When delving into the intricacies of small engine mechanisms, it is crucial to have a clear overview of the various components involved. This section serves as a comprehensive guide to the essential elements that make up the engine, providing valuable insights into their functions and interconnections. Familiarity with these parts not only aids in maintenance but also enhances troubleshooting capabilities.

Visual representations play a significant role in grasping the layout and relationships among different components. By examining detailed illustrations, users can identify specific pieces and understand how they work together to ensure optimal performance. This understanding is particularly beneficial for those seeking to repair or enhance their engine’s efficiency.

Moreover, recognizing the significance of each component contributes to better decision-making when it comes to replacements or upgrades. A well-informed approach to managing engine assembly can lead to improved longevity and functionality, ultimately making maintenance a more straightforward task. Whether for personal use or professional applications, gaining insight into engine assemblies is invaluable.

Maintenance of small engines often requires the replacement of certain components to ensure optimal performance and longevity. Understanding which elements are typically replaced can help owners keep their machinery running smoothly.

The following components are frequently replaced during engine upkeep:

- Air Filter: Essential for maintaining clean airflow and preventing debris from entering the engine.

- Fuel Filter: Keeps contaminants from clogging fuel lines and ensures smooth fuel flow.

- Spark Plug: Vital for ignition, worn spark plugs can lead to poor performance and starting issues.

- Oil Filter: Helps to keep engine oil clean and free of particles, promoting better lubrication.

- Belt: Commonly replaced due to wear, ensuring efficient power transmission to various parts.

Regular inspections and timely replacements of these components can significantly enhance the performance and reliability of small engines.

Identifying Engine Specifications

Understanding the technical details of a motor is essential for ensuring optimal performance and maintenance. By examining various characteristics, users can make informed decisions regarding repairs, replacements, and upgrades. This section highlights key features that are crucial for identifying specific requirements and capabilities of an engine.

Key Features to Consider

When assessing an engine, several attributes come into play. One should pay attention to the displacement, which refers to the total volume of the cylinders. Additionally, the power output is a significant factor, indicating the engine’s ability to perform under various conditions. Another critical element is the type of fuel used, which affects efficiency and compatibility.

Importance of Specifications

Having a clear understanding of the specifications allows users to compare different models effectively. This knowledge not only aids in the selection of appropriate components but also enhances troubleshooting efforts. Familiarity with these details ultimately leads to better maintenance practices and improved longevity of the engine.

Maintenance Tips for Longevity

Ensuring the extended life of your equipment requires consistent care and attention. Implementing simple maintenance practices can significantly enhance performance and reliability. Below are key strategies to keep your machinery running smoothly for years to come.

Regular Inspection

Conducting frequent checks of your equipment is crucial. Look for signs of wear, damage, or any irregularities that may indicate underlying issues. This proactive approach helps identify potential problems before they escalate, allowing for timely repairs and adjustments.

Proper Lubrication

Applying the right lubricants at regular intervals is essential for reducing friction and preventing premature wear. Ensure all moving parts are adequately greased, following the manufacturer’s recommendations. Proper lubrication not only enhances efficiency but also contributes to overall durability.

