The intricate workings of any machine rely heavily on the seamless interaction of various essential elements. Each element plays a vital role in ensuring smooth operation, contributing to the overall functionality and performance. Knowing how these components connect and influence one another helps in diagnosing issues and maintaining efficiency over time.

Proper maintenance is critical to extending the lifespan of such systems. By examining detailed illustrations of the internal configuration, you can gain a deeper understanding of the structural relationships within the machine. This knowledge is indispensable when it comes to performing repairs, replacements, or upgrades, allowing users to keep the equipment running at its best.

Additionally, reviewing comprehensive layouts can simplify troubleshooting, offering clarity on how each element fits into the larger framework. This systematic approach allows for more precise adjustments, ensuring optimal performance while reducing the risk of malfunction.

Understanding Key Components of Toro Dingo

In this section, we will explore the essential mechanical elements and operational systems that form the foundation of a versatile compact utility machine. By examining these elements, you’ll gain a better understanding of how the equipment functions as a cohesive unit to accomplish various tasks in challenging environments.

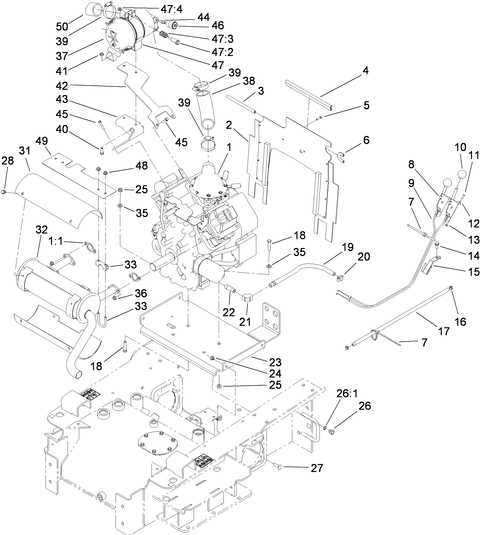

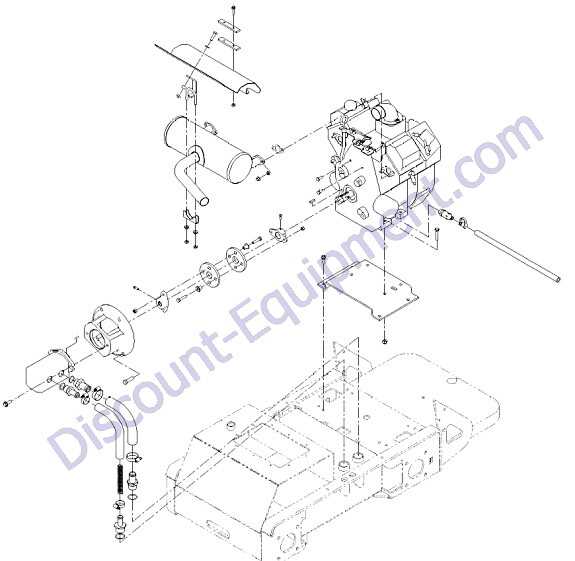

Core Drive System

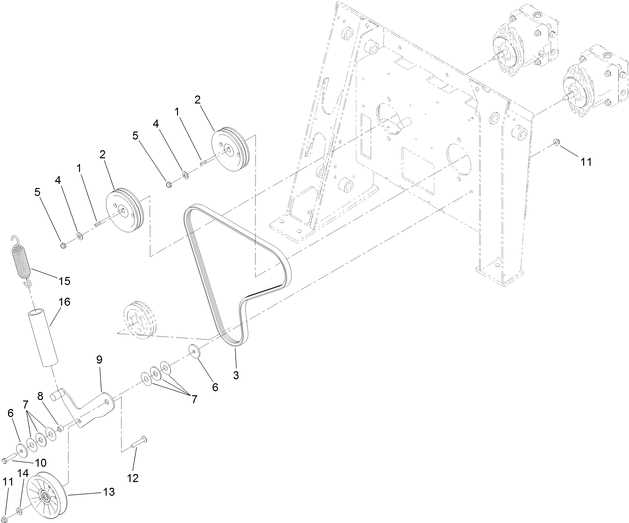

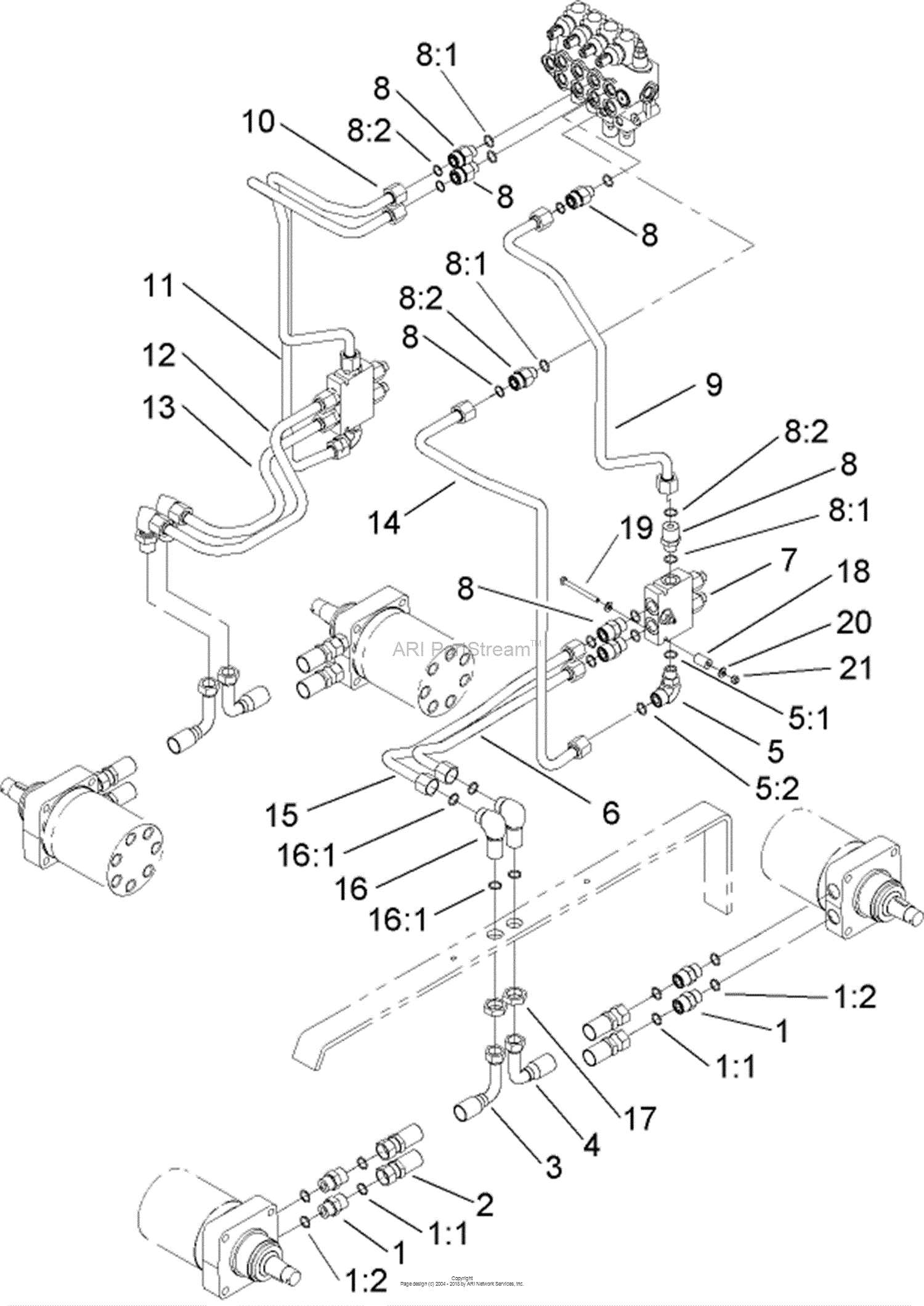

The drive mechanism is responsible for transferring power from the engine to the wheels or tracks, ensuring smooth movement across different terrains. It includes critical components like the transmission, hydraulic pumps, and motors. Each of these plays a significant role in maintaining consistent performance and maneuverability.

