When maintaining or repairing outdoor machinery, having a clear overview of its internal setup is crucial. Each mechanism is composed of numerous elements that work together to ensure efficient operation. A well-structured visual guide can simplify this process, helping users quickly identify the necessary components for replacement or service.

By familiarizing yourself with the layout of various sections, you can gain a better understanding of how the different parts interact. This knowledge enables more effective troubleshooting, allowing for swift identification of any faulty areas that require attention. A breakdown of essential elements is often the key to smooth maintenance and repairs.

Whether you’re dealing with an issue related to the engine, cutting system, or wheels, having a structured visual representation can make all the difference. The ability to locate and reco

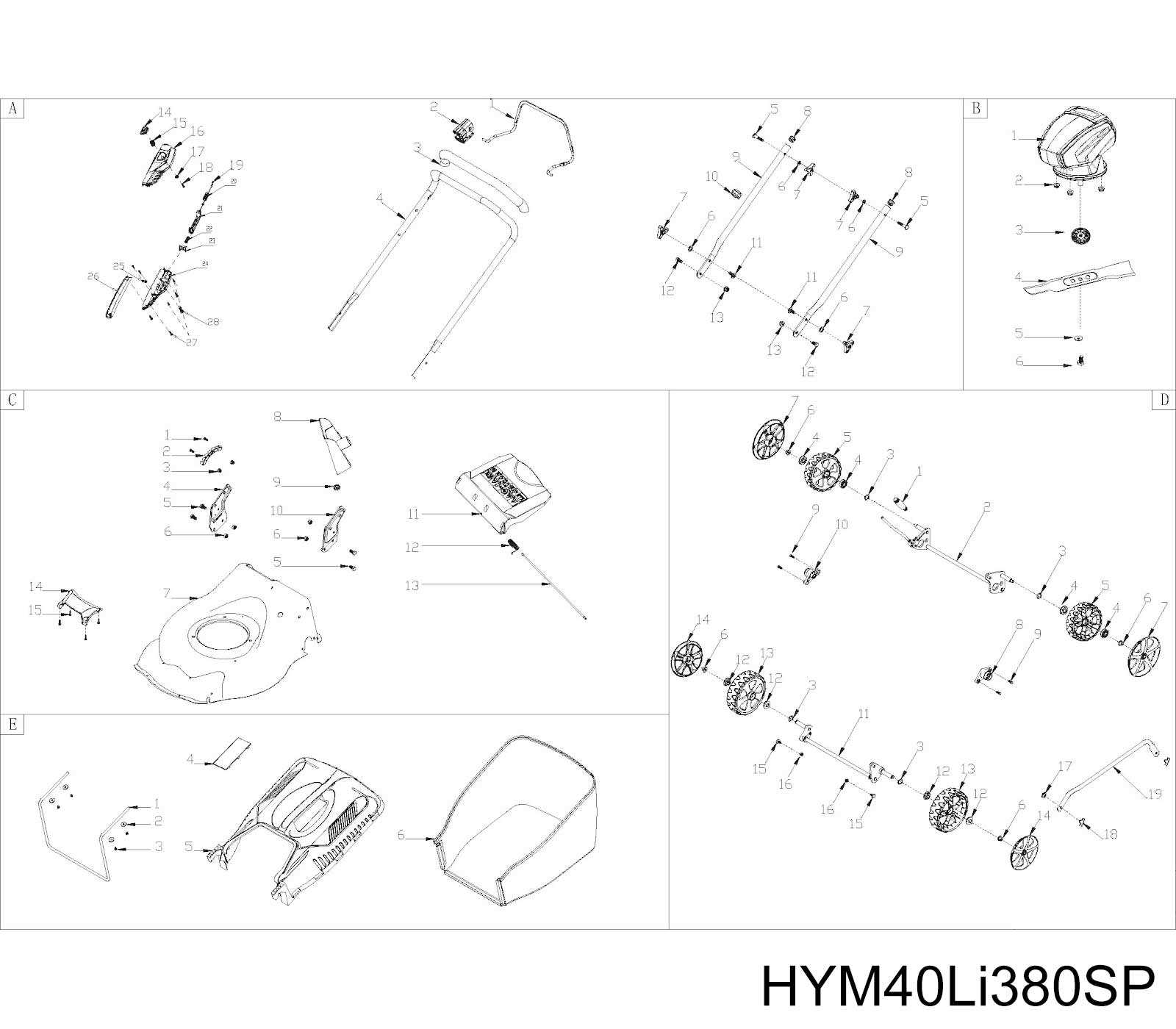

Mower Components Overview

The self-propelled cutting machine is designed with a variety of mechanical elements that work together to ensure efficient operation. Understanding these key components can help maintain the equipment and ensure longevity. Each element has a specific role, contributing to the overall functionality and performance of the machine.