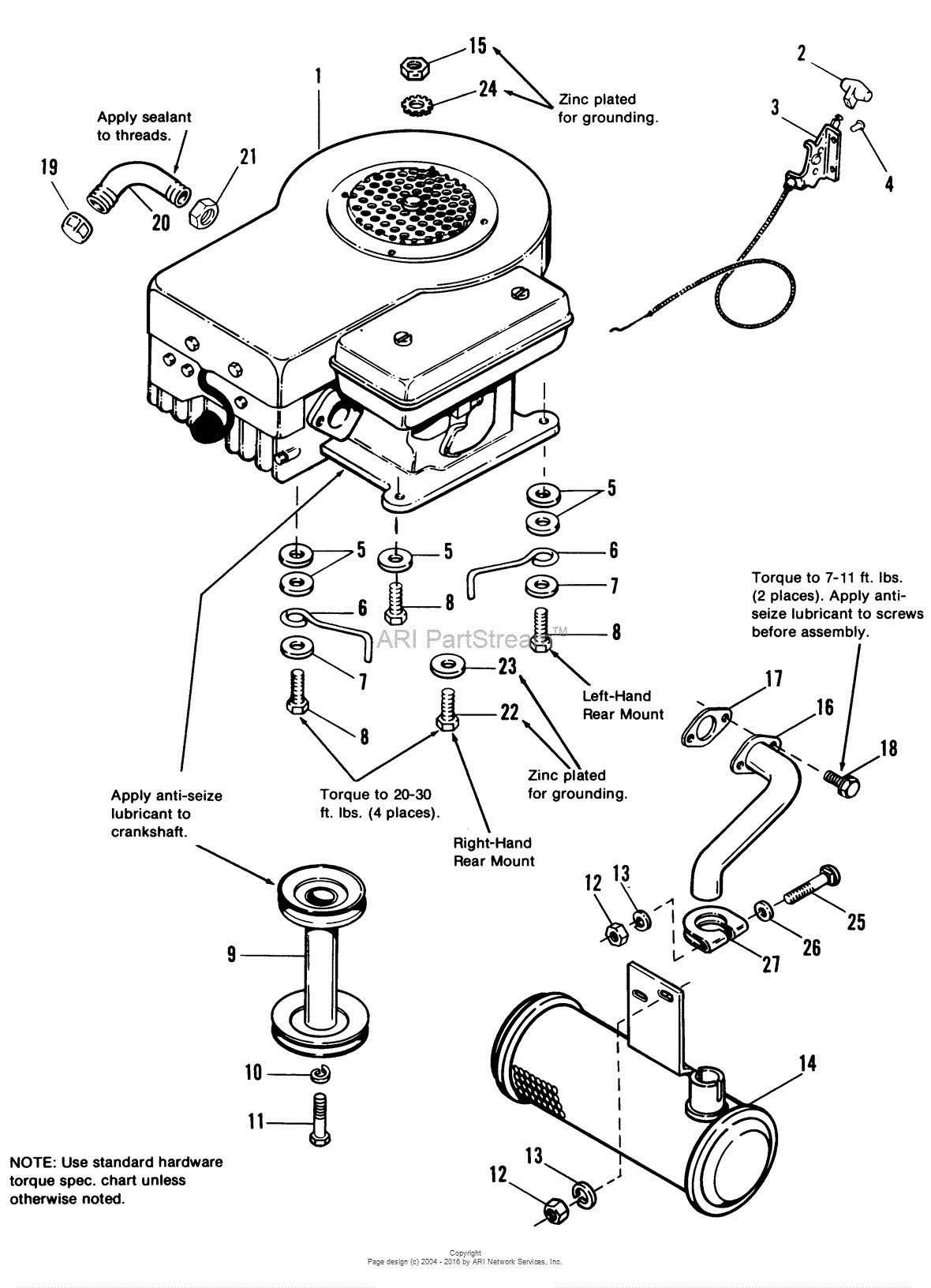

Tools Required for Repairs

To ensure efficient maintenance and repair of your small engine, having the appropriate tools is essential. These instruments facilitate effective work, allowing for accurate adjustments and replacements when necessary.

Here is a list of essential tools that may be required:

- Socket set

- Wrenches of various sizes

- Philips and flathead screwdrivers

- Pliers and wire cutters

- Torque wrench

- Oil filter wrench

- Fuel line pliers

- Spark plug socket

- Diagnostic tools

Having these tools readily available will significantly enhance your ability to perform repairs and maintenance tasks efficiently.

Where to Find Replacement Parts

Finding suitable components for your engine can be crucial for maintaining its performance. Numerous avenues exist for sourcing quality items, ensuring your machinery remains in optimal condition.

Authorized Dealers

One reliable option is to consult authorized distributors. These establishments offer original components that are specifically designed for your engine model. They guarantee compatibility and often provide expert advice on installation and maintenance.

Online Retailers

Another convenient avenue is exploring various online marketplaces. Numerous platforms specialize in engine components, presenting a vast selection of items. Make sure to verify the seller’s credibility and read customer reviews to ensure you’re purchasing high-quality products.

