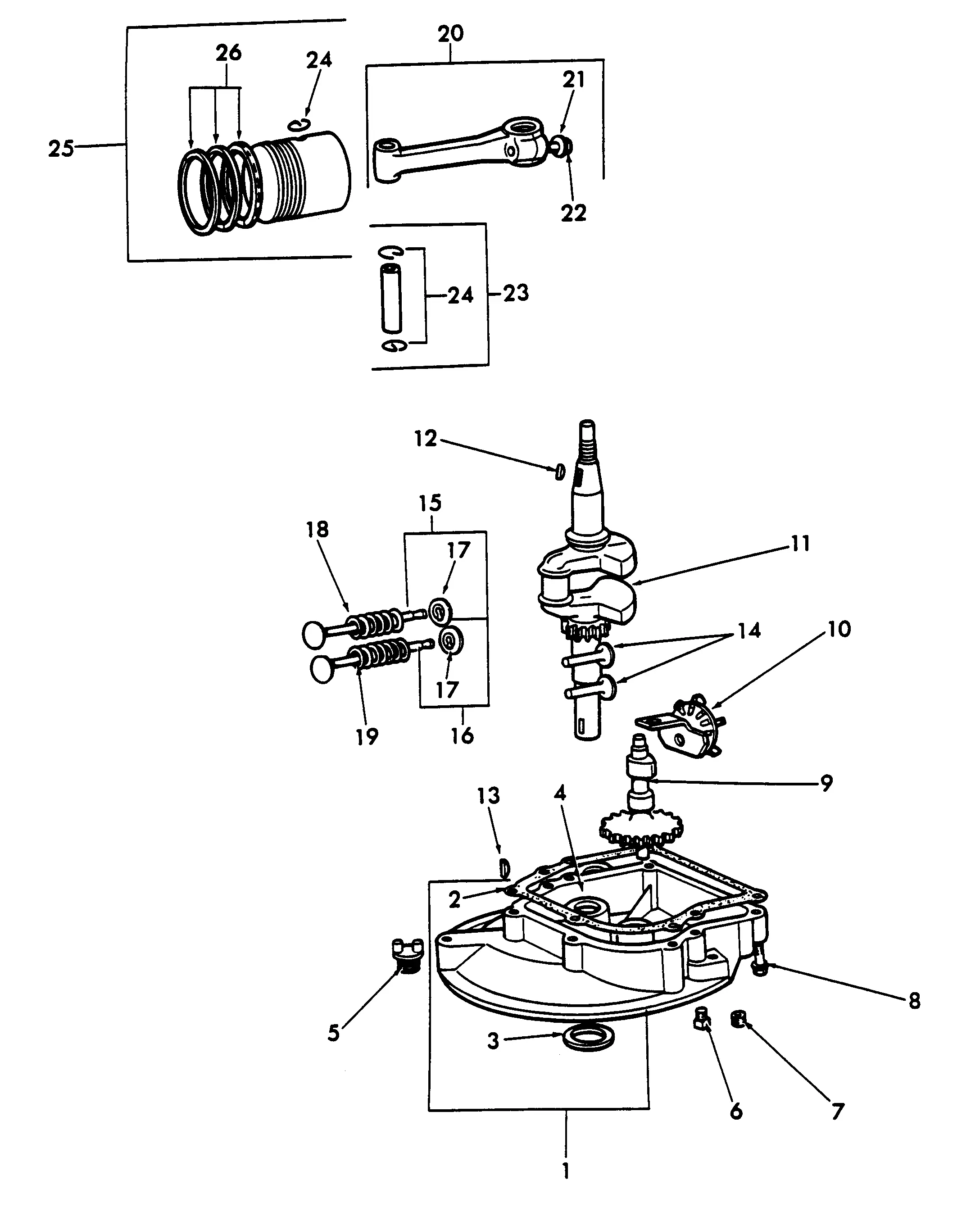

Understanding Engine Diagrams

Visual representations of machinery play a crucial role in comprehending the various components and their functions. These illustrations serve as valuable tools for both beginners and experienced mechanics, offering insights into how different elements interact within the system.

