In the world of outdoor machinery, having a clear understanding of the internal structure is essential for effective maintenance and repairs. This section delves into the intricate arrangement of various elements within a specific type of lawn care equipment, aiming to enhance the user’s knowledge and skill in handling such devices.

Grasping the configuration of essential components can significantly improve the efficiency of routine upkeep and troubleshooting. By familiarizing oneself with the visual representation of these elements, operators can pinpoint issues quickly, ensuring optimal performance and longevity of their equipment.

Additionally, this resource offers insights into the relationships between different parts, emphasizing how each contributes to the overall functionality. Whether you’re a seasoned professional or a novice, understanding these connections can lead to more informed decisions during repairs and upgrades.

Toro Z Master 6000 Overview

This section offers a comprehensive look at a top-tier landscaping machine designed for efficiency and performance. The equipment is engineered to handle various tasks, making it a favorite among professionals and enthusiasts alike.

- Robust construction for durability

- Advanced technology for enhanced performance

- Ergonomic design for user comfort

- Variety of attachments for versatility

Ultimately, this machinery excels in delivering results, whether for commercial or residential use. Its innovative features make it a reliable choice in the industry.

Key Features of the Toro Z Master

This high-performance lawn care machine is designed to provide exceptional efficiency and reliability for various landscaping tasks. With advanced engineering and innovative technology, it delivers outstanding results, making it a preferred choice among professionals.

- Powerful Engine: Equipped with a robust engine, it ensures superior performance even in challenging conditions.

- Precision Cutting: The cutting deck is engineered for optimal grass management, promoting a clean and even finish.

- Enhanced Maneuverability: Designed for agility, it allows operators to navigate tight spaces with ease.

- Durable Construction: Built with high-quality materials, it offers longevity and withstands rigorous use.

- User-Friendly Controls: Intuitive controls enhance operator comfort and reduce fatigue during extended use.

These features collectively contribute to a reliable and effective landscaping solution, ideal for both commercial and residential applications.