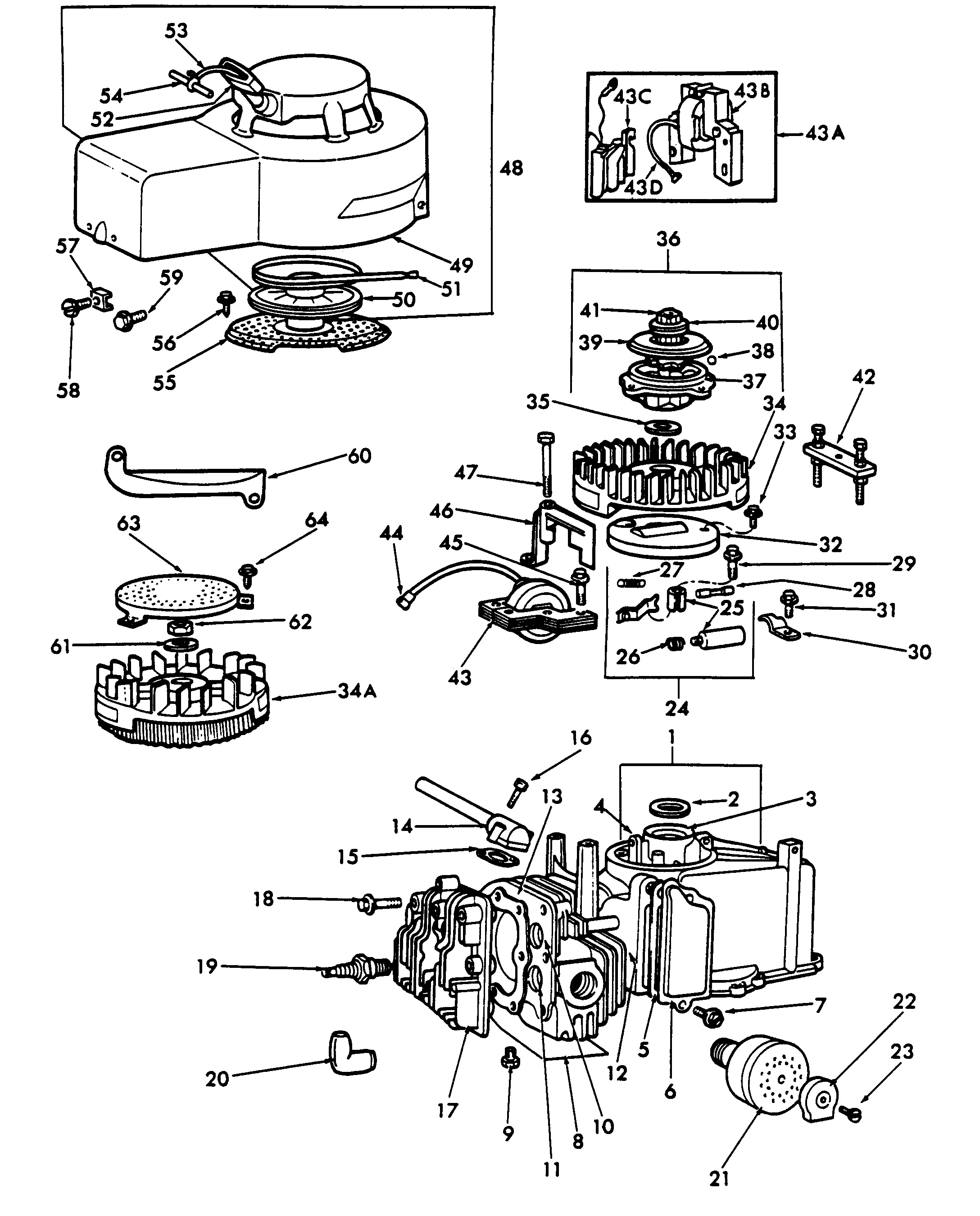

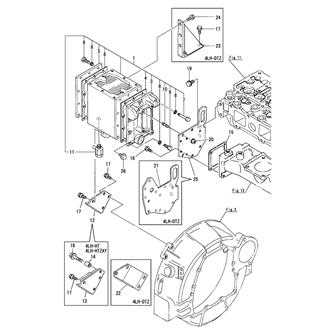

Interpreting the Parts Diagram

Understanding the visual representation of components is essential for effective maintenance and repairs. This illustration serves as a valuable tool, enabling users to identify various elements and their interconnections within the machinery.

Key Features to Consider

When examining the visual guide, pay attention to labels and symbols that denote specific components. Each part is typically numbered, facilitating easy reference to corresponding descriptions in the accompanying documentation. Recognizing these features enhances comprehension and aids in efficient troubleshooting.