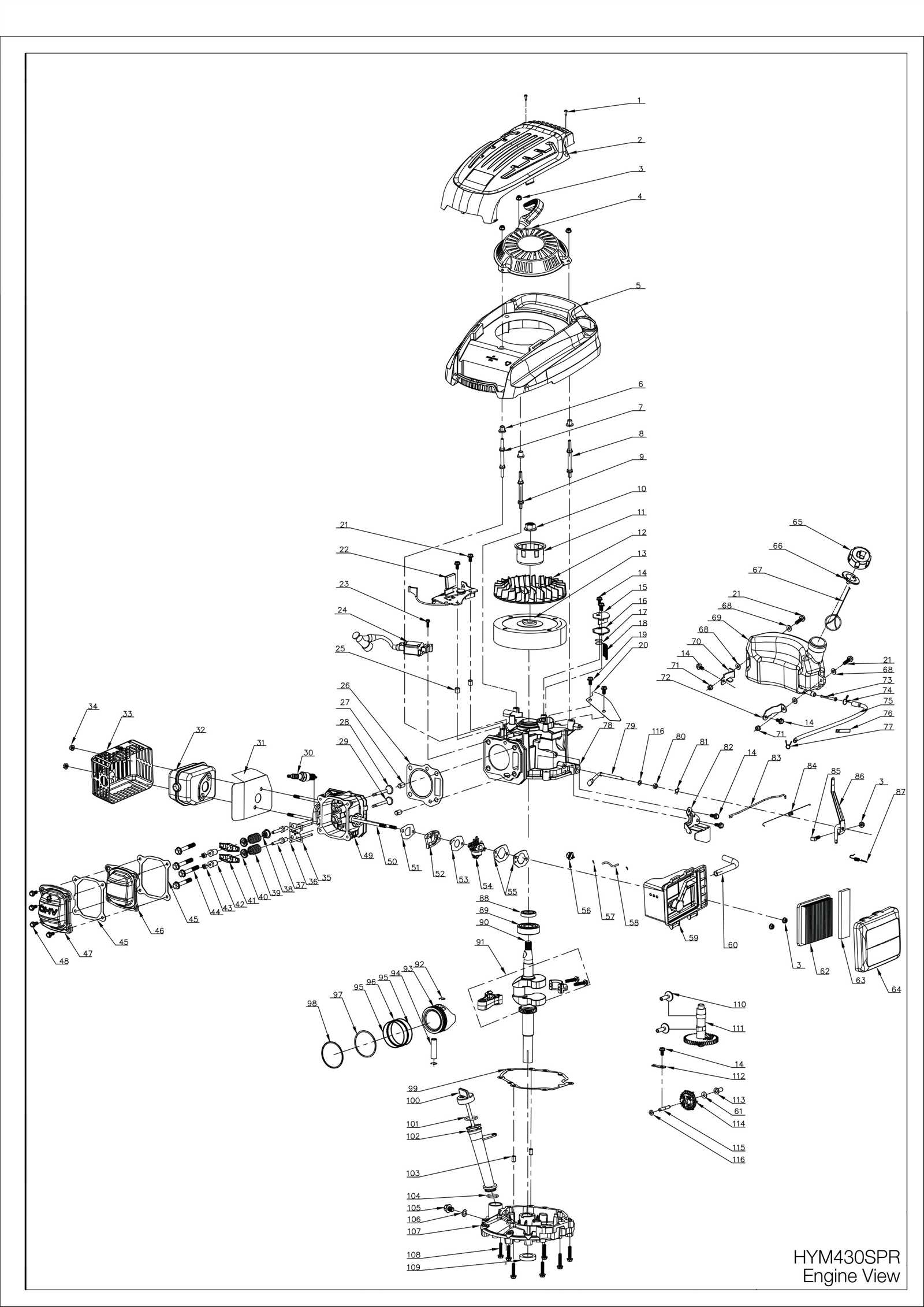

Engine: The core of the machine, responsible for powering all operations. A reliable and well-maintained motor ensures smooth performance and extends the lifespan of the device.

Blade Assembly: A critical part that handles the cutting process. Regular inspection and sharpening keep the cutting smooth and efficient, avoiding uneven results.

