Maintaining outdoor power equipment is crucial for ensuring optimal performance and longevity. A clear representation of the various components and their functions can significantly enhance the user’s ability to troubleshoot and repair issues that may arise during operation. This section provides a detailed overview of the essential elements that make up these machines, allowing enthusiasts and professionals alike to navigate repairs with confidence.

The intricate design of these machines incorporates numerous interchangeable components, each playing a vital role in the overall functionality. By familiarizing oneself with the specific arrangements and relationships between these parts, one can not only improve their repair skills but also gain a deeper appreciation for the engineering behind these powerful tools. Understanding how each piece fits into the larger system empowers users to make informed decisions when sourcing replacements or performing maintenance.

Additionally, having a well-structured visual guide enhances the learning experience, making it easier to identify and understand each part’s significance. Whether you are a seasoned technician or a new user, mastering the configuration of these essential elements can lead to more effective repairs and improved efficiency in your gardening tasks.

Understanding Lawn Mower Components

To maintain a well-groomed outdoor space, it’s essential to grasp the various elements that contribute to the efficiency of cutting machines. Each component plays a vital role, ensuring optimal performance and longevity. Familiarity with these parts helps users troubleshoot issues and perform necessary repairs or replacements.

Key Elements of a Cutting Machine

At the heart of these machines lies the engine, which provides the necessary power to operate the device. It converts fuel into mechanical energy, driving the blades and other moving parts. Another crucial component is the deck, which houses the cutting mechanism and protects the internal mechanisms from debris. This structure also affects the overall weight and maneuverability.

Importance of Regular Maintenance

Routine care of these machines is vital to ensure they function effectively. Regularly checking the blades for sharpness is important for achieving a clean cut. Additionally, monitoring the fuel system for leaks or blockages can prevent significant damage. Keeping the filter clean allows for better airflow, enhancing engine performance. Understanding these components not only aids in maintenance but also empowers users to make informed decisions about repairs and upgrades.

Key Parts of Briggs Stratton Mowers

Understanding the essential components of your outdoor equipment is crucial for optimal performance and maintenance. Each element plays a significant role in ensuring the overall efficiency and reliability of the machine. Familiarity with these key elements can help in troubleshooting issues and enhancing longevity.

