The efficiency and performance of a lawn mower depend significantly on its individual components and how they work together. A well-designed machine features various parts that contribute to its overall functionality, from the engine to the cutting mechanism. Understanding these elements is essential for maintaining and repairing the equipment, ensuring it operates at peak performance.

In this section, we will explore the intricate layout of the various elements within a specific model of riding mower. By examining the arrangement and function of each component, users can gain insights into how to best care for their machine, troubleshoot issues, and replace parts when necessary. This knowledge empowers users to extend the lifespan of their mower and improve its reliability.

Familiarity with the layout of the internal mechanisms allows for more informed decision-making regarding maintenance tasks. Whether you’re looking to perform routine checks or make specific repairs, a clear understanding of how each part fits into the overall structure will simplify the process and enhance your mowing experience.

Toro Timecutter SS4235 Parts Overview

This section provides a comprehensive look at the components and essential elements of a well-known lawn maintenance machine. Understanding the various elements that comprise this equipment is crucial for both maintenance and repair. Each piece plays a vital role in ensuring optimal functionality and performance.

Key Components

The assembly consists of several crucial parts, each designed for specific functions. The engine is the powerhouse, providing the necessary energy to operate the machine efficiently. The cutting deck is essential for achieving a clean and precise cut, while the transmission ensures smooth movement across different terrains. Additional elements, such as the wheels and frame, contribute to stability and maneuverability.

Maintenance and Repair

Regular upkeep of these components is vital for prolonging the lifespan of the equipment. Inspecting the engine and transmission periodically can help identify potential issues before they escalate. Replacing worn or damaged parts promptly is also essential to maintain performance standards and prevent further damage.

