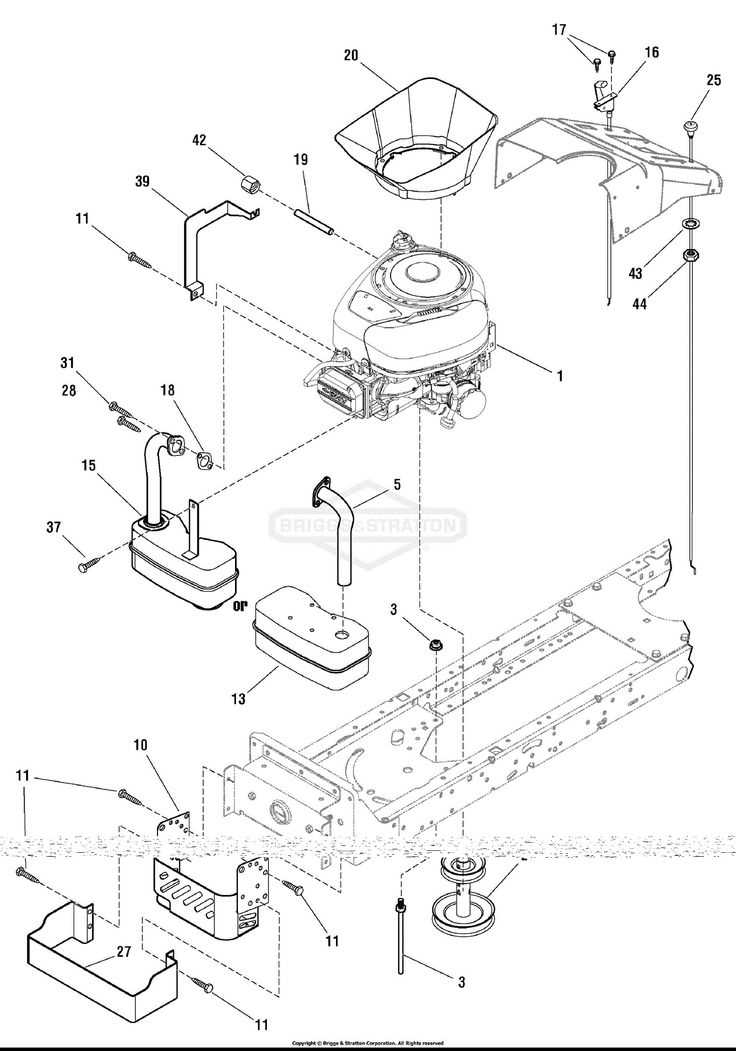

Understanding how various mechanical elements fit together is crucial for anyone working with complex systems. A clear representation of individual elements and their placement helps in identifying, maintaining, and repairing devices more efficiently. This section will explore the importance of structured visual references for mechanical assemblies.

Accurate visual tools provide a detailed view of every essential piece, allowing users to comprehend how different components interact. These depictions are indispensable for those looking to ensure long-term reliability and proper function of machines. Whether for troubleshooting or routine checks, such resources are highly valuable.

Detailed illustrations not only enhance the learning curve but also offer a straightforward approach to managing mechanical systems. Having a clear and concise view of the entire setup reduces the chances of errors during maintenance and repairs. Well-organized layouts are key to ensuring optimal performance and understanding the overall structure.

