This section provides a comprehensive look at the key elements of a compact power unit. Understanding these components is crucial for effective maintenance and repair, ensuring optimal performance.

Each component plays a vital role in the overall functionality of the unit. Familiarity with these parts can enhance troubleshooting capabilities and streamline any restoration efforts.

Utilizing a visual representation can significantly aid in grasping the layout and interconnection of these essential pieces. This knowledge ultimately supports better decision-making during repairs and upgrades.

Understanding Briggs and Stratton Engines

This section explores the fundamental aspects of small power units widely used in various applications. These machines are renowned for their reliability and efficiency, making them popular choices for outdoor equipment, lawn care tools, and more. Understanding their components and functionality can greatly enhance the maintenance and performance of such units.

Each unit consists of several key elements that work together harmoniously. The combustion chamber plays a crucial role in energy production, while the cooling system ensures optimal operating temperatures. Additionally, the fuel delivery mechanism is vital for efficient operation, contributing to the overall longevity of the equipment.

Familiarizing oneself with the layout of these machines allows for better troubleshooting and repair practices. Recognizing how each component interacts can lead to improved performance and reduced downtime, benefiting both casual users and professionals alike.

Key Components of 5HP Engine

Understanding the essential elements of a compact power unit is crucial for effective maintenance and repair. These vital components work together to ensure smooth operation and reliability, enabling the machinery to function efficiently.

One of the primary features is the crankcase, which houses the moving parts and supports the overall structure. It plays a pivotal role in protecting internal mechanisms from dirt and debris. Another important element is the cylinder, where the combustion process occurs, creating the necessary power output. This component must be durable to withstand high pressures and temperatures.

The piston is another critical part, as it moves up and down within the cylinder, converting fuel energy into mechanical energy. Complementing this is the connecting rod, which links the piston to the crankshaft, facilitating the transfer of motion. Additionally, the ignition system ignites the fuel-air mixture, ensuring timely combustion and optimal performance.

Lastly, the fuel delivery system ensures a steady flow of fuel to the combustion chamber, playing a significant role in efficiency and power output. Together, these components form the backbone of a reliable power source, making it essential to understand their functions for proper upkeep.

Common Issues with Horizontal Shaft Engines

Various challenges can arise with engines featuring a lateral crankshaft design. Understanding these common complications is essential for maintaining optimal performance and longevity.

- Starting Difficulties: Many users encounter problems when attempting to start the machine. This can be due to fuel issues, spark plug malfunctions, or battery deficiencies.

- Overheating: Engines can run excessively hot, leading to potential damage. This issue often stems from inadequate cooling or low oil levels.

- Unusual Noises: Strange sounds during operation may indicate internal wear or loose components. Regular inspection can help identify these issues early.

- Vibration: Excessive shaking can be a sign of imbalance or misalignment. Ensuring proper assembly and maintenance can mitigate this problem.

- Fuel Leaks: Leaking fuel is not only wasteful but also hazardous. Regular checks of fuel lines and connections are crucial for safety.

Addressing these common issues promptly can enhance the reliability and efficiency of lateral crankshaft machines.

Maintenance Tips for Longevity

Ensuring the durability of your outdoor power equipment requires regular attention and care. By implementing effective maintenance practices, you can enhance performance and extend the life of your machinery. Here are some essential tips to help you maintain optimal functionality.

Regular Inspections

Frequent checks on various components will help identify wear and tear early. Look for signs of damage, loose connections, and any buildup of debris. Keeping everything clean and intact can prevent larger issues down the line.

Lubrication and Cleaning

Proper lubrication is crucial for moving parts to function smoothly. Ensure you use suitable lubricants and clean surfaces to prevent corrosion. This simple practice can significantly improve efficiency and reduce friction-related problems.