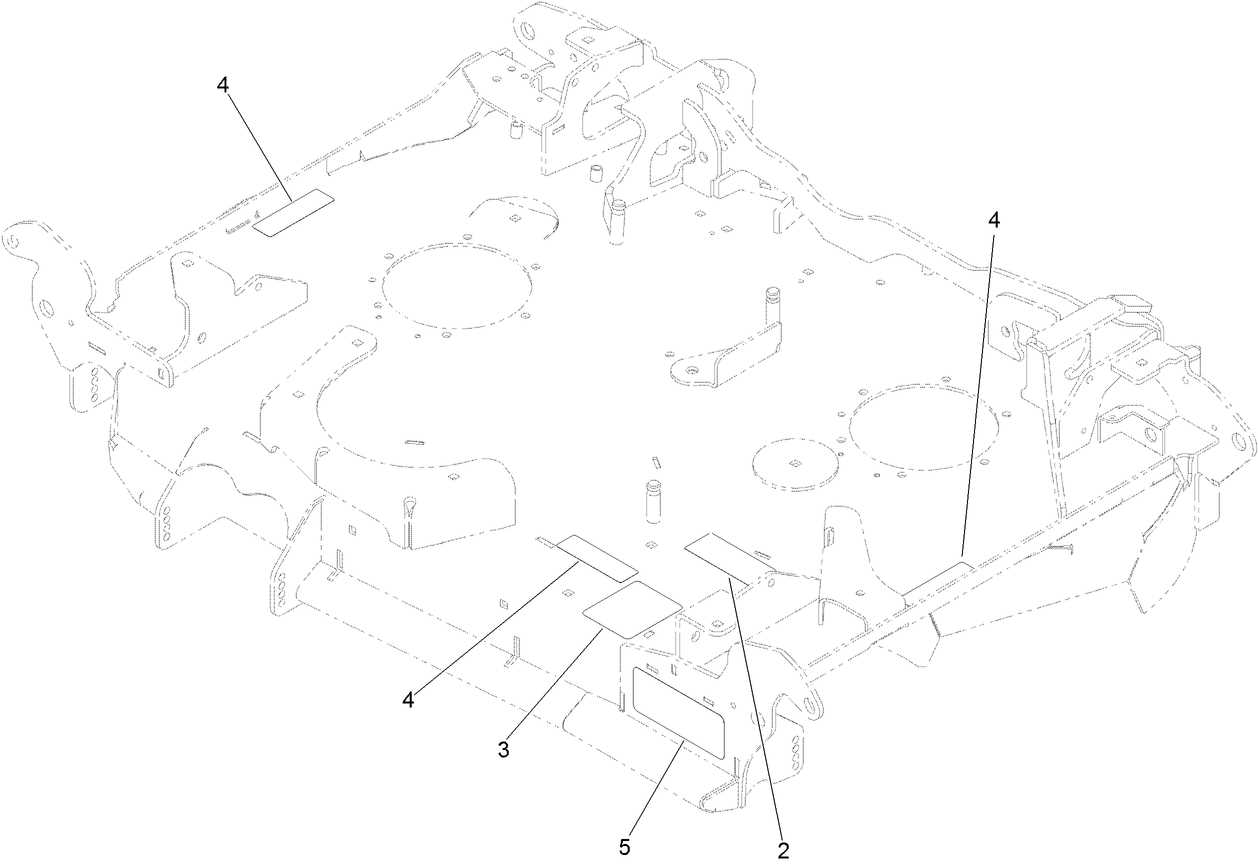

Understanding the Parts Diagram

Comprehending the visual representation of components is essential for effective maintenance and repair. This guide aims to clarify how these illustrations function, enabling users to identify and locate each element within the machinery.

Importance of Visual Representations

Visual representations serve several key purposes:

- Enhance understanding of the assembly

- Facilitate troubleshooting by highlighting connections

- Streamline ordering replacement components

- Assist in ensuring proper reassembly

Navigating the Illustration

To effectively utilize the visual guide, consider the following:

- Familiarize yourself with the overall layout.

- Identify each section and its corresponding components.

- Pay attention to part numbers for accurate ordering.

- Refer to accompanying notes or legends for additional context.

By mastering these elements, users can enhance their proficiency in managing machinery and ensure optimal performance.

Importance of Maintenance Parts

Regular upkeep of equipment is crucial for ensuring optimal performance and longevity. The right components play a vital role in sustaining functionality and preventing unexpected breakdowns. By prioritizing quality replacements and regular checks, users can significantly enhance the reliability of their machinery.

Enhancing Efficiency

Utilizing high-quality replacement components can lead to improved efficiency in operations. When machinery is equipped with the best available elements, it operates smoothly, reducing the risk of interruptions and enhancing productivity. Furthermore, efficient functioning translates into lower energy consumption, making the overall process more economical.

Preventing Costly Repairs

Investing in maintenance items not only extends the life of equipment but also minimizes the likelihood of major repairs. Regular inspections and timely replacements help identify wear and tear before they escalate into serious issues. This proactive approach saves time and resources, allowing users to focus on their core activities rather than dealing with unforeseen failures.

