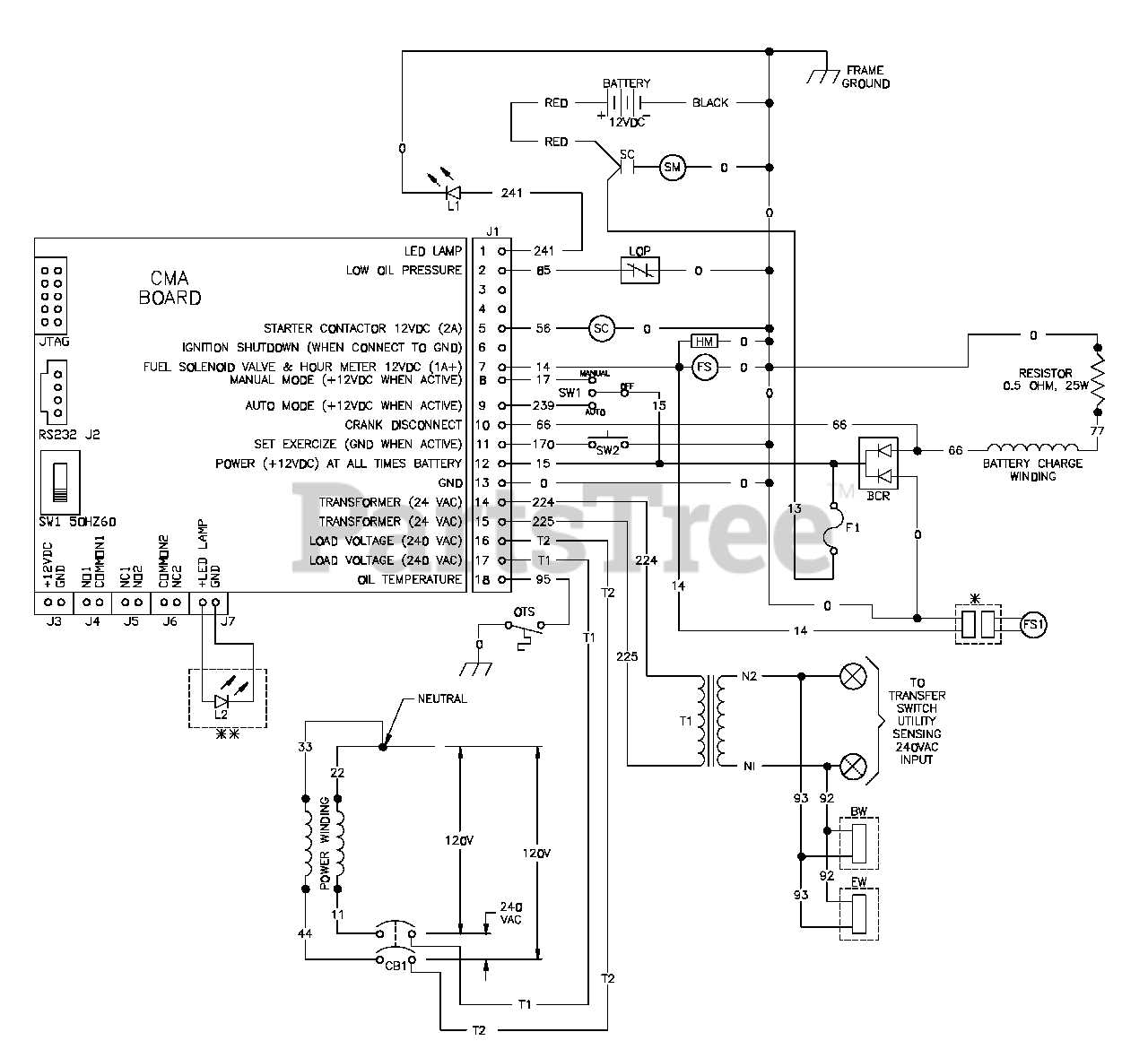

Accessing technical documentation is crucial when maintaining or repairing mechanical systems. Understanding how various elements fit together ensures smooth operation and longevity. In this guide, you’ll find helpful resources that simplify navigation through complex layouts.

Detailed visual references allow users to identify specific modules with ease, saving time during troubleshooting. Whether you’re servicing small machines or conducting more in-depth repairs, having accurate references is essential for efficient work.

Downloadable resources in organized formats enhance accessibility. They make it easy to keep critical information at hand, whether you’re working in a garage, workshop, or outdoor setting. This approach empowers users by offering clarity in every step of the maintenance process.