The Importance of Visual Aids

Utilizing visual aids can significantly enhance the understanding of mechanical systems. Here are some key benefits:

- Clarifies complex relationships between components.

- Assists in troubleshooting and maintenance tasks.

- Facilitates learning for individuals new to engine mechanics.

Common Components in Illustrations

Typically, these visuals include various essential elements, each represented to indicate its location and role:

- Crankshaft

- Piston

- Valves

- Fuel System

- Ignition System

Understanding each component’s placement and function within the system is vital for effective operation and repair.

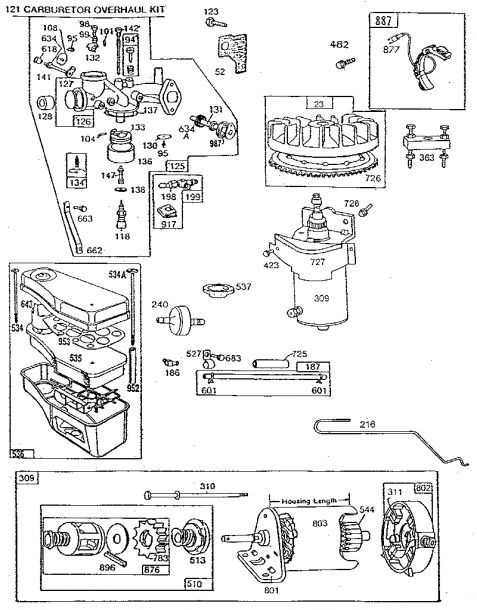

How to Read Parts Diagrams

Understanding schematic representations is essential for effective maintenance and repair. These visual guides provide an overview of components and their relationships, making it easier to identify what is needed for a project. Familiarity with these representations can significantly enhance the efficiency of troubleshooting and assembly processes.

Identifying Components

When examining a schematic, start by noting the various elements depicted. Each item is usually labeled with a unique identifier, which corresponds to a list or legend included with the schematic. Pay attention to the shape and size of each representation, as these can offer clues about the function and compatibility of the components.

Understanding Relationships

The connections between elements are crucial for comprehending how the entire system operates. Lines or arrows typically illustrate how components interact, indicating flow or operational sequences. Recognizing these relationships helps in assembling or disassembling machinery correctly.

Practice is key to mastering the interpretation of these visual aids. Regularly consulting and working with these schematics will enhance your skills, enabling you to tackle repair tasks with confidence.

Common Issues in Small Engines

Small engines are widely utilized in various applications, from gardening tools to generators. Despite their versatility, these engines can experience a range of issues that affect performance and reliability. Understanding these common problems can aid in effective maintenance and troubleshooting.

One frequent challenge is fuel-related complications, which can stem from stale gasoline or improper fuel mixtures. Another common issue involves ignition system failures, where components like spark plugs and coils can malfunction, leading to starting difficulties. Additionally, air flow restrictions due to dirty filters can significantly impair engine efficiency.

| Issue | Symptoms | Possible Solutions |

|---|---|---|

| Fuel Contamination | Engine sputters or fails to start | Replace fuel and clean the tank |

| Ignition Failure | No spark or hard starting | Inspect and replace spark plug or ignition coil |

| Clogged Air Filter | Reduced power or stalling | Clean or replace air filter |

| Overheating | Excessive heat or smoke | Check coolant levels and ensure proper ventilation |

Maintenance Tips for Longevity

Ensuring the extended life of your small engine requires regular care and attention. Implementing a few simple practices can significantly enhance performance and reliability over time. By focusing on proactive measures, you can prevent common issues and maintain optimal functionality.

1. Regular Oil Changes: Frequent oil changes are essential to keep the engine running smoothly. Use high-quality lubricants and follow the manufacturer’s recommendations for intervals.