Common Replacement Components

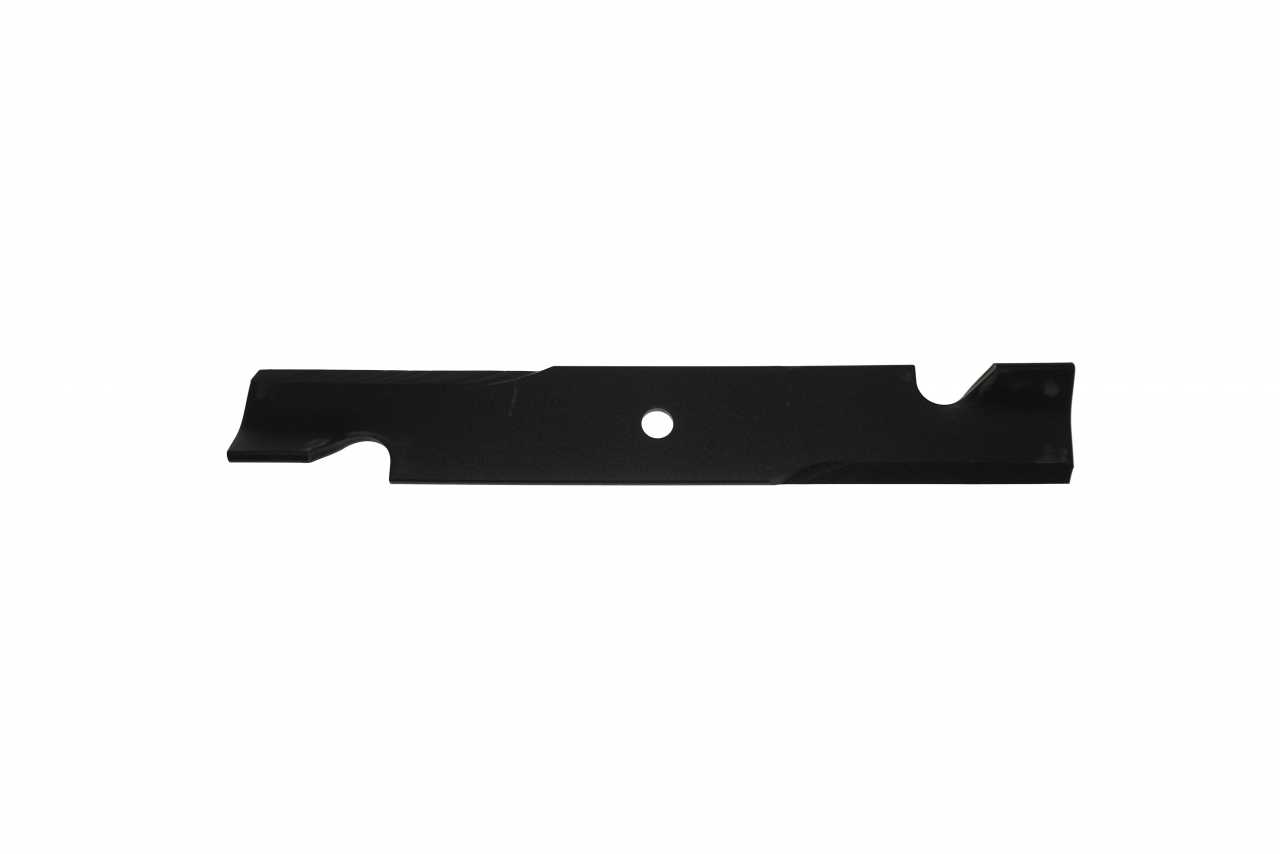

In any machinery, certain elements are more prone to wear and tear, necessitating regular maintenance and timely replacements. Understanding these crucial components can enhance the efficiency and longevity of your equipment.

Key Components to Monitor

- Filters

- Belts and Hoses

- Blades

- Battery

Signs of Wear

- Reduced performance

- Strange noises during operation

- Visible damage or cracks

How to Use the Parts Diagram

Understanding the visual representation of components is crucial for effective maintenance and repair tasks. This guide provides insights on how to interpret and utilize these illustrations to ensure proper identification and handling of each element. By familiarizing yourself with the layout and symbols used, you can streamline your work and enhance efficiency.

To begin, it’s essential to locate the specific section that corresponds to the area you are examining. Each illustration is typically divided into segments that highlight different assemblies. Pay attention to the numbers and labels accompanying each component, as they serve as references for ordering replacements or conducting repairs.

| Step | Description |

|---|---|

| 1 | Identify the assembly you need to work on. |

| 2 | Refer to the accompanying legend or key for symbols and numbers. |

| 3 | Cross-reference with your service manual for detailed instructions. |

| 4 | Gather necessary tools and components before starting the task. |

| 5 | Follow the visual cues to assemble or disassemble parts as needed. |

By following these steps, you can effectively navigate the visual guides, ensuring a smoother process whether you are replacing an item or performing maintenance. Proper use of these resources not only saves time but also minimizes the risk of errors during repairs.

Identifying Wear and Tear

Understanding the signs of deterioration is crucial for maintaining optimal performance and longevity of equipment. Recognizing these indicators early can prevent significant issues and costly repairs, ensuring that machinery functions efficiently for an extended period.

Common Signs of Deterioration

Look for visible cracks, unusual noises, or irregular movement. These symptoms often signal that components are wearing down and may require immediate attention. Regular inspections can help catch these issues before they escalate.

Importance of Timely Maintenance

Proactive care is essential in minimizing the impact of wear and tear. Addressing minor issues promptly can lead to ultimate performance and reliability, reducing downtime and enhancing the lifespan of your equipment.

Ordering Genuine Toro Parts

When it comes to maintaining your equipment, acquiring authentic components is essential for optimal performance and longevity. This ensures that your machinery operates efficiently, minimizing downtime and enhancing reliability.

