Filters: These elements keep

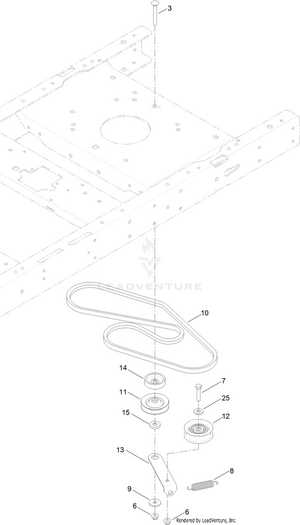

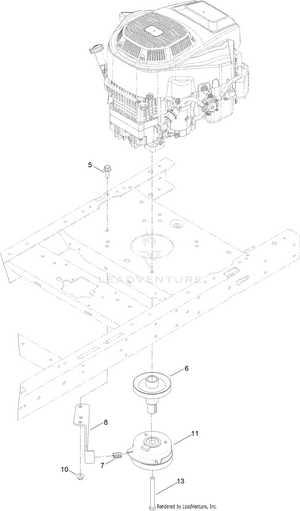

Understanding the SW5000 Cutting Deck Assembly

The cutting deck is a crucial component designed for delivering an efficient and smooth mowing experience. Its design focuses on optimizing grass cutting, ensuring even trimming across various terrains. Understanding the structure of this mechanism can greatly aid in maintaining its efficiency and diagnosing potential issues.

Key Components of the Mowing Platform

The assembly consists of multiple interconnected parts that work together to achieve precise cutting. Central to this are the blades, which rotate at high speeds to trim the grass evenly. These blades are mounted onto a sturdy spindle system that ensures stability and smooth operation. The platform itself is designed to be adjustable, allowing users to set the desired cutting height for different types of terrain.

Maintaining Optimal Performance

Proper maintenance of the cutting platform is essential for extending its lifespan and ensuring high-quality results. Regular inspection

Engine Specifications and Performance Details

This section provides an overview of the engine’s characteristics and operational efficiency. Understanding these elements is crucial for assessing the machine’s capabilities and ensuring optimal functionality during use.