2. Clean Air Filters: Air filters prevent dirt and debris from entering the engine. Regularly inspect and clean or replace the filter to ensure proper airflow and efficient operation.

3. Spark Plug Inspection: A well-functioning spark plug is crucial for effective ignition. Check the spark plug periodically for wear and replace it as needed to maintain optimal performance.

4. Fuel Quality: Always use fresh, high-quality fuel to prevent issues related to stale or contaminated gasoline. Consider adding a fuel stabilizer if the engine will not be used for an extended period.

5. Regular Cleaning: Keep the exterior and components of the engine clean to prevent the buildup of dirt and grime. This practice not only improves aesthetics but also helps identify potential problems early.

6. Seasonal Maintenance: Before and after the usage season, conduct thorough checks and maintenance tasks. This includes inspecting all components, tightening bolts, and ensuring everything is in good working order.

By incorporating these practices into your routine, you can enhance the durability and efficiency of your engine, ensuring it remains a reliable asset for years to come.

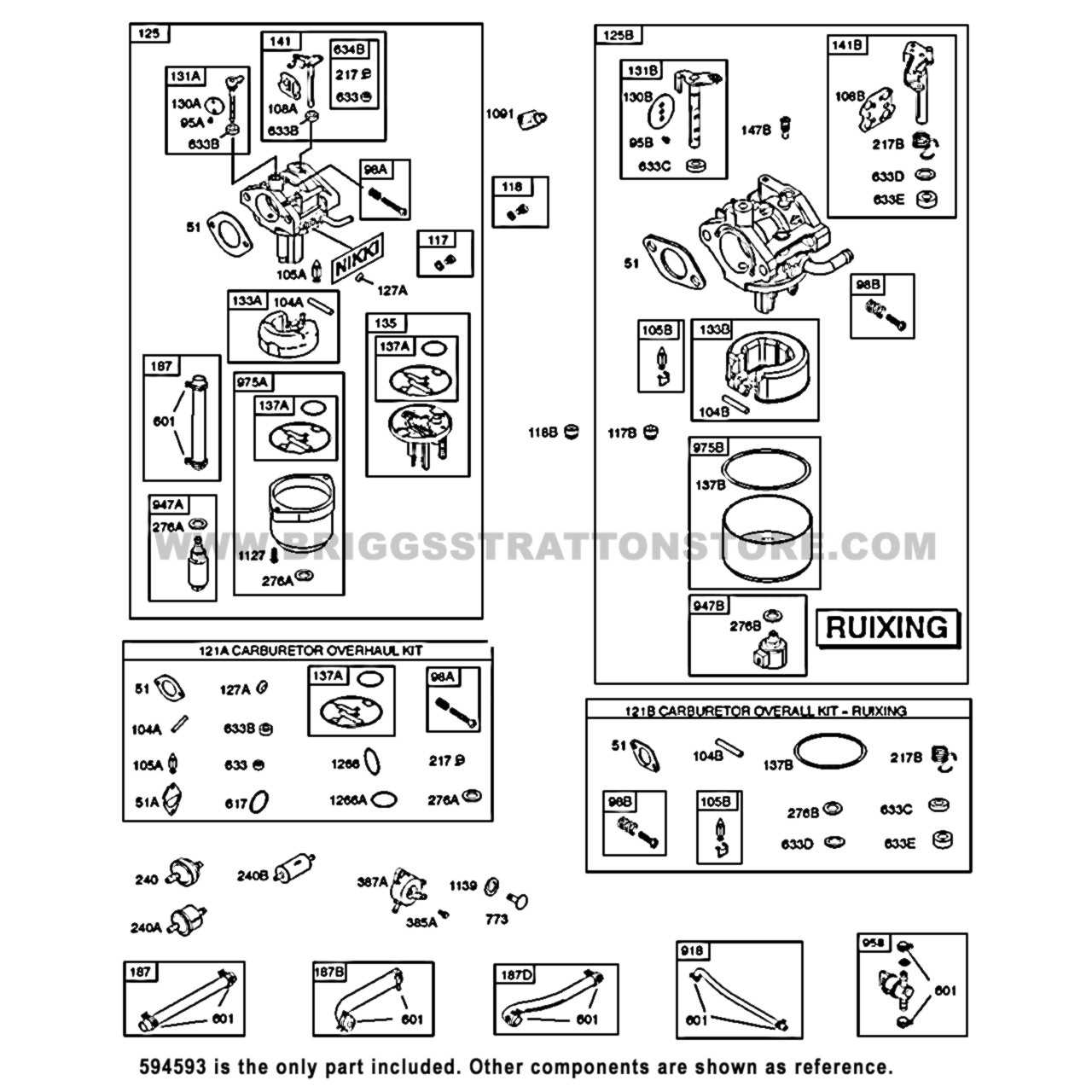

Identifying Replacement Parts

When maintaining small engines, recognizing the correct components for replacement is essential for ensuring optimal performance. This section focuses on the process of identifying necessary elements for effective repairs or upgrades. Understanding the various parts and their functions can help in troubleshooting issues and prolonging the lifespan of the equipment.

Common Components and Their Functions

Small engines consist of several crucial components, each playing a specific role in the overall operation. Familiarizing yourself with these elements will aid in accurate identification and replacement. Below is a list of some of the most commonly replaced components:

| Component Name | Description | Common Issues |

|---|---|---|

| Cylinder Head | Encases the combustion chamber, facilitating compression and combustion. | Overheating, cracks, or gasket failure. |

| Piston | Moves up and down within the cylinder, creating power through combustion. | Wear and tear, scoring, or excessive clearance. |

| Carburetor | Mixes air and fuel for optimal combustion efficiency. | Clogs, leaks, or improper adjustments. |

| Ignition Coil | Generates the electrical spark needed to ignite the air-fuel mixture. | Weak spark, misfires, or complete failure. |

Tips for Identifying Components