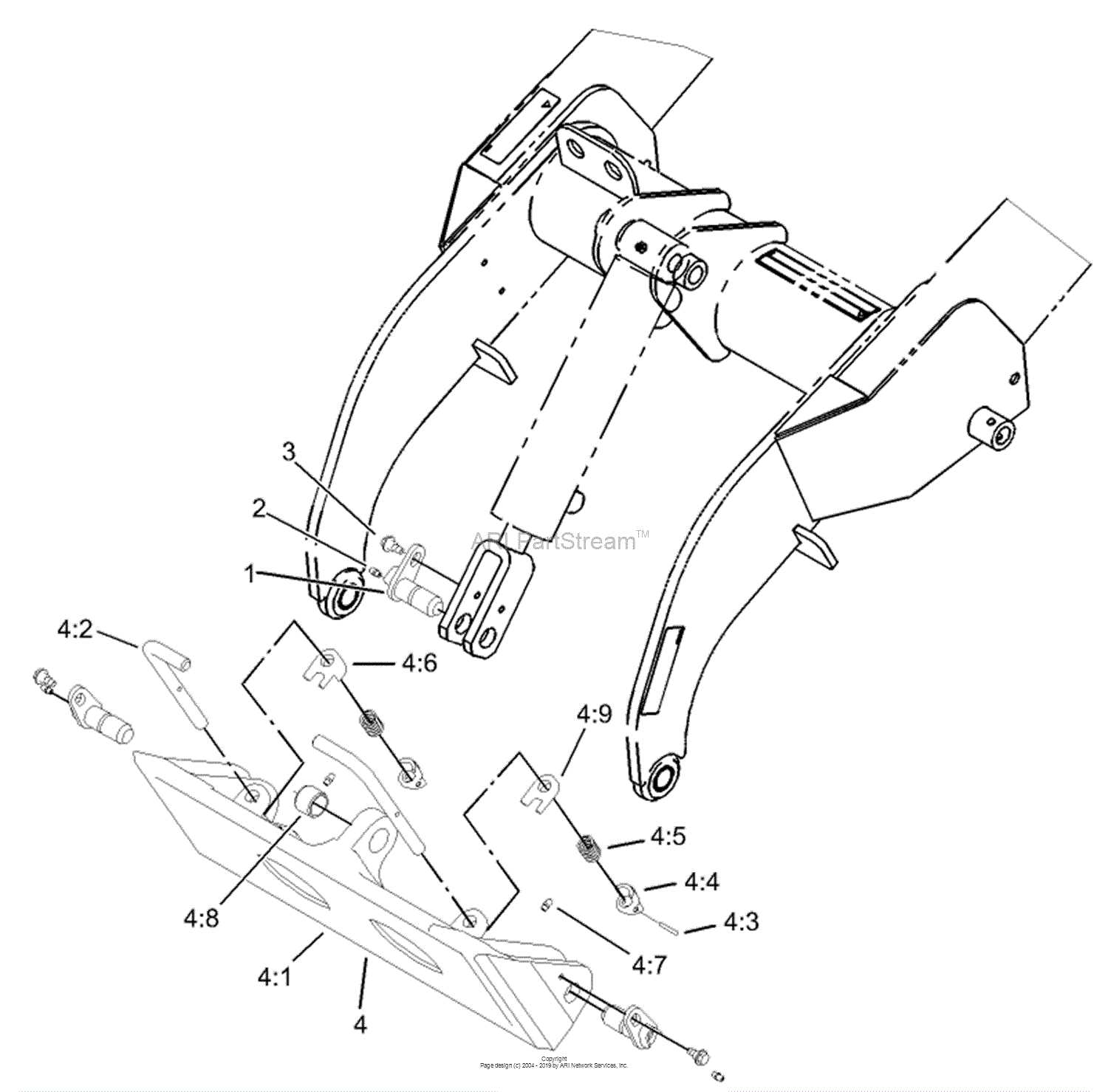

Attachment Interfaces

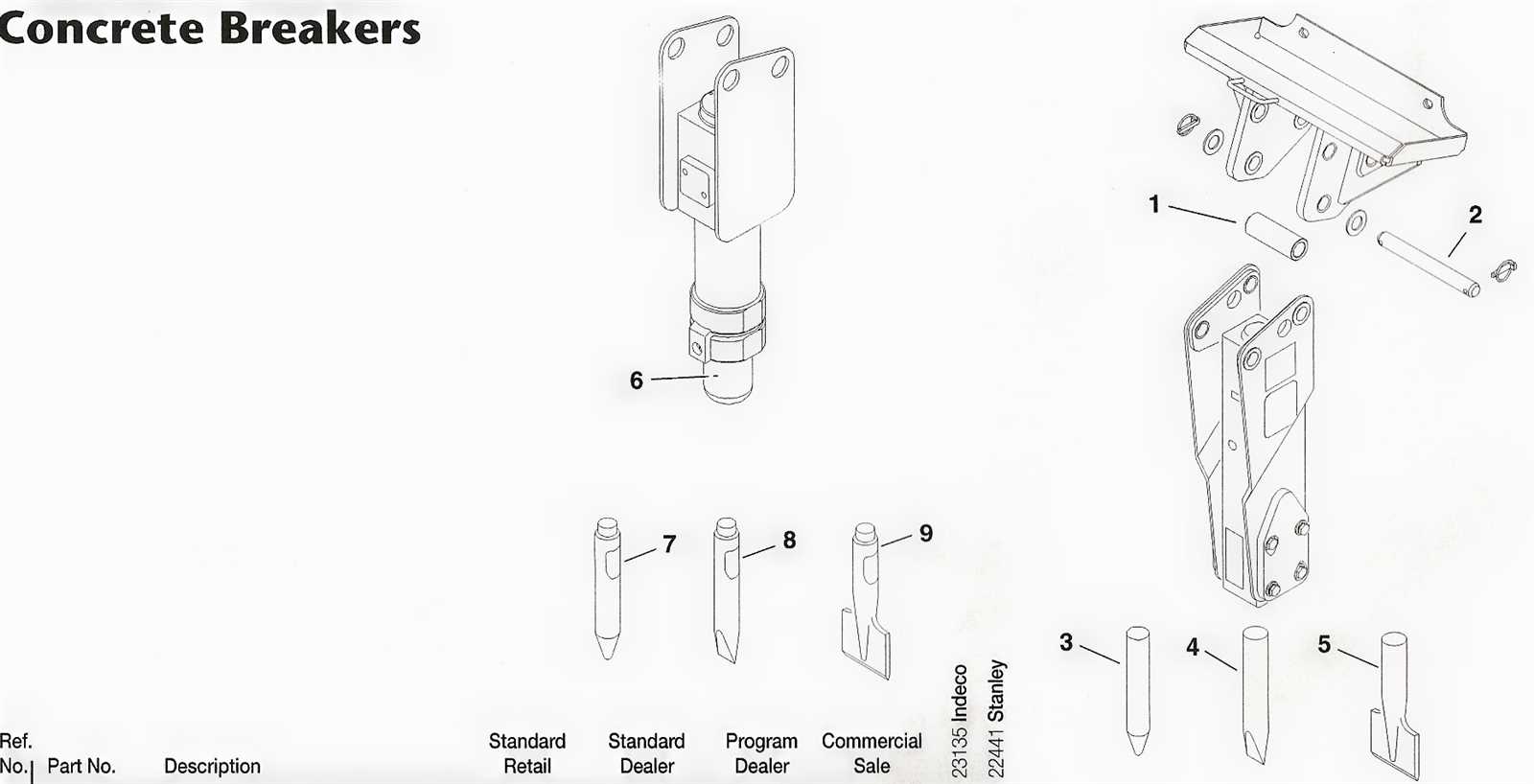

A pivotal aspect of this type of equipment is its adaptability to a wide range of tools. The interfaces that allow the connection of attachments must be sturdy and reliable. The mounting systems and hydraulic couplings ensure secure attachment and efficient operation of auxiliary equipment, allowing for seamless transitions between different tasks.