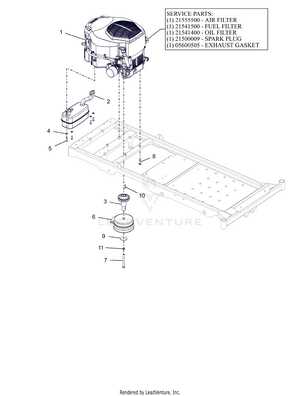

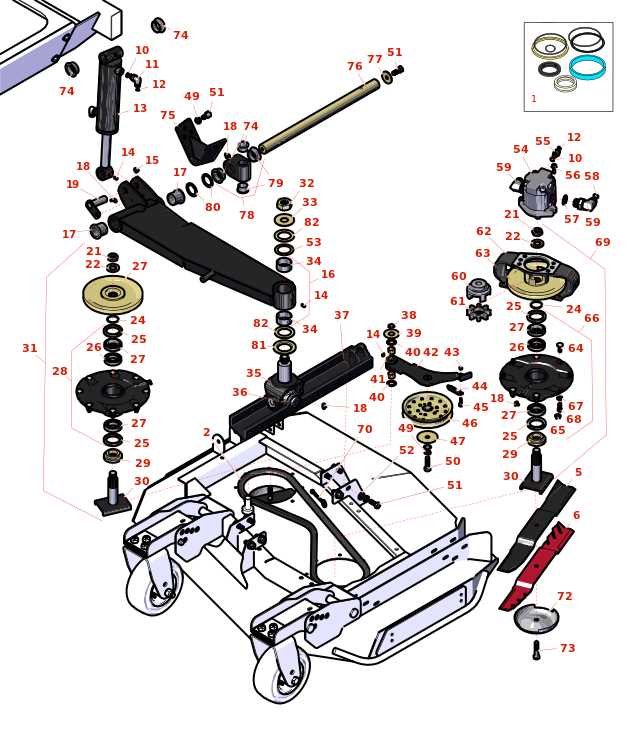

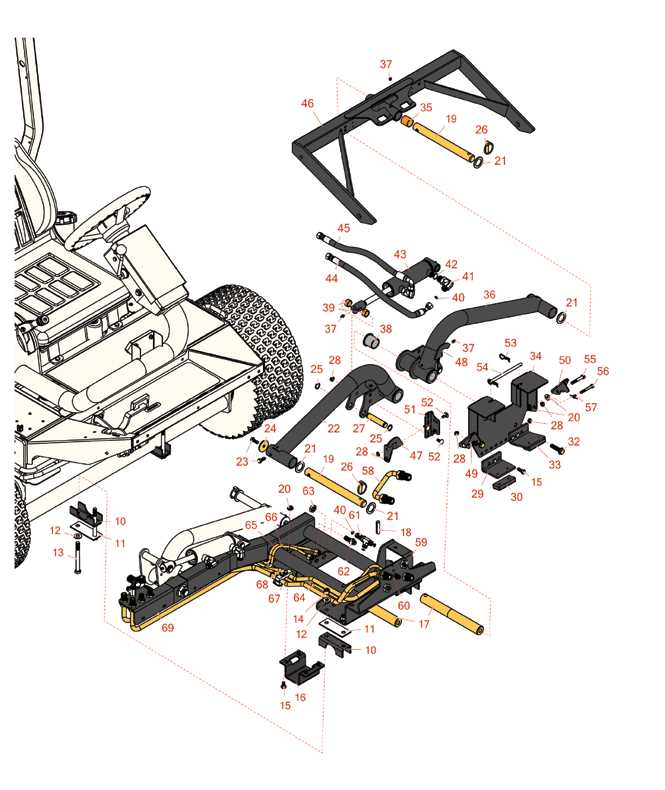

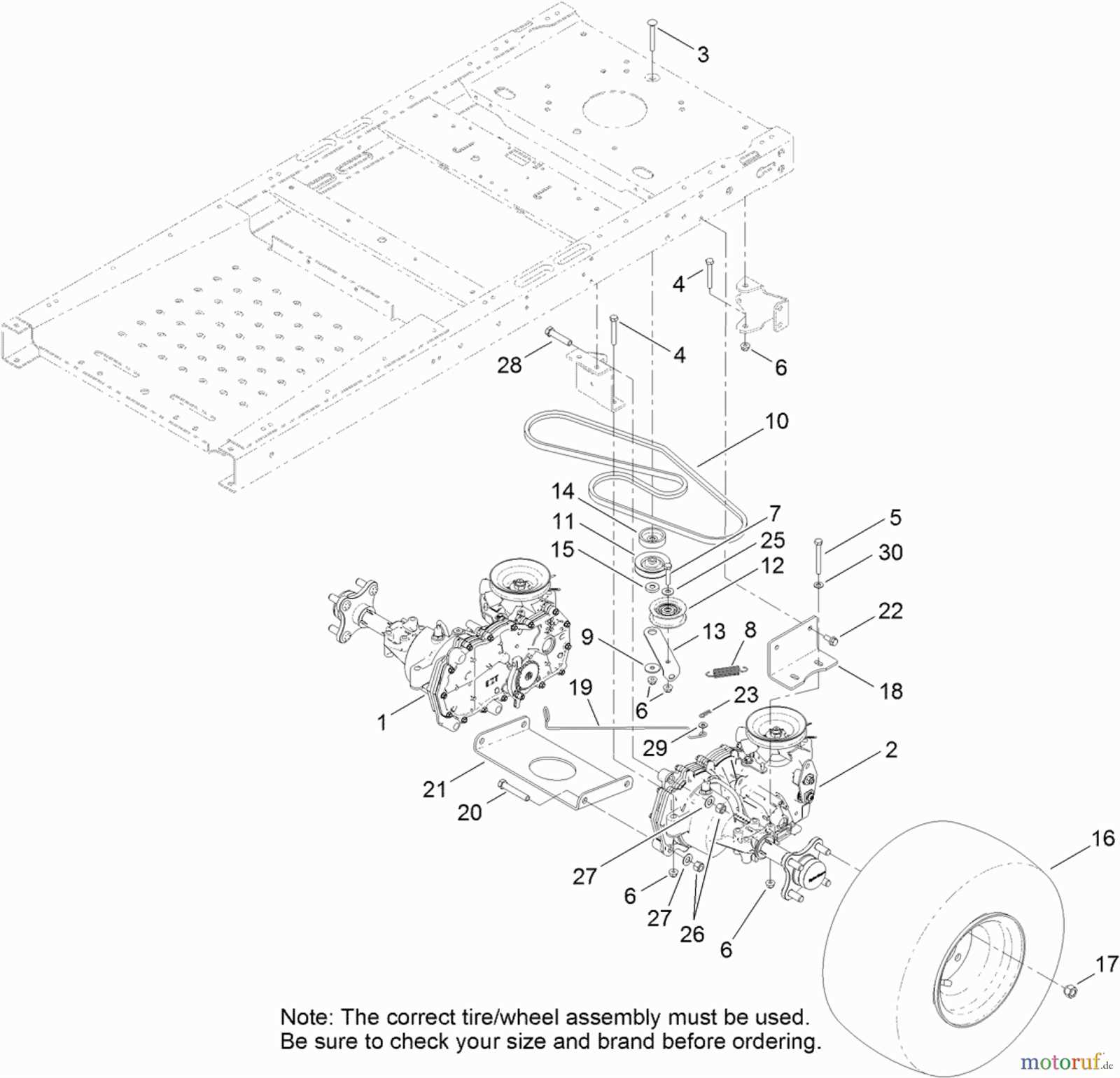

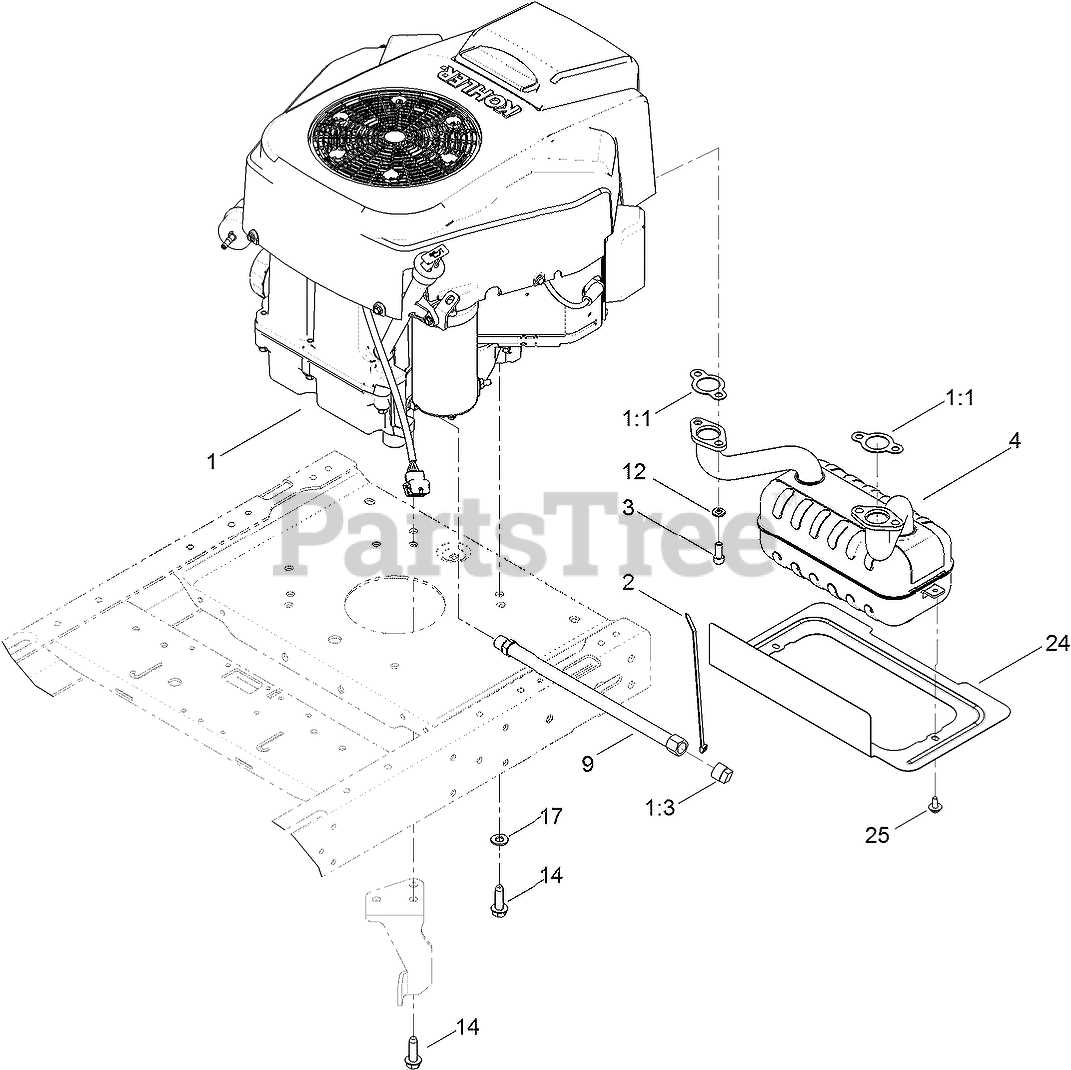

Understanding the Parts Diagram

The visual representation of components plays a crucial role in comprehending the structure and function of any machinery. It serves as a guide for users to identify individual elements and their relationships within the overall system. This understanding is essential for maintenance, repairs, and ensuring optimal performance.

Each section of the visual representation provides valuable insights into the assembly and function of the various components. Familiarizing oneself with these elements can significantly enhance the efficiency of troubleshooting and repairs.

| Component | Description | Function |

|---|---|---|

| Engine | Power source for the machinery | Drives the entire system |

| Chassis | Frame supporting all components | Provides structural integrity |

| Blade Assembly | Cuts through vegetation | Facilitates trimming and mowing |