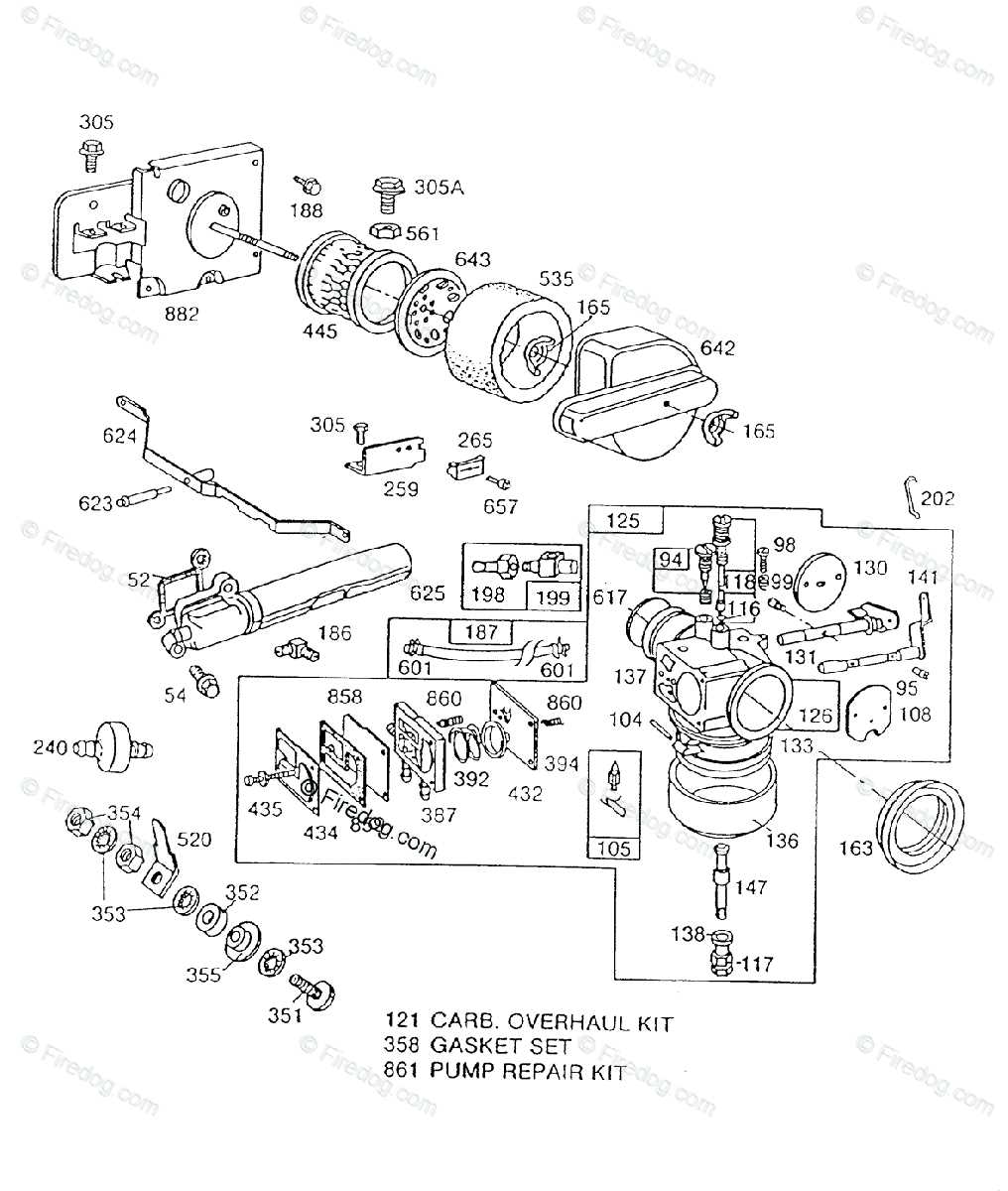

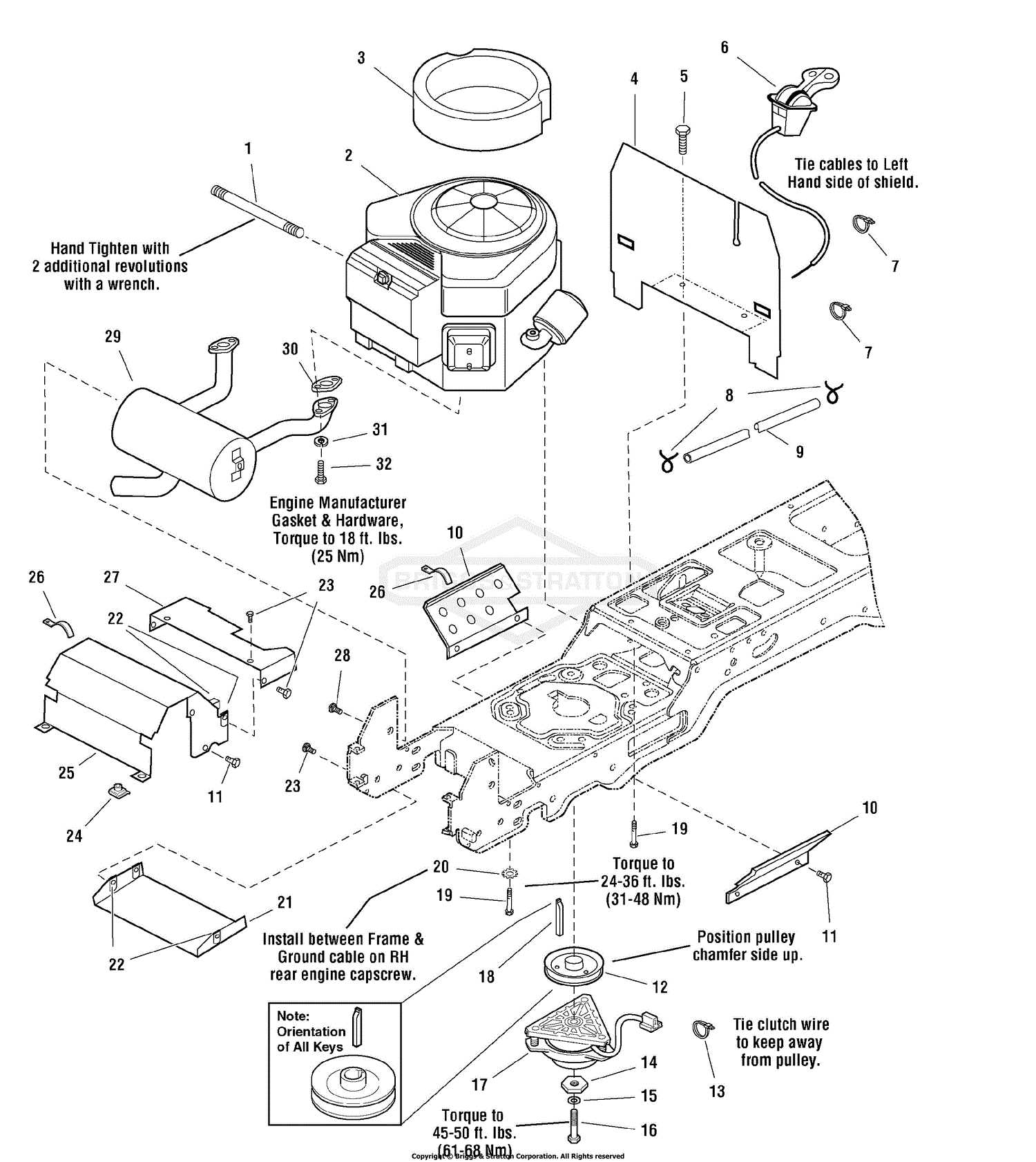

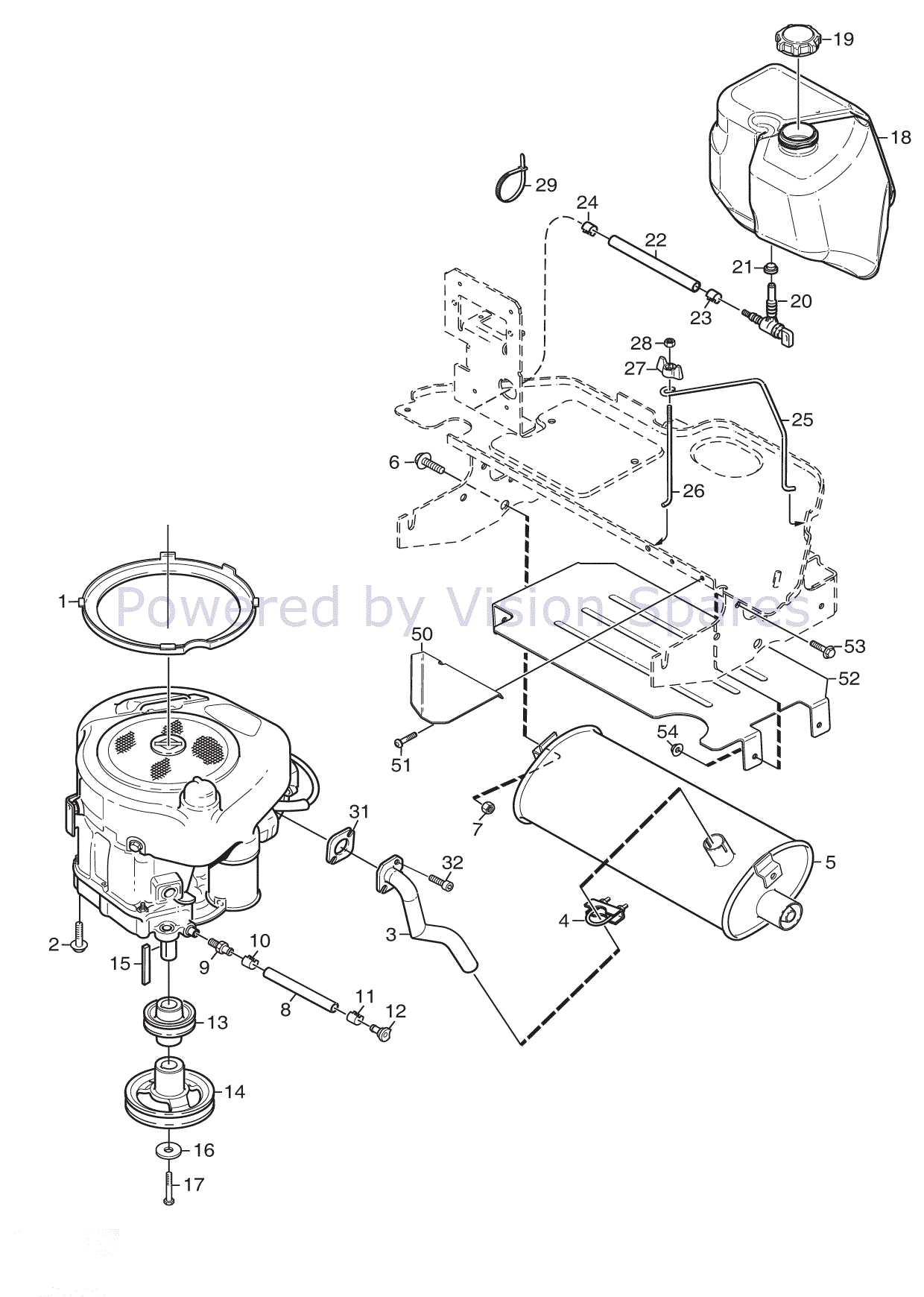

Engine Assembly

The engine assembly serves as the heart of the device, providing the necessary power to drive its various functions. This component includes crucial elements such as the carburetor, spark plug, and fuel tank. Ensuring that these parts are in good condition can significantly impact the starting and running performance.

Cutting System

The cutting system consists of blades and related mechanisms that determine the quality of the cut. Sharp, well-maintained blades contribute to a clean finish, while the housing protects these components from damage and debris. Regular inspections and timely sharpening are essential for maintaining cutting efficiency.

Importance of Regular Maintenance