Regular maintenance and inspection of these components are crucial for ensuring optimal performance and longevity of the machine.

Drive System Breakdown

The drive system in any compact utility loader is a crucial component, ensuring smooth and efficient movement across different terrains. Understanding its inner workings can help operators maintain optimal performance and address potential issues early. This section explores the key elements that contribute to the effective operation of this mechanism, focusing on the interaction between its primary parts.

| Component | Function | |||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Hydraulic Motors | Power the wheels or tracks, converting hydraulic energy into mechanical motion. | |||||||||||||||||||||

| Control Valves | Regulate the flow of hydraulic fluid, ensuring precise control over speed and direction. | |||||||||||||||||||||

| Pumps | Generate hydraulic pressure, supplying the necessary force to drive the loader. | |||||||||||||||||||||

| Transmission | Distributes power from the engine to the hydraulic system, coordinating the movement of the loader. |

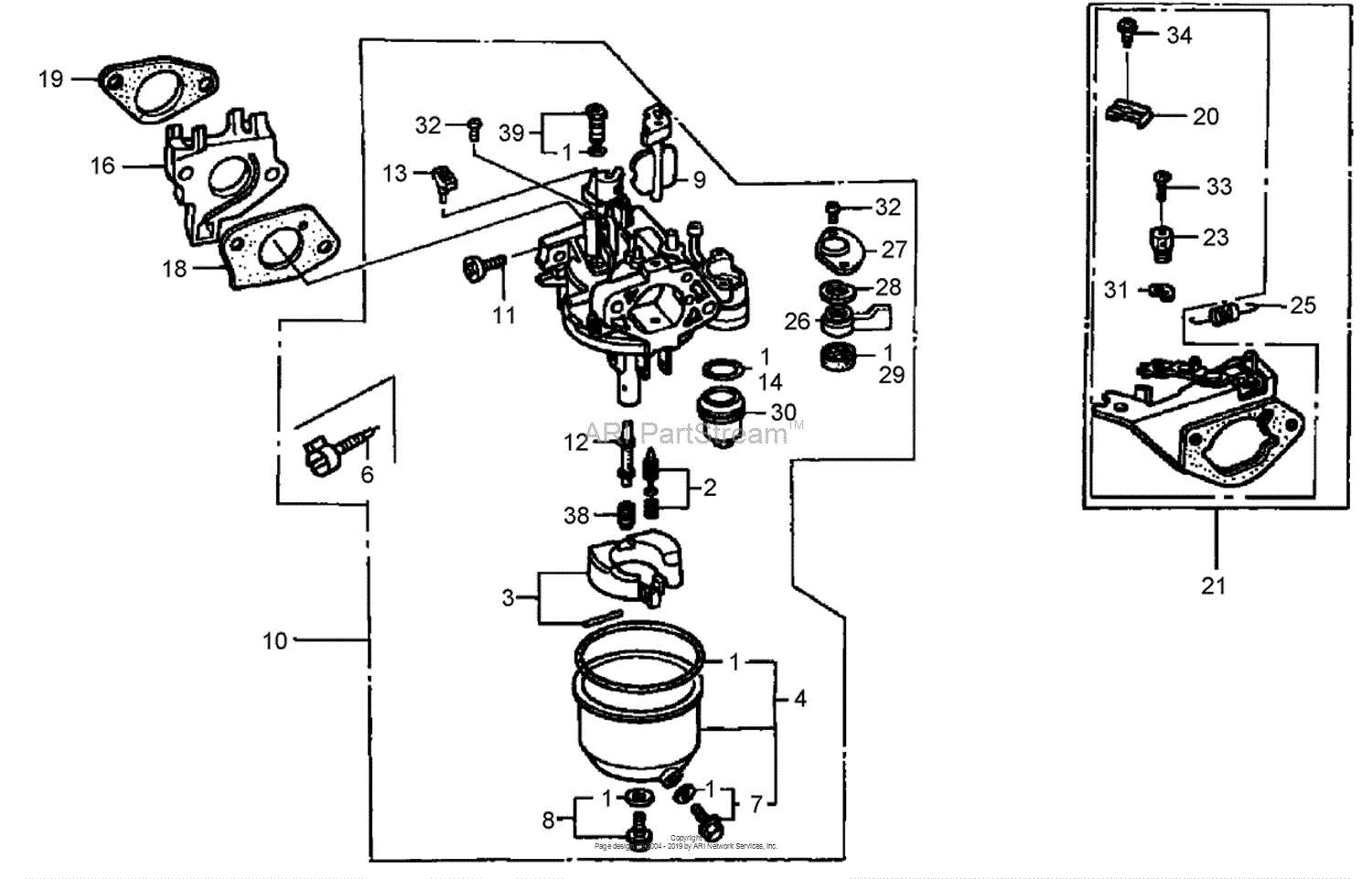

Engine Parts and Their FunctionUnderstanding the components of an engine is crucial for maintaining its performance and longevity. Each element plays a specific role in the smooth operation of the entire system. By recognizing the purpose and function of these elements, users can effectively troubleshoot issues and ensure proper maintenance. The cylinder block forms the main structure of the engine, housing critical elements like pistons and coolant passages. It provides the foundation for the engine’s operation, maintaining stability under high pressure. The piston moves within the cylinder, transforming fuel combustion into mechanical energy. This repetitive motion drives the crankshaft, enabling the machine to perform its intended tasks. Meanwhile, the crankshaft converts the linear movement of the piston into rotational motion, essential for transferring power to other parts of the