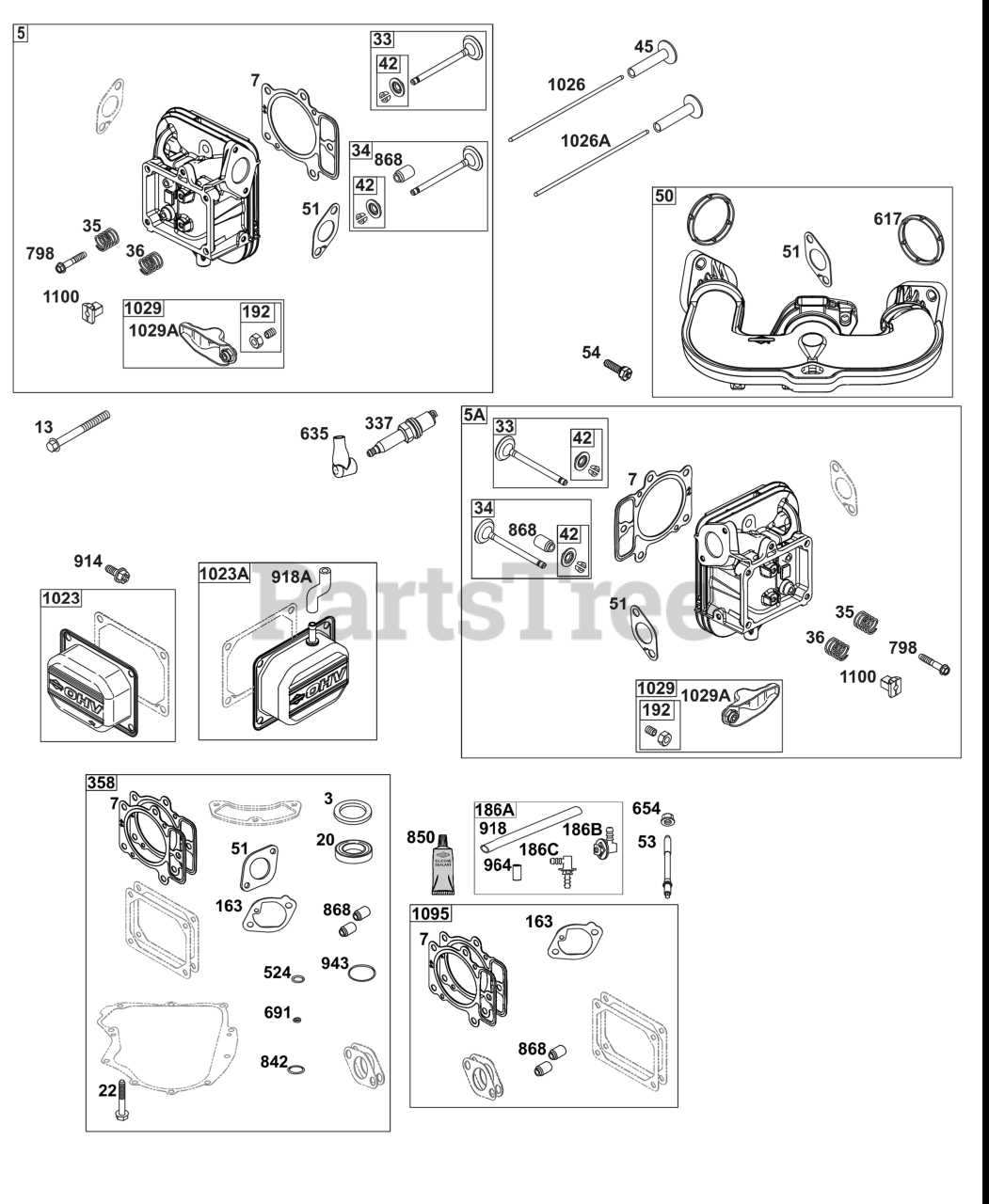

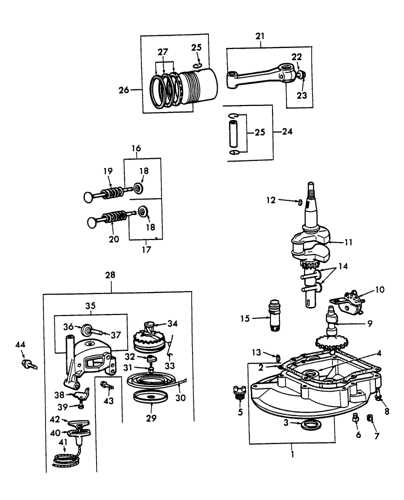

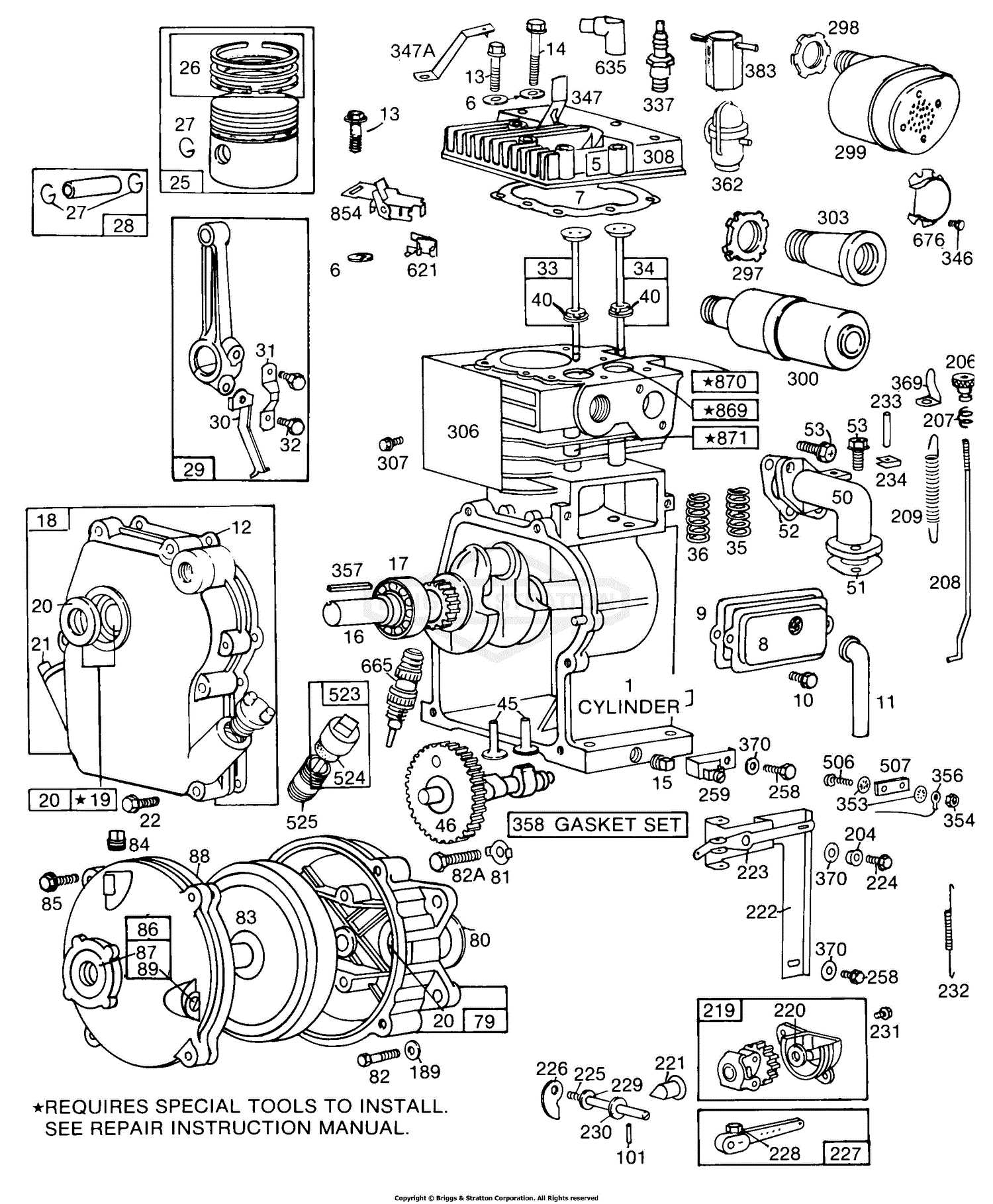

Overview of Key Engine Components

Understanding the primary elements of a motor is crucial for maintaining optimal performance and ensuring longevity. Each part plays a vital role in the operation, contributing to the overall efficiency and reliability. Familiarizing yourself with these elements can help identify potential issues and improve maintenance strategies.

Main Structural Elements

The core of any motor consists of several interconnected components that ensure smooth functionality. The cylinder is a critical component where combustion occurs, while the piston moves within the cylinder to convert pressure into motion. Other parts like the crankshaft and camshaft help in transferring and controlling the energy produced.

Support and Control Systems

A motor also relies on various support mechanisms for cooling, lubrication, and fuel regulation. Systems such as the fuel intake manage the flow of fuel, while the exhaust directs gases out of the motor. Cooling mechanisms are essential to prevent overheating, and proper lubrication reduces friction between moving parts, ensuring smooth operation.