Exploring Briggs and Stratton Repair Guides

Maintenance manuals provide essential knowledge for restoring equipment to optimal condition. These resources help users understand mechanical systems, offering step-by-step instructions for troubleshooting and upkeep.

What Can You Learn from These Manuals?

- Detailed procedures for routine maintenance

- Solutions to common mechanical issues

- Assembly and disassembly tips for efficient repairs

How to Use These Resources Effectively

- Identify the issue and

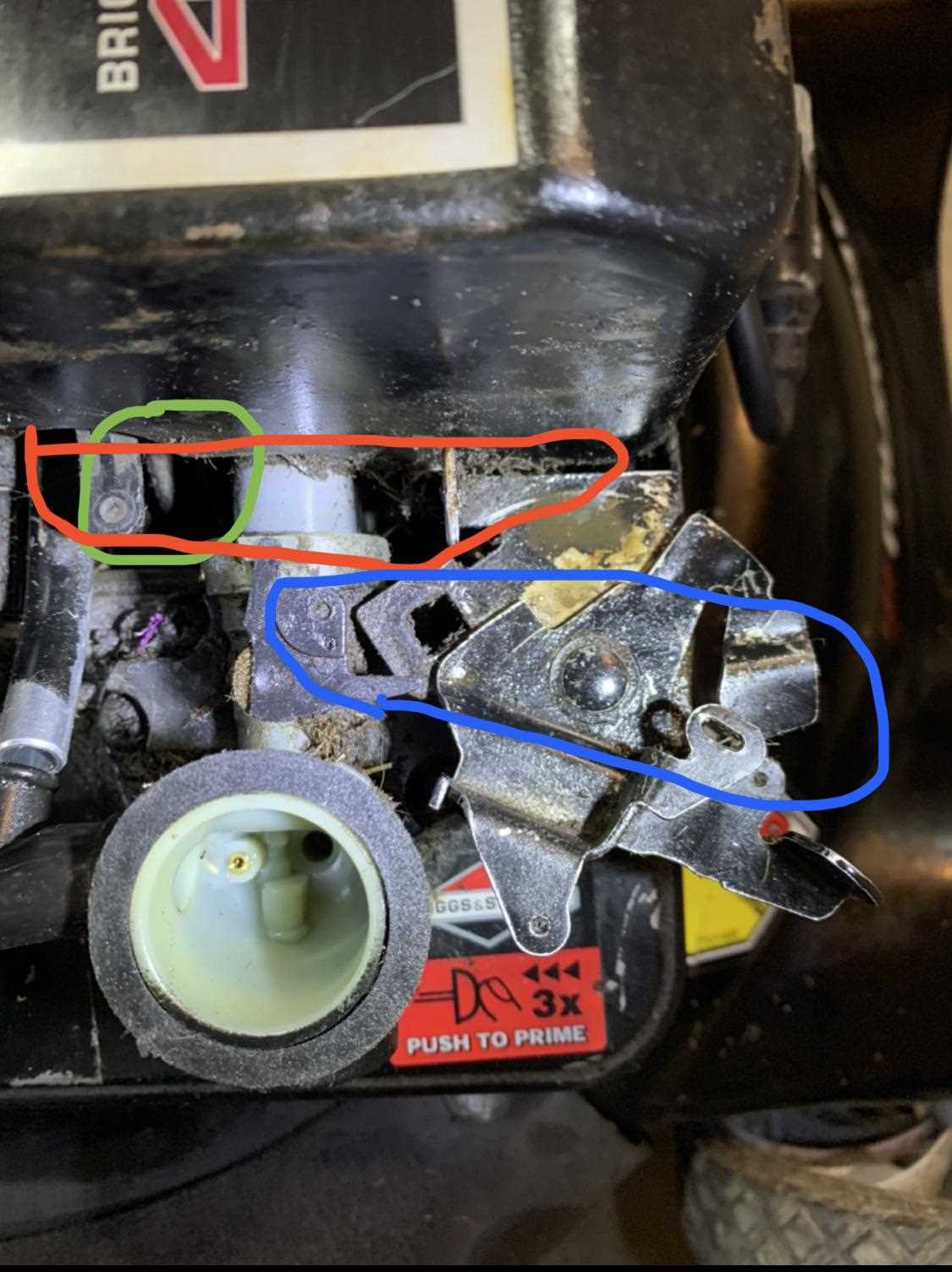

How to Identify Engine Components

Understanding the various elements of a small engine is essential for troubleshooting and maintenance. Each component plays a distinct role in ensuring smooth operation, and recognizing these parts will make it easier to maintain the machine over time.

- Cylinder Block: The core structure where the piston moves. It holds vital parts that contribute to fuel combustion.