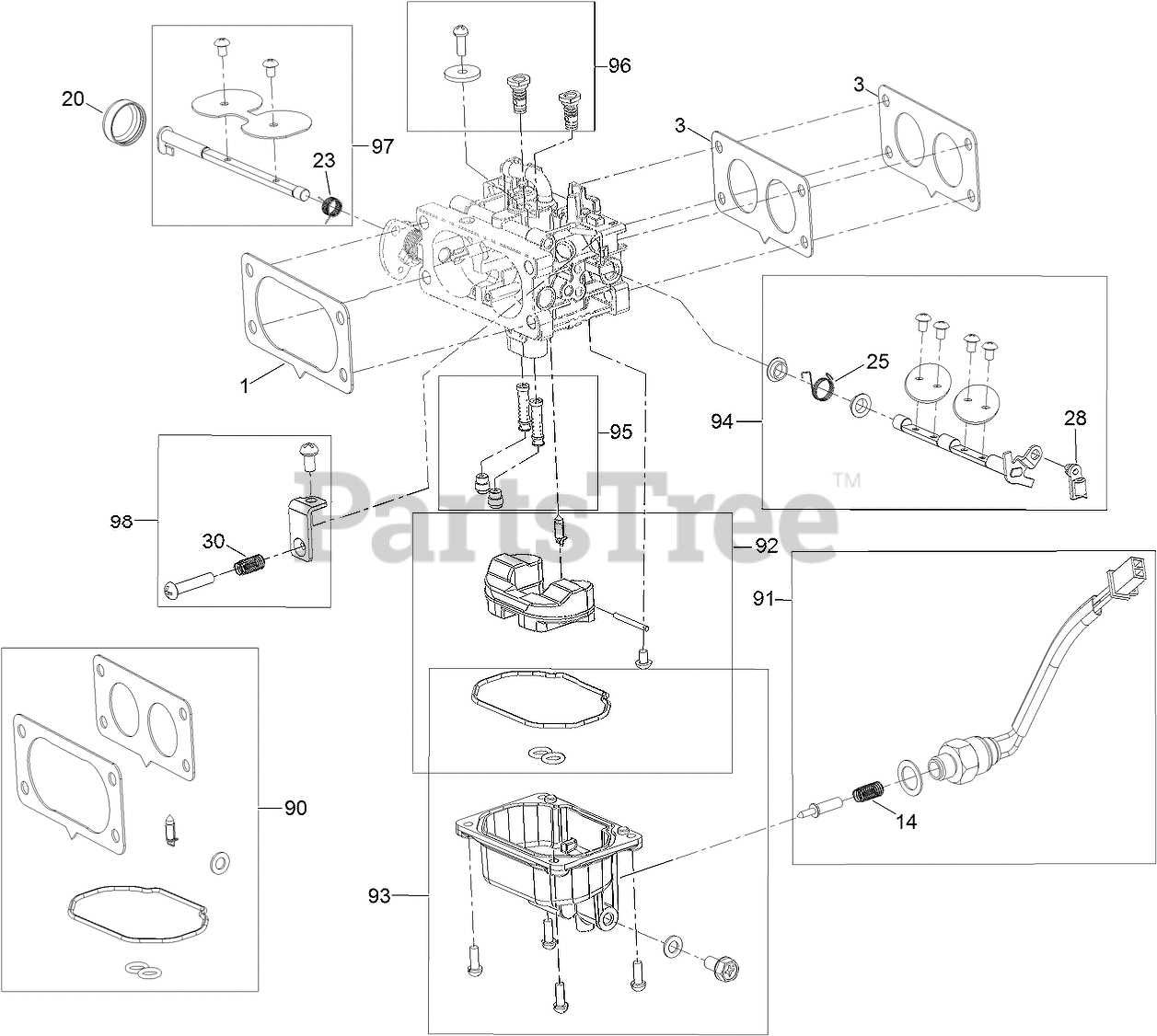

Engine Type: The power source is typically a four-stroke configuration, renowned for its reliability and fuel efficiency. This design contributes to a smoother operation and reduces emissions compared to two-stroke counterparts.

Displacement: With a substantial engine displacement, this unit delivers ample torque and horsepower, facilitating effortless maneuverability across various terrains.

Cooling System: Equipped with an air-cooled mechanism, the engine maintains an optimal temperature under load, preventing overheating and enhancing durability.

Fuel System: Featuring a robust carburetor, the fuel delivery system ensures consistent performance and responsiveness, allowing for quick acceleration and smooth operation.

Power Output: The engine’s output is generally rated at a significant horsepower, enabling it to tackle challenging tasks with ease, thus improving productivity.

Torque: With high torque ratings, the engine provides excellent pulling power, making it suitable for a variety of applications.

Operational Efficiency: Designed for minimal fuel consumption, this engine type enhances overall efficiency, leading to reduced operating costs and extended working hours.

Safety Mechanisms and User Precautions

Ensuring safety while operating machinery is paramount. Understanding the built-in protective features and following recommended practices can significantly reduce the risk of accidents and enhance the overall user experience. This section will explore the essential safety mechanisms integrated into the equipment and outline precautions that operators should take.

Key Safety Features

- Emergency Stop Button: A prominently placed button that halts all operations instantly in case of an emergency.

- Safety Guards: Physical barriers designed to prevent contact with moving parts, minimizing the risk of injury.

- Engine Shutdown Sensors: Automatic systems that turn off the engine if critical parameters are exceeded, such as overheating or oil pressure loss.

- Foot Pedal Interlock: Requires the operator to engage the foot pedal to start the machine, ensuring hands are free and focused on control.

User Precautions

- Read the operator’s manual thoroughly before use to familiarize yourself with the machinery’s functions and safety features.

- Always wear appropriate personal protective equipment (PPE), including gloves, eye protection, and sturdy footwear.

- Inspect the equipment regularly for any signs of wear or damage, addressing any issues before operation.

- Maintain a clean work area free from obstacles to ensure safe maneuverability.

- Never operate the machine while under the influence of substances that may impair judgment or coordination.

By adhering to these safety measures and understanding the mechanisms in place, users can contribute to a safer operating environment and promote longevity of the equipment.

