In the realm of lawn care, efficient machinery plays a vital role in maintaining beautiful outdoor spaces. Whether it’s for residential or commercial purposes, having a clear understanding of the machinery’s elements enhances its usability and longevity. By familiarizing oneself with the various components, users can ensure optimal performance and timely maintenance.

Every piece of equipment is designed with specific functionalities in mind, and knowing how these elements work together is crucial. This knowledge not only aids in troubleshooting but also empowers users to perform routine checks and repairs effectively. Each component contributes to the overall functionality, creating a seamless experience when operating the machine.

Ultimately, gaining insight into the intricacies of these mechanical structures allows users to appreciate the engineering behind them. Understanding how parts interrelate not only improves operation but also ensures the machinery remains in top condition for years to come. Emphasizing education in this area can significantly enhance the ownership experience.

This section aims to provide a comprehensive guide on the various components that make up a specialized lawn care machine, highlighting their functions and significance. Understanding these elements is crucial for effective maintenance and operation, ensuring optimal performance and longevity of the equipment.

Key Components of the Lawn Equipment

The machine consists of several vital components, each playing a specific role in its overall functionality. Below are the primary elements commonly found in this type of equipment:

| Component |

Description |

| Engine |

Powers the equipment and provides necessary propulsion. |

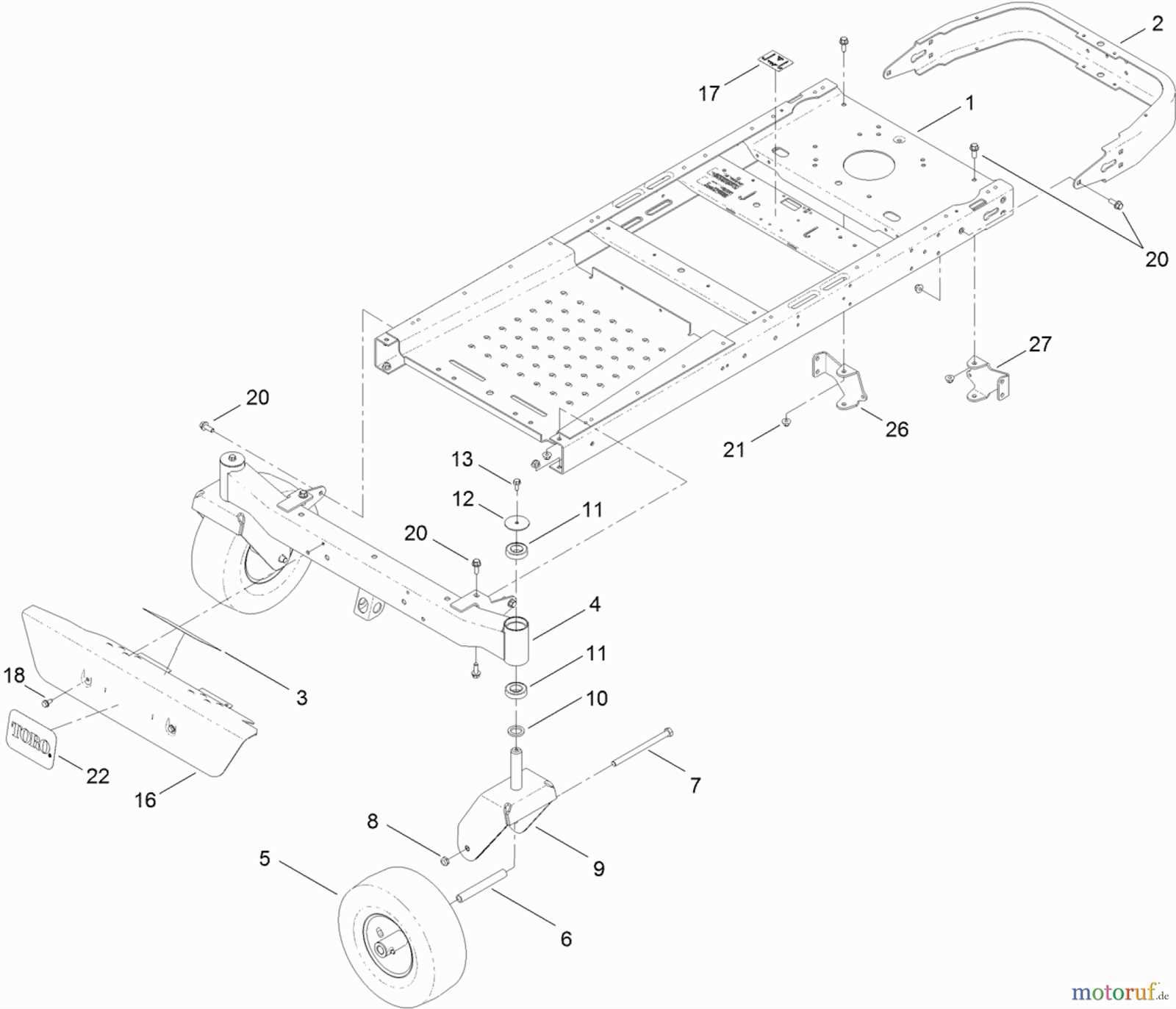

| Chassis |

The frame that supports all other components and ensures stability. |

| Transmission |

Transfers power from the engine to the wheels, enabling movement. |

| Deck |

Houses the cutting blades and is responsible for the quality of the cut. |

| Wheels |

Facilitate mobility and maneuverability across various terrains. |

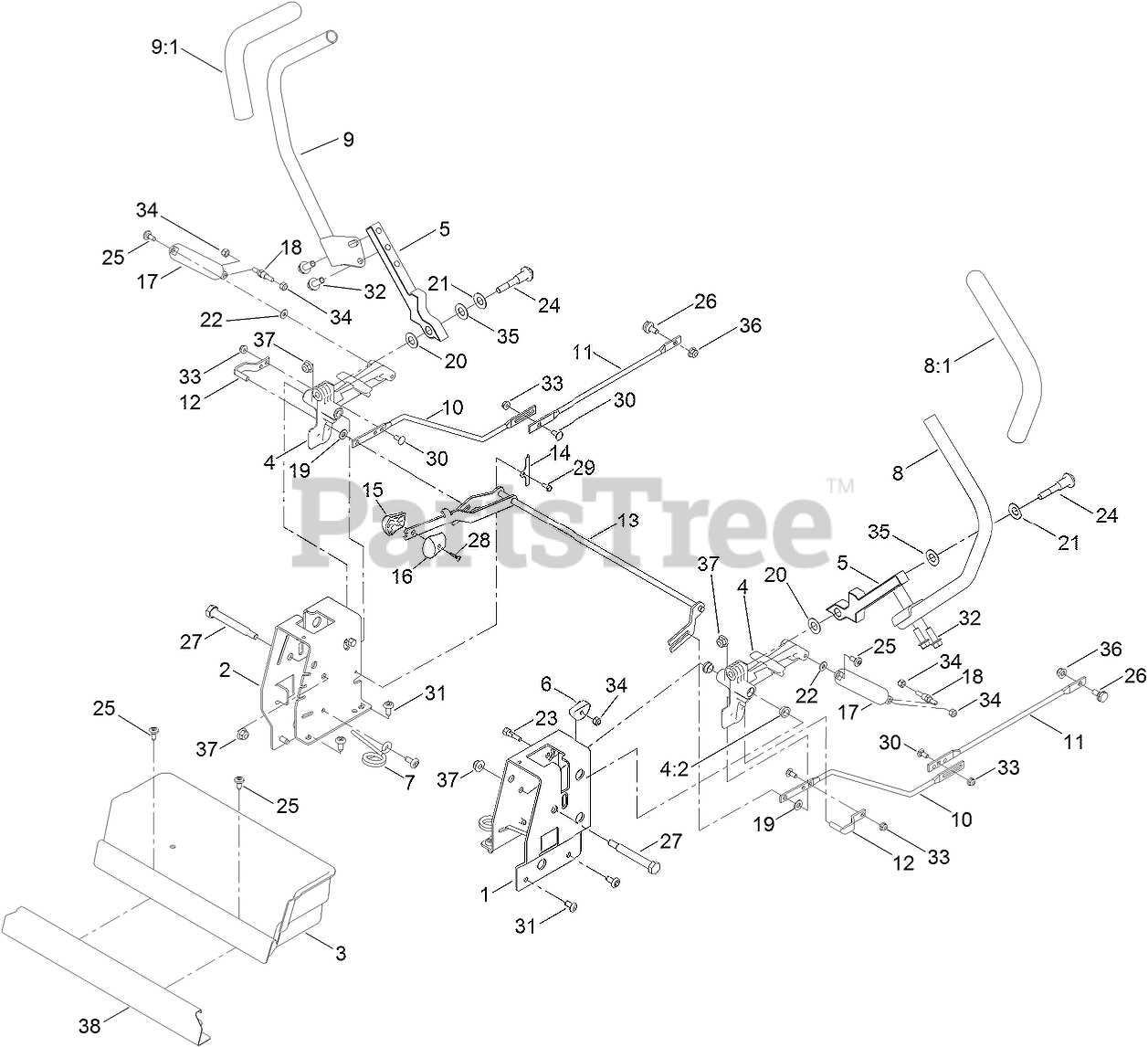

| Steering System |

Allows for precise control and navigation while operating. |

Importance of Regular Maintenance

To ensure the longevity and efficiency of the machine, regular upkeep of these components is essential. Each part requires specific attention and care, which can greatly enhance the overall performance and reliability.

Understanding Mower Component Functions