system. Another key element is the camshaft, which controls the opening and closing of the intake and exhaust valves. Its precise timing is essential for proper airflow and exhaust management, directly impacting engine efficiency. Additionally, the fuel injector delivers fuel in a fine mist into the combustion chamber, ensuring the right air-fuel mixture for optimal combustion and power generation. Attachments and Accessories CompatibilityWhen it comes to enhancing the functionality of compact machinery, understanding the compatibility of various add-ons is crucial. These components not only expand the capabilities of the machine but also ensure efficient operation across diverse tasks. By selecting the right accessories, operators can maximize productivity and maintain the longevity of their equipment. Various Add-Ons: The range of available attachments can significantly influence the versatility of your machinery. Common add-ons include buckets, forks, and grapples, each designed for specific tasks. Ensuring these attachments fit well is essential for seamless operation and optimal performance. Accessory Selection: It’s vital to consider compatibility with existing equipment before purchasing additional tools. Different models may have unique specifications, so always consult compatibility guidelines to avoid any issues. Investing in well-matched accessories can enhance workflow and reduce the risk of mechanical problems. Benefits of Compatibility: Utilizing compatible components not only improves efficiency but also enhances safety. Mismatched parts can lead to operational failures or accidents, emphasizing the importance of thorough compatibility checks. Prioritizing well-suited attachments ensures a smoother, safer work experience. In conclusion, understanding the relationship between machinery and its accessories is fundamental for any operator aiming for high performance and reliability. Careful consideration of compatibility can lead to improved outcomes and greater satisfaction in various applications. Fuel System Component Identification