Wheels and Drive System: These components allow for easy movement and stability across various surfaces. Proper alignment and maintenance are essential for smooth maneuvering.

Maintenance

Key Components of Toro SR4 Mower

Understanding the essential elements of this machine is crucial for maintaining peak performance and ensuring long-lasting durability. Each part plays a role in delivering efficient cutting, smooth operation, and user-friendly functionality.

Engine and Power System

The engine is the driving force behind the entire system, providing the necessary power for operation. Ensuring the engine is regularly serviced will keep the machine running efficiently and prolong its lifespan.

- Air filter – ensures clean air intake

- Fuel tank – holds fuel supply for the engine

- Oil reservoir – provides lubrication for smooth functioning

- Check the alignment of the blade with the cutting deck.

- Ensure all fasteners are tightened to avoid looseness during operation.

- Inspect the blade for any signs of damage before

Fuel System and Maintenance Tips

Maintaining the fuel system is essential for the long-term performance and efficiency of any equipment. Regular checks and cleaning can prevent breakdowns and ensure smooth operation, especially in outdoor machinery that is frequently exposed to harsh environments. Understanding the basic maintenance tasks helps prolong the lifespan of the engine and its components.

Inspecting the Fuel Lines and Filter

One of the most critical aspects of fuel system care is routinely inspecting the fuel lines for cracks or leaks. Damaged lines can lead to poor performance or even dangerous situations. Additionally, cleaning or replacing the fuel filter ensures that the engine receives a steady flow of clean fuel, free from debris or contaminants.

Preventing Fuel System Issues

Using high-quality fuel and stabilizers is key to avoiding common issues such as clogging or engine misfires. Additionally, regularly running the engine ensures that fuel doesn’t sit idle for too long, which could lead to