Efficient lawn maintenance equipment relies on a variety of interconnected parts that work together to ensure smooth operation. These components serve specific roles, contributing to the overall performance and durability of the machine. By gaining insight into the purpose and operation of each part, you can better understand how to keep your equipment functioning optimally.

| Component |

Function |

| Engine |

The powerhouse of the equipment, converting fuel into mechanical energy. |

| Blades |

Responsible for cutting the grass, these sharp elements spin at high speeds to trim lawns effectively. |

| Wheels |

Provide mobility and support, allowing smooth movement across different terrains. |

| Control Levers |

Enable the operator to manage direction and speed with precision and ease. |

Key Features of Toro Mowers

The essential characteristics of modern outdoor equipment are designed to deliver efficiency and precision in maintaining large areas. Built for durability, these machines offer a blend of performance and ease of use, making them ideal for a variety of conditions and terrains. The combination of advanced engineering and user-friendly controls ensures a smooth and productive experience.

Efficient Power Management: With optimized engines, these machines provide consistent power output, enabling long-lasting operations without compromising on fuel efficiency.

Enhanced Maneuverability: The design emphasizes agility, allowing for quick and responsive movements that can handle obstacles with ease.

Durable Construction: The frame and cutting components are made from robust materials, ensuring long-term use even under challenging conditions. This focus on durability minimizes the need for frequent maintenance.

User-Centric Controls: Intuitive interfaces and ergonomic features make it simple to operate, allowing both professionals and casual users to handle the equipment with confidence.

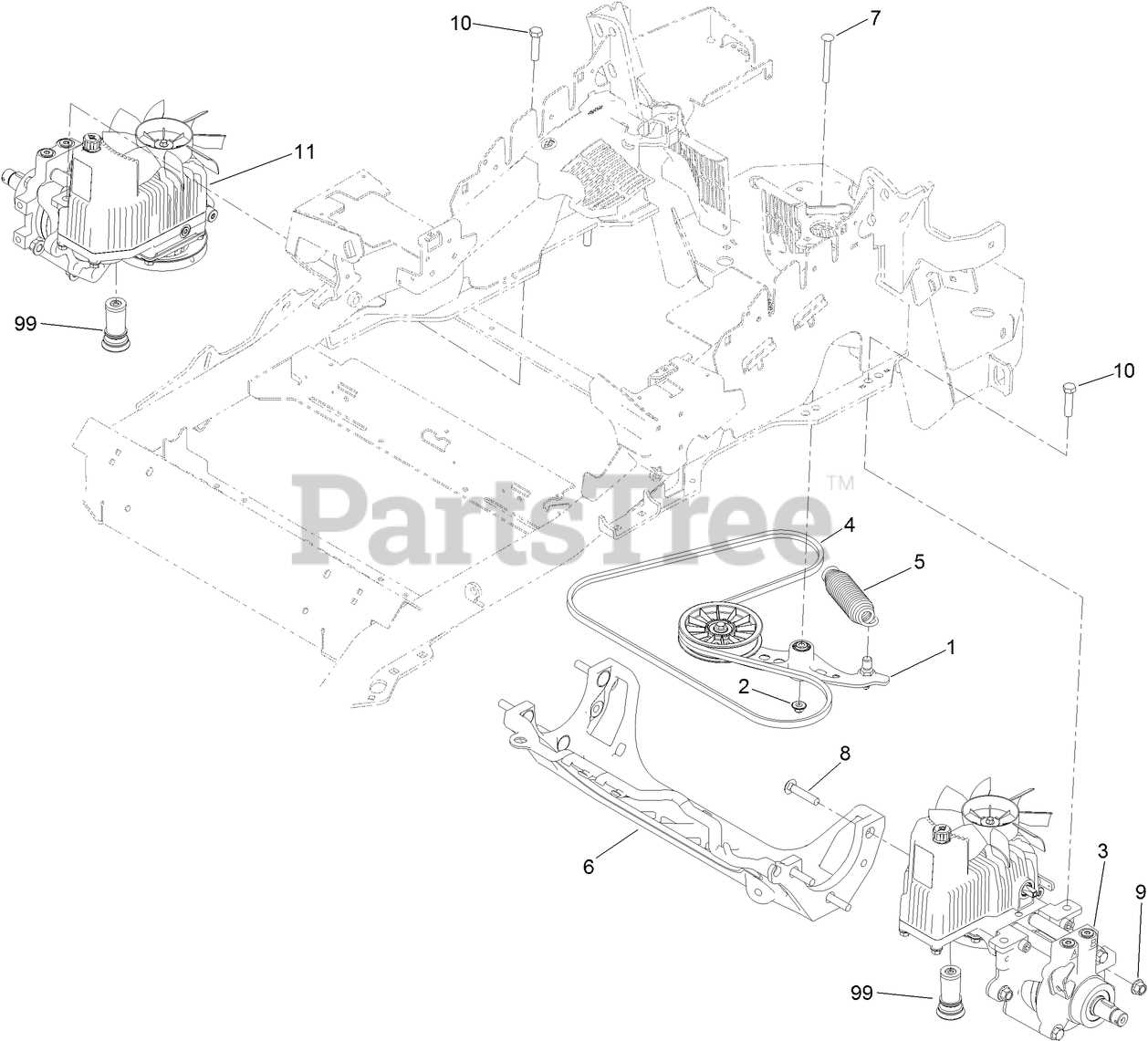

Commonly Used Replacement Parts

Over time, outdoor equipment requires the replacement of various essential components to ensure smooth operation. Regular upkeep helps maintain the efficiency and longevity of the machine, preventing sudden breakdowns during use.

One of the most frequently changed items is the cutting mechanism, which often needs attention after extended use. Another critical element that may require substitution is the drive system, particularly in high-demand environments. Additionally, the hydraulic components might need occasional checks and replacements to sustain reliable performance. Proper maintenance and timely replacement of these key elements contribute to optimal functionality and prolonged lifespan of your machine.

