In the realm of vehicular maintenance, grasping the layout of crucial mechanical elements is essential for both enthusiasts and professionals. A thorough comprehension of how various components interact can significantly enhance performance and longevity.

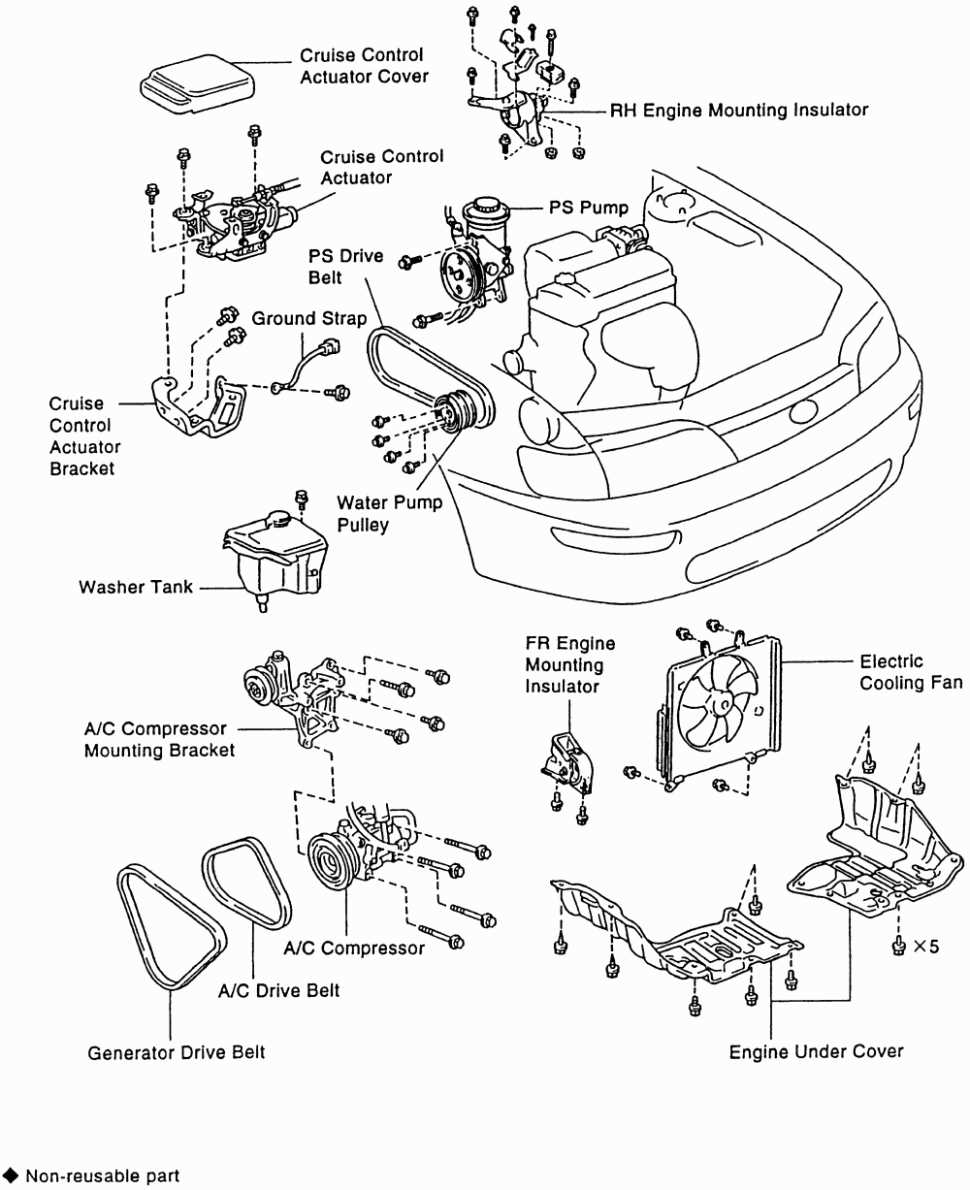

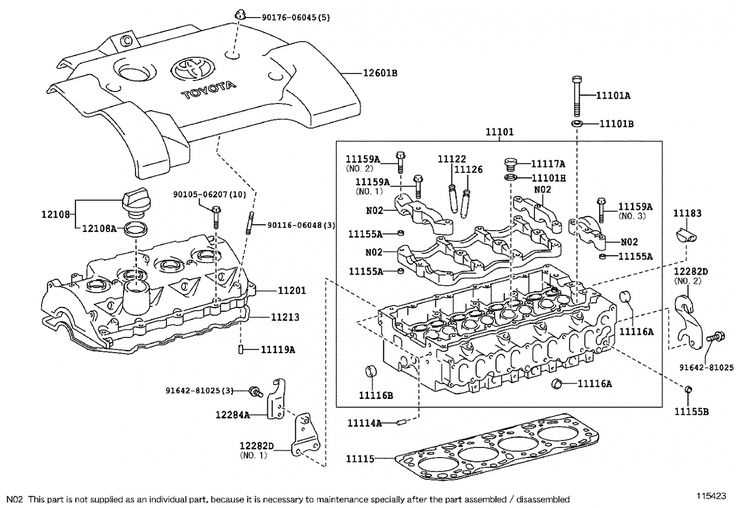

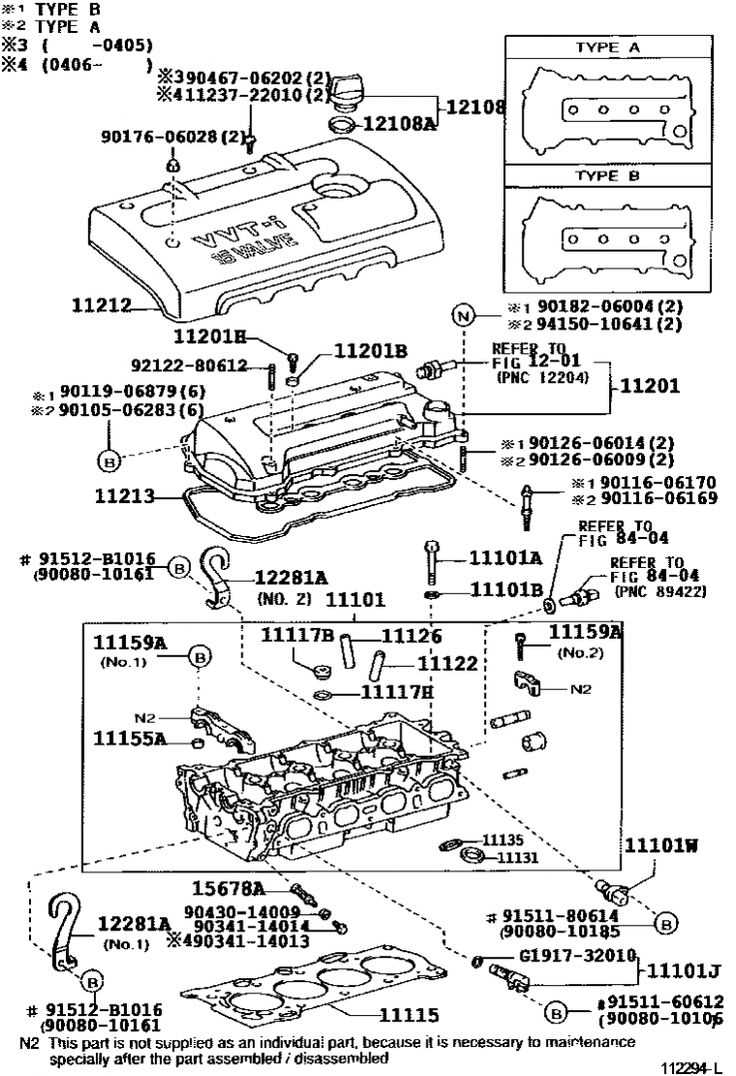

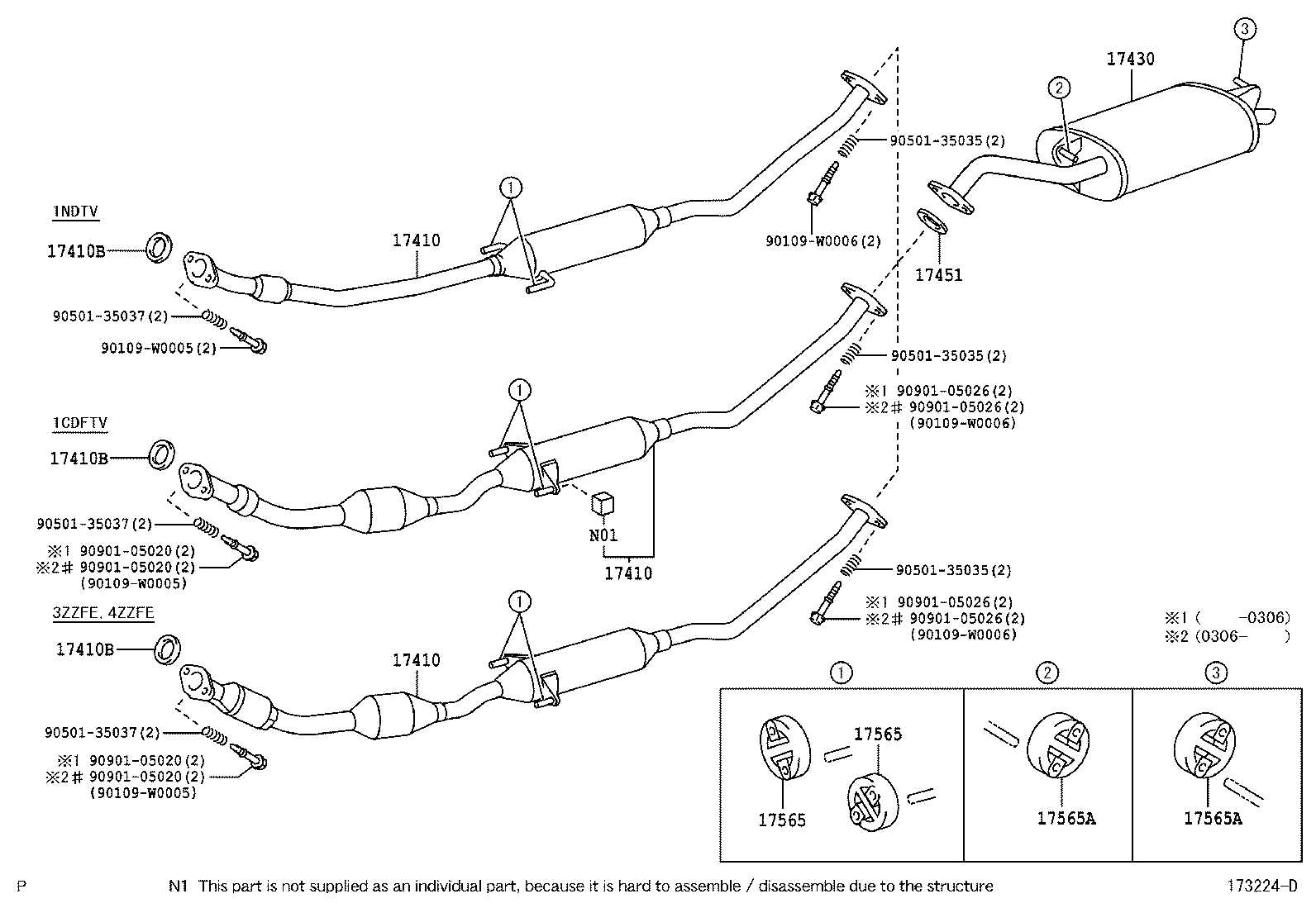

To facilitate effective repairs and upgrades, it is vital to explore a visual representation that highlights the relationship between individual components. This knowledge empowers individuals to make informed decisions regarding maintenance and modifications.