- Flywheel: Helps control engine speed by storing rotational energy, ensuring a stable performance.

- Carburetor: Mixes air and fuel in the right ratio, preparing it for ignition in the engine chamber.

- Ignition Coil: Converts low-voltage energy into high-voltage sparks that ignite the air-fuel mixture.

- Read Ahead: Before starting, go through the entire section to understand the steps involved.

- Gather Tools Early: Ensure all necessary tools and supplies are ready to avoid interruptions.

- Follow Sequence: Stick to the recommended order of steps to prevent mistakes.

- Take Notes: Jot down important points or modifications for future reference.

- Use Visual Aids: Diagrams or illustrations can offer valuable insight into tricky procedures.

- Manufacturer Websites: Many producers offer free downloads of technical files directly from their official support pages.

- Online Libraries: Specialized digital archives often collect and store instructional guides and assembly layouts for a variety of models.

- Community Forums: Enthusiast communities sometimes share rare or hard-to-find documents that may not be available elsewhere.

- E-commerce Platforms: Some sellers bundle technical documentation with purchased products or provide access through support links.

- Original components often meet strict quality standards.

- Alternative options may offer varying degrees of reliability.

- Using original components can result in better efficiency and longevity.

- Initial savings may lead to higher replacement costs if alternatives fail prematurely.

- Investing in original components may offer better long-term value.

- Assessing warranty and service options can further influence cost decisions.

- Compatibility with existing machinery

- Material quality and durability

- Manufacturer’s guidelines

- Performance ratings

- Consult user manuals for detailed information on specifications.

- Visit reputable websites specializing in mechanical components.

- Seek recommendations from professionals or experienced users.

- Cracks: Visible fractures on surfaces may suggest that a part is nearing failure.

- Discoloration: Changes in color can indicate overheating or prolonged exposure to harsh conditions.

- Looseness: Components that feel loose may not function effectively and could lead to malfunction.

- Corrosion: Rust or oxidation can weaken metal parts, reducing their integrity.

- Inspect regularly for any visible signs of damage.

- Listen for unusual noises during operation, which may indicate internal wear.

- Check fluid levels and quality, as contamination can signal wear.

- Follow a maintenance schedule to replace worn parts before they fail.

Tips for Using Repair Manuals

Effective use of repair guides can save time and prevent unnecessary complications during maintenance. These resources are designed to provide clear instructions, helping users troubleshoot and fix equipment efficiently.