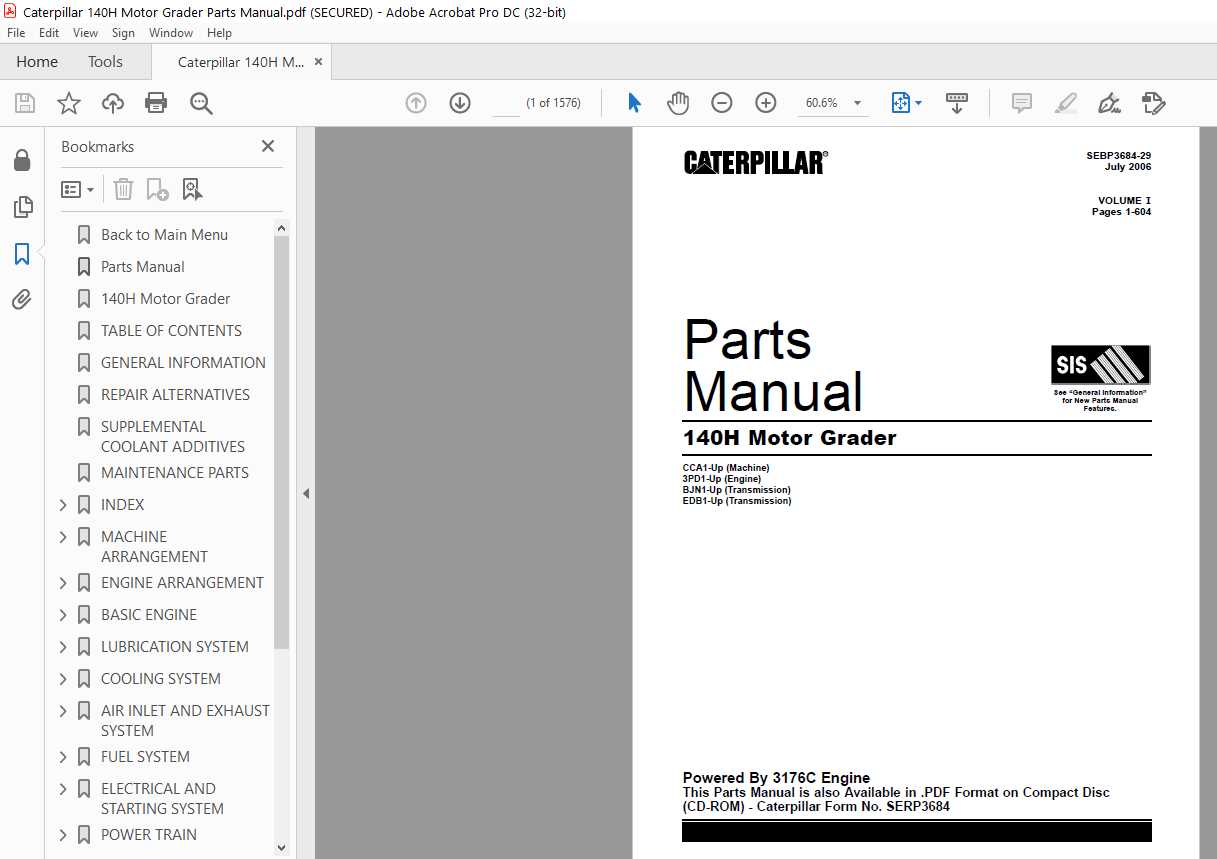

Drive System Parts Breakdown

The drive system is a critical component that enables the equipment to move efficiently. Understanding how it functions is essential for maintaining optimal performance. Below is a detailed overview of the key elements that make up the mechanism responsible for movement.

Main Components

The system consists of several interconnected elements, each playing a vital role in transmitting power. Key elements include the transmission, pulleys, and belts, which work together to ensure seamless motion.

Component Overview

Component Description Transmission Responsible for transferring power from the engine to the wheels. Pulleys Cutting Deck Components Explained

The cutting deck is a crucial element of lawn care machinery, designed to efficiently trim grass and maintain a neat appearance in outdoor spaces. Understanding its components is essential for proper maintenance and optimal performance. Each part plays a specific role, contributing to the overall effectiveness of the machine.

Key Elements of the Cutting Deck

At the core of the cutting deck is the blade assembly, which rotates at high speed to achieve a precise cut. This assembly is often complemented by a belt system that transfers power from the engine, ensuring consistent performance. Additionally, the deck housing provides structural support while preventing grass clippings from escaping during operation.

Support and Adjustment Features

Support wheels are another vital component, allowing the cutting deck to glide smoothly over uneven terrain, minimizing scalping. Furthermore, height adjustment mechanisms enable operators to customize cutting levels, adapting to different grass types and conditions. This combination of features ensures a versatile and efficient cutting experience.

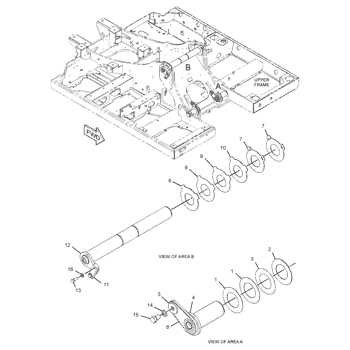

Wheels and Axle Diagram for SR4

The configuration of wheels and axles plays a crucial role in the overall performance and stability of any machinery. Understanding the layout and interaction between these components is essential for effective maintenance and troubleshooting. A well-organized visual representation can greatly aid in comprehending the mechanics involved.

Wheels are fundamental for mobility, providing the necessary traction and support. They come in various sizes and designs to suit different operational needs. The choice of wheels affects the machine’s handling, efficiency, and overall performance.

Axles serve as the central shaft that connects the wheels, allowing them to rotate. Their design must ensure durability and stability, bearing the weight of the machine while facilitating smooth movement. Proper alignment and integrity of the axles are vital for optimal function.

A comprehensive understanding of the wheel and axle arrangement will enhance the effectiveness of any operational task, ensuring reliability and safety during use.

Engine Components and Performance

The efficiency and functionality of any motor heavily rely on its fundamental elements. These components work in unison to ensure optimal operation, influencing both power output and overall efficiency. Understanding how each part contributes to the system is essential for maintaining peak performance.

Key elements include the cylinders, which house the combustion process, and the crankshaft, responsible for converting linear motion into rotational energy. The intake and exhaust systems play crucial roles in managing airflow, directly affecting combustion efficiency. Additionally, fuel delivery mechanisms must precisely balance air and fuel to achieve maximum power without sacrificing efficiency.

Regular maintenance of these components is vital. A well-tuned engine not only improves performance but also extends the lifespan of the entire system. Monitoring wear and tear on essential parts ensures that the engine runs smoothly and efficiently, reducing the risk of breakdowns.