By examining the configuration of these integral systems, one can delve deeper into the intricacies of automotive engineering. Ultimately, this understanding serves as a foundation for achieving optimal functionality and reliability in any vehicle.

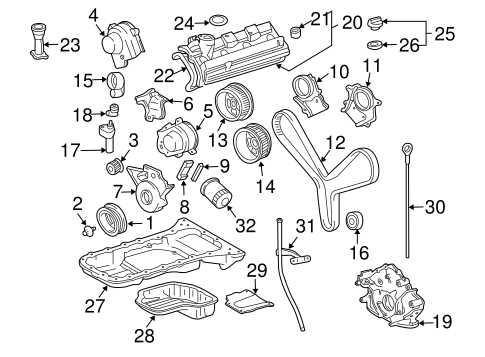

Overview of 2004 Toyota Corolla Engine

This section provides a comprehensive examination of a compact vehicle’s mechanical heart, focusing on its vital components and their interactions. Understanding how these elements work together is essential for maintenance and performance optimization.

Performance: The design emphasizes fuel efficiency and reliability, making it a popular choice among drivers. With an optimal balance between power and economy, this model stands out in its class.

Components: Key elements include the combustion chamber, intake and exhaust systems, and various sensors. Each plays a crucial role in ensuring smooth operation and compliance with environmental standards.

Overall, a thorough grasp of these intricacies will empower owners to make informed decisions regarding upkeep and upgrades.

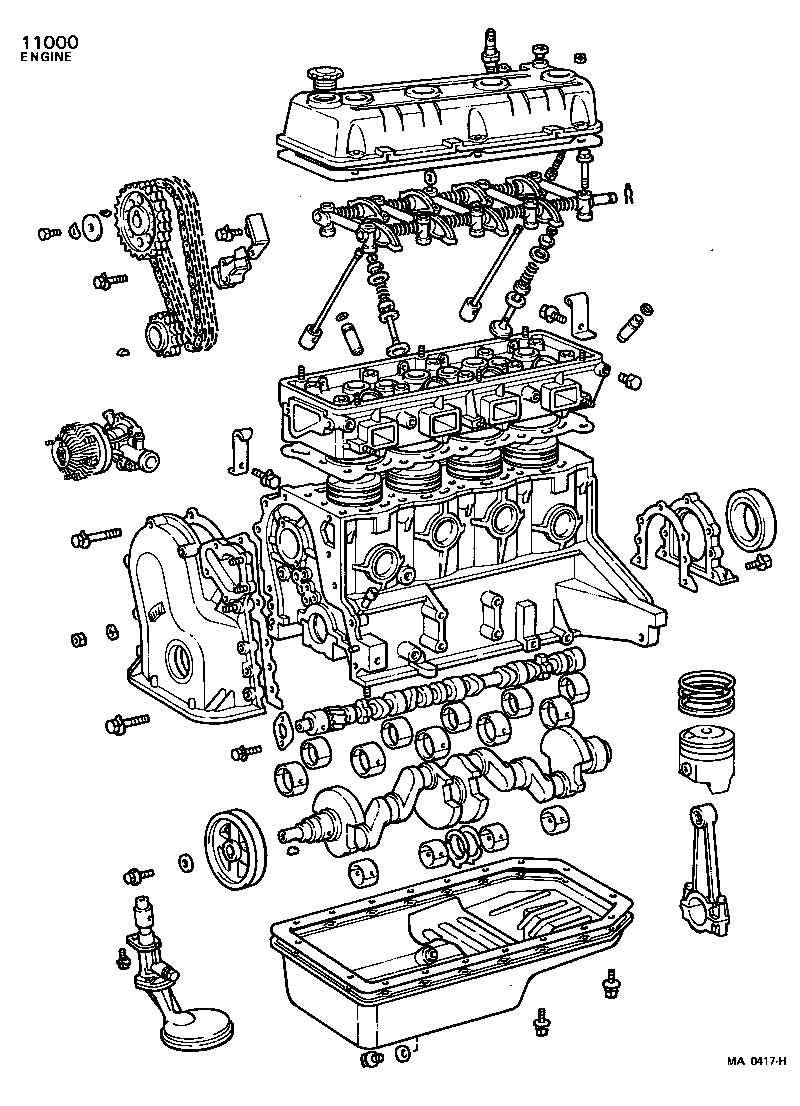

Key Components of the Engine

Understanding the essential elements of a power unit is crucial for anyone interested in automotive mechanics. These components work together to ensure optimal performance, efficiency, and longevity of the vehicle’s propulsion system.