Benefits of Familiarity

Acquainting oneself with the layout can significantly streamline the process of replacing or repairing components. By becoming familiar with the arrangement and functionality of each element, users can execute maintenance tasks more confidently and reduce the likelihood of errors.

Exploring Troubleshooting Techniques

When encountering issues with outdoor power equipment, understanding effective methods for diagnosing and resolving problems is crucial. This section delves into various strategies that can assist users in identifying potential malfunctions, ensuring optimal performance and longevity of their machinery.

One of the first steps in troubleshooting is to conduct a thorough inspection of the machine. Visual examination allows operators to spot any obvious signs of wear, damage, or disconnection that may affect functionality. It is essential to check components such as the fuel system, ignition elements, and air intake to confirm they are clean and functioning correctly.

Listening to unusual sounds during operation can also provide valuable insights. Any irregular noises may indicate internal issues requiring immediate attention. Furthermore, monitoring performance changes can help pinpoint specific areas of concern, guiding users in implementing targeted solutions.

Consulting manuals and online resources can enhance the troubleshooting process. Many manufacturers provide detailed guidelines that can clarify operational procedures and maintenance recommendations. Engaging with online communities can also offer additional support and advice from experienced users who may have faced similar challenges.

In summary, utilizing systematic approaches and resources is key to efficiently addressing issues with outdoor machinery. By being proactive and informed, users can ensure their equipment remains in excellent working condition.

Understanding Engine Assembly

Engine assembly is a crucial aspect of mechanical engineering, encompassing the arrangement and integration of various components to create a functional power source. This process involves numerous elements that work in harmony to ensure optimal performance and efficiency.

Key Components of Engine Assembly

- Block: The foundation that houses the cylinder and other critical parts.

- Piston: A moving part that plays a vital role in converting fuel energy into mechanical motion.

- Cylinder Head: A cover that seals the top of the cylinder, containing essential valves and spark plugs.

- Crankshaft: A component that transforms linear motion from the piston into rotational motion.

- Camshaft: Responsible for controlling the timing of the engine’s valves.

Assembly Process Overview

- Begin with the preparation of the engine block, ensuring it is clean and free of debris.

- Install the pistons and connecting rods, securing them within their designated cylinders.

- Attach the cylinder head, making sure to align it correctly with the block.

- Integrate the crankshaft and camshaft, ensuring they rotate freely without obstruction.

- Complete the assembly by adding auxiliary components such as the ignition system and fuel delivery mechanisms.

Understanding the intricacies of engine assembly not only aids in maintenance but also enhances the ability to troubleshoot potential issues effectively.

Recognizing OEM vs. Aftermarket Parts

Understanding the distinction between original equipment manufacturer (OEM) components and alternative options is essential for ensuring the longevity and efficiency of your machinery. Each type has its unique characteristics that can significantly influence performance and reliability.

OEM components are produced by the original manufacturer and are specifically designed to fit and function with the equipment they were intended for. These parts typically adhere to strict quality standards, ensuring a seamless integration into your machinery.

On the other hand, aftermarket components are made by third-party manufacturers and may offer a variety of options, often at a lower price point. While some of these alternatives can match the quality of OEM parts, others may not provide the same level of performance or durability, making it crucial to research and choose wisely.

Ultimately, the choice between OEM and aftermarket components depends on individual needs and preferences. Careful evaluation can lead to informed decisions that enhance the efficiency and lifespan of your equipment.

Safety Precautions During Maintenance

Ensuring safety during maintenance tasks is essential for both personal well-being and equipment longevity. By adhering to certain guidelines, individuals can minimize risks associated with machinery handling. These precautions not only protect the user but also help maintain the operational integrity of the equipment.

Proper Personal Protective Equipment

Wearing suitable protective gear is crucial when performing maintenance work. This includes safety goggles to shield the eyes from debris, gloves to protect the hands from sharp edges, and sturdy footwear to prevent slips and falls. Using ear protection may also be advisable when working with loud machinery.

Equipment Inspection and Preparation

Before commencing any maintenance procedures, a thorough inspection of the machinery should be conducted. Ensure that the equipment is turned off and disconnected from power sources. Check for any signs of wear or damage that could pose hazards during servicing. Proper preparation significantly reduces the likelihood of accidents occurring.