| Transmission | Transfers power from the engine | Enables movement and operation |

| Wheels | Support mobility | Allow movement across terrain |

Key Components of the Timecutter

This section delves into the essential elements that constitute a high-performance mowing machine, focusing on their functions and interactions. Understanding these vital components is crucial for effective maintenance and operation, ensuring optimal performance and longevity of the equipment.

Among the primary elements are the cutting deck, engine, transmission system, and control mechanisms. Each part plays a pivotal role in the overall functionality of the machine, contributing to its efficiency and user experience. Below is a detailed overview of these components.

| Component | Description |

|---|---|

| Cutting Deck | The platform where the blades are located, designed for efficient grass cutting. |

| Engine | Provides the power needed for the machine to operate and perform mowing tasks. |

| Transmission System | Transfers power from the engine to the wheels, allowing for movement and maneuverability. |

| Control Mechanisms | Includes levers and pedals that enable the operator to steer and manage the machine’s functions. |

| Wheels | Support the machine’s movement and stability during operation on various terrains. |

Importance of Regular Maintenance

Routine upkeep is essential for the longevity and performance of any mechanical equipment. By adhering to a scheduled maintenance routine, users can prevent potential issues before they escalate, ensuring that the machinery operates smoothly and efficiently. This proactive approach not only extends the lifespan of the equipment but also enhances its reliability and safety during use.

Benefits of Consistent Upkeep

Regular maintenance provides numerous advantages, including improved efficiency and reduced operational costs. Well-maintained machinery tends to consume less fuel and operate at optimal levels, resulting in lower energy expenses. Additionally, timely inspections and repairs can identify wear and tear early, preventing costly breakdowns and repairs in the future.