To accurately identify the required components for replacement, consider the following tips:

- Refer to the equipment’s manual for specific component information.

- Consult online resources or forums for guidance on common issues.

- Take photos of the existing components before removal for reference.

Where to Find Diagrams Online

Locating visual representations of components and their arrangements can significantly enhance your understanding of mechanical systems. Whether you’re troubleshooting an issue or planning a repair, these resources can provide essential guidance.

Here are some valuable online platforms to explore:

- Manufacturer Websites: Official sites often have comprehensive resources, including manuals and visual aids.

- Online Retailers: E-commerce platforms frequently provide product listings that include detailed images and descriptions.

- Technical Forums: Community-driven forums can be a treasure trove of information, where users share diagrams and insights.

- YouTube Channels: Video tutorials sometimes include step-by-step guides accompanied by visual references.

- Documentation Archives: Websites dedicated to preserving manuals and technical documents can be extremely helpful.

Utilizing these sources will help you gain a better grasp of component layouts and functionality, making your maintenance or repair tasks more manageable.

Tools Needed for Repairs

To effectively conduct maintenance and repairs on small engines, having the right instruments is essential. A well-equipped workspace not only facilitates the process but also enhances safety and efficiency. Whether you are a seasoned mechanic or a novice, familiarizing yourself with the necessary tools can make a significant difference.

Wrenches are vital for loosening and tightening bolts and nuts. A set of various sizes will ensure you can tackle different components with ease. Additionally, screwdrivers in both flathead and Phillips types are necessary for accessing various screws throughout the machinery.

Another important tool is the socket set, which allows for greater torque and easier manipulation of fasteners. For cleaning and maintenance, cleaning brushes and compressed air can help remove debris and ensure all parts function smoothly. Finally, a multimeter is invaluable for diagnosing electrical issues, providing insights into voltage and current flow.

Having these essential instruments on hand can simplify repairs, reduce downtime, and extend the lifespan of the equipment. Investing in quality tools will pay off in the long run, ensuring your engine runs optimally.