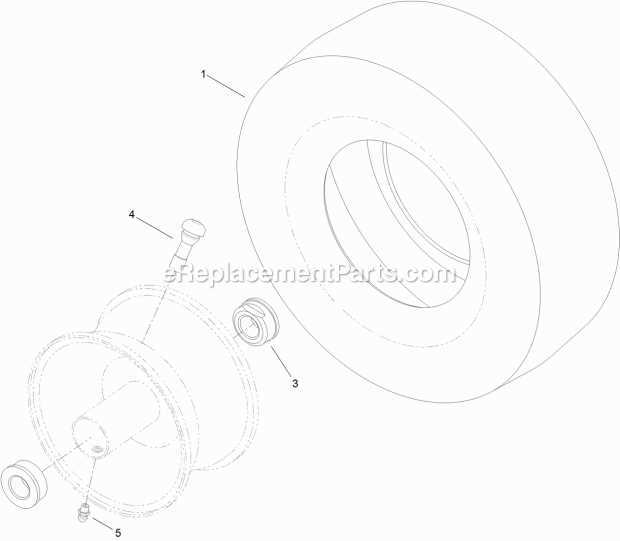

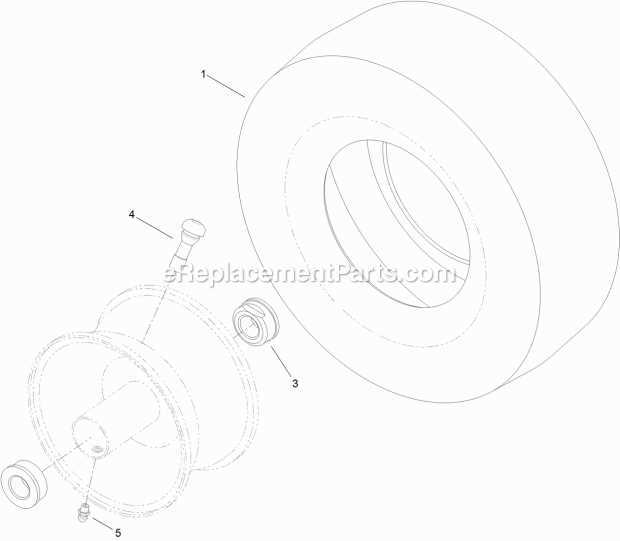

Blade System and Replacement Process

The cutting mechanism is a critical component of any mowing device, designed to efficiently trim grass and ensure a clean finish. Understanding its structure and how to maintain or replace it is essential for optimal performance and longevity. This section outlines the system’s key features and provides a step-by-step guide for changing the blades when necessary.

Key Features of the Cutting Mechanism

- Blade Type: The mechanism typically utilizes high-quality steel blades designed for durability and effective cutting.

- Adjustment Mechanism: Many systems allow for height adjustments to achieve the desired grass length.

- Protection Features: Safety guards are often included to protect users from debris and ensure safe operation.

Steps for Blade Replacement

- Preparation: Ensure the device is powered off and the engine is cool. Gather necessary tools, such as a wrench and safety gloves.

- Access the Cutting Mechanism: Raise the deck and secure it in position to gain access to the blades.

- Remove the Old Blades: Carefully unfasten the bolts holding the blades in place, taking care to remember the orientation.

- Install New Blades: Position the new blades as per the manufacturer’s instructions and secure them with bolts.

- Check Alignment: Ensure the blades are aligned correctly and adjust if necessary to prevent uneven cutting.

- Lower the Deck: Once everything is secure, lower the deck back into its operating position.

- Test Run: Start the engine and test the mower to ensure everything functions smoothly.

Regular maintenance of the cutting system will enhance the efficiency and effectiveness of the mowing equipment. Keeping an eye on blade condition and knowing how to replace them can prevent issues and extend the life of the machinery.