The fuel system is crucial for the proper functioning of any machinery, ensuring that the engine receives the necessary energy to operate efficiently. Understanding the various components within this system is essential for effective maintenance and troubleshooting. Each part plays a specific role in the fuel delivery process, from storage to combustion. Key elements of the fuel system include the fuel tank, which stores the liquid; the fuel pump, responsible for transporting the fuel to the engine; and the fuel filter, which removes impurities to protect the engine from damage. Additionally, fuel lines facilitate the movement of fuel between these components, while the injector ensures an optimal mixture for combustion. Recognizing these parts and their functions allows for better management and repair of the overall system. Proper identification of these components can significantly enhance the efficiency and longevity of the engine. Regular checks and maintenance of each part ensure that the fuel system operates smoothly, preventing potential issues that could lead to costly repairs or operational downtime. Electrical Wiring Layout and Diagram

This section presents a comprehensive overview of the electrical circuitry and layout commonly found in compact utility vehicles. Understanding the arrangement of electrical connections is crucial for troubleshooting and maintenance, ensuring that all components function efficiently and reliably. The electrical wiring is designed to facilitate the seamless operation of various systems within the machine. Each wire serves a specific purpose, connecting key elements such as the ignition, lights, and control panels. Proper identification of these connections is essential for effective repairs and modifications. Key Components: The main components in the circuitry include the battery, fuses, switches, and connectors. Each element plays a vital role in the overall performance of the equipment, contributing to its safety and operational effectiveness. Understanding the Layout: Familiarity with the wiring layout allows operators and technicians to quickly locate issues. Regular inspections and maintenance can help prevent electrical failures and extend the lifespan of the vehicle. In summary, a thorough grasp of the electrical circuitry layout enhances the ability to perform repairs and ensures optimal functionality of the equipment. This knowledge is indispensable for anyone involved in the upkeep and operation of such machinery. Operator Platform Design FeaturesThe design of the operator platform plays a crucial role in enhancing the overall functionality and comfort of compact machinery. This aspect encompasses various ergonomic and operational elements that ensure ease of use and efficiency for the operator. Understanding these design features can significantly improve productivity and user satisfaction. Ergonomic Considerations

Comfort and accessibility are paramount in the design of the operator platform. Features such as adjustable seating, intuitive control placements, and adequate legroom contribute to a more pleasant working experience. Operators can work longer and more efficiently when they are comfortable and positioned correctly. Visibility and ControlEffective visibility is essential for safe and efficient operation. The platform’s design includes strategic positioning of controls and displays, ensuring that the operator has a clear view of the working environment. This feature minimizes blind spots and enhances situational awareness.

Cooling System Parts and Upkeep

The cooling mechanism is essential for maintaining optimal operating temperatures in machinery. Proper functionality prevents overheating and ensures the longevity of components. Regular maintenance and understanding the various elements of this system can significantly enhance performance and reliability. Key Components of the Cooling Mechanism