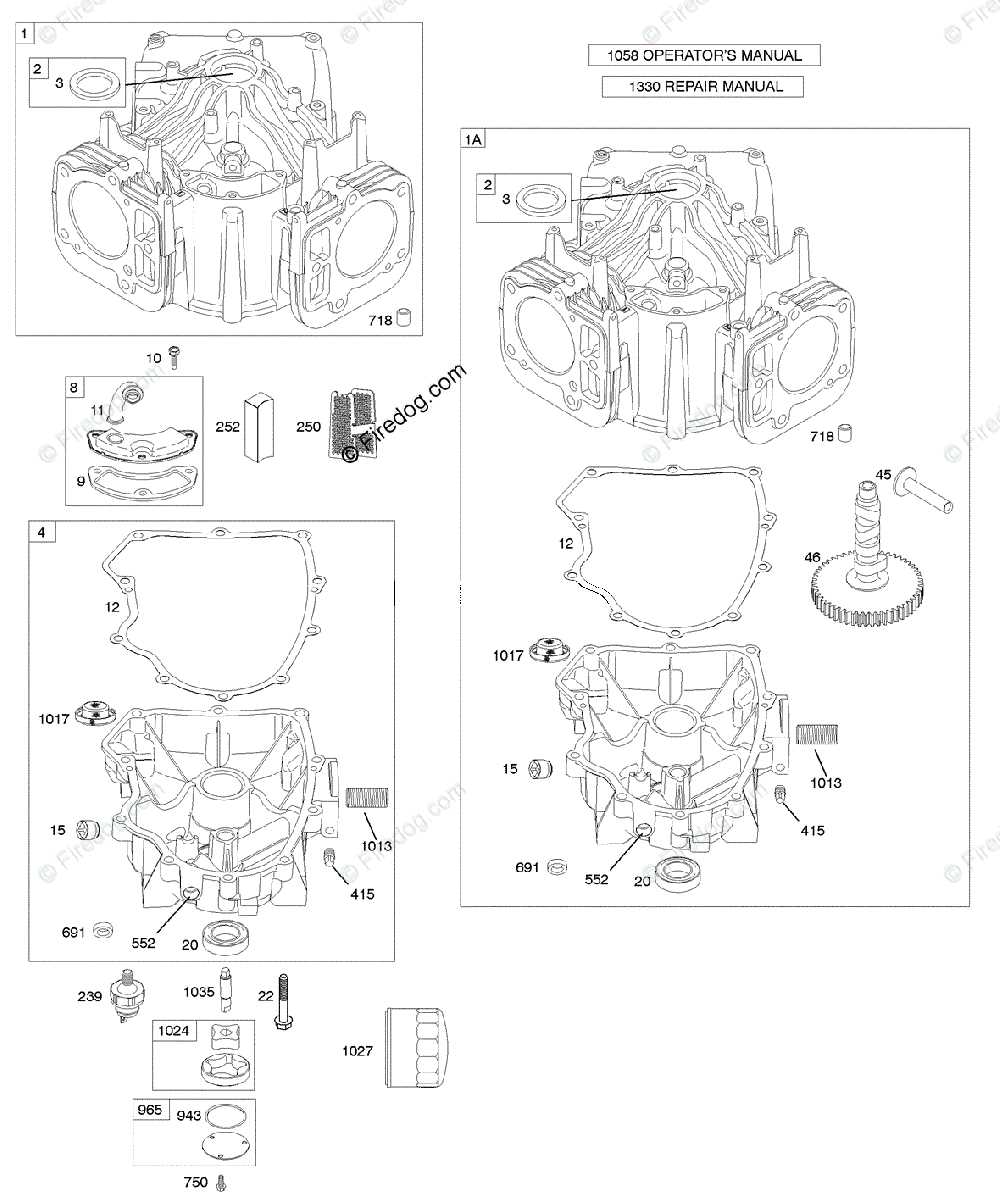

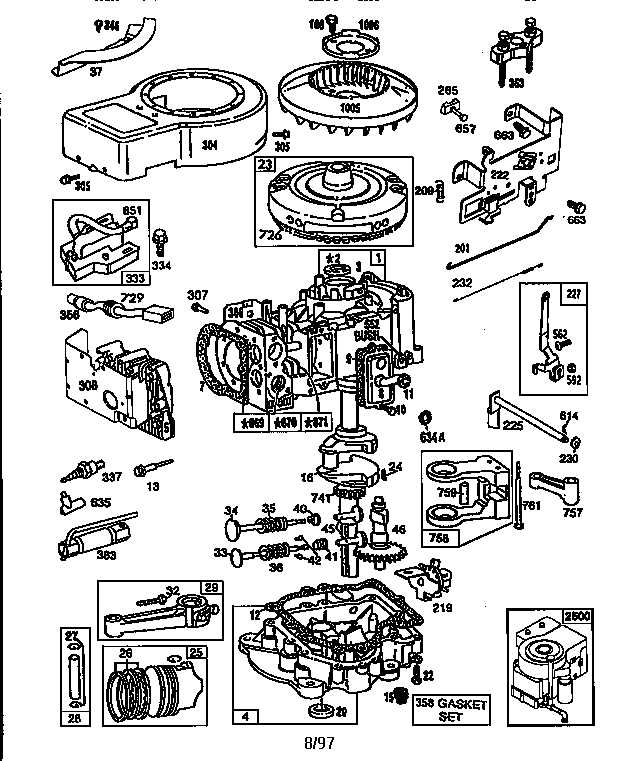

Common Parts in Briggs Engines

Internal combustion mechanisms rely on various components that work in unison to generate power. These elements, though differing slightly across different models, share many similarities in design and function. Understanding these core components can help ensure smooth operation and ease troubleshooting efforts.

Main Structural Components

The key structural elements include various metallic sections that house the moving parts. These are built to withstand high levels of heat and pressure, providing a robust framework for the system’s operation. A central rotating piece converts force into movement, ensuring the flow of energy throughout the system.

Supportive Systems and Components

Supporting systems include mechanisms responsible for air intake, fuel delivery, and exhaust. These parts ensure that fuel is efficiently burned and that waste gases are expelled safely. Additionally, cooling mechanisms prevent overheating, while filtration units keep contaminants from damaging sensitive areas.

Identifying Essential Engine Elements

Understanding the core components of a mechanical system is crucial for maintaining its performance and longevity. Recognizing these vital elements helps in troubleshooting and ensuring proper upkeep.

- Cylinder Block: The foundation of the entire system, housing key moving parts and ensuring smooth operation.

- Piston Assembly: Converts pressure into motion, driving other connected mechanisms and providing the necessary force.

- Crankshaft: Transforms the movement of the piston into rotational energy, transferring it to other sections for further use.

- Valve System: Regulates the flow of gases, ensuring that intake and exhaust are precisely timed for optimal efficiency.

- Cooling Mechanism: Prevents overheating by managing the temperature during prolonged operation, maintaining system stability.

