The intricate design of small engines is vital for their efficient operation and longevity. Knowing the various elements that comprise these machines can significantly enhance maintenance practices and troubleshooting techniques. Each component plays a specific role, contributing to the overall functionality of the system.

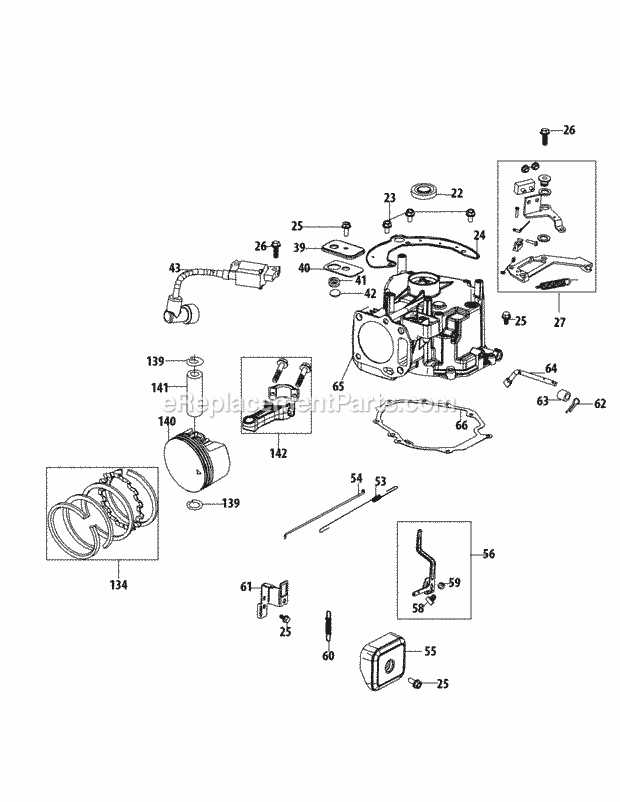

When examining the internal structure, a detailed visual representation is invaluable. It allows enthusiasts and technicians to identify parts and understand how they interact within the assembly. Such insights are essential for anyone looking to repair or optimize engine performance.

In this section, we will explore a comprehensive illustration showcasing the various elements found in a common engine model. By familiarizing yourself with these components, you will be better equipped to handle repairs and replacements, ensuring your machine runs smoothly for years to come.

Understanding Briggs and Stratton 140cc

This section aims to explore the intricacies of a popular engine model known for its reliability and efficiency. Delving into its components and functionality will enhance your comprehension of its design and maintenance needs.

Key Features

- Compact size suitable for various applications

- Robust construction ensuring durability

- Ease of maintenance contributing to longevity

Common Applications

- Lawn mowers

- Generators

- Pressure washers

Key Components of the Engine

Understanding the essential elements of an engine is crucial for maintenance and repair. Each part plays a significant role in the overall functionality and performance.

- Fuel System: Responsible for delivering fuel to the combustion chamber, ensuring efficient operation.

- Ignition System: Initiates combustion by generating a spark, crucial for starting the engine.

- Cooling System: Maintains optimal operating temperatures, preventing overheating.

- Crankshaft: Converts linear motion from the pistons into rotational energy, driving the engine.

- Piston: Moves within the cylinder, compressing the air-fuel mixture for ignition.

Familiarity with these components allows for effective troubleshooting and enhances the understanding of engine mechanics.

Common Issues with 140cc Models

Small engines often encounter a range of frequent problems that can hinder performance and reliability. Understanding these issues can help users maintain their equipment more effectively and enhance its longevity.

Starting Difficulties

Many users report challenges with ignition, which may stem from stale fuel or a clogged spark plug. Regular maintenance, including fuel changes and inspections, is crucial to prevent these issues.

Overheating

Another prevalent concern is overheating, typically caused by inadequate airflow or oil levels. Keeping the cooling fins clear and checking oil regularly can mitigate this risk. Timely intervention is essential to ensure optimal function and avoid damage.