Benefits of Authentic Components

Using genuine components guarantees compatibility and quality. These items are designed to meet stringent standards, providing the ultimate assurance that your machinery will function as intended. Investing in original parts is an investment in your equipment’s future.

How to Order

To procure authentic components, it’s advisable to contact authorized dealers or visit official websites. Make sure to have your equipment model information ready to facilitate the ordering process. Reliable sources will provide the best options for your needs.

DIY Repairs and Tools Needed

Undertaking maintenance tasks can be both rewarding and cost-effective. Having the right equipment and understanding of the components involved are crucial for successful repairs. This section will guide you through essential tools and techniques for tackling common issues that may arise.

Basic Tools are indispensable for any repair project. A good set of screwdrivers, wrenches, and pliers will allow you to handle most tasks. Additionally, a socket set can make it easier to work with various fasteners. Always ensure your tools are in good condition to avoid any mishaps during repairs.

Specialized Equipment may also be necessary depending on the specific job. For instance, a torque wrench ensures that fasteners are tightened to the manufacturer’s specifications. Furthermore, having a multimeter on hand is beneficial for diagnosing electrical issues and ensuring proper functionality.

Before you begin any repair, it’s essential to review the components involved. Familiarizing yourself with the layout and functionality will make the process smoother. Many resources are available that provide detailed illustrations and descriptions of parts, enabling you to identify and address issues effectively.

Finally, always prioritize safety. Wear protective gear such as gloves and goggles, and work in a well-ventilated area. By equipping yourself with the right tools and knowledge, you can confidently undertake repairs and maintain your equipment efficiently.

Consulting Professional Services

Engaging with expert advisory solutions can significantly enhance operational efficiency and strategic decision-making. Professionals in this field offer tailored guidance, ensuring organizations navigate complexities and optimize resources effectively. Their insights are invaluable for achieving long-term goals and overcoming industry challenges.

Through comprehensive assessments and customized strategies, these specialists empower businesses to streamline processes and implement best practices. They foster innovation and adaptability, equipping teams with the necessary tools to thrive in a competitive landscape.

Investing in professional consultancy not only facilitates immediate improvements but also lays a solid foundation for sustained growth and success. By leveraging expert knowledge, organizations can confidently tackle future obstacles and seize emerging opportunities.

Benefits of Regular Upkeep

One of the most notable advantages of consistent maintenance is the prevention of unexpected failures. Regular check-ups allow for early detection of potential issues, which can be addressed before they escalate into costly repairs. Additionally, a well-maintained machine operates more efficiently, resulting in lower energy consumption and reduced operational costs.

| Benefits | Description |

|---|---|

| Enhanced Performance | Regular upkeep ensures that machinery operates at peak efficiency. |

| Increased Lifespan | Timely maintenance extends the overall life of the equipment. |

| Cost Savings | Prevention of major repairs translates to significant financial savings. |

| Safety Improvements | Well-maintained machines reduce the risk of accidents and injuries. |

| Higher Resale Value | Regular maintenance can lead to a better resale price for the equipment. |

In conclusion, committing to regular maintenance not only ensures the smooth operation of machinery but also enhances overall efficiency and safety. It is a proactive approach that yields long-term benefits for users.

Resources for Toro Owners

Maintaining and operating outdoor equipment effectively requires access to reliable resources. Owners of specialized machinery can benefit from comprehensive guides, technical documentation, and community support. These tools ensure optimal performance and longevity of the equipment, empowering users to tackle repairs and enhancements with confidence.

Documentation and Guides

Access to manuals and user guides is essential for understanding the specifications and maintenance routines of your machinery. Here are some valuable resources:

| Resource Type | Description | Link |

|---|---|---|

| User Manuals | Detailed instructions on operation and maintenance. | Visit Manuals |

| Maintenance Guides | Step-by-step procedures for upkeep and troubleshooting. | Explore Guides |

| Parts Catalogs | Comprehensive listings of components and accessories. | View Catalogs |

Community Support

Connecting with fellow enthusiasts can provide invaluable insights and tips. Online forums and local clubs often share experiences and solutions:

| Community Type | Description | Link |

|---|---|---|

| Online Forums | Platforms for discussions, troubleshooting, and advice. | Join Forums |

| Local Clubs | Groups that meet for events and shared interests. | Find Clubs |