Guide to Maintaining Engine Parts

Proper upkeep of mechanical components is essential to ensure the longevity and performance of your machine. Regular inspections and routine care can prevent unexpected failures and extend the lifespan of the system. This section provides key steps to help you maintain critical elements of your equipment effectively.

Regular Inspection and Cleaning

- Check for any signs of wear or damage in all moving parts.

- Keep components free from dirt and debris to prevent blockages and ensure smooth operation.

- Use appropriate cleaning agents for different surfaces to avoid corrosion or damage.

Lubrication and Adjustments

- Regularly apply the correct lubricant to all friction points to reduce wear.

- Ensure all bolts and screws are properly tightened to avoid loosening over time.

- Adjust settings as necessary to maintain optimal performance and efficiency.

How to Find Replacement Components

When it comes to maintaining mechanical devices, it’s crucial to locate the correct substitute elements to ensure smooth operation and durability. Whether you’re handling everyday upkeep or more complex repairs, identifying the right items can be a straightforward process if approached methodically.

Research model specifics: Start by gathering information on the specific model you’re working on. Having a detailed understanding of the machinery helps narrow down the list of potential replacements quickly and accurately.

Use trusted sources: Look for reliable suppliers and official distributors to avoid compatibility issues. Many platforms offer detailed listings and filters, allowing you to pinpoint the exact components that meet your needs.

Lastly, always compare product descriptions and user reviews to ensure you’re choosing the right replacement. A little extra effort in the selection process can significantly extend the lifespan of your equipment.