Routine care is essential for ensuring the longevity and efficiency of any mechanical equipment. By performing consistent checks and servicing, users can avoid significant malfunctions and enhance performance. Regular upkeep not only safeguards the machine but also contributes to optimal functionality, ultimately saving time and money in the long run.

Enhancing Performance

Keeping machinery in top shape is crucial for achieving peak efficiency. Regular inspections allow for the identification of minor issues before they escalate into major problems. This proactive approach ensures that the equipment operates smoothly, delivering the best results.

Cost-Effectiveness

Investing time in consistent maintenance can lead to substantial savings. Addressing small repairs promptly prevents costly breakdowns and extends the lifespan of the equipment. Moreover, well-maintained machinery consumes less fuel, further reducing operational costs.

Common Issues and Solutions

In the realm of outdoor equipment, users often encounter various challenges that can hinder performance. Understanding these common problems and their corresponding solutions can significantly enhance the operational efficiency of your machinery.

| Issue | Possible Cause | Solution |

|---|---|---|

| Engine won’t start | Empty fuel tank or stale fuel | Refill with fresh gasoline |

| Excessive vibration | Worn or damaged blades | Inspect and replace blades as needed |

| Uneven cutting | Improper blade height or dull blades | Adjust blade height and sharpen blades |

| Overheating | Blocked air vents or low oil | Clear vents and check oil levels |

| Difficulty in starting | Faulty spark plug | Inspect and replace spark plug if necessary |

