Understanding the configuration of various mechanical elements is essential for anyone who works with complex machinery. A well-organized visual guide can make it easier to identify and locate specific elements, ensuring smoother maintenance and repairs. With clear insight into how each element interacts, troubleshooting becomes significantly more straightforward.

The layout showcases how different components come together to form a cohesive system. This guide will help clarify the relationships between critical pieces and offer a more intuitive understanding of the overall structure. Having this information at hand is a valuable resource for ensuring long-term efficiency and reliability.

By examining each individual part of the machine, you will gain a better perspective on the inner workings and learn how to approach regular maintenance tasks more effectively. A clear understanding of the setup is crucial for anyone looking to keep the system in top condition.

Understanding the Components of Subaru EX40

When it comes to maintaining efficient operation, it’s essential to have a clear understanding of the core elements involved in the engine. By familiarizing yourself with the key mechanisms and how they interact, you can ensure better performance and longevity.

Main Engine Sections

The internal structure can be broken down into several critical areas. Each section works together to provide power, efficiency, and reliability. Knowing these segments helps in recognizing how they contribute to overall functionality.

Important Mechanical Elements

The mechanical framework includes various interconnected units that play specific roles. These range from controlling airflow to ensuring smooth combustion, all while maintaining precise synchronization.

Engine Layout and Key Elements

The engine’s configuration plays a crucial role in its performance and efficiency. Understanding the arrangement of main components helps in both maintenance and repair tasks. Below is an overview of the essential elements and how they are positioned within the engine block.

- Cylinder Block: The foundation that houses the cylinders and supports other components. Its position directly influences the overall operation.

- Pistons: Located within the cylinders, these parts move up and down, generating the power needed for the engine to function.

- Crankshaft: Converts the linear motion of the pistons into rotational energy. It is typically placed near the lower section of the engine.

- Camshaft: Controls the opening and closing of valves and is often positioned either above or alongside the crankshaft.

