The intricate design of marine propulsion systems is essential for optimal performance and reliability. This section delves into the various elements that constitute these engines, offering a clear view of their interrelationships and functions. A comprehensive understanding of these components is crucial for effective maintenance and troubleshooting.

By examining a detailed representation of these elements, enthusiasts and professionals alike can better grasp how each piece contributes to the overall functionality. This insight not only aids in repairs but also enhances the longevity of the equipment, ensuring that every outing on the water is a successful one.

In the following sections, we will explore each component in detail, highlighting their specific roles and importance. Understanding these mechanical parts will ultimately empower users to manage their engines with confidence and precision.

Suzuki DT40 Overview

This section provides a comprehensive examination of a specific outboard motor model, detailing its key features and functionalities. It is designed for those seeking insights into the performance and capabilities of this particular engine type.

| Feature | Description |

|---|---|

| Engine Type | Two-stroke, lightweight design for optimal efficiency |

| Power Output | 40 horsepower, suitable for various boating activities |

| Fuel System | Advanced fuel delivery for improved performance |

| Cooling System | Water-cooled operation ensures consistent performance |

| Weight | Compact and manageable weight for easy handling |

Understanding Parts and Functions

Gaining insight into the components of a watercraft engine is essential for effective maintenance and optimal performance. Each element plays a significant role in the overall functionality, ensuring that the machine operates smoothly and efficiently. Recognizing how these individual elements interact can enhance troubleshooting efforts and prolong the lifespan of the engine.

| Component | Function |

|---|---|

| Cylinder | Houses the piston and facilitates combustion. |

| Piston | Converts the energy from combustion into mechanical movement. |

| Carburetor | Mixes air and fuel for optimal combustion. |

| Exhaust System | Removes exhaust gases produced during combustion. |

| Ignition System | Ignites the air-fuel mixture at the correct time. |

Common Issues with Suzuki DT40

Understanding the frequent challenges associated with a particular outboard motor can enhance maintenance and performance. Many users encounter similar problems, which can often be attributed to specific components or operational practices.

Typical Problems

- Overheating due to insufficient cooling water flow

- Fuel system clogs impacting engine efficiency

- Ignition failures leading to starting issues

- Unusual vibrations indicating potential wear or damage

Preventive Measures

Regular inspections and maintenance can mitigate many of these issues. Here are some effective strategies:

- Check the cooling system regularly to ensure unobstructed water flow.

- Inspect fuel lines and filters for debris and leaks.

- Test ignition components to ensure proper functionality.

- Monitor for any unusual sounds or vibrations during operation.

Maintenance Tips for Optimal Performance

Regular upkeep is essential to ensure that your marine engine operates at its best. Implementing effective maintenance practices can significantly enhance its longevity and efficiency.

- Routine Inspections: Conduct periodic checks of all components to identify wear and tear.

- Cleanliness: Keep the engine area free of debris and salt deposits to prevent corrosion.

- Fluid Levels: Regularly monitor and replenish oil and coolant to maintain optimal operating temperatures.

In addition to these basics, consider the following advanced tips:

- Replace Filters: Change fuel and oil filters according to the manufacturer’s schedule to ensure clean operation.

- Propeller Maintenance: Inspect and clean the propeller regularly to prevent performance issues caused by fouling or damage.

- Battery Care: Ensure that the battery terminals are clean and connections are tight to maintain electrical efficiency.

By following these guidelines, you can help ensure that your engine remains reliable and performs at its peak, providing an enjoyable experience on the water.

How to Identify Replacement Parts

Recognizing components that need substitution can be crucial for maintaining optimal performance. Understanding the specific features of each element ensures seamless integration and functionality. Here are key steps to help you accurately identify necessary replacements:

- Examine Existing Components: Carefully inspect the current items for any identifying markings or numbers.

- Consult Manuals: Reference user guides or technical literature for detailed descriptions and specifications.

- Utilize Online Resources: Visit forums or websites dedicated to similar machinery for shared insights and experiences.

- Seek Expert Advice: Engage with professionals or enthusiasts who may provide additional information or recommendations.

By following these guidelines, you can ensure that the correct elements are acquired, thereby enhancing overall reliability and performance.

Benefits of Using Genuine Components

Opting for authentic elements in machinery maintenance ensures enhanced performance and longevity. Genuine components are crafted to meet the specific standards set by the manufacturer, which results in better compatibility and reliability.