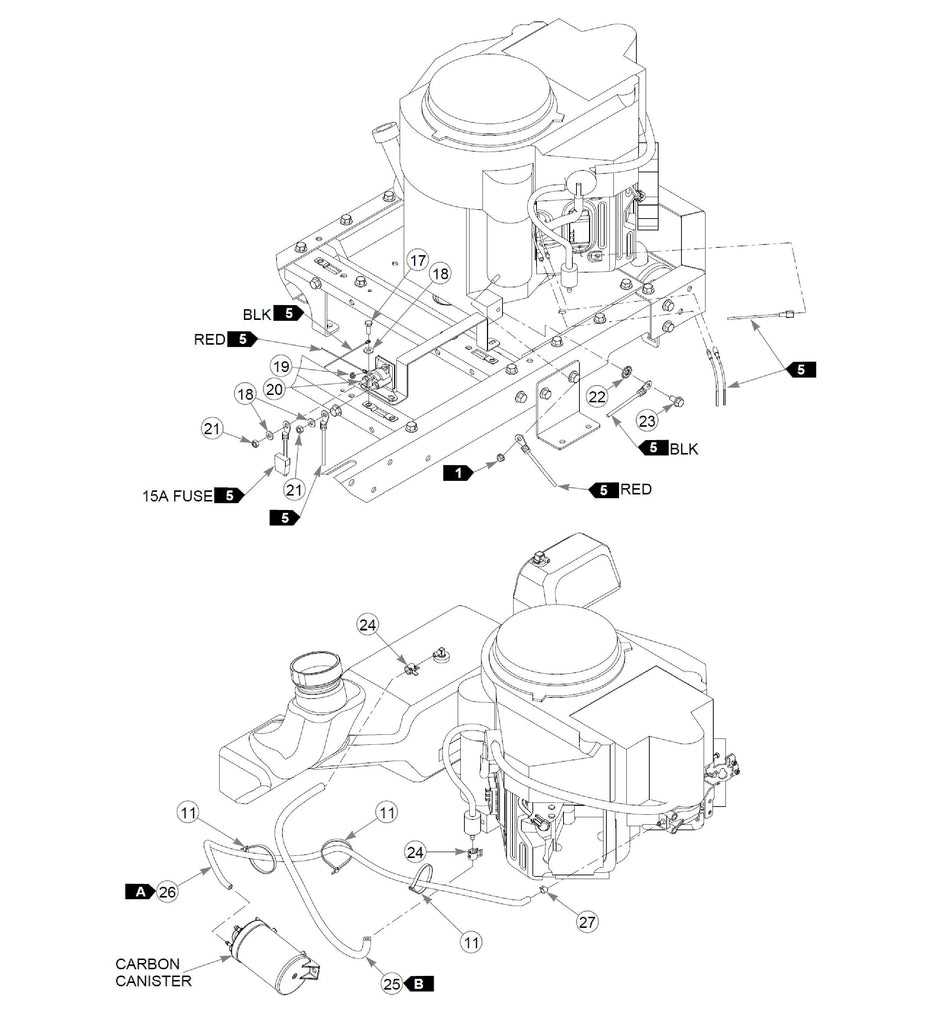

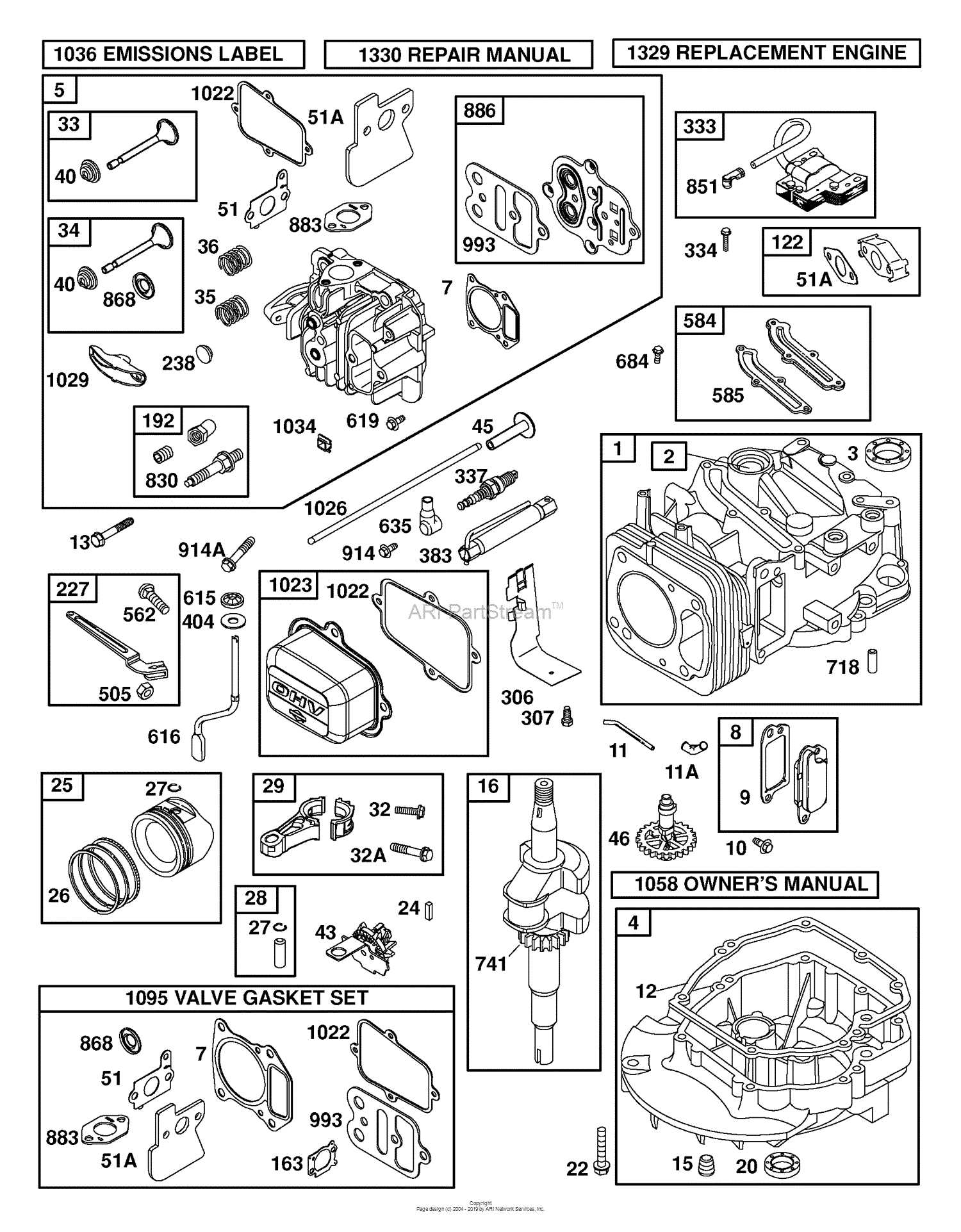

Reading the Parts Diagram

Understanding the assembly illustration is crucial for effective maintenance and repair of your equipment. This visual guide provides a comprehensive view of all components, making it easier to identify and locate specific elements during service tasks.

Here are some key points to consider when interpreting the illustration:

- Labels: Each component is usually labeled with a unique identifier, which helps in cross-referencing with the parts list.

- Grouping: Elements are often grouped by function, allowing you to focus on related sections for repairs or replacements.

- Orientation: Pay attention to the orientation of parts, as they may appear differently when viewed from various angles.

By familiarizing yourself with the assembly illustration, you’ll enhance your ability to troubleshoot issues efficiently and ensure your machinery operates at peak performance.

Replacing Worn Out Components

Maintaining the efficiency of your machine requires timely replacement of aged or damaged elements. Regularly checking these components not only ensures optimal performance but also extends the lifespan of your equipment. Identifying which parts need replacement can prevent further issues and save you from costly repairs down the line.