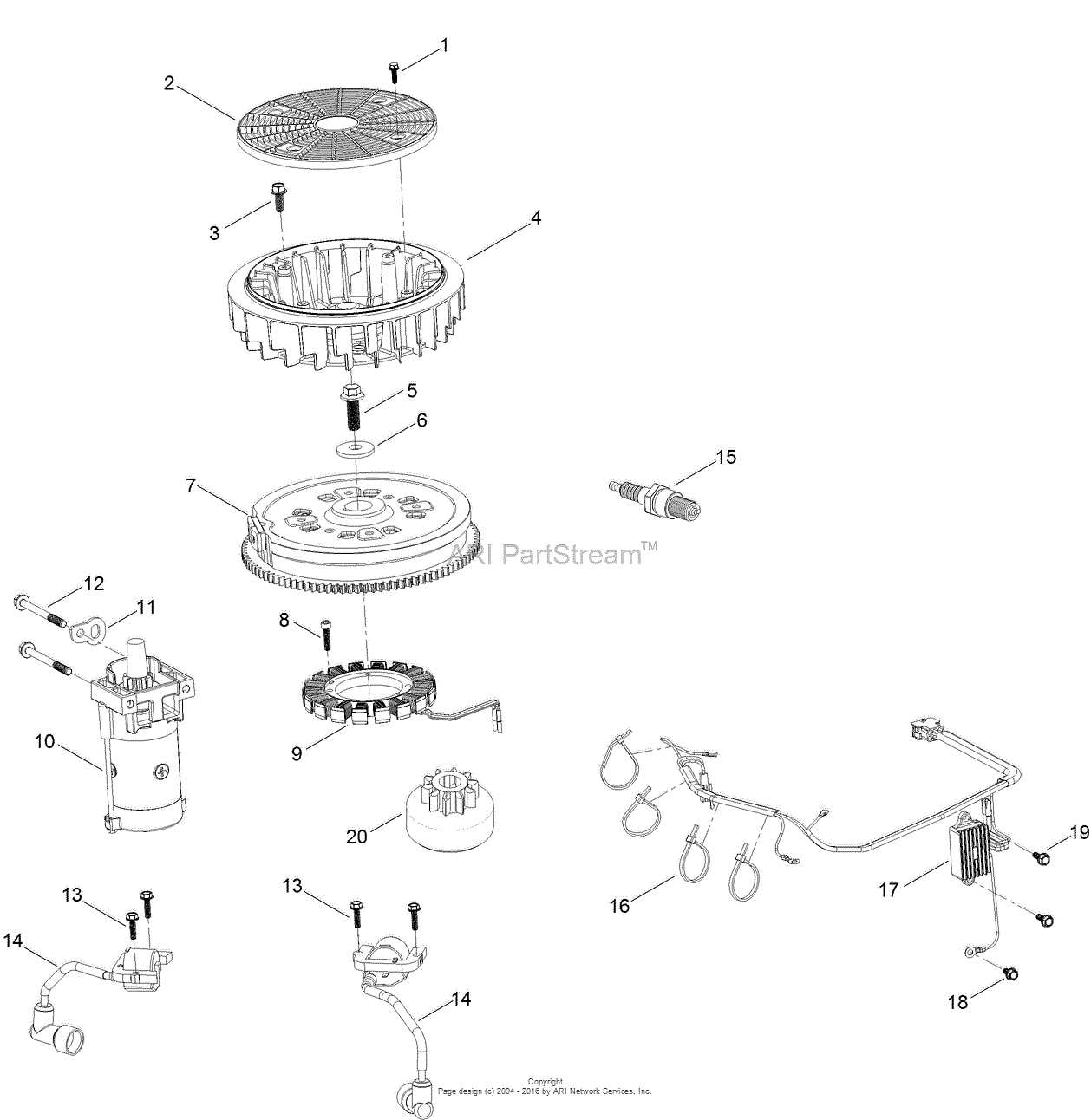

Electrical System Overview for DIY Repairs

The electrical framework of a riding mower plays a crucial role in its overall functionality. Understanding this system is essential for anyone looking to perform maintenance or repairs. A well-organized setup ensures that the machine operates smoothly and efficiently, providing reliable performance throughout its usage.

In essence, the electrical system comprises several key components, including the battery, wiring harness, ignition switch, and various sensors. Each part contributes to the mower’s ability to start, run, and respond to operator commands. Regular inspection of these elements can prevent potential issues, ensuring longevity and optimal operation.

For those embarking on DIY repair projects, familiarizing oneself with the layout and function of each component can be highly beneficial. This knowledge enables users to diagnose problems effectively and execute necessary repairs with confidence. Furthermore, having access to a comprehensive visual representation can simplify the repair process, making it easier to locate specific parts and understand their interconnections.

Safety is paramount when working with electrical systems. Always disconnect the power source before conducting any maintenance to avoid accidents. Additionally, using appropriate tools and protective gear will enhance safety during the repair process.

By gaining a clear understanding of the electrical configuration, enthusiasts can take proactive steps to ensure their equipment remains in peak condition. Whether it’s replacing a faulty switch or rewiring a connection, the ability to navigate this system empowers users to maintain their machines effectively.