Enhanced Safety and Performance

Ensuring that equipment is properly serviced contributes significantly to the safety of the operator and those nearby. Regular checks can help detect potential hazards, such as leaks or worn parts, that could pose risks during operation. Furthermore, consistent maintenance helps maintain peak performance, allowing users to achieve the best results in their tasks while minimizing the likelihood of unexpected downtime.

Identifying Replacement Parts Easily

When maintaining and repairing your equipment, understanding how to quickly locate the necessary components can save you time and effort. Having a clear reference for each element will enable you to perform repairs efficiently and ensure the longevity of your machinery.

To streamline the process of identifying the right components, consider the following steps:

- Consult the User Manual: Start by reviewing the documentation that came with your equipment. This manual often contains valuable information about each component’s function and specifications.

- Utilize Online Resources: Many manufacturers provide online databases where you can search for parts based on your equipment model. These resources often include images and descriptions to aid in identification.

- Label Components: During disassembly, label each component as you remove it. This practice will help you keep track of which parts need replacement and make reassembly easier.

By following these guidelines, you can enhance your ability to identify the necessary components for your equipment, ensuring a smoother repair experience.

Common Issues and Solutions

When operating a lawn maintenance machine, users may encounter several typical challenges that can impact performance and efficiency. Understanding these common problems and their respective solutions is essential for ensuring smooth operation and prolonging the lifespan of the equipment.

1. Engine Won’t Start: One frequent issue is difficulty in starting the engine. This can be caused by a drained battery, faulty ignition switch, or fuel supply problems. To address this, check the battery charge, ensure the ignition is functioning correctly, and verify that there is an adequate fuel supply.

2. Uneven Cutting: Another common concern is uneven cutting, which can result from dull blades, improper tire pressure, or an uneven deck. To resolve this, sharpen or replace the blades, check and adjust the tire pressure, and ensure the cutting deck is level.

3. Excessive Vibration: Excessive vibration during operation can indicate loose components or unbalanced blades. Inspect all fasteners and tighten as necessary, and check the blades for damage or imbalance. Balancing the blades can significantly reduce vibrations and improve cutting performance.

4. Clogging: Grass clippings or debris can sometimes clog the discharge chute, affecting performance. Regular cleaning of the chute and deck will help maintain optimal airflow and prevent clogs. Additionally, avoid mowing in overly wet conditions, as this can exacerbate the issue.

By recognizing and addressing these common challenges, users can enhance the functionality of their lawn care equipment and achieve better results during operation.

Where to Purchase Genuine Parts

When it comes to maintaining your outdoor equipment, sourcing authentic components is crucial for ensuring optimal performance and longevity. Reliable suppliers provide a variety of options for acquiring original replacements that are specifically designed for your machine. This guarantees compatibility and efficiency, ultimately enhancing your equipment’s functionality.

One of the best approaches to find genuine components is to visit the manufacturer’s official website. They often have dedicated sections where you can search for and order specific items directly. Additionally, authorized dealers and service centers are excellent resources, as they not only sell authentic replacements but also have knowledgeable staff who can assist with any inquiries.

Another effective method is to explore reputable online marketplaces that specialize in equipment accessories. These platforms often feature a wide selection of original items, complete with user reviews to guide your choices. Always ensure that the seller is verified to avoid counterfeit products.

Local hardware and gardening supply stores may also carry a range of original components. Visiting these establishments allows you to speak directly with staff who can provide recommendations based on their expertise. Building a relationship with local suppliers can often lead to additional support and resources for future maintenance needs.

DIY Repairs and Tools Needed

When it comes to maintaining your lawn care equipment, understanding how to perform repairs yourself can save both time and money. Knowing the essential tools and techniques is crucial for effective troubleshooting and ensuring your machinery operates smoothly.

To successfully complete repairs, you’ll need a range of tools that cater to different tasks. Here is a list of commonly required tools:

- Socket set

- Wrenches (both standard and adjustable)

- Screwdrivers (flathead and Phillips)

- Pliers

- Utility knife

- Torque wrench

- Cleaning brushes

- Oil and grease for lubrication

Before starting any repair, it’s essential to have a clean workspace and organize your tools. Additionally, referring to an equipment manual can provide valuable insights into specific maintenance tasks.