When choosing original pieces, users can experience several advantages:

| Advantage | Description |

|---|---|

| Quality Assurance | Authentic components undergo rigorous testing to ensure durability and efficiency. |

| Optimal Performance | These parts are designed to function seamlessly with existing systems, providing enhanced functionality. |

| Warranty Protection | Using original elements often helps maintain the warranty of the equipment, safeguarding the investment. |

| Long-Term Cost Savings | Investing in genuine parts can reduce the frequency of repairs and replacements, leading to lower overall costs. |

In summary, selecting authentic components contributes significantly to the efficiency and lifespan of the machinery, making it a wise choice for any user.

Repair Procedures for Common Failures

This section addresses the essential steps to rectify frequent issues encountered in marine engines. Proper maintenance and timely interventions can significantly enhance performance and longevity.

Engine Won’t Start: Begin by checking the fuel supply and ensuring that the ignition system functions correctly. Inspect the battery connections and replace any faulty components.

Overheating: Examine the cooling system for blockages or leaks. Ensure the water pump operates efficiently, and clean the heat exchanger if necessary.

Strange Noises: Identify the source of unusual sounds, as they may indicate wear or misalignment. Tighten loose parts and replace any worn bearings or belts to prevent further damage.

Loss of Power: Assess fuel filters and air intakes for obstructions. Regular cleaning and replacement of these elements can restore optimal engine performance.