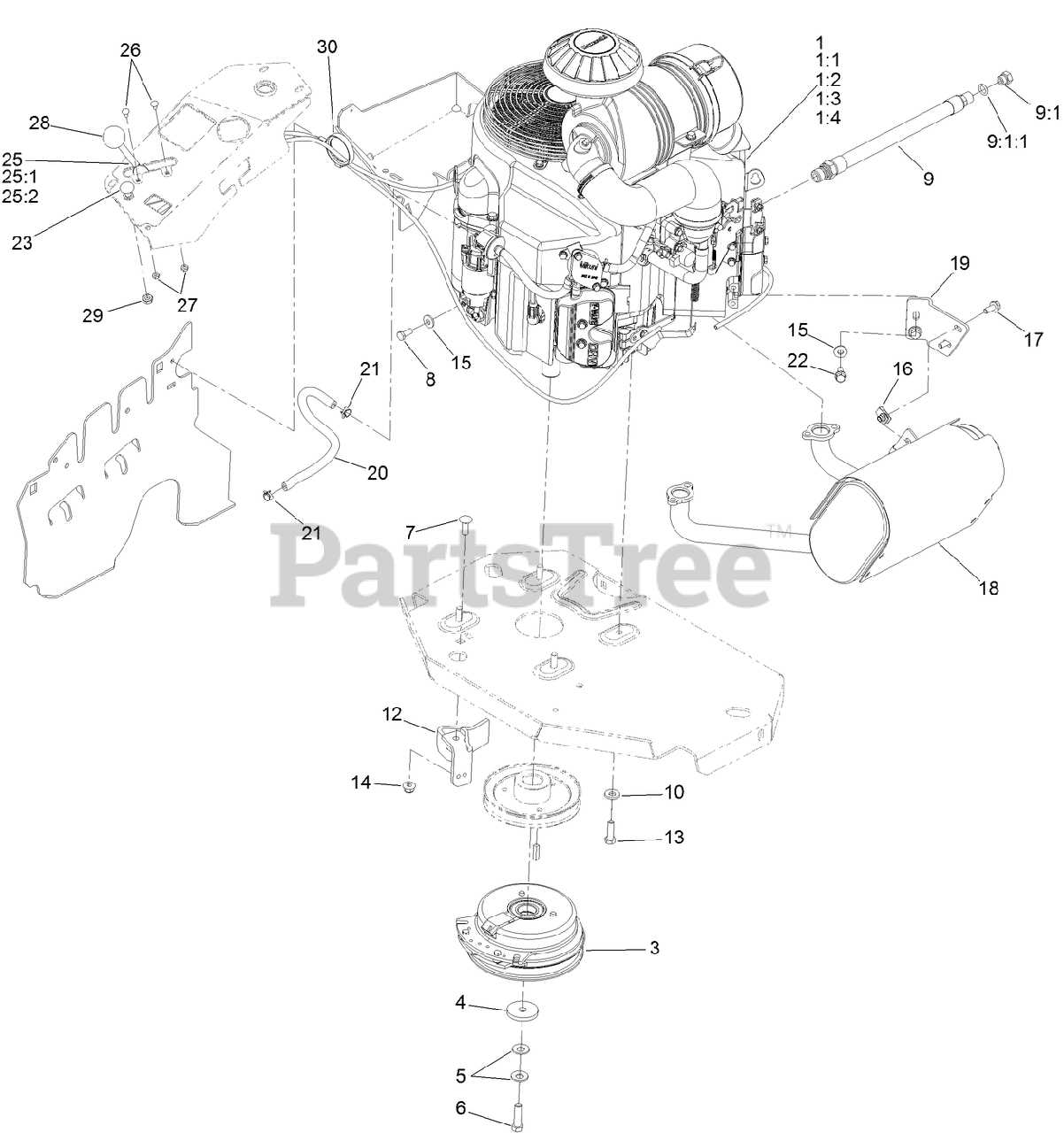

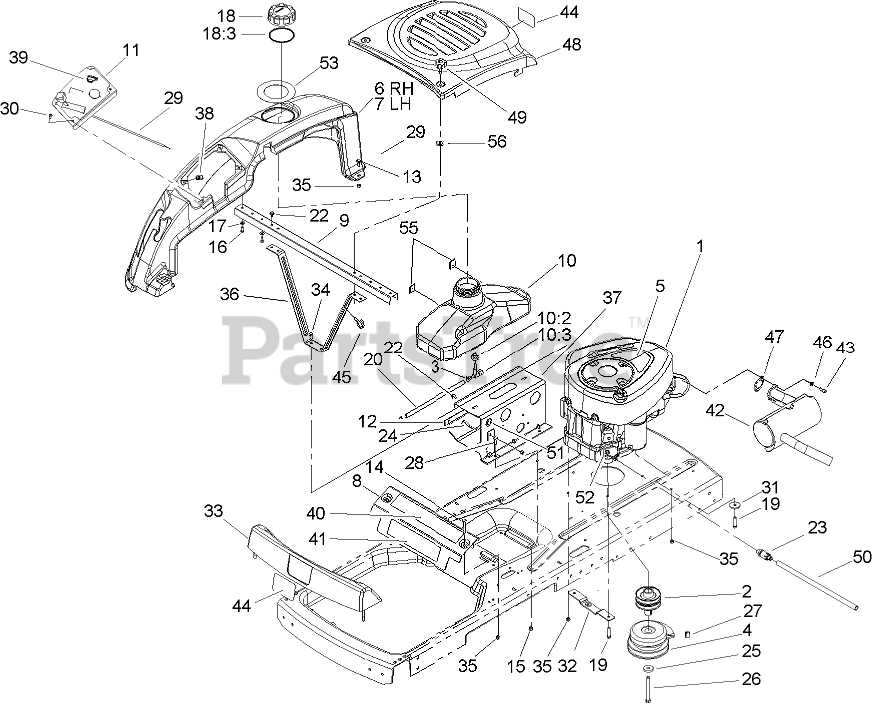

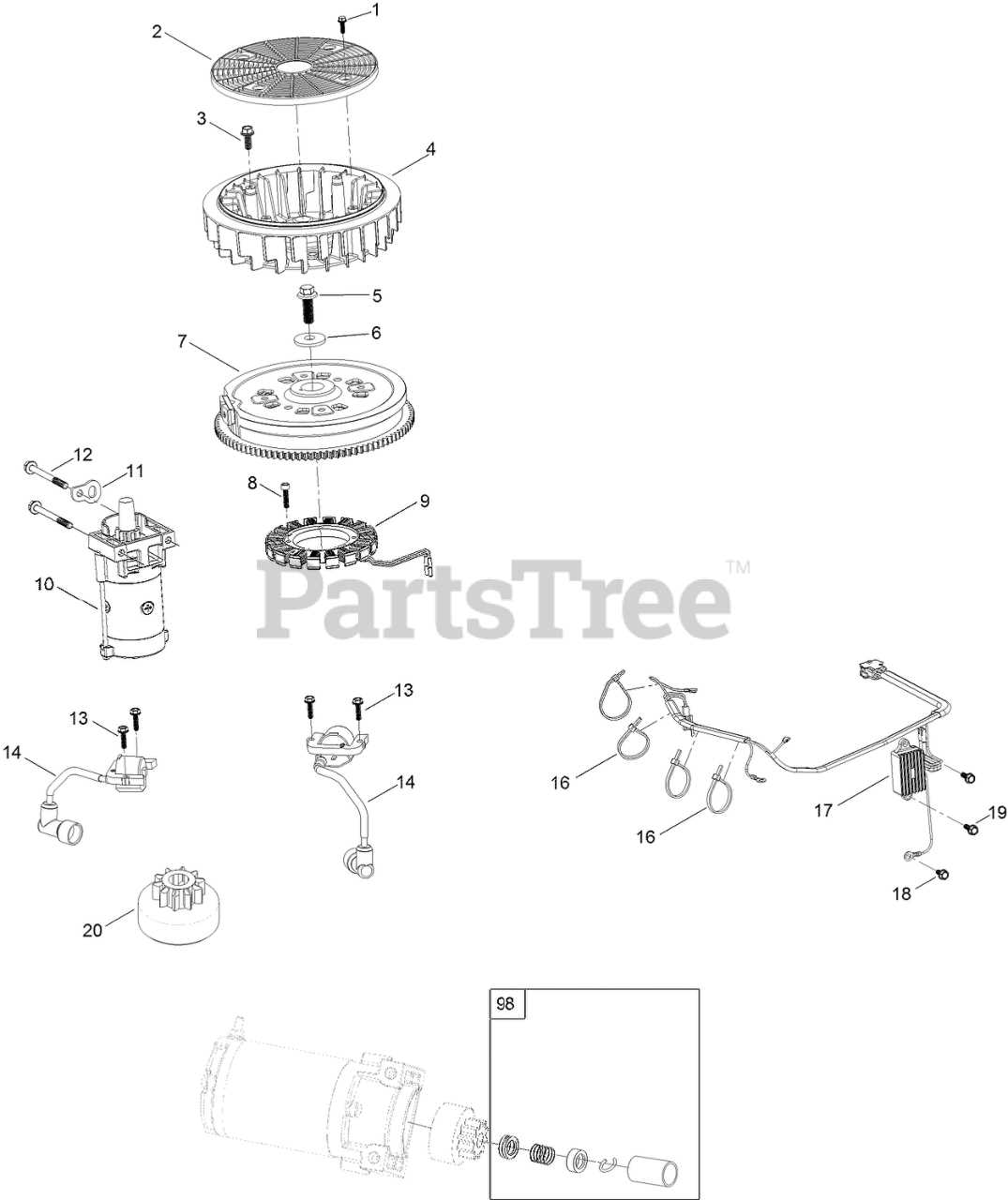

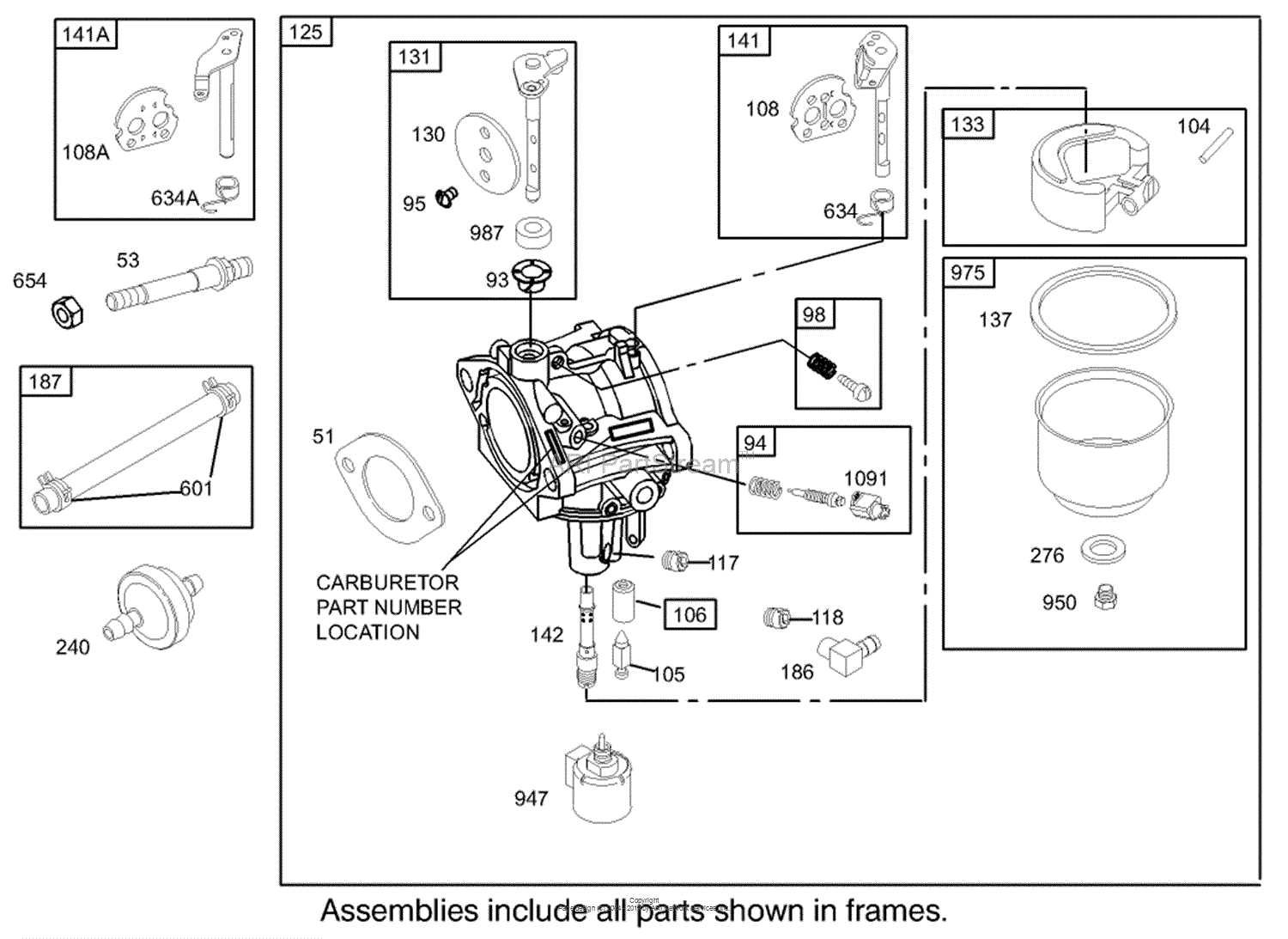