Approaching these manuals

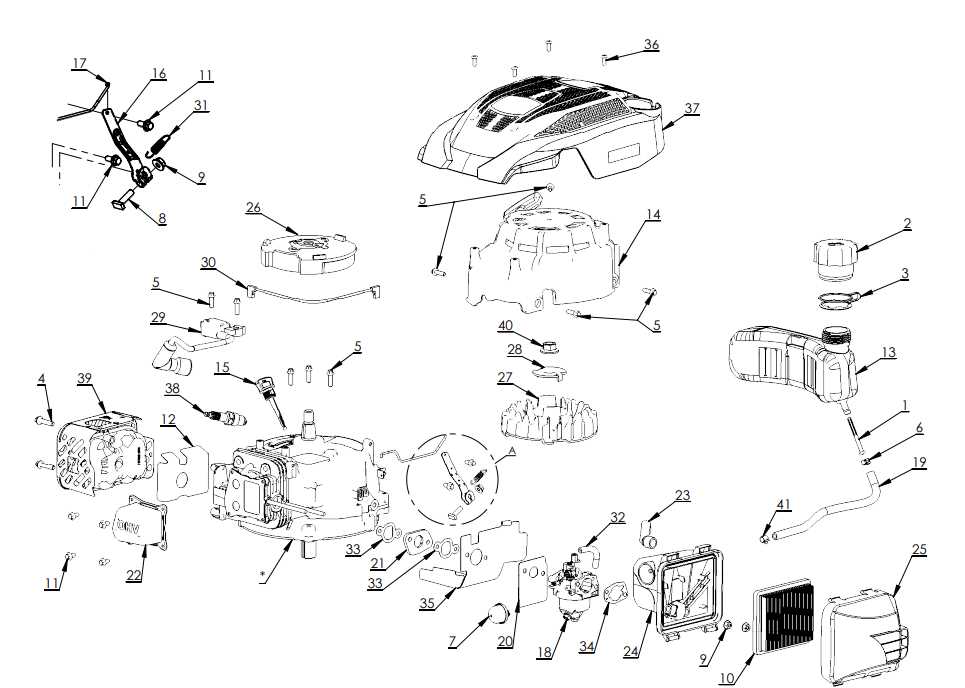

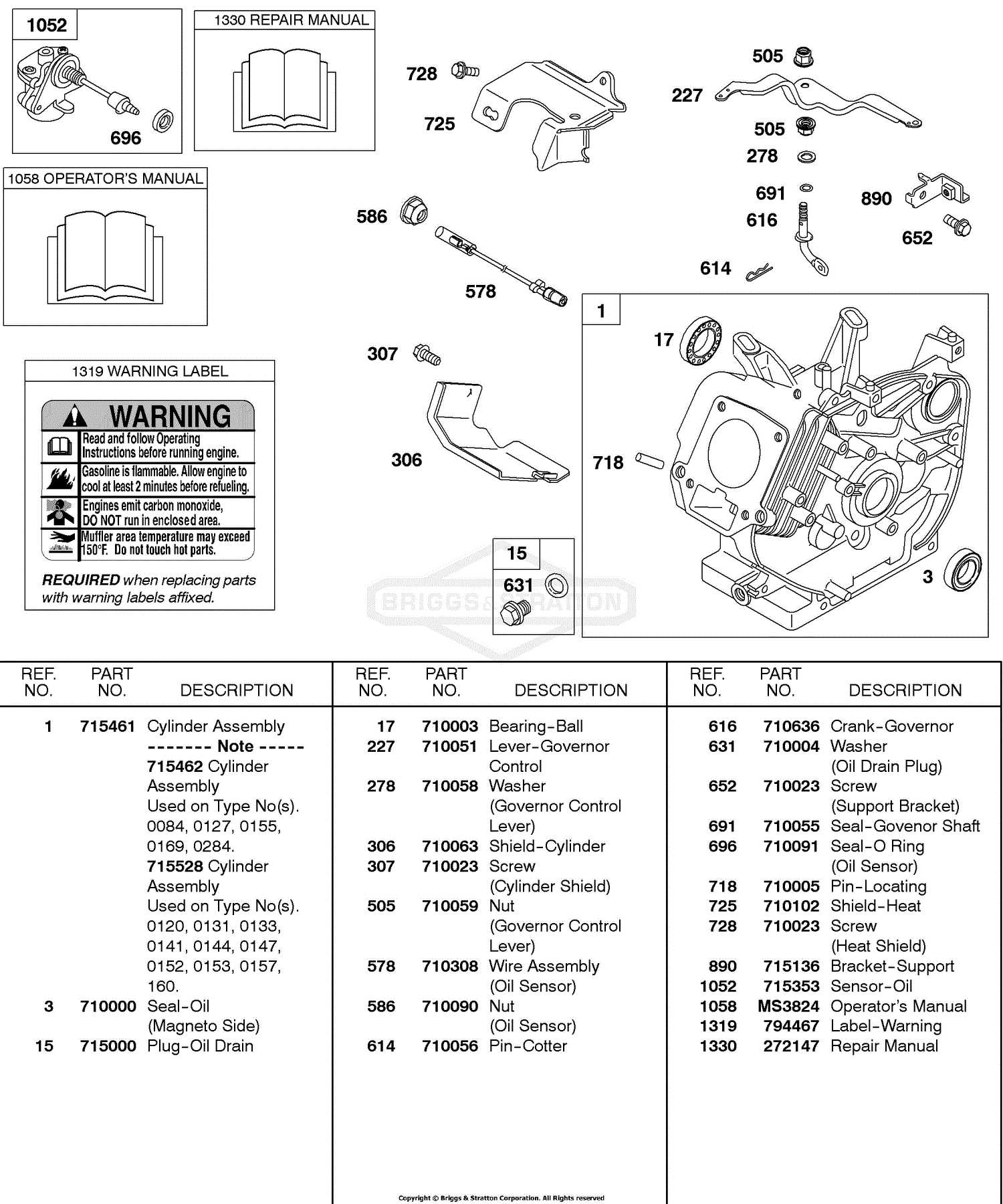

Understanding the Parts Breakdown

Exploring how individual components come together helps provide a clear picture of how a machine functions. By examining each element and its role, one can better appreciate the synergy between different sections of the equipment, making it easier to perform maintenance or repairs.

Component Function Engine Block Forms the core structure, housing key internal elements. Carburetor Regulates the mix of air and fuel for combustion efficiency. Flywheel Stores rotational energy, stabilizing engine speed. Where to Find PDF Schematics

Locating technical blueprints in a portable document format can be essential for repairs and maintenance. Whether working on engines, tools, or machinery, accessing detailed layouts ensures that every component is correctly identified and assembled.

Using these sources helps ensure that the right data is at hand, reducing guesswork during repairs and enabling more efficient troubleshooting processes.