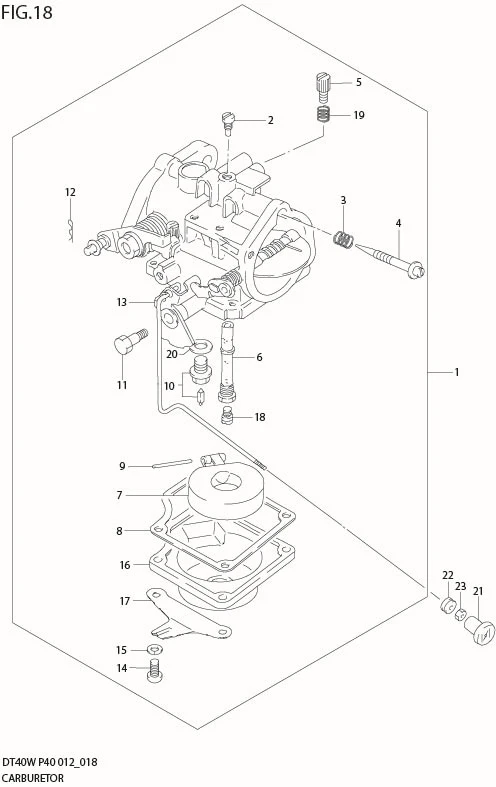

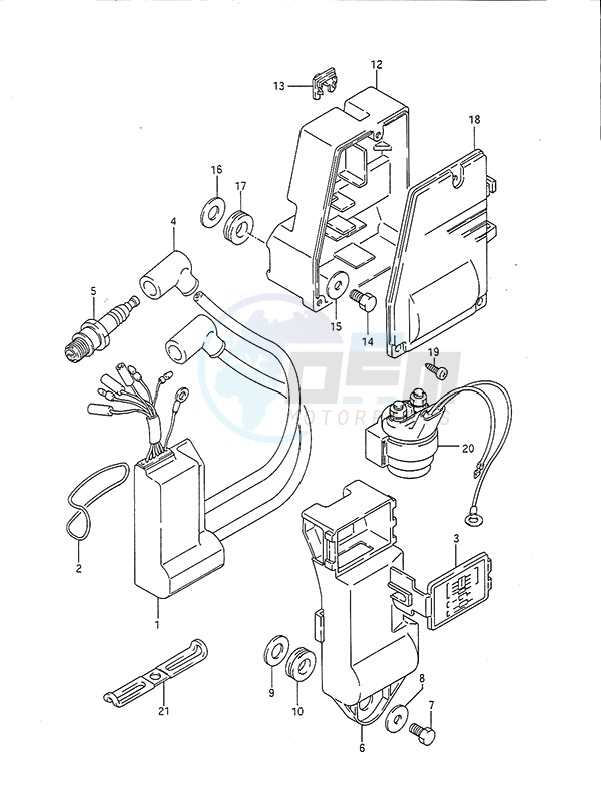

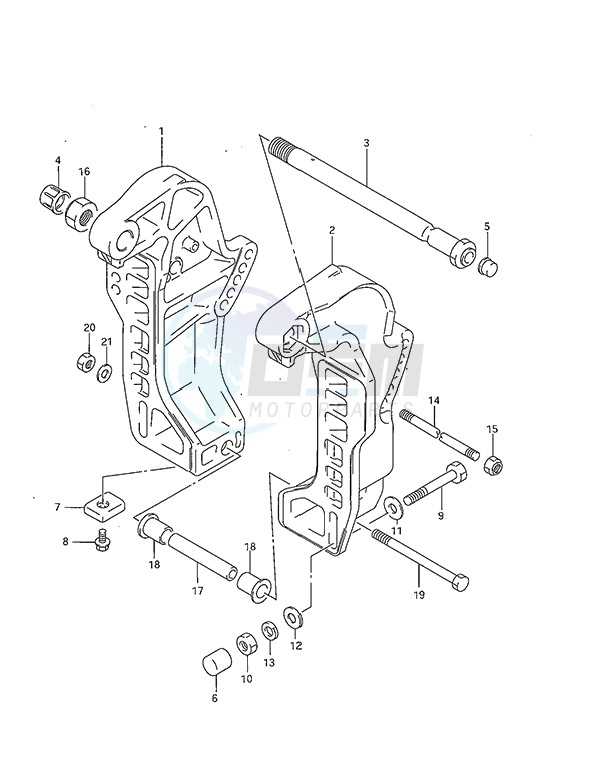

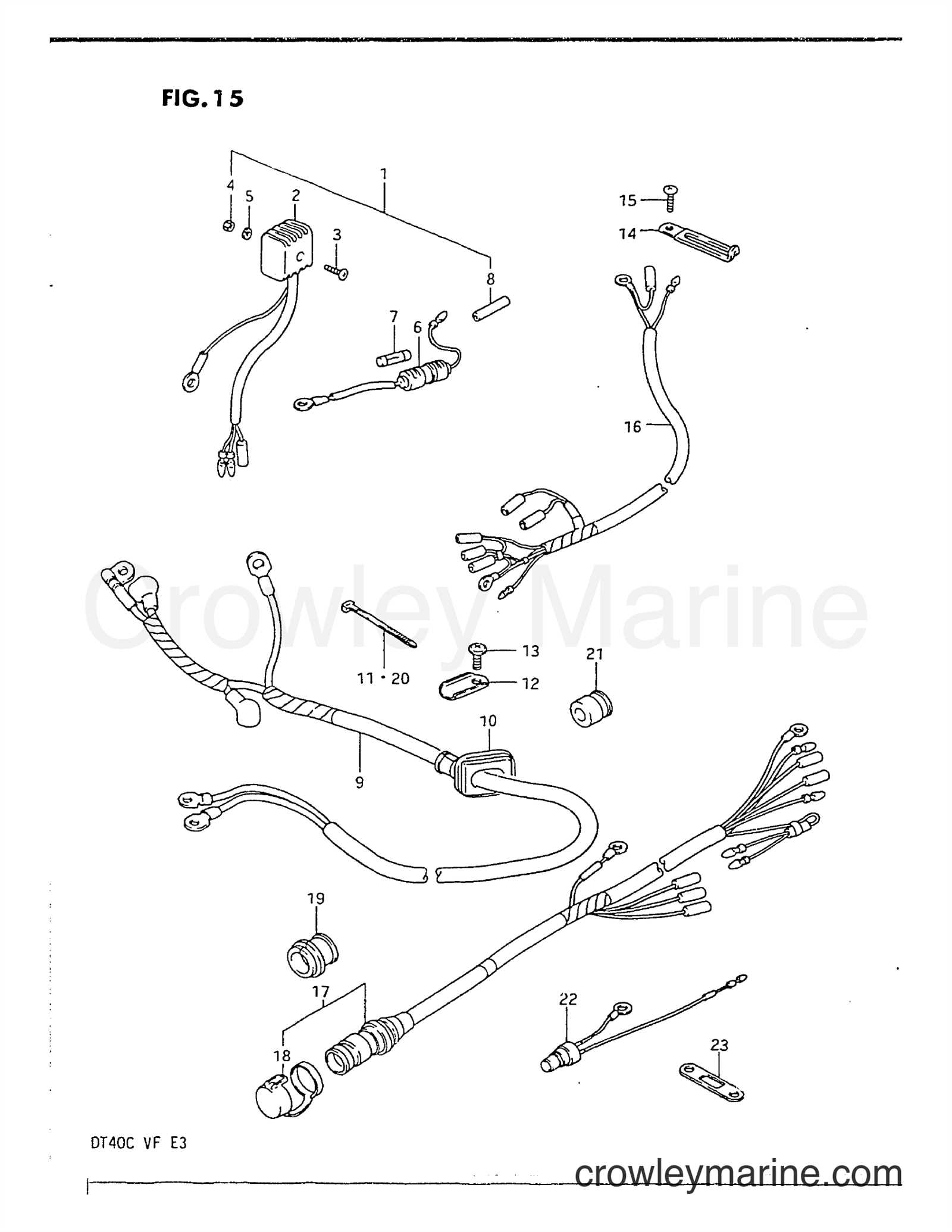

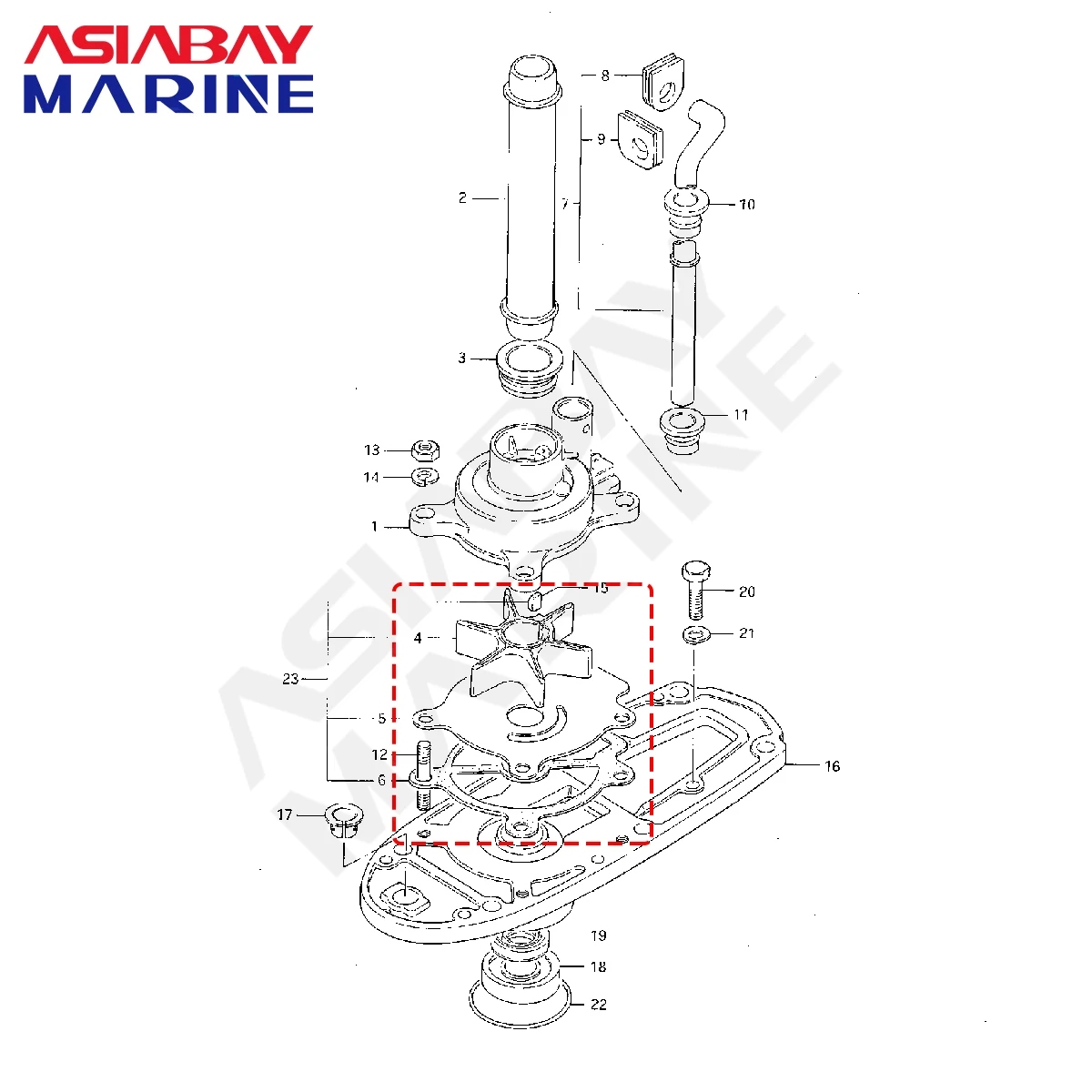

Parts Diagram: Key Components Explained

This section delves into the essential elements that constitute a specific model of an outboard engine. Understanding these components is crucial for effective maintenance and troubleshooting, ensuring optimal performance during operation.