Main Functional Units

- Block: The core structure that houses various parts and withstands internal pressures.

- Cylinders: Spaces where fuel and air mixture is compressed and ignited, generating power.

- Pistons: Movable elements that convert energy from combustion into mechanical motion.

- Crankshaft: Transforms linear motion from the pistons into rotational energy to drive the wheels.

Supporting Components

- Camshaft: Regulates the timing of valve openings and closings, crucial for proper airflow.

- Valves: Control the intake of the air-fuel mixture and the expulsion of exhaust gases.

- Timing Belt: Ensures synchronized movement between the crankshaft and camshaft.

- Oil Pump: Distributes lubrication throughout the system, reducing friction and wear.

Understanding Engine Diagrams

Comprehending the layout and components of a vehicle’s power unit is essential for both maintenance and troubleshooting. These visual representations serve as a guide, illustrating the intricate relationships between various elements and their functions within the assembly. A thorough understanding of these visuals can significantly enhance one’s ability to diagnose issues and perform repairs effectively.

Each symbol and line in these illustrations carries meaning, indicating how different elements interact and where they are positioned. Familiarity with these schematics enables individuals to identify components quickly, facilitating efficient problem-solving and servicing.

| Component | Description |

|---|---|

| Block | Main structure housing the cylinders and supporting various parts. |

| Pistons | Move up and down within cylinders, converting fuel energy into mechanical motion. |

| Crankshaft | Transforms the linear motion of the pistons into rotational energy. |

| Camshaft | Controls the timing of valve openings and closings, crucial for airflow. |

| Valves | Regulate the intake of air-fuel mixture and exhaust of combustion gases. |

By examining these visuals and understanding the associated terminology, one can develop a clearer picture of how each component contributes to the overall operation. This knowledge not only aids in repairs but also empowers enthusiasts to appreciate the complexity of automotive design.

Functions of Engine Parts Explained

This section delves into the various components that contribute to the overall functionality of a motor. Each element plays a critical role in ensuring optimal performance, efficiency, and longevity. Understanding these roles provides insight into how these mechanisms work together harmoniously.

| Component | Function |

|---|---|

| Cylinder Block | Houses the cylinders and provides structural integrity. |

| Pistons | Convert fuel energy into mechanical motion. |

| Cylinder Head | Seals the combustion chamber and houses intake/exhaust valves. |

| Crankshaft | Transforms linear motion of pistons into rotational motion. |

| Camshaft | Controls the timing of valve openings and closings. |

| Fuel Injector | Delivers fuel to the combustion chamber at precise intervals. |

| Exhaust Manifold | Collects exhaust gases from multiple cylinders and directs them out. |