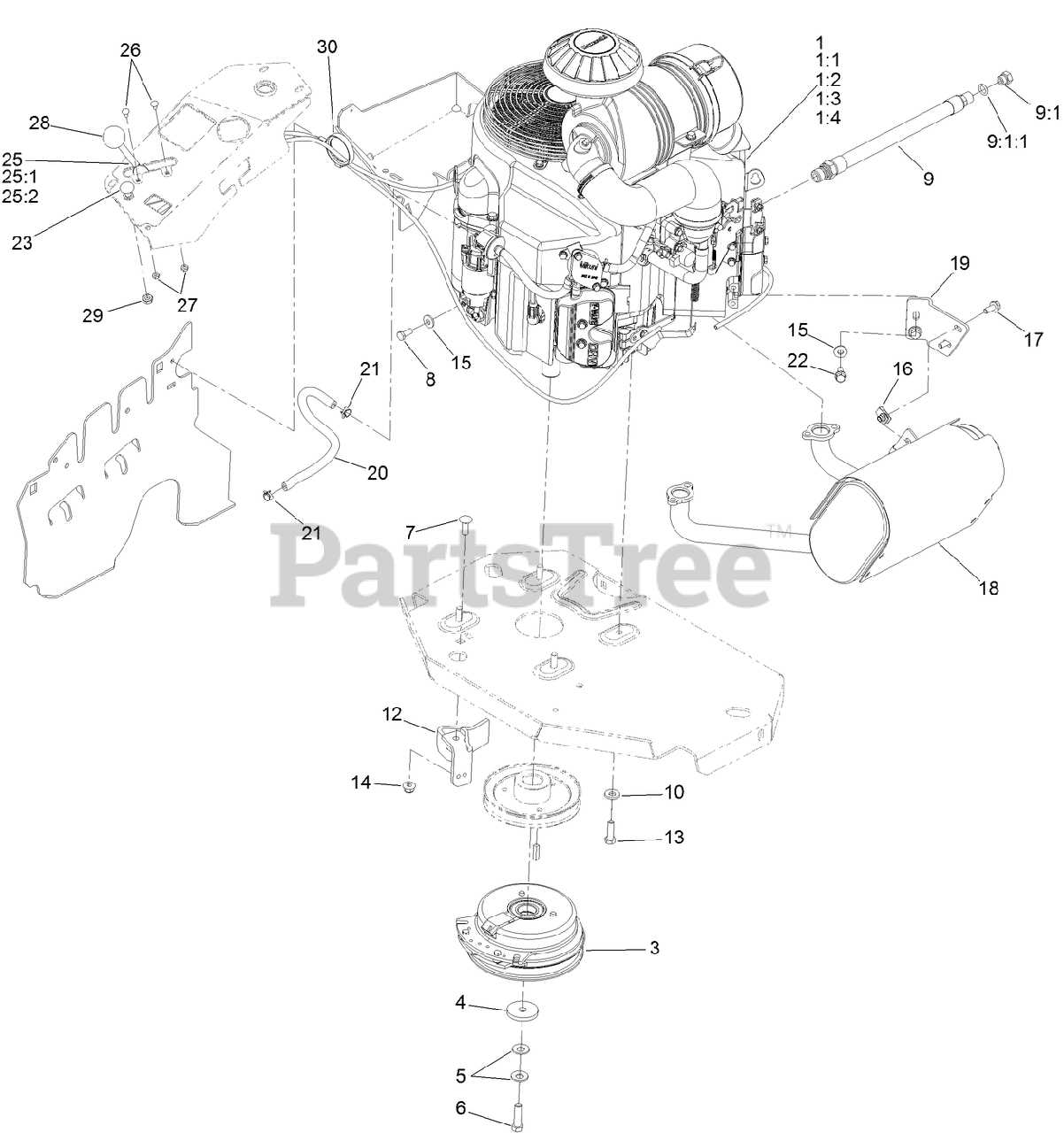

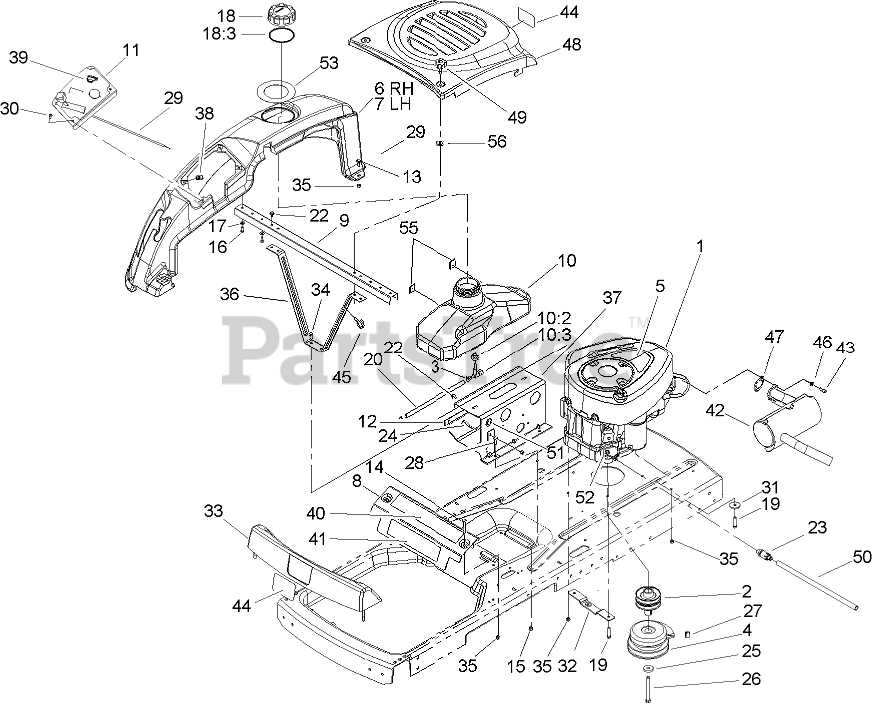

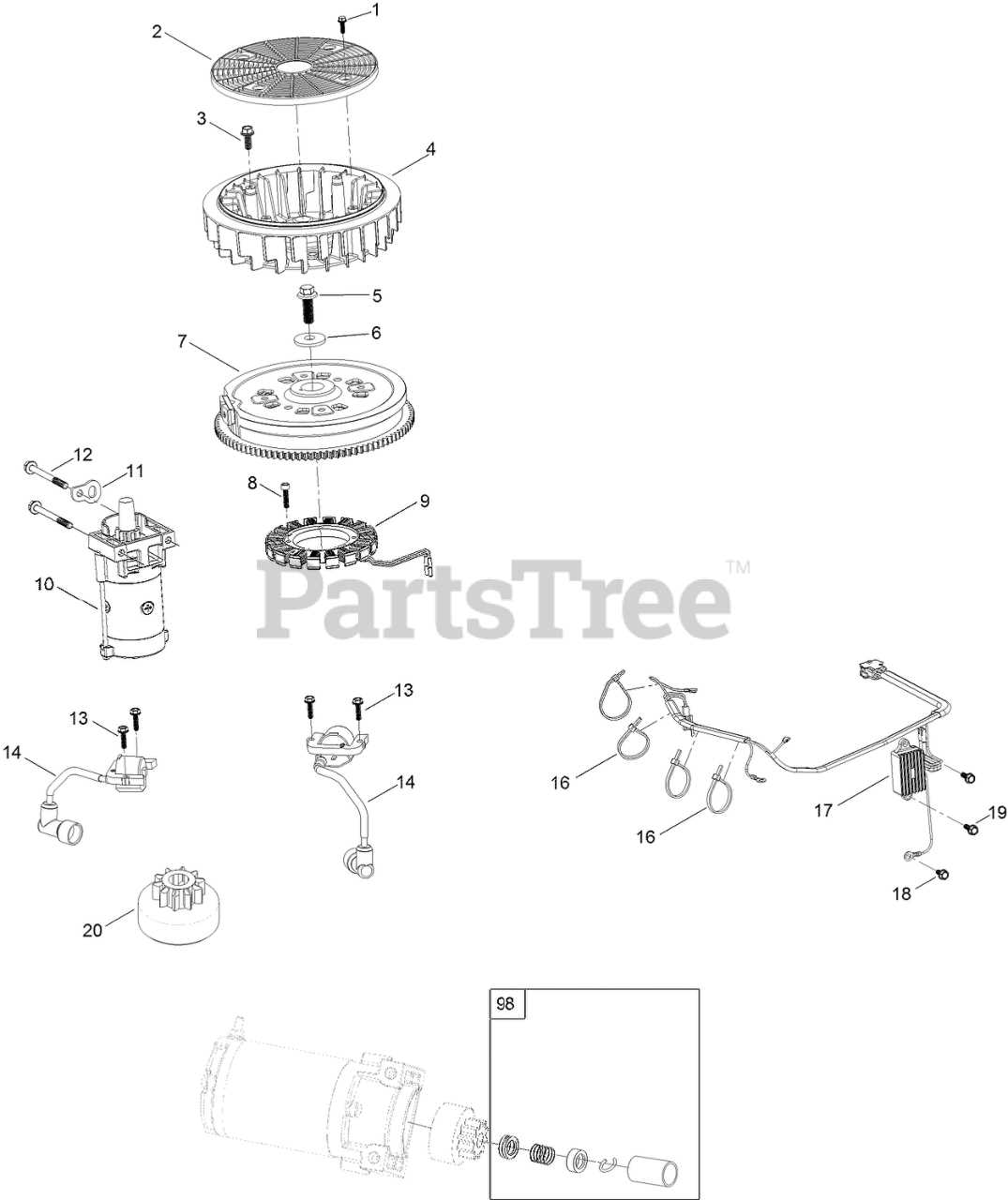

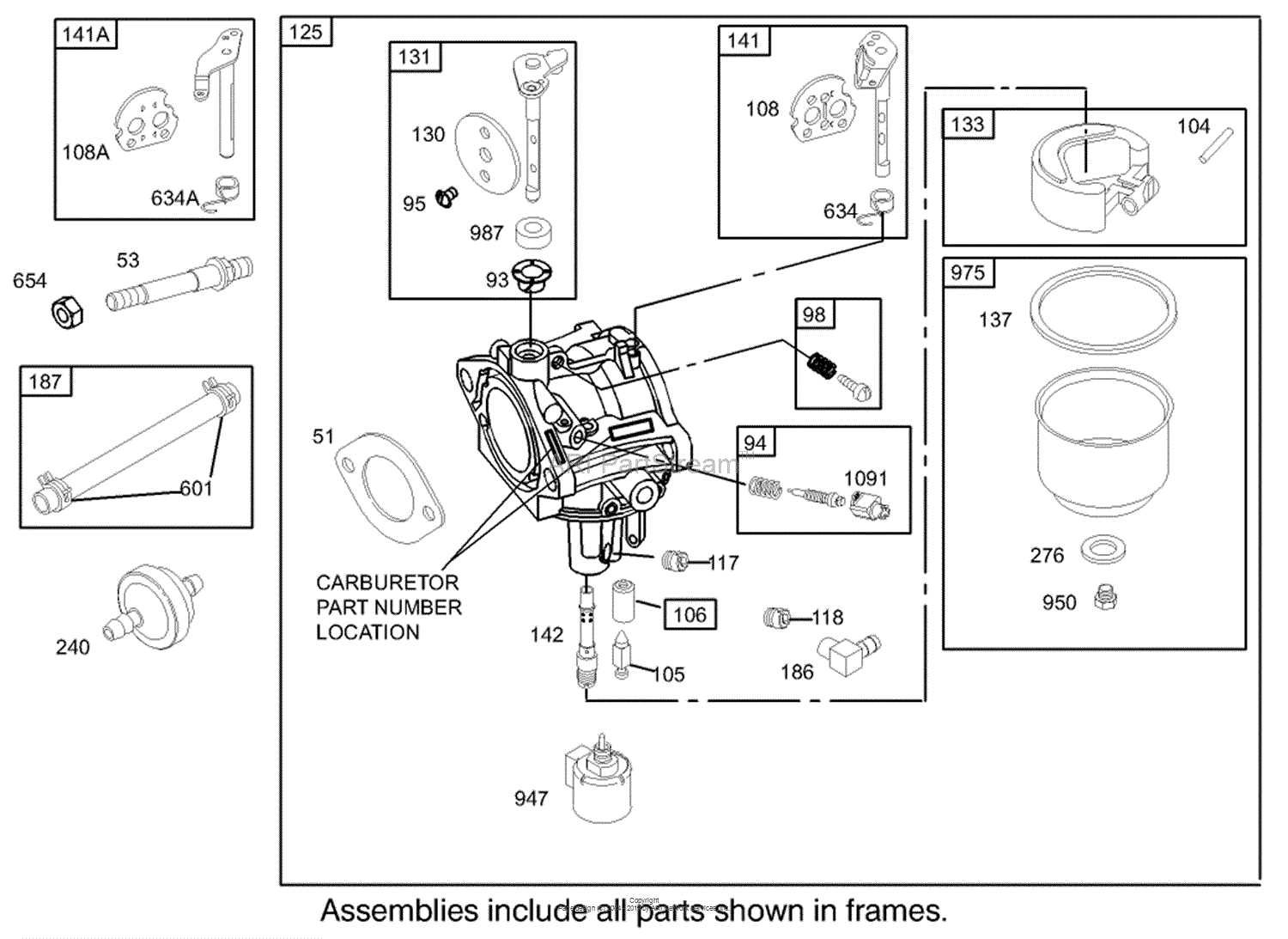