Comparing Genuine and Aftermarket Parts

When it comes to equipment maintenance, the choice between original manufacturer components and alternative options is significant. Understanding the differences can help users make informed decisions, potentially impacting performance and longevity.

Quality and Performance

Original components are designed specifically for particular models, ensuring optimal compatibility and performance. Conversely, alternatives may vary in quality. Consider the following:

Cost Considerations

One of the main reasons for choosing alternatives is cost savings. However, it’s essential to weigh the potential drawbacks:

How to Choose Replacement Components

Selecting suitable components for your machinery can significantly impact its performance and longevity. It is crucial to ensure that the new elements match the specifications and quality of the originals. A well-informed choice will help maintain efficiency and reliability.

Understanding Specifications

Before purchasing replacements, familiarize yourself with the essential specifications. Key factors to consider include:

Research and Sources

Utilizing reliable sources can guide your selection process. Consider the following approaches:

Making an informed decision will enhance the efficiency and reliability of your equipment.

Signs of Wear in Key Parts

Understanding the signs of deterioration in essential components is crucial for maintaining the functionality of your equipment. Regular inspection can help identify issues early, preventing further damage and ensuring optimal performance.

Common indicators of wear include:

Routine maintenance is vital. Here are some tips for monitoring the condition of critical components:

Best Practices for Engine Maintenance

Regular upkeep of an engine is crucial for ensuring its longevity and optimal performance. Implementing effective strategies can help prevent costly repairs and enhance efficiency. By adhering to essential maintenance practices, individuals can enjoy a smoother operation and reduce the risk of unexpected breakdowns.

Routine Inspection and Cleaning

Conducting frequent examinations of the engine components is vital. Look for signs of wear or damage, and ensure that all parts are free from dirt and debris. Cleaning not only enhances performance but also extends the life of various components. Regularly check the air filter and fuel system to maintain proper airflow and fuel delivery.

Timely Oil Changes

One of the most important maintenance tasks is changing the lubricant regularly. Fresh oil reduces friction, improves efficiency, and protects the engine from overheating. It is advisable to follow the manufacturer’s recommendations regarding oil change intervals. Additionally, always use the appropriate type of lubricant for optimal results.

How to Interpret Exploded Views

Understanding detailed visual representations can greatly enhance your ability to assemble or disassemble mechanical devices. These illustrations provide a comprehensive breakdown of components, showcasing how each element interacts with others within a larger system. By analyzing these visuals, you can gain insight into the construction and functionality of the equipment.

To effectively read these illustrations, start by familiarizing yourself with the layout. Look for labeled parts and their respective numbers, which correspond to accompanying descriptions or lists. This will help you identify each component’s role and importance. Additionally, pay attention to the orientation and positioning of elements, as this can indicate how they fit together during assembly.

Next, consider the sequence of assembly or disassembly depicted in the visuals. Often, these representations follow a logical progression, guiding you through the process step by step. Take note of any special instructions or warnings included in the text, as these can provide crucial tips for handling specific components safely and effectively.

Finally, practice makes perfect. The more you engage with these visual guides, the more comfortable you will become in interpreting them. With time, you will develop the skills necessary to quickly and accurately understand complex mechanical assemblies, leading to more efficient repairs or constructions.

Using Part Numbers for Quick Search

In the world of machinery, having a clear method to identify components can greatly enhance efficiency. Utilizing specific identifiers allows users to swiftly locate necessary items within catalogs or databases. This approach not only saves time but also reduces the likelihood of errors in ordering and assembly.

Component identification is essential for effective maintenance and repair. By relying on unique identifiers, users can easily access detailed information, including specifications and compatibility. This streamlined process ensures that the right elements are selected for each task.

Furthermore, familiarity with part numbers enables users to engage in more productive discussions with suppliers and technicians. Knowledge of these identifiers can facilitate smoother transactions and enhance overall communication regarding the required items.

Where to Download Updated Diagrams

Finding the latest visual references for equipment components is essential for effective maintenance and repairs. Various online platforms offer resources to access these updated visuals, making it easier for users to identify and acquire necessary items. Here are some reliable sources where you can find these valuable resources.

Official Manufacturer Websites

Visiting the official websites of manufacturers is one of the best ways to obtain accurate and current resources. These sites often provide downloadable content directly related to their products.

Online Retailers and Forums

Many online retailers and community forums specialize in maintenance equipment. These platforms frequently share resources, including updated visuals, enhancing accessibility for users.

Source Type Website Example Manufacturer Website example-manufacturer.com Online Retailer example-retailer.com Community Forum example-forum.com