Main Elements

- Engine Block: The core structure housing critical components.

- Piston Assembly: Responsible for converting fuel energy into mechanical motion.

- Cylinder Head: Encloses the combustion chamber, playing a key role in performance.

- Fuel System: Includes various parts for fuel delivery and atomization.

- Cooling System: Essential for maintaining optimal operating temperatures.

Additional Components

- Ignition System: Manages the spark generation for combustion.

- Exhaust System: Directs exhaust gases away from the engine.

- Transmission: Facilitates power transfer from the engine to the propeller.

Familiarity with these elements enhances understanding of their interactions, leading to better handling and care of the engine.

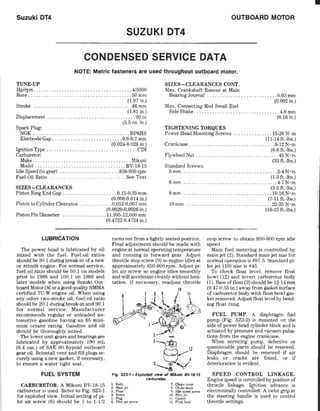

Tools Needed for Parts Replacement

Replacing components in an outboard engine requires a set of essential instruments to ensure the process is efficient and effective. Having the right tools at your disposal not only simplifies the task but also minimizes the risk of damage to the engine and its parts. Below, you’ll find a list of commonly used tools that will aid in the replacement process.

Essential Instruments

Among the key instruments needed are wrenches, which come in various sizes to accommodate different fasteners. Additionally, screwdrivers–both flathead and Phillips–are crucial for removing screws that hold components together. A set of pliers is also beneficial for gripping and pulling parts as necessary.

Specialty Tools

In some cases, specialized tools may be required to tackle specific tasks. For instance, a torque wrench ensures that bolts are tightened to the manufacturer’s specifications, preventing any potential issues. Furthermore, a multimeter can help diagnose electrical problems, making it easier to address any faults during replacement.

Where to Purchase Suzuki Parts

Finding components for your watercraft can be a straightforward process if you know where to look. Various options are available, ranging from authorized retailers to online marketplaces, ensuring you can acquire the necessary items for maintenance and repair.

One reliable source is the official dealer network, where you can obtain genuine replacements designed specifically for your model. These outlets often provide expert advice and assistance, ensuring you make informed choices. Additionally, many local marine shops stock essential items and can help with installation queries.

Online platforms also offer a vast selection of options. Websites specializing in marine supplies often feature competitive pricing and a wide range of products, making it easy to compare and find what you need. Always verify the reputation of the seller and check customer reviews to ensure quality.

Lastly, consider forums and community groups dedicated to boating enthusiasts. Members frequently share insights on where to find the best deals and may even have suggestions for used components that are still in excellent condition.

Upgrading Your Engine

Enhancing the performance of your outboard motor can significantly improve its efficiency and longevity. By implementing various modifications, you can optimize power output, fuel consumption, and overall responsiveness. This section will explore several methods to upgrade your engine, ensuring you get the best possible performance on the water.

Essential Upgrades

- Propeller Replacement: Switching to a high-performance propeller can greatly increase speed and acceleration.

- Fuel System Improvement: Upgrading the fuel filter and injectors can enhance fuel delivery and efficiency.

- Ignition System Enhancement: Installing a high-output ignition coil can improve spark quality, leading to better combustion.

- Exhaust System Modification: A performance exhaust can reduce back pressure and improve exhaust flow.

Maintenance Tips for Upgrades

To ensure the effectiveness of the upgrades, regular maintenance is crucial. Consider the following tips:

- Check all connections and fittings for leaks.

- Regularly inspect the propeller for damage.

- Replace filters and fluids according to the manufacturer’s recommendations.

- Monitor engine performance after upgrades to ensure optimal functionality.

By following these suggestions and implementing the right upgrades, you can significantly enhance the performance and reliability of your outboard motor.