- Valves: Responsible for regulating air and

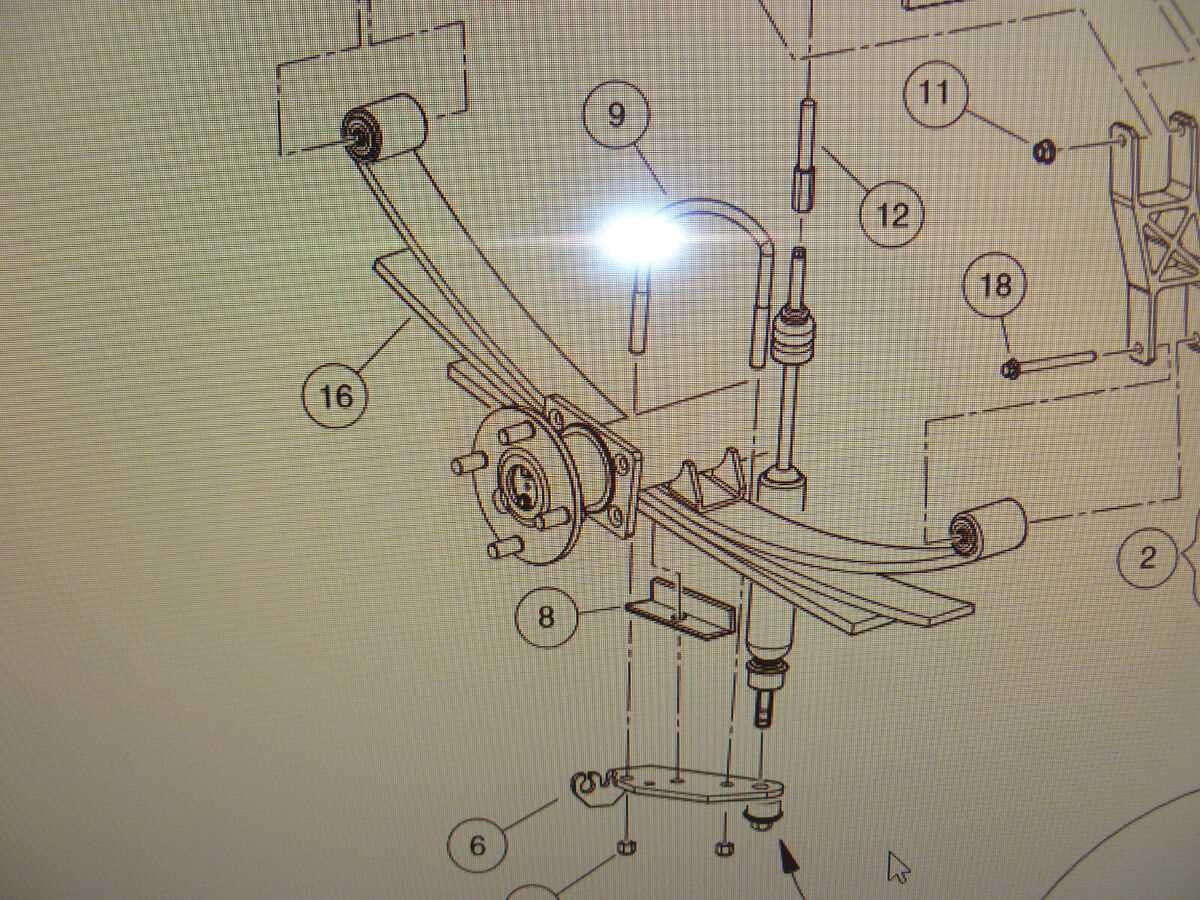

Crankshaft Assembly and Related Parts

The crankshaft assembly is a vital component responsible for converting linear energy into rotational force. This process ensures that the engine operates efficiently and powers various mechanisms. The entire unit works in harmony with several interconnected elements, each playing a crucial role in the overall functionality of the engine system.

Main Components of the Crankshaft Assembly

The crankshaft, together with bearings and seals, ensures smooth operation by maintaining precise alignment and minimizing friction. These elements must be robust to handle the immense pressure and movement within the engine. Additionally, connecting rods and pistons are directly linked to the crankshaft, transmitting the force required to rotate the assembly.

Critical Associated Parts

Beyond the main rotating shaft, various supporting components are essential. This includes the timing gears and the

Air Filter and Maintenance Tips

Regular upkeep of the air filter is essential for ensuring efficient performance and prolonging the life of any equipment. A clean filter allows for proper airflow, which is vital for optimal operation. Failing to maintain the filter can lead to reduced efficiency and potential mechanical issues. This section provides practical guidance on how to care for and inspect the filter regularly.

Cleaning the Air Filter

Begin by removing the filter carefully, avoiding any damage to surrounding components. Once removed, check for dirt buildup. If the filter appears clogged or heavily soiled, it should be cleaned using a mild detergent and water. Make sure it is completely dry before reinstalling to avoid any moisture-related damage.

Replacing the Air Filter

Over time, the filter may wear out or become too dirty for effective cleaning. In such cases, replacing it with a new one is necessary. Always

Ignition System Overview

The ignition system plays a crucial role in starting and operating engines efficiently. It ensures that the necessary electrical spark is generated to ignite the fuel mixture at the right moment, allowing the engine to run smoothly.

Key components of the system include the spark plug, ignition coil, and the control mechanism, all working together to maintain proper timing and energy delivery. Each element is designed to ensure the engine receives consistent power, optimizing performance and reliability.

Regular maintenance of these components is essential for preventing misfires and ensuring longevity. Understanding how these elements function helps in diagnosing potential issues early, keeping the engine in optimal condition.

Fuel System Structure and Components

The fuel system plays a crucial role in the efficient operation of internal combustion engines. It encompasses various elements designed to store, deliver, and manage fuel, ensuring optimal performance and reliability. Understanding the configuration and functionality of these components is essential for maintaining and troubleshooting engine performance.

Key components of the fuel system include the fuel tank, which serves as a reservoir for the fuel; the fuel pump, responsible for transporting fuel to the engine; and the fuel injectors, which atomize the fuel for effective combustion. Additionally, fuel filters are critical for removing impurities from the fuel, protecting the engine from potential damage.

Each element within this system works in harmony to ensure that the right amount of fuel is delivered at the appropriate pressure and timing, contributing to overall engine efficiency and emissions control. Regular maintenance of these components is vital for sustaining engine performance and longevity.

Cooling Mechanism and Its Importance

The cooling system plays a crucial role in maintaining optimal operating temperatures within an engine. Its primary function is to dissipate excess heat generated during combustion, ensuring that components operate efficiently and reducing the risk of overheating. By managing the engine’s temperature, this system contributes to improved performance and longevity.

In any engine, the cooling mechanism consists of various elements working in harmony. Radiators, water pumps, and thermostats are vital components that help circulate coolant and regulate temperatures effectively. When the engine runs, coolant absorbs heat and flows through the radiator, where it dissipates heat into the surrounding air. This process prevents potential damage caused by extreme temperatures and helps maintain a stable operating environment.