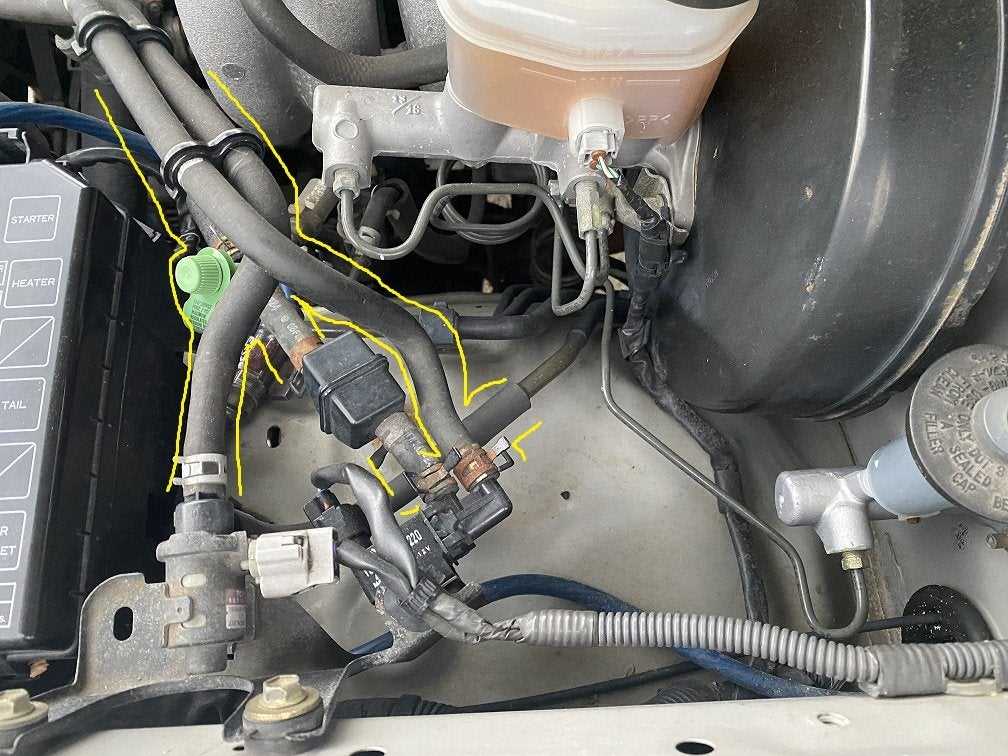

Common Issues in Engine Parts

Understanding the frequent challenges associated with mechanical components is essential for maintaining optimal performance. Various elements can experience wear and tear over time, leading to a range of operational problems. Identifying these common issues early can help prevent more severe complications down the line.

Frequent Complications

- Overheating: Excessive heat can lead to significant damage, often caused by insufficient coolant or a failing thermostat.

- Oil Leaks: Deterioration of seals and gaskets can result in oil escaping, which may compromise lubrication and increase friction.

- Fuel System Problems: Clogs in injectors or a failing fuel pump can disrupt the flow, affecting overall efficiency.

- Electrical Failures: Corroded connections or faulty sensors can lead to misfires and erratic performance.

Preventative Measures

- Regular Maintenance: Consistent checks can identify issues before they escalate.

- Quality Fluids: Using high-grade oils and coolants can enhance performance and longevity.

- Prompt Repairs: Addressing minor issues immediately can prevent them from developing into major repairs.

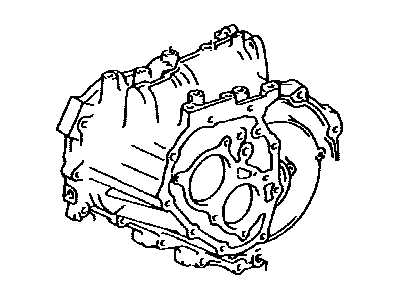

Replacement Parts for Toyota Corolla

Maintaining optimal performance of your vehicle often requires the replacement of specific components over time. Understanding which elements are essential for upkeep can significantly enhance longevity and efficiency. This section provides an overview of crucial substitutes that ensure your automobile operates smoothly.

| Component | Description | Function |

|---|---|---|

| Alternator | Electrical generator | Charges the battery and powers the electrical system |

| Starter Motor | Electric motor | Engages the engine’s flywheel to start the vehicle |

| Fuel Pump | Mechanical or electric pump | Delivers fuel from the tank to the engine |

| Radiator | Cooling system component | Dissipates heat from the engine coolant |

| Brake Pads | Friction material | Facilitates stopping by creating friction against the brake rotor |

Each of these elements plays a vital role in the overall functionality and reliability of your vehicle. Regular checks and timely replacements can prevent more significant issues down the road.