Maintenance Recommendations

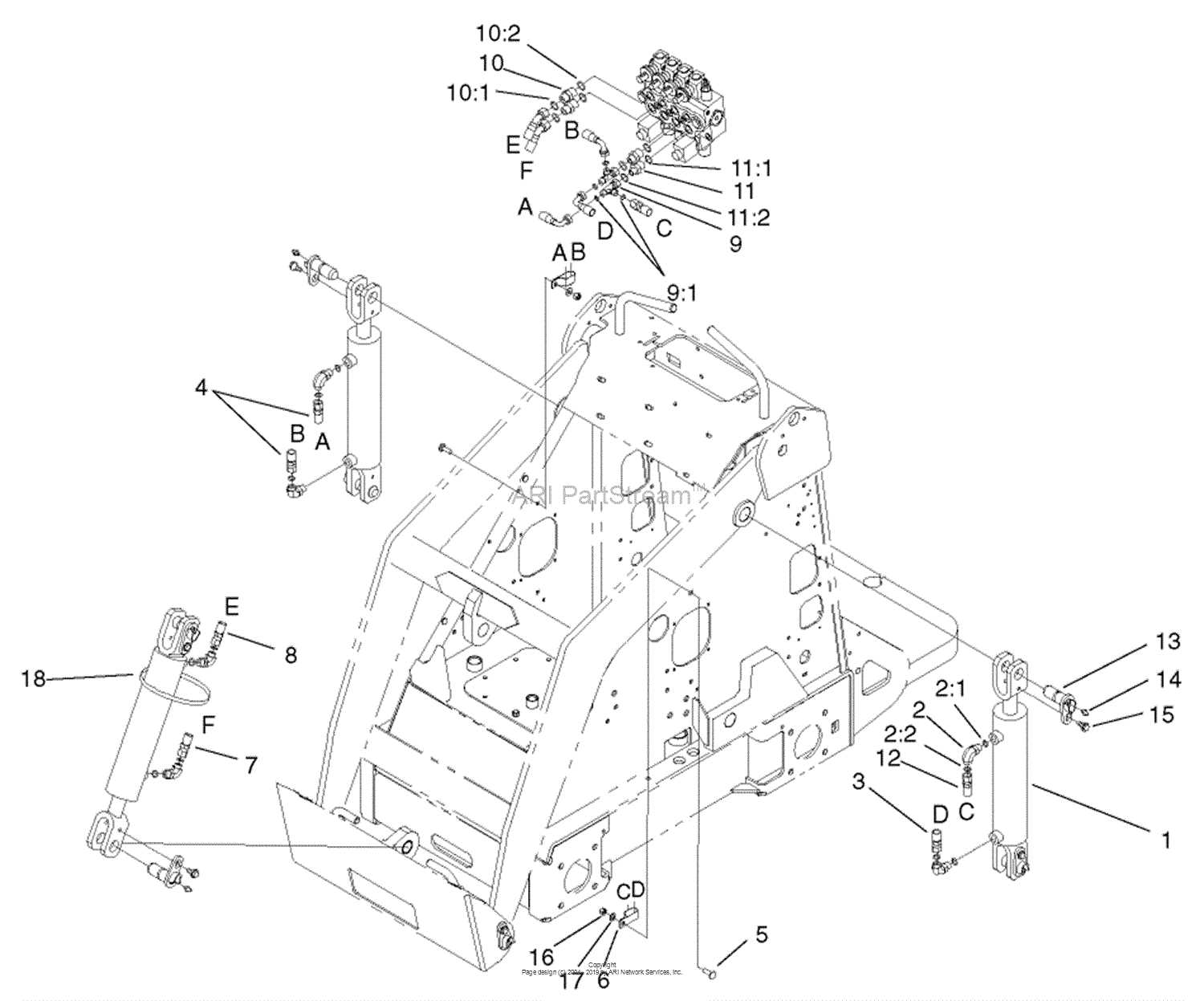

Loader Arm Mechanism DetailsThe loader arm mechanism is a crucial component that facilitates various lifting and carrying tasks in compact machinery. This system is designed to enhance the efficiency of operations by providing a reliable means of handling heavy loads while maintaining stability and control. Understanding the intricacies of this mechanism is essential for optimizing performance and ensuring longevity in demanding environments. The loader arm operates through a series of interconnected parts, including hydraulic cylinders, pivot points, and structural supports. These components work together to achieve precise movements, allowing the operator to maneuver and position loads with ease.

Regular maintenance of the loader arm mechanism is essential for optimal functionality. Inspecting hydraulic fluid levels, checking for leaks, and ensuring that all components are securely fastened can significantly extend the lifespan of the system. Common Replacement Parts for Toro DingoIn the realm of compact utility vehicles, maintaining optimal performance often necessitates the timely replacement of certain components. Understanding which elements are frequently replaced can help ensure the longevity and efficiency of the machinery. Key items that users typically seek to replace include the engine oil filter, essential for maintaining engine health, and the air filter, which prevents dust and debris from entering the engine. Additionally, hydraulic hoses are crucial for effective power transfer and should be inspected regularly for wear and tear. Another important component is the battery, as a reliable power source is vital for starting and operating the equipment. The drive belt is also a common focus for replacement, as it ensures the smooth operation of the transmission system. Lastly, users often look for new treads for enhanced traction and performance on various terrains. |

|---|