Neglecting the cooling system can lead to severe consequences, including engine failure and costly repairs. Regular maintenance, such as checking coolant levels and inspecting for leaks, ensures that this system functions correctly. An efficient cooling mechanism not only enhances performance but also contributes to fuel efficiency, making it an essential aspect of any vehicle’s overall functionality.

Piston and Cylinder Breakdown

The efficient functioning of an engine largely depends on the intricate relationship between the piston and the cylinder. Understanding this connection is essential for maintaining optimal performance and ensuring longevity. This section delves into the various components and their roles within this critical system.

Components of the Piston and Cylinder Assembly

- Piston: The movable component that compresses the fuel-air mixture.

- Cylinder: The chamber in which the piston operates, providing space for combustion.

- Piston Rings: Seals that prevent the escape of gases and maintain compression.

- Cylinder Head: The top part of the cylinder that houses the combustion chamber.

- Connecting Rod: Links the piston to the crankshaft, converting linear motion to rotational motion.

Functionality and Interaction

The piston moves up and down within the cylinder, creating a vacuum that draws in the fuel-air mixture. Upon ignition, the resulting explosion forces the piston back down, generating power. The rings play a crucial role in ensuring a tight seal, while the cylinder head allows for efficient gas exchange. Regular maintenance of these components is vital for avoiding issues such as loss of compression and increased wear.

- Inspect piston rings for wear.

- Check cylinder walls for scoring or damage.

- Ensure proper lubrication throughout the assembly.

Exhaust System Components Explained

The exhaust system is a crucial aspect of a vehicle’s operation, responsible for directing harmful gases away from the engine and ensuring optimal performance. Understanding its components can help in maintaining and enhancing efficiency. Each part plays a specific role in managing exhaust flow and minimizing emissions.

Key Components of the Exhaust System

- Exhaust Manifold: This component collects exhaust gases from the engine cylinders and channels them into the exhaust system.

- Catalytic Converter: A vital part that transforms harmful pollutants into less harmful emissions before they exit the vehicle.

- Resonator: This section helps reduce noise produced by the exhaust gases, balancing sound levels within the vehicle.

- Muffler: Designed to minimize noise, it allows for a smoother flow of exhaust gases while reducing sound output.

- Exhaust Pipes: These pipes connect the various components of the system, guiding gases from the engine out of the vehicle.

Importance of Each Component

Each part of the exhaust system serves a unique function that contributes to overall vehicle performance. A well-maintained system ensures efficient exhaust flow, reduces noise, and helps meet emission standards. Regular inspection and timely replacement of worn components can lead to better fuel efficiency and a longer lifespan for the vehicle.

Valve Operation and Timing Mechanism

The functioning of valves and their synchronization within an engine is crucial for optimal performance. This process ensures that the intake and exhaust gases flow at the right moments, contributing to efficient combustion and energy production. Understanding this mechanism provides insight into how engines manage air and fuel intake while expelling exhaust gases.

The timing of valve movements is orchestrated by a system often linked to the crankshaft. As the crankshaft rotates, it drives the camshaft, which in turn controls the opening and closing of the valves. Precise alignment is essential; any deviation can lead to poor engine performance or even mechanical failure. Variable valve timing systems enhance efficiency by adjusting the timing based on the engine’s operational conditions, optimizing both power output and fuel economy.

Additionally, valve lifters play a significant role in this operation. These components translate the motion from the camshaft to the valves, ensuring they respond accurately to the cam profile. Regular maintenance and inspection of these elements are vital, as wear and tear can lead to timing issues and affect the overall efficiency of the engine.

Gasket and Seal Functions in Subaru EX40

In any mechanical system, components must work together seamlessly to ensure optimal performance and durability. Essential to this integration are gaskets and seals, which serve critical roles in maintaining integrity and functionality. These elements prevent leakage of fluids and gases, protecting internal parts from contamination and ensuring efficiency.

Importance of Gaskets

Gaskets are vital for creating a tight seal between two surfaces, preventing fluid loss and maintaining pressure within the system. They are typically made from materials that can withstand various temperatures and pressures, contributing to the longevity of the engine components. Proper installation and material selection are crucial for effective sealing, as even minor imperfections can lead to significant operational issues.

Role of Seals

Seals complement gaskets by providing additional protection against the ingress of dirt and moisture. They are designed to fit snugly around moving parts, ensuring that lubricants stay contained and preventing wear caused by friction. The choice of seal material and design directly impacts the efficiency and lifespan of the engine, making them indispensable for optimal functionality.