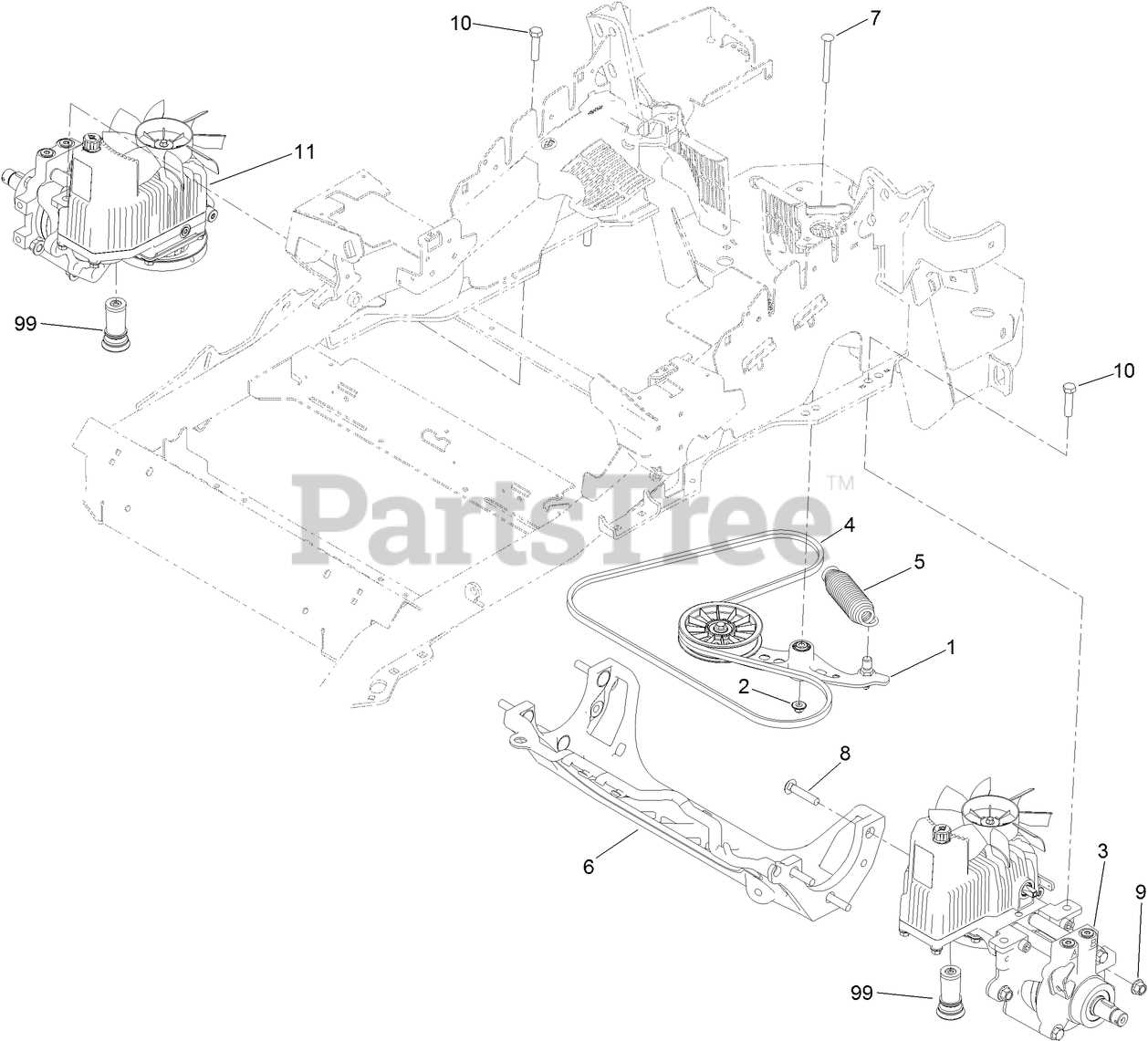

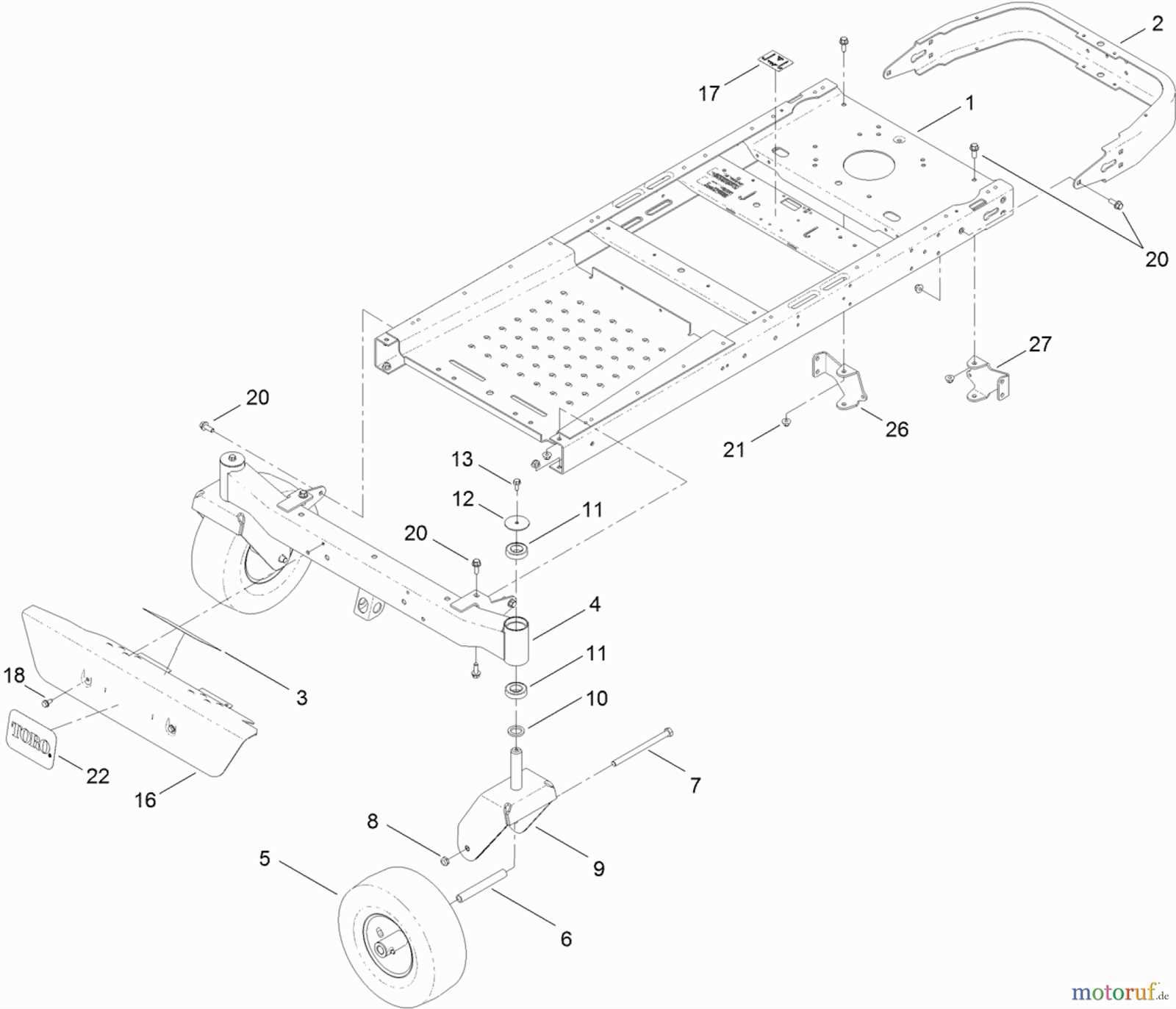

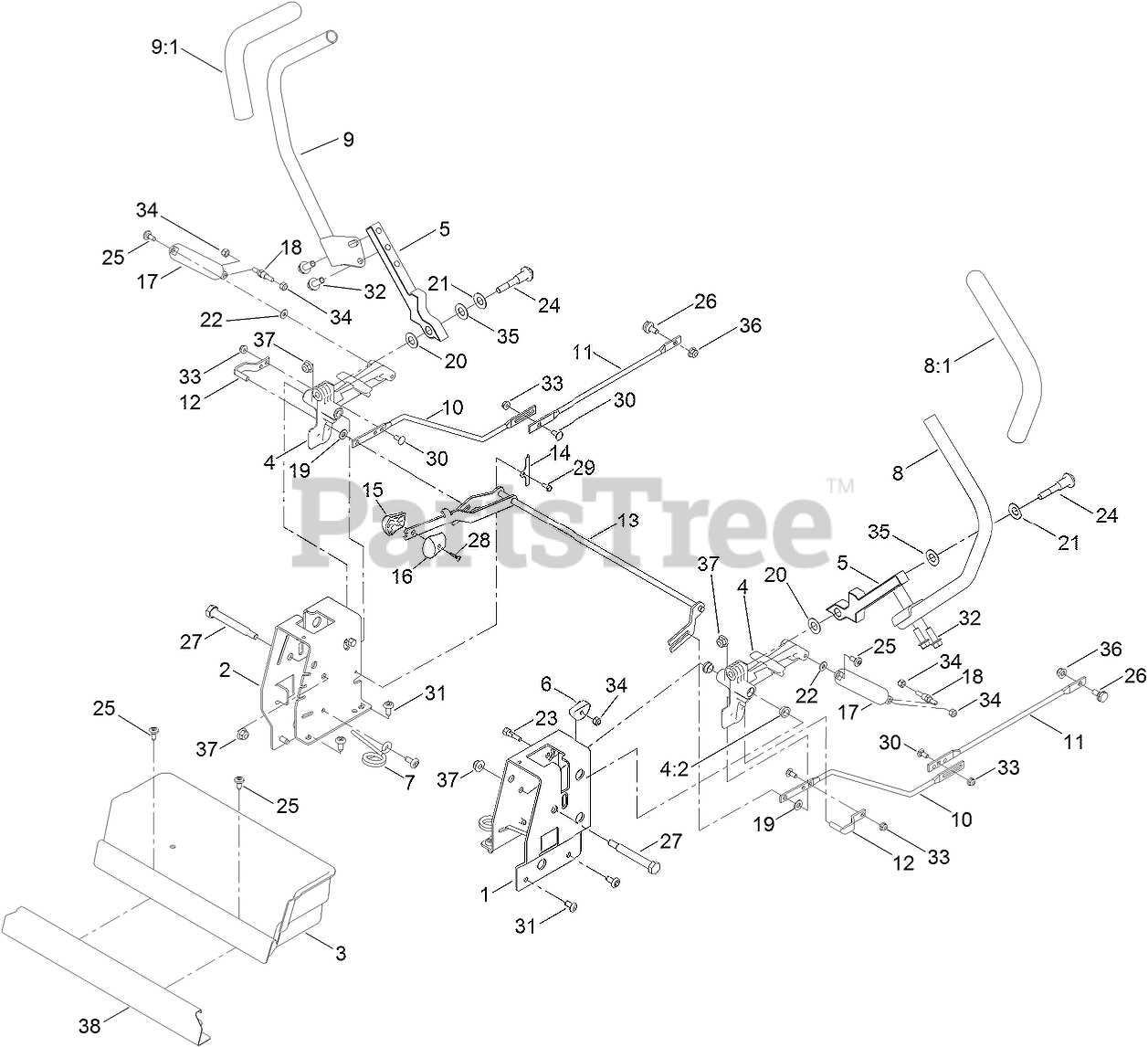

Interpreting the Parts Diagram

Understanding how various elements are organized in a visual reference is essential for proper maintenance and repair tasks. By identifying different components and their relationships, you can easily navigate the entire system, ensuring smooth and efficient work. This visual guide offers a structured way to break down the machinery into manageable sections.