How to Identify Parts Easily

Recognizing components within a mechanical assembly can often be challenging. However, understanding the various elements and their functions can significantly simplify the process. By utilizing systematic approaches and resources, you can efficiently pinpoint the necessary items for your repairs or maintenance tasks.

Here are some effective strategies to help you identify components:

| Method | Description |

|---|---|

| Reference Manuals | Consulting the user manuals can provide detailed descriptions and images of each component, aiding in identification. |

| Online Resources | Utilizing websites and forums dedicated to mechanical equipment can offer insights and visuals shared by other users. |

| Part Numbers | Identifying components through their unique identifiers can streamline the search process, especially when ordering replacements. |

| Visual Comparison | Comparing the physical attributes of the suspected parts with known references can help confirm their identity. |

Employing these methods can greatly enhance your efficiency in locating and recognizing the required elements, ensuring smoother maintenance or repair processes.

Importance of Regular Maintenance

Consistent upkeep is crucial for ensuring optimal performance and longevity of any mechanical equipment. By adhering to a regular maintenance schedule, users can prevent potential issues, enhance efficiency, and ultimately save costs associated with repairs and replacements.

Benefits of Regular Upkeep

Routine care not only extends the lifespan of machinery but also improves its reliability and functionality. It minimizes the risk of unexpected breakdowns and enhances safety for users.

Key Maintenance Tasks

| Task | Frequency | Purpose |

|---|---|---|

| Oil Change | Every 50 hours | Reduces wear and tear |

| Air Filter Cleaning | Every 25 hours | Improves airflow |

| Spark Plug Replacement | Annually | Ensures efficient ignition |

Where to Find Replacement Parts

Locating suitable components for your engine can be straightforward if you know where to search. Various resources are available to ensure you can maintain and repair your equipment effectively.

- Online Retailers: Websites specializing in machinery often have a wide range of items.

- Local Hardware Stores: Many neighborhood shops stock essential components for engines.

- Manufacturer’s Website: The official site typically provides detailed catalogs and ordering options.

- Specialty Shops: Stores focusing on outdoor equipment often carry specific items you may need.

- Second-hand Marketplaces: Consider platforms where individuals sell used components at lower prices.

By exploring these avenues, you can enhance your chances of finding the right pieces for your maintenance tasks.

Step-by-Step Repair Guide

This section aims to provide a comprehensive approach to fixing small engines, focusing on the necessary procedures and tips for effective maintenance.

- Gather Tools:

- Wrenches

- Screwdrivers

- Replacement components

- Cleaning supplies

- Identify the Issue:

- Observe engine behavior

- Check for leaks or unusual noises

- Review performance problems

- Disassemble Carefully:

- Document each step

- Organize parts for easy reassembly

- Keep screws and small components in a safe place

- Inspect Components:

- Check for wear and damage

- Clean dirt and debris

- Replace any faulty items

- Reassemble Engine:

- Follow your documentation

- Ensure all parts are secure

- Perform final checks before starting

- Test Functionality:

- Start the engine in a safe area

- Monitor performance

- Make adjustments as necessary

Following these steps will help ensure successful repairs and optimal operation.

Tools Required for Repairs

When undertaking maintenance or fixing tasks, having the right instruments is essential for ensuring efficiency and effectiveness. Proper tools not only streamline the process but also enhance safety and precision during repairs.

Basic Hand Tools: A set of wrenches, screwdrivers, and pliers forms the foundation of any toolkit. These instruments are crucial for loosening or tightening components and accessing hard-to-reach areas.

Specialty Equipment: Depending on the nature of the repairs, certain specialized tools may be necessary. For instance, socket sets and torque wrenches allow for accurate fastening, while diagnostic tools can help identify underlying issues.

Safety Gear: Always prioritize safety by using protective eyewear and gloves. This ensures that while delving into repairs, the risk of injury is minimized.