Finally, always prioritize safety by wearing protective gear, such as gloves and goggles, and ensure that your machinery is powered down before beginning any repair work. By being well-prepared and informed, you can effectively tackle common issues and extend the lifespan of your equipment.

Safety Tips for Maintenance

Proper maintenance of machinery is crucial for ensuring optimal performance and longevity. Adhering to safety guidelines not only protects the equipment but also safeguards the operator and surrounding individuals. This section highlights essential precautions to take during maintenance tasks.

General Precautions

Before beginning any maintenance procedure, it is vital to prepare adequately. Always wear appropriate personal protective equipment (PPE) such as gloves, goggles, and sturdy footwear. Ensure that the work area is well-lit and free of clutter to prevent accidents. Additionally, familiarize yourself with the machinery’s user manual and safety instructions, as they provide valuable information regarding specific maintenance procedures.

Operational Safety

When performing maintenance, always turn off the machinery and disconnect it from the power source to prevent accidental startup. If the machine requires adjustments or repairs, use proper tools and techniques to avoid damaging components or causing injury. Keep hands and loose clothing away from moving parts, and never attempt to make adjustments while the machine is running.

| Safety Tip | Description |

|---|---|

| Wear PPE | Always use gloves, goggles, and protective footwear during maintenance tasks. |

| Disconnect Power | Ensure the machinery is turned off and unplugged before beginning work. |

| Use Correct Tools | Utilize the appropriate tools for maintenance to prevent accidents and damage. |

| Maintain Clean Workspace | Keep the area tidy to minimize risks of trips and falls. |

Maximizing Mower Performance

To achieve optimal results from your lawn care equipment, it is essential to focus on enhancing its overall efficiency and effectiveness. Regular maintenance and attention to various components can significantly impact the machine’s operation, ensuring it runs smoothly and delivers a pristine cut.

Regular Maintenance Practices

Maintaining your mower involves several key practices that contribute to its longevity and performance. Frequent inspections, cleanings, and replacements of worn-out parts play a crucial role in keeping the equipment in peak condition. Consider implementing a routine maintenance schedule to address these tasks.

Upgrading Key Components

Investing in high-quality replacement components can elevate the performance of your mower. Upgrades may include sharper blades, improved filters, and more efficient belts, which can enhance cutting efficiency and reduce strain on the engine.

| Maintenance Task | Frequency | Importance |

|---|---|---|

| Inspect Blades | Every use | Ensures clean cuts |

| Change Oil | Every season | Improves engine life |

| Clean Air Filter | Monthly | Enhances air flow |

| Check Belts | Every few uses | Prevents breakdowns |

Customer Support and Resources

When it comes to maintaining and repairing outdoor machinery, having access to reliable assistance and comprehensive resources is essential. Users can benefit from various support options that facilitate the identification of issues and the acquisition of necessary components. This section aims to highlight the available avenues for obtaining help and valuable information regarding machinery upkeep.

Technical Assistance: For any inquiries or troubleshooting, a dedicated support team is often available to provide expert advice. Users can reach out via phone or online chat to get immediate assistance. It is advisable to have the model information handy for more efficient service.

Online Resources: Many manufacturers offer extensive online libraries that include user manuals, maintenance guides, and instructional videos. These resources can be invaluable for users looking to perform repairs or upgrades themselves. It is recommended to regularly check these platforms for updates or new information.

Community Forums: Engaging with fellow users through community forums can be a great way to share experiences and solutions. Many platforms provide a space for discussions where individuals can ask questions, share tips, and learn from one another’s expertise.

Local Dealers: Authorized dealers often carry a variety of components and accessories. They can also provide professional advice and service options for those who prefer assistance from trained technicians. Establishing a relationship with a local dealer can enhance the overall ownership experience.