Maintenance Tips for Engine Longevity

Ensuring the durability of your vehicle’s power source requires regular attention and care. By adhering to a set of best practices, you can significantly extend the lifespan of these crucial components, maintaining optimal performance and efficiency.

| Tip | Description |

|---|---|

| Regular Oil Changes | Frequent replacement of lubricant helps reduce friction and prevents wear. |

| Check Coolant Levels | Maintaining proper fluid levels prevents overheating and potential damage. |

| Replace Air Filters | Clean filters enhance airflow, improving combustion efficiency and performance. |

| Inspect Belts and Hoses | Regular checks for wear can prevent breakdowns and costly repairs. |

| Monitor Fuel Quality | Using high-quality fuel ensures better performance and cleaner operation. |

Tools Required for Engine Repair

Successful maintenance of a vehicle’s internal mechanisms requires a specific set of instruments that ensure precision and efficiency. Proper tools not only facilitate repairs but also enhance safety and reliability during the process.

- Socket Set: Essential for removing and tightening bolts.

- Wrench Set: Useful for gripping and turning fasteners in tight spaces.

- Torque Wrench: Ensures that connections are tightened to the manufacturer’s specifications.

- Screwdrivers: A variety of sizes and types are needed for different screws.

- Pliers: Ideal for gripping, twisting, and cutting wires or components.

- Oil Filter Wrench: Specialized tool for easy removal of oil filters.

- Jack and Jack Stands: Necessary for lifting the vehicle safely off the ground.

- Diagnostic Scanner: Helps in identifying issues by reading error codes.

Having the right tools on hand can significantly simplify the repair process, allowing for a more thorough and effective approach to vehicle maintenance.