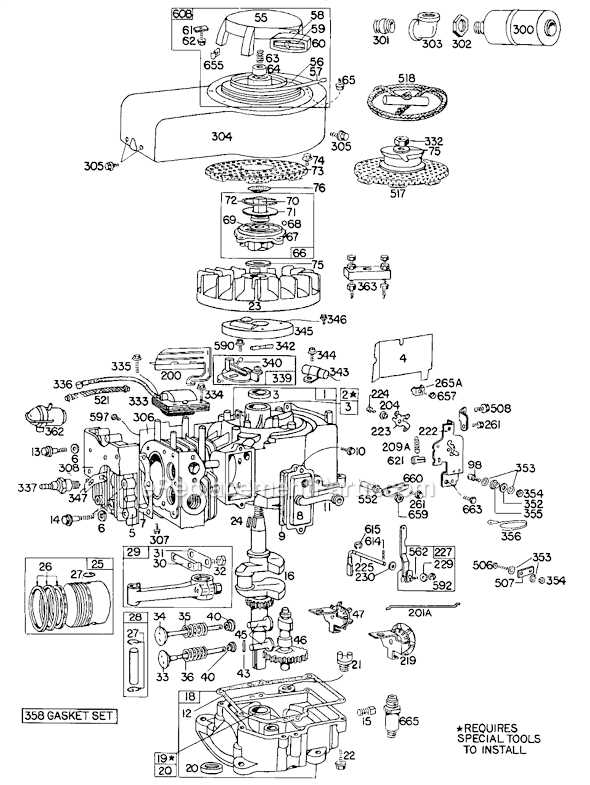

Understanding Engine Functionality and Parts

This section delves into the intricate mechanisms that enable a motor to operate effectively. By comprehending the individual components and their roles, one can appreciate the complexity and precision involved in machinery designed for performance and efficiency.

Core Components of a Motor

Each machine is composed of various essential elements that work in unison to produce motion and power. These fundamental units serve specific purposes, contributing to the overall functionality.

| Component | Function |

|---|---|

| Piston | Converts pressure into mechanical energy. |

| Crankshaft | Transforms linear motion into rotational motion. |

| Valves | Regulate the flow of air and fuel into the combustion chamber. |

| Spark Plug | Ignites the air-fuel mixture to initiate combustion. |

The Role of Maintenance

Regular upkeep is crucial to ensure the longevity and efficiency of the machinery. Understanding the function of each component aids in identifying potential issues and performing timely repairs.

Visual Breakdown of Engine Components

Understanding the various elements that make up a mechanical system is crucial for effective maintenance and repair. A clear visualization of these components aids in grasping their functions and interrelationships. This section delves into a structured representation of these essential features, facilitating easier identification and comprehension.

Key Components Overview

Each element plays a significant role in the overall functionality of the machinery. By familiarizing yourself with their arrangements and interactions, you can enhance your technical knowledge and troubleshooting skills.

| Component | Description |

|---|---|

| Crankshaft | Transforms linear motion into rotational motion, enabling power transfer. |

| Piston | Moves within the cylinder, creating compression and power strokes. |

| Fuel System | Supplies fuel to the combustion chamber for energy production. |

| Ignition System | Initiates combustion by igniting the fuel-air mixture. |

| Cooling System | Regulates temperature to prevent overheating during operation. |

Importance of Familiarity

Acquiring knowledge about these components is vital for anyone involved in repair or assembly tasks. A thorough understanding not only promotes efficiency but also extends the lifespan of the machine.

Tips for Extending Engine Lifespan

Maintaining the longevity of your power unit requires consistent care and attention. By adopting certain practices, you can significantly enhance its performance and durability. Here are some essential strategies to ensure your machinery operates efficiently for years to come.

Regular maintenance is crucial. This includes changing the oil and filters at recommended intervals to prevent buildup and ensure smooth operation. Clean components not only perform better but also reduce wear and tear.

Pay attention to the cooling system. Keeping it clean and free of obstructions allows for proper heat dissipation, preventing overheating and potential damage. Check coolant levels frequently to ensure optimal functioning.

Using high-quality fuel and lubricants can make a noticeable difference. Inferior products can lead to deposits and sludge, which impair efficiency. Invest in reliable supplies to maintain optimal performance.

Proper storage is equally important. When not in use, store your equipment in a dry, protected area to prevent rust and corrosion. Consider using covers to shield them from dust and debris.

Lastly, familiarize yourself with the operational guidelines. Understanding how to use your machinery correctly minimizes the risk of misuse, which can lead to premature failures. Following these tips can help prolong the life of your unit and ensure dependable performance.