Breaking Down the Visual Reference

When analyzing a visual representation, it’s helpful to focus on key sections. These areas often correspond to specific functionalities, making it easier to pinpoint what needs attention. Follow these steps:

- Identify main assemblies and their subcomponents.

- Note any symbols or labels that indicate specific functions.

- Check for any connections or links between different areas.

Using the Reference for Repairs

This visual layout becomes especially useful when troubleshooting or replacing worn-out elements. Follow these tips to enhance your process:

- Locate the section that corresponds to the issue you’re facing.

- Match the component in question with its representation.

- Maintenance Tips for Mower Parts

Proper care of essential machine components ensures longer life and better performance. Regular upkeep can prevent common issues and reduce the need for frequent repairs. Following a routine will help keep the equipment in top condition.

- Clean the cutting blades: After each use, remove any debris, grass clippings, and dirt that may have accumulated. Sharp and clean blades ensure efficient operation.

- Inspect belts and pulleys: Check for wear, cracks, or tension issues. Tighten or replace them as needed to maintain smooth functioning.

- Lubricate moving parts: Ensure that all joints, bearings, and other movable areas are well-lubricated to reduce friction and prevent early deterioration.

- Check tire pressure: Keep the tires properly inflated to provide better traction and a smoother ride.

- Replace filters: Air and oil filters should be checked regularly and replaced according to the manufacturer’s recommendations for optimal performance.

By adhering to these tips, you can

Identifying Worn Components

Over time, various mechanical elements of equipment can show signs of wear, which may lead to decreased performance and potential damage. Recognizing these symptoms early can help prevent more significant issues and costly repairs.

Common Indicators of Wear

Frequent indications that a component may be wearing down include unusual noises, vibrations, or inconsistent functionality. Parts may also appear visibly worn, such as cracks, fraying, or general deterioration in material quality.

Steps to Inspect for Wear

Regularly checking for wear involves both visual and functional inspections. Start by examining all moving parts, feeling for any looseness or rough movements. It’s also essential to lubricate components where needed, ensuring that excessive friction hasn’t caused significant damage. In addition, replacing worn parts promptly can avoid more extensive repairs later.

Parts Diagram Reference Guide

Understanding how various components of equipment are organized can significantly simplify maintenance and repairs. A clear illustration of the system’s structure allows users to quickly identify necessary elements, ensuring the proper functioning of the machine. This section offers an easy-to-navigate guide for visualizing the relationships between essential mechanical elements.

Component Layout Overview

Each mechanical assembly is made up of multiple elements that work together. A well-structured layout provides insight into the arrangement, helping you recognize how these elements interact and where to locate them for repair or replacement.

Detailed Breakdown by Section

This breakdown divides the equipment into key areas, presenting the main functional groups. Each area is designed to perform specific tasks, and understanding the layout ensures smoother troubleshooting.

| Section |

Main Elements |

Description |

| Engine Assembly |

Pulleys, Belts |

Drives the system and connects to various components for power distribution. |

| Chassis |

Frame, Axles |

Supports the entire structure, providing stability and movement. |

| Control Unit |

Levers, Cables |

Allows for user input to manage the

Ordering Genuine Toro Parts

When it comes to maintaining your equipment, sourcing original components is crucial to ensure longevity and optimal performance. Selecting the right replacements can prevent potential issues and extend the lifespan of your machine, keeping it running smoothly.

Why Choose Original Components?

Genuine replacements are specifically designed for your machine, ensuring a perfect fit and reliable function. These authentic options have undergone rigorous testing, guaranteeing that they meet the highest standards of quality and durability.

How to Find the Right Replacements

To locate the appropriate parts for your equipment, it’s essential to use accurate identification methods. Cross-referencing the model and serial numbers can help you pinpoint exactly what you need, minimizing downtime and avoiding potential mismatches.

DIY Repairs: What You Need

Undertaking your own repairs can save time and money, while also offering the satisfaction of resolving mechanical issues independently. To get started, having the right tools and supplies is essential for addressing common mechanical problems efficiently. This section outlines key resources that will help make repairs smoother and more effective.

Essential Tools

To handle basic fixes, you’ll need a solid set of tools. A reliable wrench, screwdrivers, and pliers should always be on hand. In addition, having a set of socket wrenches, a hammer, and utility knife can help address more complicated repairs.

Additional Supplies

Aside from tools, having the right supplies is just as important. Keep lubricants, sealants, and spare fasteners available to prevent small issues from becoming larger ones. Be prepared with extra belts, filters, and gaskets to replace worn-out components when necessary.

| Tool |

Purpose |

| Wrench |

Tightening and loosening bolts |

| Screwdrivers |

Handling screws of various sizes |

| Socket wrenches |

Working with

Safety Precautions During Maintenance

Regular upkeep is crucial to ensure the longevity and performance of your equipment. However, safety must be a top priority during any servicing activity. Proper preparation, use of the right tools, and a clear understanding of the task ahead can prevent injuries and accidents. It is essential to take necessary steps to protect both yourself and those around you while handling mechanical components.

| Precaution |

Description |

| Wear Protective Gear |

Always use appropriate safety gear such as gloves and safety goggles to avoid physical harm from debris or sharp components. |

| Disconnect Power Source |

Before performing any repairs or inspections, ensure the power source is completely disconnected to avoid accidental starts. |

| Work in a Well-Ventilated Area |

Ensure your workspace has proper ventilation, especially when dealing with fuel or lubricants, to avoid inhalation of harmful fumes. |

| Use Correct Tools |

Common Issues and Solutions

Maintaining equipment can often lead to various challenges that users may encounter. Understanding these common problems and their solutions can significantly enhance the overall experience and ensure efficient operation. Below are some frequent issues along with recommended remedies.

Frequent Problems

- Difficulty starting the machine

- Uneven cutting results

- Overheating during operation

- Unusual noises while in use

Proposed Solutions

-

Check the fuel level and ensure it’s clean and uncontaminated. If starting issues persist, inspect the spark plug for wear or damage.

-

Adjust the cutting height and sharpen the blades to achieve a uniform cut. Regular maintenance of the blades is essential for optimal performance.

-

Ensure proper airflow around the engine by clearing any debris that may be obstructing it. Additionally, verify that the oil level is adequate.

-

Inspect all moving parts for loose components. Tighten any bolts or screws that may have come loose over time to reduce unwanted noise.

Frequently Asked Questions

This section addresses common inquiries regarding maintenance and repair of lawn care equipment. Here, we provide insights into essential components, troubleshooting methods, and effective solutions for various issues that may arise during operation.

What are the most common issues faced?

Many users experience challenges such as difficulty starting, uneven cutting, or excessive vibrations. Understanding the root causes of these problems can greatly aid in timely resolutions and ensure the longevity of your equipment.

How can I find the right components for repairs?

To ensure compatibility, it is advisable to consult the user manual or manufacturer’s website for a comprehensive list of recommended items. Additionally, seeking assistance from local retailers or online forums can provide valuable guidance on suitable replacements.

|

|