| Maintenance Task | Frequency | Benefits |

|---|---|---|

| Check oil levels | Every use | Prevents engine damage |

| Clean air filter | Monthly | Improves airflow |

| Inspect spark plug | Every season | Enhances ignition |

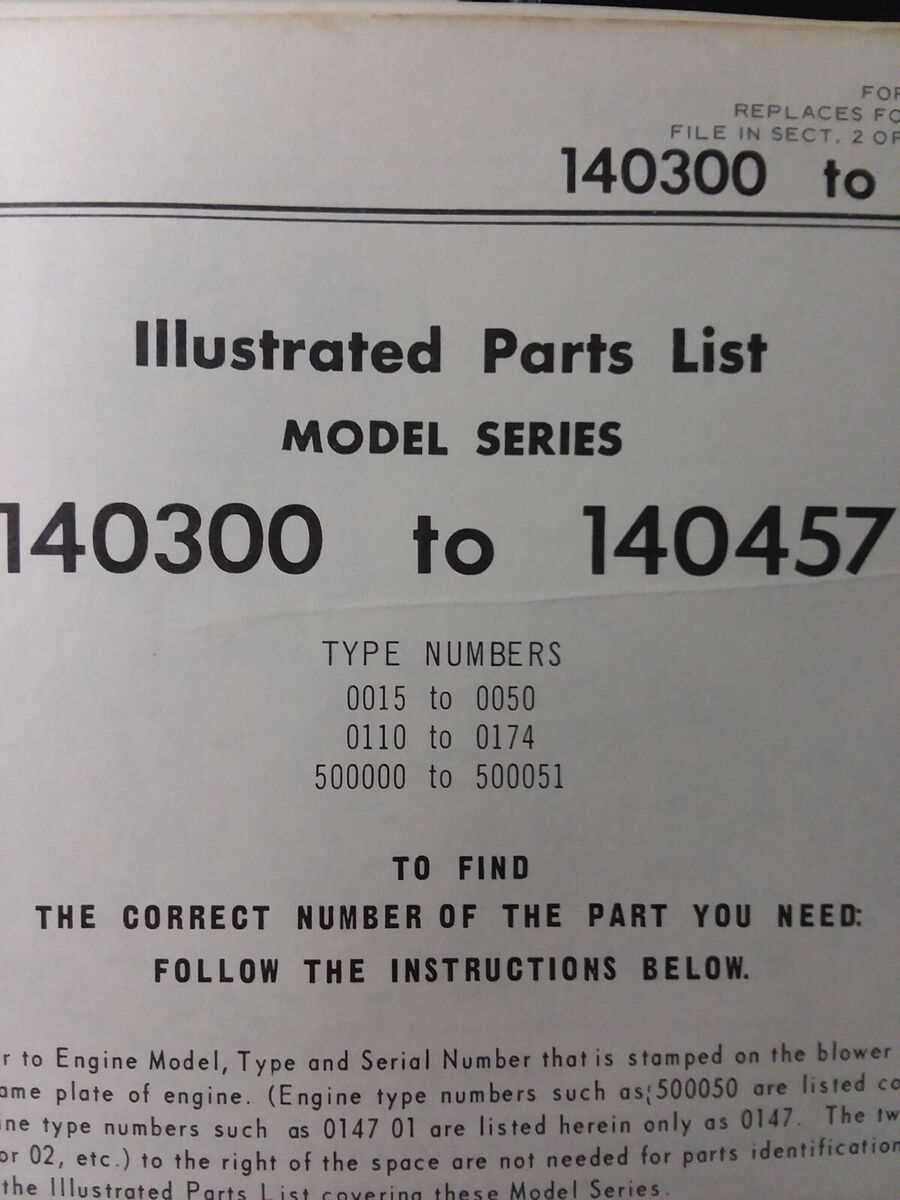

Parts Availability and Sources

Access to essential components for small power units is crucial for maintenance and repair. Understanding where to find these elements can significantly enhance the longevity and performance of your equipment. Various channels are available, ranging from online retailers to local supply stores, ensuring you can easily obtain the necessary items.

Online Retailers

Many websites specialize in offering a wide range of components for power units. These platforms often provide detailed descriptions, diagrams, and customer reviews, making it easier to select the correct item. Additionally, they frequently feature competitive pricing and delivery options that enhance convenience.

Local Suppliers

Visiting nearby stores can also be beneficial. Local suppliers often carry popular components and can provide immediate access, which is advantageous for urgent repairs. Establishing a relationship with these suppliers may lead to helpful advice and additional support in sourcing hard-to-find items.

Assembly and Disassembly Instructions

Understanding the steps for assembling and disassembling your machinery is crucial for maintenance and repairs. Proper techniques ensure longevity and optimal performance while minimizing the risk of damage. This guide outlines essential procedures that will aid in handling components effectively.

Disassembly: Begin by removing all fasteners carefully to avoid stripping. Keep track of each piece, as organization will simplify reassembly. If necessary, take photos during the process to reference later. Utilize appropriate tools to prevent injury and damage to parts.