Identifying Signs of Wear

Common indicators of worn-out components include unusual noises, decreased power, or difficulty starting. Pay attention to any changes in performance, as these can signal that specific elements are no longer functioning properly. Regular inspections are essential for catching these issues early.

Steps for Replacement

Once you’ve identified the components that need replacing, consult the appropriate diagrams for guidance. Gather the necessary tools and ensure you have the correct replacements on hand. Follow the manufacturer’s instructions closely for installation, and always dispose of old parts responsibly. Properly maintaining your equipment can significantly enhance its performance and reliability.

Identifying Model-Specific Parts

Understanding the specific components of your machine is essential for effective maintenance and repair. Each model features unique elements that contribute to its performance, and recognizing these parts can significantly enhance your ability to troubleshoot issues and carry out replacements. Familiarity with the exact specifications not only aids in ensuring compatibility but also streamlines the overall repair process.

To identify the necessary components for your specific model, start by locating the model number, typically found on a label attached to the machine. This number serves as a key reference when searching for replacement elements, as it allows you to access detailed resources that provide accurate information tailored to your machine’s design.

Consulting online resources and manuals can further assist in matching parts to your model. Many manufacturers offer detailed lists and diagrams that illustrate each component’s location and function. Utilizing these resources can clarify the purpose of each element, making it easier to identify what you need.

Finally, consider joining online forums or communities dedicated to machine maintenance. Engaging with fellow enthusiasts can provide invaluable insights and recommendations, often leading to the discovery of trusted suppliers and resources for obtaining the specific components required for your repairs.

Tools Needed for Repairs

Proper maintenance of outdoor machinery requires specific instruments to ensure efficient and safe repairs. Having the right tools on hand can simplify the process and enhance the longevity of your equipment. Below is a list of essential implements that can aid in performing various tasks effectively.

Essential Hand Tools

Start with basic hand tools such as wrenches and screwdrivers. These are crucial for loosening and tightening components. A socket set can also be invaluable, allowing for greater torque and easier access to hard-to-reach bolts. Additionally, a reliable pair of pliers will assist in gripping and twisting wires or other materials.

Specialized Equipment

For more complex repairs, consider investing in specialized equipment. A torque wrench ensures that you apply the correct force when fastening components, preventing damage. A multimeter is essential for electrical diagnostics, helping to identify issues within the system. Lastly, a good-quality cleaning kit will keep your machinery in top condition, allowing for smooth operation.

Tips for Troubleshooting Problems

When facing issues with your equipment, a systematic approach can help identify and resolve common malfunctions. By understanding the key components and their functions, you can diagnose problems more effectively and ensure smooth operation.

Common Issues and Their Solutions

| Issue | Possible Cause | Solution |

|---|---|---|

| Engine won’t start | Empty fuel tank or stale fuel | Refill with fresh fuel |

| Unusual noises | Loose parts or debris | Inspect for loose components and remove any foreign objects |

| Poor performance | Clogged air filter | Clean or replace the air filter |

| Excessive vibration | Worn or unbalanced blades | Sharpen or replace blades as necessary |

General Maintenance Tips

Regular upkeep can prevent many issues before they arise. Make it a habit to check fluid levels, replace filters, and clean components. Keeping your equipment in optimal condition enhances performance and extends its lifespan.

Where to Find Replacement Parts

When it comes to maintaining your equipment, sourcing quality components is essential for optimal performance. Whether you’re looking for specific elements or comprehensive kits, various options are available to ensure you find what you need.

Online Retailers

- Websites specializing in outdoor machinery often have extensive inventories.

- Popular e-commerce platforms may also offer a wide range of items.

- Manufacturer websites frequently provide direct access to genuine components.

Local Dealers and Repair Shops

- Authorized dealers typically stock original equipment and knowledgeable staff.

- Local repair shops may have access to various brands and types of components.

- Networking with other users can lead to recommendations for reliable sources.

By exploring these avenues, you can ensure your machinery remains in top condition and functions as intended.