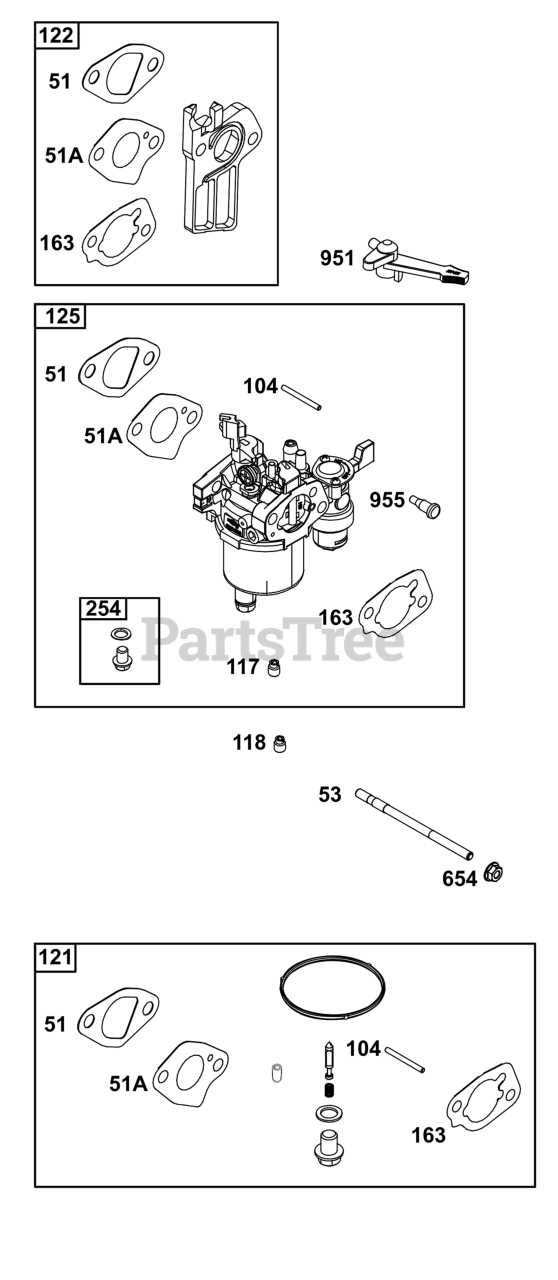

Compatibility of Parts for Different Models

Understanding the compatibility of components across various models is crucial for maintaining optimal performance and efficiency. Different designs may share similar characteristics, enabling interchangeable use of certain elements. However, it is essential to ensure that the selected components fit seamlessly to avoid operational issues.

Factors Influencing Compatibility

Several factors determine whether specific components can be used across different models:

- Design Specifications: Each model may have unique dimensions and features that dictate which elements can be swapped.

- Material Composition: The materials used in manufacturing components can affect their durability and performance when mixed with other designs.

- Functional Requirements: Some parts serve particular functions that may not be replicated in other models, impacting overall efficiency.

Commonly Interchangeable Components

Despite the variations, there are several components that are often compatible across different designs:

- Air filters

- Fuel lines

- Spark plugs

- Gaskets

It is advisable to consult the manufacturer’s guidelines or a knowledgeable technician to ensure compatibility before proceeding with replacements or upgrades.

DIY Troubleshooting for Engine Issues

When dealing with performance problems in small machinery, understanding common challenges can lead to effective solutions. This section aims to guide you through simple diagnostic techniques to identify and resolve common difficulties.

Identifying Symptoms

Recognizing the signs of malfunction is the first step toward resolution. Here are common indicators to watch for:

- Unusual noises during operation

- Difficulty starting or frequent stalling

- Excessive vibration or shaking

- Reduced power output

Basic Troubleshooting Steps

Once you’ve noted the symptoms, follow these steps to troubleshoot effectively:

- Check the fuel supply for quality and quantity.

- Inspect air filters for clogs or blockages.

- Examine spark plugs for wear or fouling.

- Look for leaks in hoses or connections.

- Ensure all bolts and screws are tight and secure.

By following these guidelines, you can tackle basic issues and keep your machinery running smoothly. If problems persist, consider consulting a professional for further assistance.

Best Practices for Regular Engine Maintenance

To ensure optimal performance and longevity of your mechanical equipment, it is crucial to adhere to a consistent maintenance routine. Regular care not only prevents unexpected failures but also enhances efficiency and reliability over time. By following a few key practices, you can keep your machinery running smoothly and efficiently.

Regular Inspection and Cleaning

Routine inspections help identify potential issues before they escalate into significant problems. Check for signs of wear and tear, such as cracks or leaks, and ensure all components are securely attached. Additionally, cleaning various parts regularly helps maintain peak performance, as dirt and debris can hinder functionality.

Fluid Levels and Quality

Monitoring fluid levels is essential for the proper operation of your equipment. Ensure that all necessary fluids, including oils and fuels, are at optimal levels and free from contaminants. Regularly changing these fluids will help maintain engine health and improve overall performance.