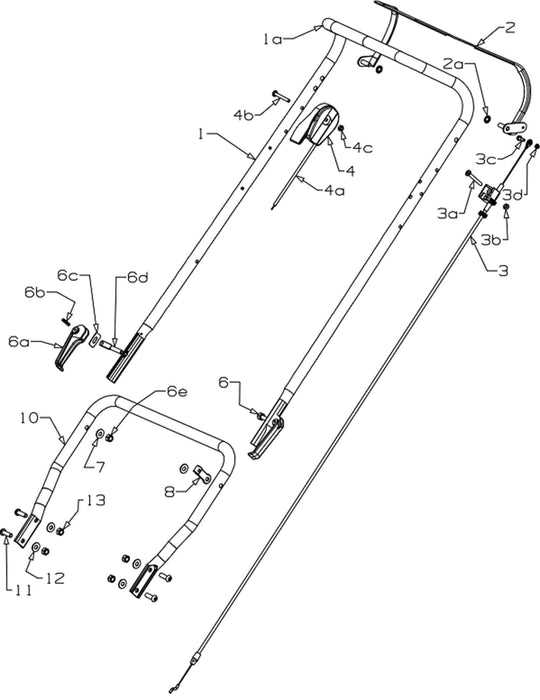

Handle and Control Mechanism Layout

The arrangement of handles and control components plays a crucial role in the overall functionality and user experience of any machinery. Understanding this layout enhances operational efficiency, allowing for intuitive use and precise adjustments. Proper design not only improves handling but also ensures safety during operation.

Key Elements of the Layout

- Grip Design: Ergonomically designed grips ensure comfort during prolonged use.

- Control Placement: Strategic positioning of controls enhances accessibility and minimizes distraction.

- Feedback Mechanism: Incorporating tactile feedback aids the operator in maintaining control.

Benefits of Effective Arrangement

- Increased operational efficiency through quick access to essential controls.

- Enhanced user comfort, reducing fatigue during extended use.

- Improved safety features, allowing for immediate response in critical situations.

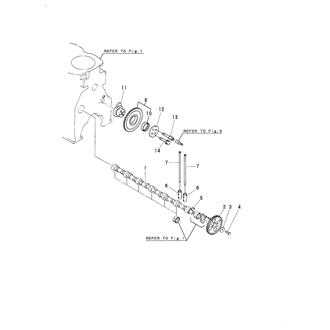

Transmission System and Functions

The transmission system plays a crucial role in ensuring the efficient transfer of power within machinery. It is responsible for conveying energy from the engine to the wheels or blades, allowing for smooth operation and optimal performance. Understanding its components and functions is essential for maintaining and troubleshooting equipment effectively.

Key Components of the Transmission System

- Gearbox: This component adjusts the power and torque delivered to the wheels, facilitating various speeds and loads.

- Clutch: The clutch engages and disengages the engine from the transmission, allowing for smooth starts and stops.

- Driveshaft: It transmits power from the transmission to the wheels, ensuring effective motion.

- Linkages: These connect the various components, allowing for synchronized movement and operation.

Functions of the Transmission System

- Power Transfer: It effectively transfers power from the engine to the drivetrain, enabling movement.

- Torque Modification: The system adjusts torque according to the load and speed requirements, enhancing performance.

- Speed Control: It provides the ability to change speeds, ensuring adaptability in different operating conditions.

- Direction Control: The transmission allows for forward and reverse movement, providing versatility in operation.

Mower Safety Features

Ensuring user safety is paramount when operating lawn maintenance equipment. Various mechanisms and designs are integrated to minimize risks and enhance protection during usage. These features play a crucial role in preventing accidents and ensuring a secure working environment.

One significant aspect is the presence of an automatic shut-off mechanism. This feature stops the blades instantly if the operator loses control or if the device is lifted off the ground, significantly reducing the chance of injury. Additionally, enhanced grip and ergonomic controls allow for better handling, helping users maintain stability while maneuvering.

Moreover, many models include a safety bar that must be engaged to operate the mower. This ensures that the user maintains control at all times, as releasing the bar automatically disables the cutting mechanism. Furthermore, robust guards and shields are designed to deflect debris, protecting the operator from flying objects during operation.

Incorporating these safety enhancements not only improves user confidence but also promotes responsible equipment usage. Adhering to safety protocols and understanding the equipment’s features can lead to a more efficient and secure lawn care experience.

Blade Mechanism and Assembly Guide

The blade mechanism is a critical component in ensuring effective cutting performance. Proper assembly and maintenance are essential for optimal functionality and durability of the equipment. In this section, we will outline the key steps to assemble the blade and ensure it operates smoothly.

Understanding the Blade Mechanism

The blade operates through a combination of mechanical parts that work together to provide a clean and efficient cut. Ensuring that each part is aligned correctly is crucial for preventing wear and tear and maintaining the equipment’s overall performance.