Assembly: When reassembling, follow the reverse order of disassembly. Ensure each component fits snugly and securely. Refer to documentation for torque specifications to guarantee connections are firm yet not over-tightened. Regular checks post-assembly will help in identifying any issues early on.

Performance Enhancements for Engines

Improving the efficiency and power output of small power units can significantly enhance overall performance. By focusing on several key modifications, users can achieve noticeable improvements in functionality and durability. These enhancements range from simple adjustments to more advanced upgrades that target specific aspects of the machinery.

Intake and Exhaust Modifications

Optimizing the airflow into and out of the unit is crucial for enhancing combustion efficiency. Upgrading the intake system can lead to better airflow, allowing for more fuel to be burned effectively. Additionally, improving the exhaust flow reduces back pressure, enabling the unit to expel gases more efficiently. Aftermarket filters and performance mufflers are common upgrades that facilitate these changes.

Tuning and Calibration Adjustments

Fine-tuning the fuel delivery and ignition timing can dramatically impact performance. Adjusting the carburetor settings ensures that the right air-fuel mixture is achieved, while optimizing the ignition timing can improve power delivery and throttle response. These adjustments are essential for maximizing output and achieving smooth operation. Regular maintenance and proper tuning are vital to maintaining these enhancements over time.

Safety Precautions While Working

When engaging in maintenance or repairs on machinery, it is crucial to prioritize safety. Implementing protective measures helps prevent accidents and injuries. Understanding the importance of proper techniques and equipment can enhance your working environment significantly.

Here are some essential safety tips:

| Precaution | Description |

|---|---|

| Wear Protective Gear | Always use appropriate safety equipment such as gloves, goggles, and masks to shield yourself from potential hazards. |

| Ensure Proper Ventilation | Work in a well-ventilated area to minimize exposure to fumes and vapors that could be harmful. |

| Disconnect Power Sources | Before starting any maintenance, make sure to disconnect any power sources to avoid accidental starts. |

| Keep Workspace Clean | A tidy workspace reduces the risk of slips, trips, and falls. Organize tools and materials properly. |

| Read Manuals Carefully | Familiarize yourself with operation and safety manuals to ensure you understand the equipment you are working on. |

Following these guidelines will contribute to a safer working experience and help you perform tasks effectively.

Replacing Engine Components: A Guide

Maintaining optimal performance often involves swapping out various elements of your machinery. Understanding the process of replacing these crucial components can greatly enhance the longevity and efficiency of your device. This guide offers insights into the steps necessary for successful replacements, ensuring that your equipment runs smoothly.

Begin by gathering the appropriate tools and new components, as having everything on hand streamlines the process. Carefully follow the manufacturer’s specifications to ensure compatibility and proper installation. Always disconnect any power source before starting, prioritizing safety during your work.

When removing old components, take note of their positioning and connections. This observation helps in accurately placing the new parts. After installation, conduct thorough checks to confirm that everything is securely attached and functioning as intended.

Regular replacements not only improve performance but also prevent potential failures that could lead to costly repairs. Embrace this maintenance routine to keep your machinery in top shape and ensure long-lasting usability.

Understanding Engine Specifications and Ratings

When assessing the performance of a power unit, it is essential to grasp the various specifications and ratings that define its capabilities. These indicators provide insight into how well the unit will function for specific tasks, influencing decisions for both casual users and professionals alike.

Key Specifications to Consider

Important metrics include displacement, power output, and torque. Displacement refers to the total volume of all the cylinders, which directly impacts the overall performance. Power output indicates the energy produced, while torque reflects the unit’s ability to perform work efficiently at different speeds.

Importance of Ratings

Ratings such as horsepower and RPM (revolutions per minute) are crucial for understanding operational limits and efficiency. Horsepower quantifies the engine’s ability to perform work over time, whereas RPM indicates the speed at which the unit can operate. Together, these ratings help users select the appropriate model for their needs.

Customer Support and Resources

Access to reliable assistance and useful materials is essential for maintaining your equipment effectively. This section aims to provide guidance on where to find support and various resources that can enhance your experience with your machine.

| Resource Type | Description | Link |

|---|---|---|

| User Manuals | Comprehensive guides that include operational instructions and maintenance tips. | Download here |

| FAQs | Commonly asked questions and answers to assist with typical issues. | View FAQs |

| Contact Support | Direct access to customer service representatives for personalized help. | Contact Us |