Cleaning Supplies: Keeping the workspace tidy is vital. Having rags, brushes, and appropriate solvents on hand aids in maintaining cleanliness and organization throughout the repair process.

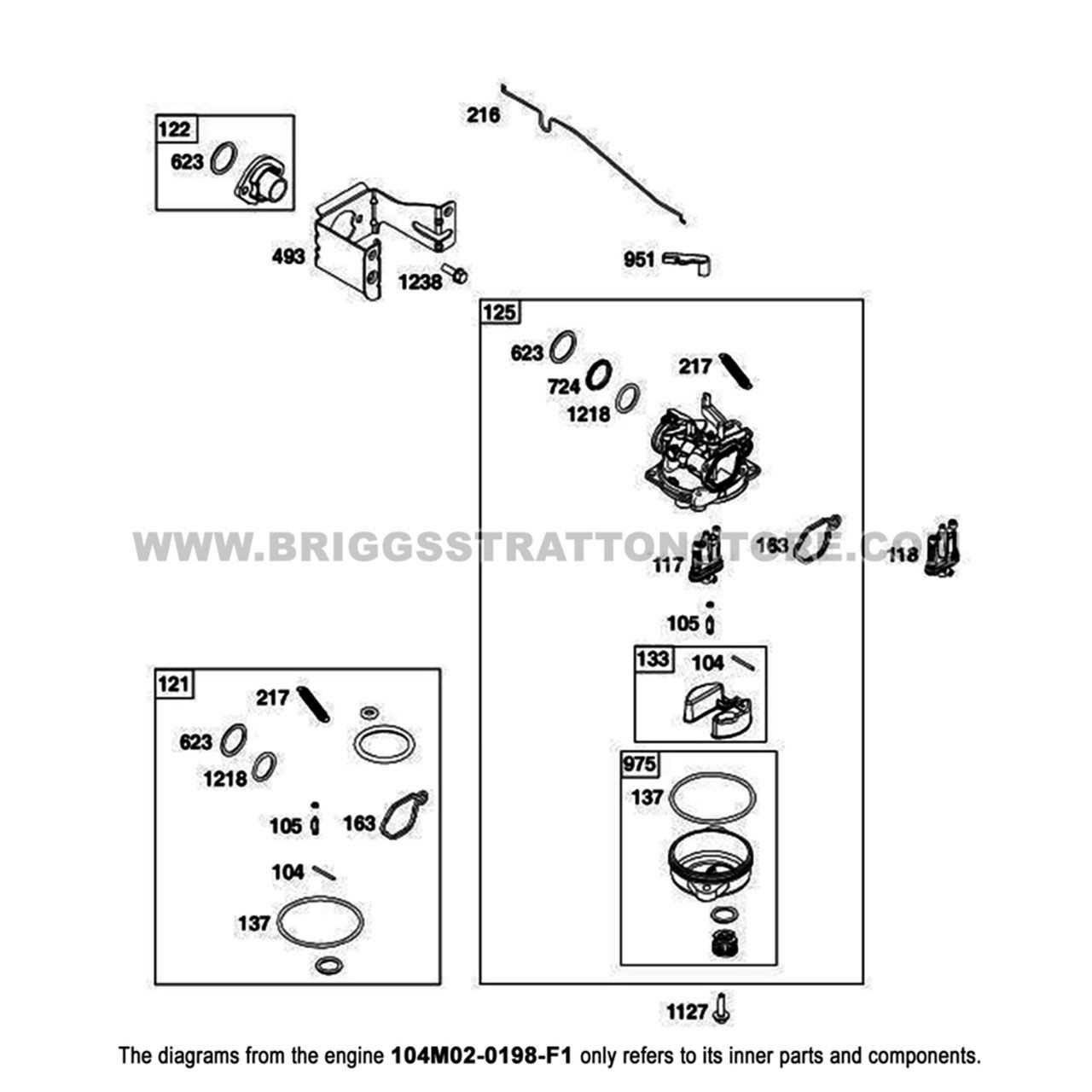

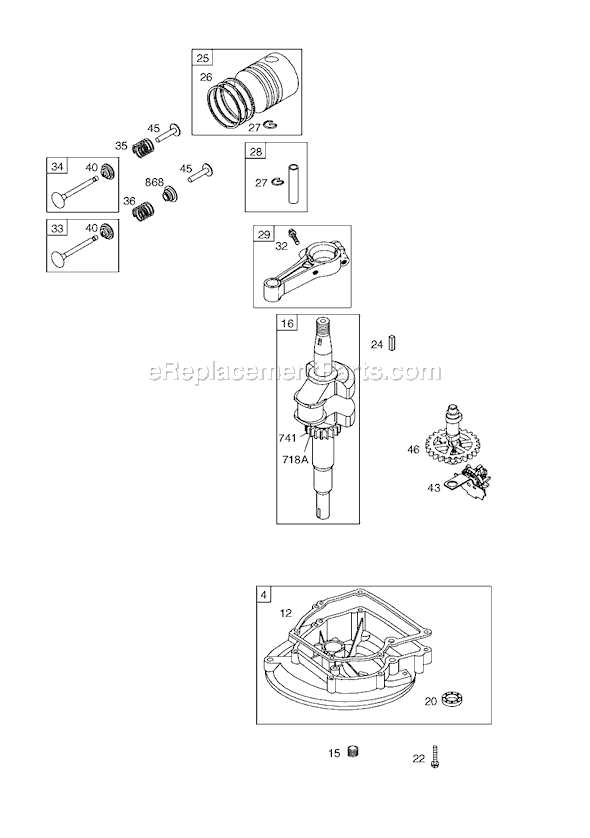

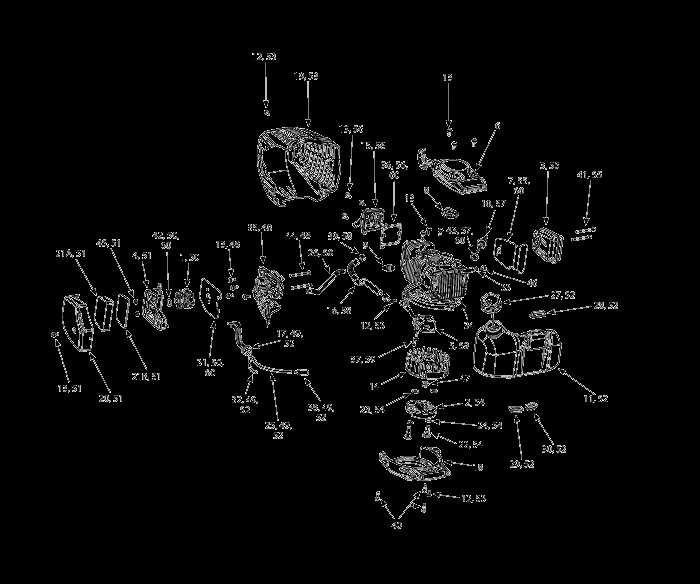

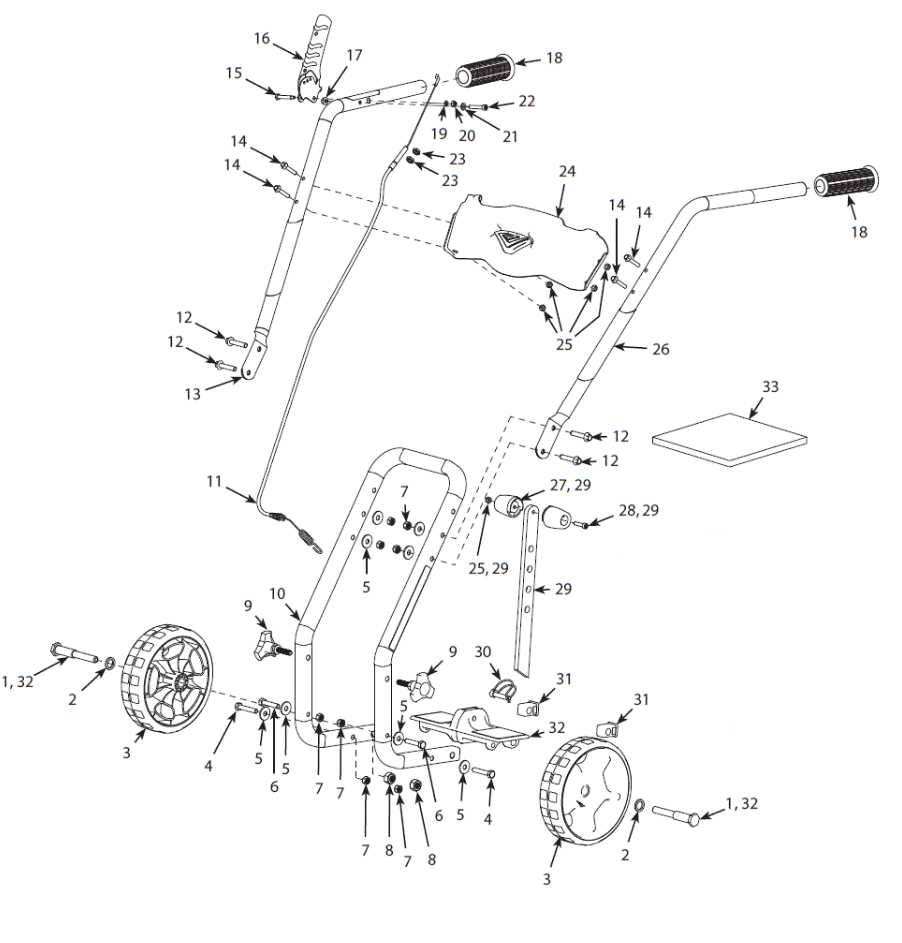

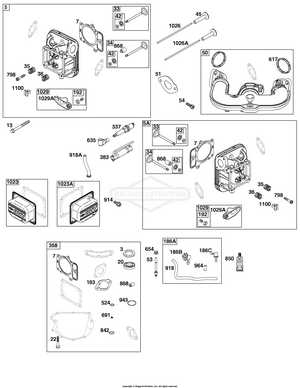

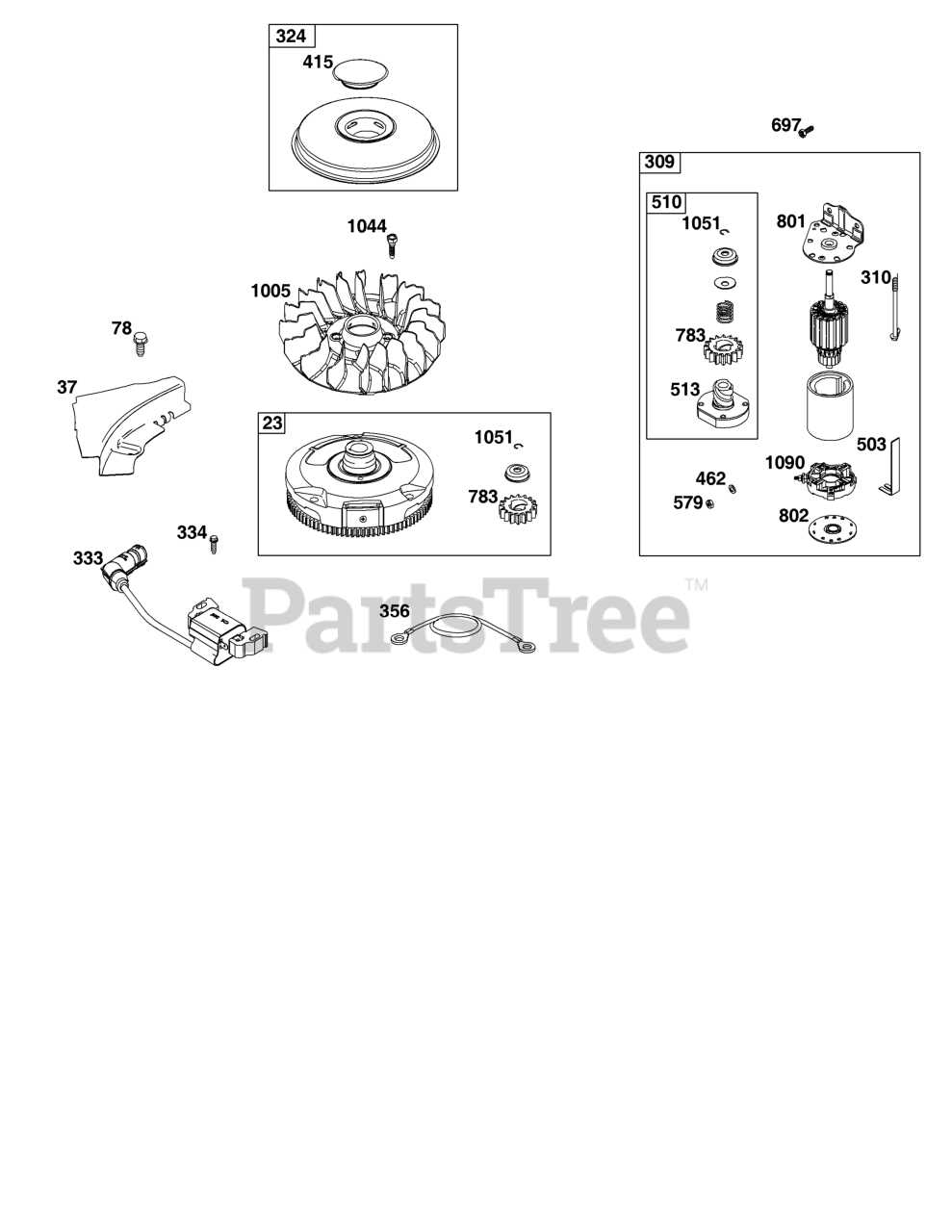