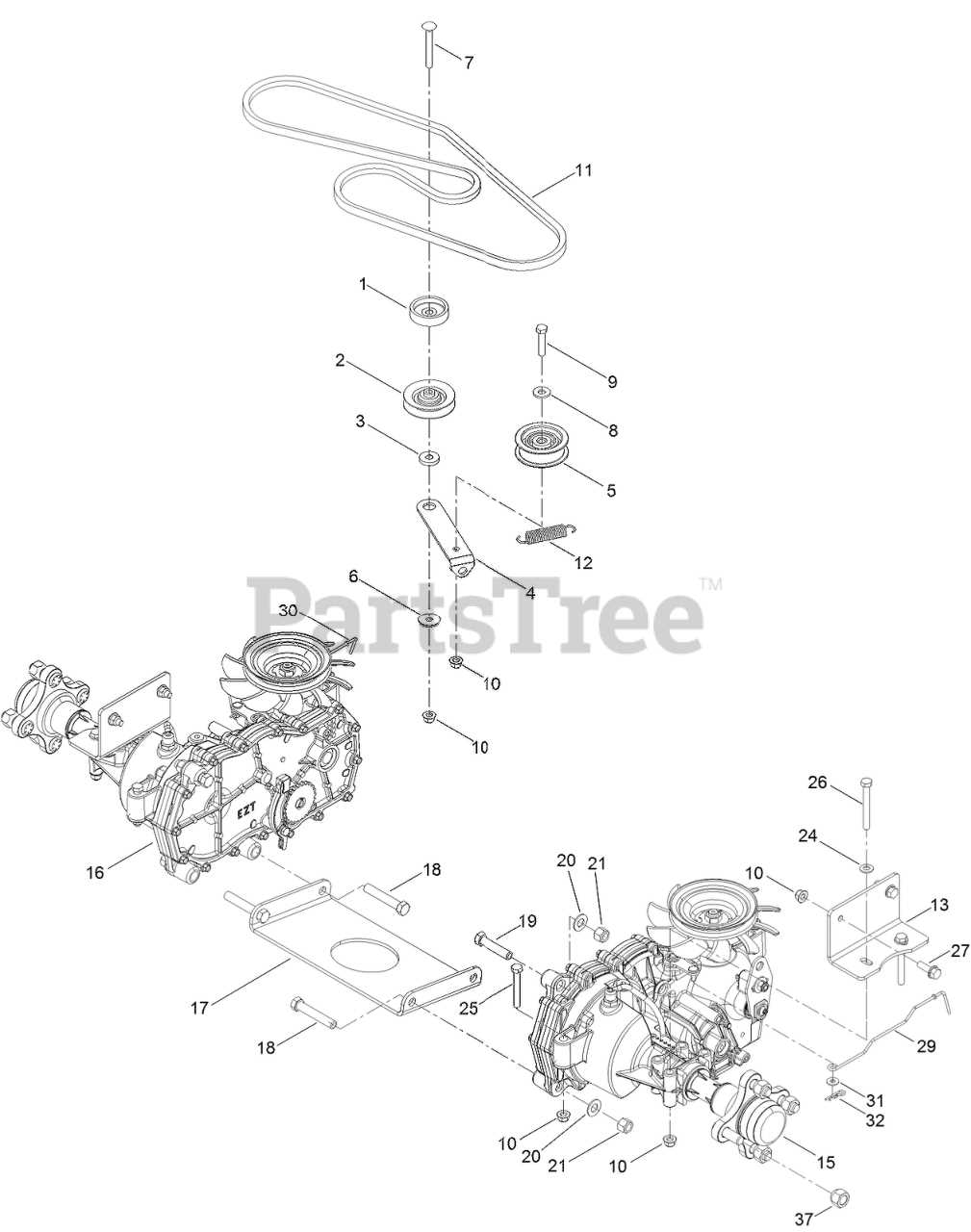

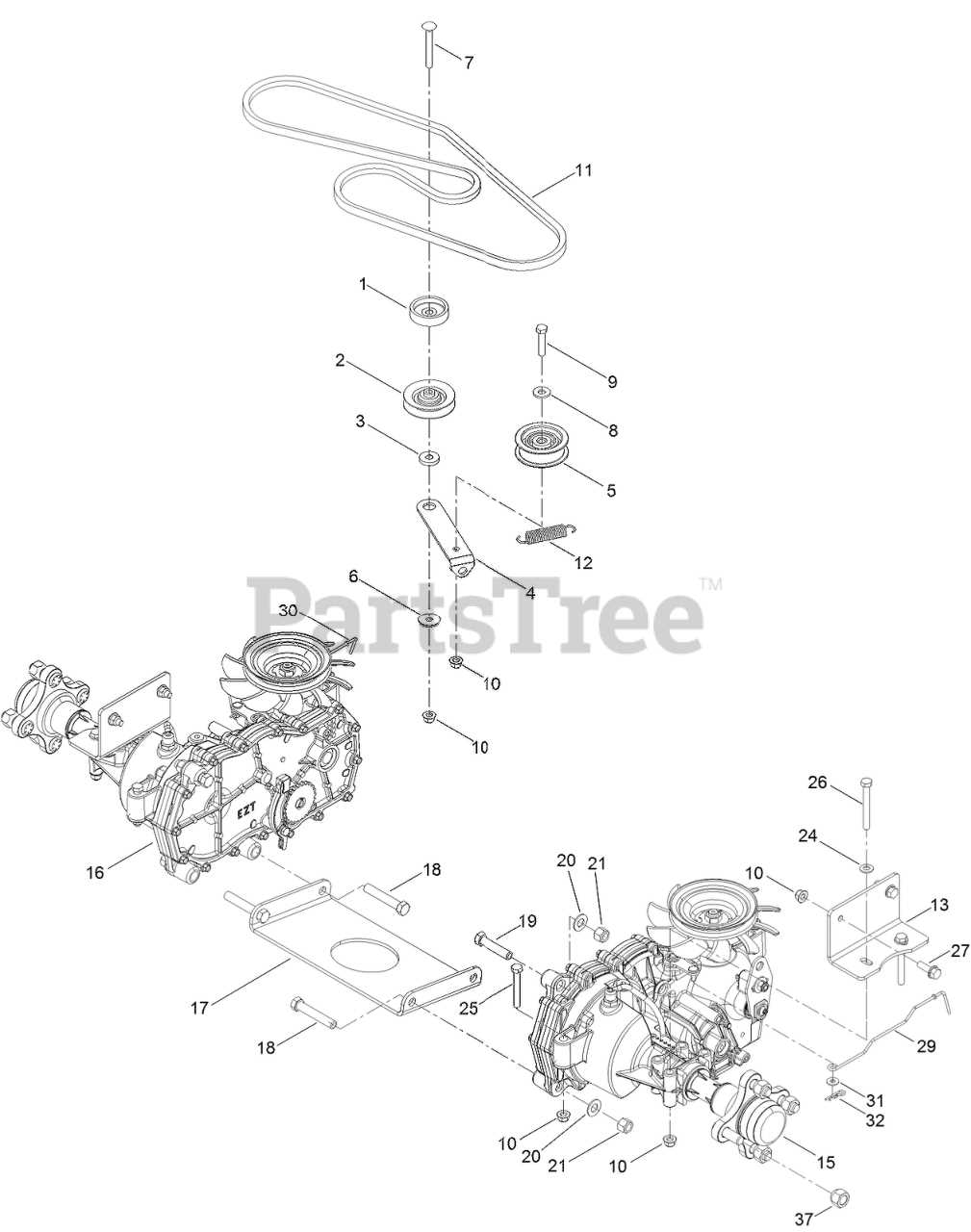

Hydraulic System and Steering Control Insights

The efficiency of the hydraulic system and steering mechanism plays a vital role in the overall performance of mowing equipment. This section delves into the intricacies of these systems, highlighting their components, functions, and importance in achieving optimal maneuverability and responsiveness.

Hydraulic systems convert fluid power into mechanical energy, enabling smooth operation and precise control of various functions. Steering control, closely linked to the hydraulic setup, ensures that the operator can navigate effortlessly, enhancing user experience and reducing physical strain.

| Component |

Function |

| Hydraulic Pump |

Generates flow and pressure to drive the system |

| Control Valve |

Regulates the direction and flow of hydraulic fluid |

| Actuator |

Converts hydraulic energy into mechanical motion |

| Reservoir |

Holds hydraulic fluid for system operation |

| Steering Cylinder |

Facilitates turning by controlling wheel angle |

Understanding the interplay between these elements is essential for maintenance and troubleshooting. Regular inspection and proper care of the hydraulic components ensure long-lasting performance and reliability, leading to enhanced productivity.