Disassembling Your Engine Safely

Taking apart your motor requires careful planning and attention to detail to avoid accidents and damage. Following proper procedures ensures that each component is handled appropriately, allowing for an effective reassembly process later. By prioritizing safety and organization, you can successfully navigate this crucial task.

Before starting, ensure that you have all necessary tools and protective gear at hand. This preparation not only enhances safety but also streamlines the disassembly process. Disconnect the power source and remove any fuel to minimize risks during handling.

As you begin the disassembly, work systematically and label each part as you remove it. This practice helps maintain organization and prevents confusion during reassembly. Take photographs if necessary to document the configuration of components, which can serve as a useful reference later on.

Be mindful of any sharp edges or moving parts, and ensure that you are working in a well-lit area. If you encounter resistance when removing a component, do not force it; instead, double-check for any additional fasteners or connections that may be preventing removal. Patience and attention to detail are essential during this process.

Once all parts are disassembled, clean them thoroughly before inspection or replacement. Proper maintenance will not only prolong the life of each component but also contribute to the overall performance of your machinery. By adhering to these safety measures, you can confidently undertake the task of disassembling your motor.

Step-by-Step Repair Guide

This guide aims to assist you in the effective restoration of a small engine, providing you with clear instructions for each step of the process. Whether you are a seasoned mechanic or a novice, following these steps will help you identify and resolve common issues, ensuring optimal performance and longevity of your equipment.

Preparation for Repair

Before beginning the repair process, gather all necessary tools and components. Ensure that you have a clean workspace and proper safety gear. Familiarize yourself with the engine’s layout and components to make the repair more efficient. Reviewing the user manual can provide valuable insights into troubleshooting common problems.

Repair Process

Start by diagnosing the issue through a thorough inspection. Check for signs of wear, leaks, or damage. Once the problem is identified, proceed to disassemble the necessary parts carefully. Replace or repair any faulty components, ensuring each piece is correctly installed. Finally, reassemble the engine and conduct a test run to confirm the repairs have restored functionality.

Upgrading Your Engine Performance

Enhancing the efficiency and output of your small motor can significantly improve its overall functionality and longevity. This section explores various methods to boost performance, focusing on key components and adjustments that can lead to noticeable improvements. Whether for recreational use or daily tasks, optimizing your engine can elevate your experience and satisfaction.

Essential Modifications

One of the most effective ways to enhance your engine’s capability is through modifications to essential components. Upgrading the air intake system allows for better airflow, increasing combustion efficiency. Coupling this with a high-performance exhaust can further enhance the power output by reducing back pressure. Together, these changes can create a more dynamic engine environment.

Tuning and Maintenance

Regular tuning is crucial for achieving optimal performance. Adjusting the carburetor settings ensures a balanced fuel-air mixture, which is vital for efficient operation. Additionally, maintaining spark plugs and ensuring they are in excellent condition can improve ignition efficiency. Regular oil changes and using high-quality lubricants can also prevent wear and tear, thus maintaining engine health over time.

Investing time and resources into these upgrades can lead to a more powerful and reliable engine. Understanding the interplay between different components allows for informed decisions that can maximize performance and efficiency.

Resources for Further Learning

Expanding your knowledge about small engine maintenance and repair can significantly enhance your understanding and skills. There are numerous resources available that cater to both beginners and experienced individuals looking to deepen their expertise in this field. Utilizing various materials will provide valuable insights and practical guidance.

| Resource Type | Description | Link |

|---|---|---|

| Books | Comprehensive guides covering maintenance, repair techniques, and troubleshooting tips. | Amazon |

| Online Courses | Interactive courses that offer in-depth instruction on engine repair and diagnostics. | Udemy |

| YouTube Channels | Visual tutorials that demonstrate practical repair procedures and maintenance practices. | YouTube |

| Forums | Communities where enthusiasts share knowledge, experiences, and troubleshooting advice. |