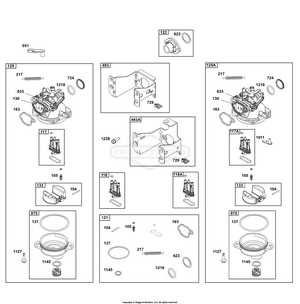

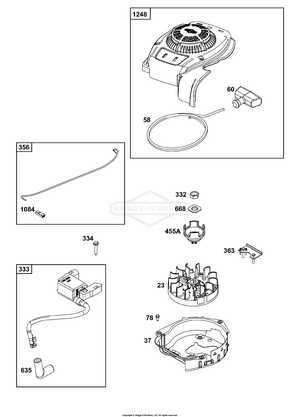

Visuals: Parts Diagram Overview

This section provides an essential visual reference for understanding the various components of the engine. Having a clear representation of each element facilitates better maintenance and repairs, ensuring longevity and optimal performance.

Importance of Visual References

Utilizing visual aids can greatly enhance comprehension. They serve as a guide, making it easier to identify, locate, and replace specific elements within the engine. Key benefits include:

- Improved accuracy in repairs

- Quicker identification of necessary components

- Enhanced understanding of the assembly

Common Components Illustrated

In the visual references, you can expect to see a variety of critical components, such as:

- Fuel system parts

- Ignition system elements

- Cooling components

- Lubrication systems

- Structural framework

These illustrations not only aid in recognizing parts but also assist in visualizing how each piece interacts within the overall system, contributing to efficient operation and maintenance.

Safety Tips During Repairs

Engaging in maintenance tasks can be rewarding, but it’s crucial to prioritize safety to prevent accidents. Proper preparation and awareness can significantly enhance your experience and ensure a secure environment.

Always wear appropriate protective gear, such as gloves and goggles, to shield yourself from potential hazards. This simple step can minimize risks associated with flying debris and sharp objects.

Before starting any work, disconnect the power source or fuel supply. This precaution will help avoid unintentional activation and ensure a safer repair process.

Keep your workspace organized and well-lit. Clutter can lead to distractions and accidents, while good visibility allows you to see what you’re doing clearly.

Lastly, consult the user manual or online resources to familiarize yourself with the equipment. Understanding its components can prevent mistakes and promote effective repairs.

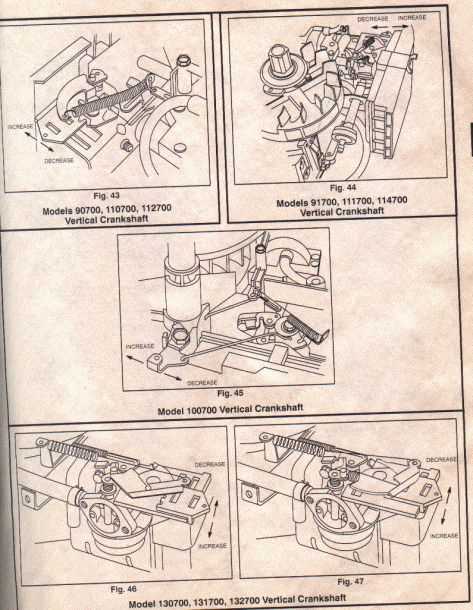

Upgrading Your Engine Performance

Enhancing the efficiency of your motor can lead to significant improvements in power and responsiveness. By focusing on key components and making informed adjustments, you can achieve a more dynamic performance, whether for recreational or professional purposes.

Key Areas to Focus On

Consider upgrading the air intake and exhaust systems, as these modifications can greatly influence airflow and combustion efficiency. Additionally, tuning the ignition system may optimize timing and enhance overall engine response.

Performance Parts Overview

| Component | Benefit |

|---|---|

| High-Flow Air Filter | Improves airflow, enhancing combustion |

| Performance Muffler | Reduces backpressure, increasing power |

| Upgraded Spark Plug | Improves ignition efficiency for better performance |

| Tuning Kit | Optimizes fuel mixture and ignition timing |

Warranty Information and Claims

This section provides essential details regarding the coverage and procedures related to product guarantees. Understanding the terms can help users navigate claims effectively and ensure their equipment remains in optimal condition.

Coverage typically includes repairs or replacements for manufacturing defects under specified conditions. Users must retain their purchase receipts and register their products to qualify for warranty services.

| Warranty Duration | Coverage Details | Claim Process |

|---|---|---|

| 1 Year | Defects in materials and workmanship | Contact customer service with proof of purchase |

| 2 Years | Extended coverage for select models | Fill out claim form and submit online |

| Lifetime | Specific components as per manufacturer guidelines | Direct service center visit required |

For further assistance, consult the official documentation or contact customer support directly to clarify any queries related to warranties or claims.

Frequently Asked Questions About Parts

This section addresses common inquiries related to components for small engines. Understanding these elements can enhance your maintenance efforts and ensure optimal performance.

What are the signs that a component needs replacement?

Typically, you may notice reduced efficiency, unusual noises, or visible wear. If performance issues arise, it’s wise to inspect the relevant elements closely.

How can I find the correct replacement for my engine?

Refer to your engine’s manual for specific details. Alternatively, many suppliers offer guides that help identify compatible components based on model numbers.

Are aftermarket options reliable?

Aftermarket alternatives can be both effective and economical, but it’s essential to choose reputable brands to ensure durability and compatibility.

What is the best way to maintain these components?

Regular cleaning and timely inspections play a crucial role in prolonging the lifespan of engine components. Following a consistent maintenance schedule is recommended.