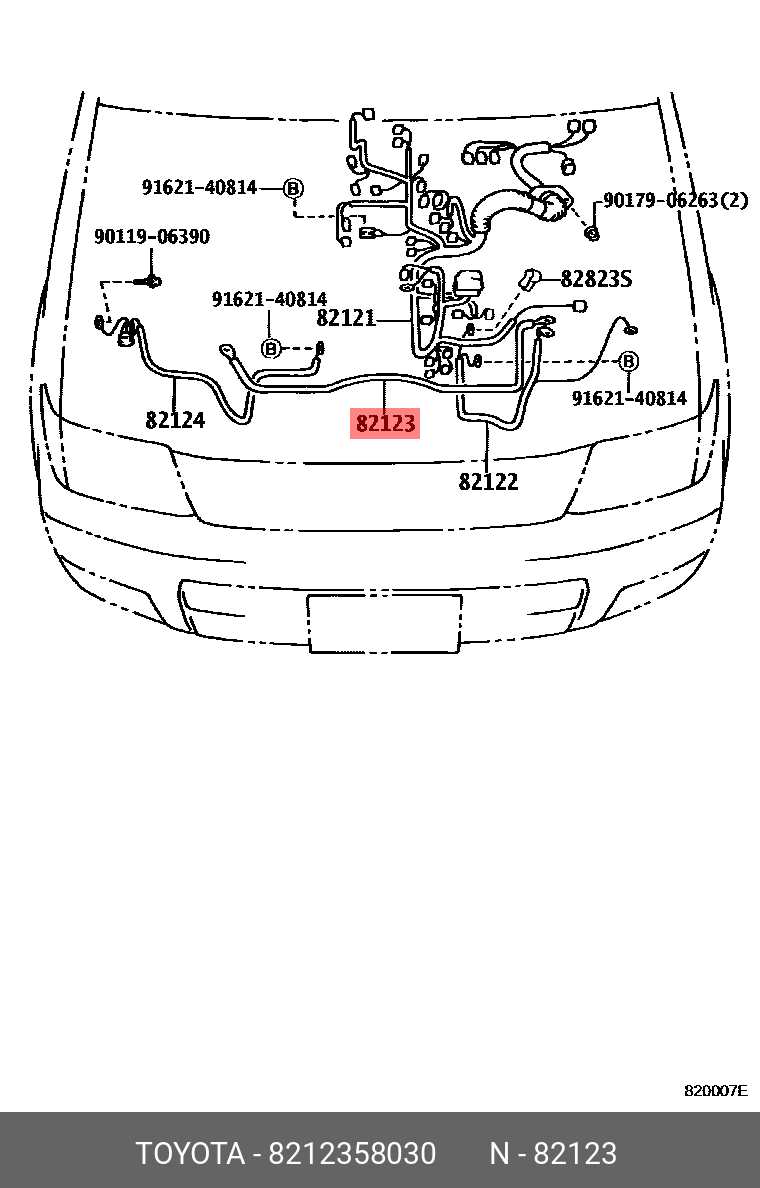

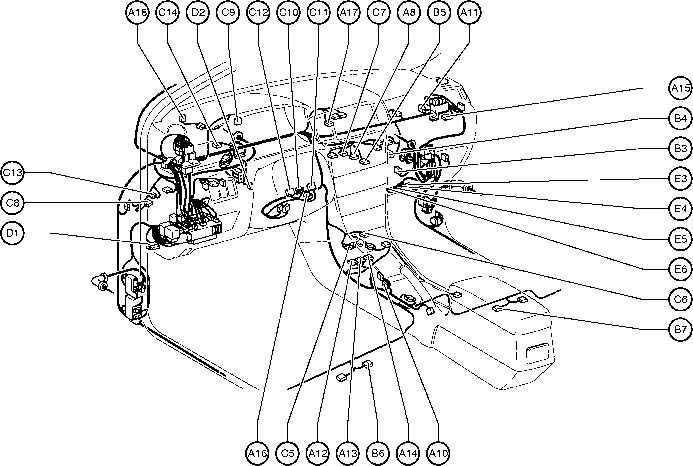

How to Read an Engine Diagram

Understanding a mechanical layout can greatly enhance your ability to troubleshoot and maintain your vehicle. These illustrations serve as valuable resources, providing a visual representation of components and their relationships. Learning how to interpret these images effectively is crucial for anyone looking to delve deeper into automotive mechanics.

Key Elements of the Layout

When examining an illustration, it’s important to familiarize yourself with the symbols and notations used. Each part is usually represented by a specific shape or icon, which can indicate its function or connection to other elements. Pay close attention to labels, as they often provide essential information regarding the specifications and placement of each component.

Reading the Connections

The relationships between various elements are often depicted with lines or arrows. These connections can signify different types of interactions, such as flow paths or electrical links. Understanding these connections is vital for diagnosing issues and ensuring all components work harmoniously. Start by tracing the lines from one part to another to see how they interact within the overall system.

| Symbol | Description |

|---|---|

| Circle | Represents a rotating component |

| Rectangle | Indicates a fixed element or housing |

| Arrow | Shows direction of flow or movement |

| Dashed Line | Represents a connection that can be optional or variable |

By mastering these fundamentals, you’ll be better equipped to navigate and utilize these visual tools effectively, enhancing your understanding of automotive systems.

Comparative Analysis with Other Models

This section explores the distinctions and similarities between various vehicle designs, highlighting performance, reliability, and overall mechanics. By understanding these aspects, one can better appreciate the nuances that define different models in the automotive market.

Performance Metrics

- Acceleration rates

- Fuel efficiency comparisons

- Handling characteristics

Reliability Ratings

- Maintenance frequency

- Common issues reported

- Longevity of components

By delving into these factors, one can identify the ultimate strengths and weaknesses of each model, leading to informed choices for potential buyers.

Upgrades for Enhanced Engine Performance

Improving the overall functionality and power output of a vehicle can be achieved through various modifications. These enhancements not only increase efficiency but also elevate the driving experience, providing more responsiveness and agility on the road.

Popular Modifications

- Cold Air Intake Systems

- High-Performance Exhausts

- ECU Remapping

- Performance Spark Plugs

- Upgraded Fuel Injectors

Benefits of Upgrades

- Improved horsepower and torque.

- Enhanced fuel efficiency.

- Better throttle response.

- Reduced turbo lag in boosted models.

- Overall smoother driving experience.

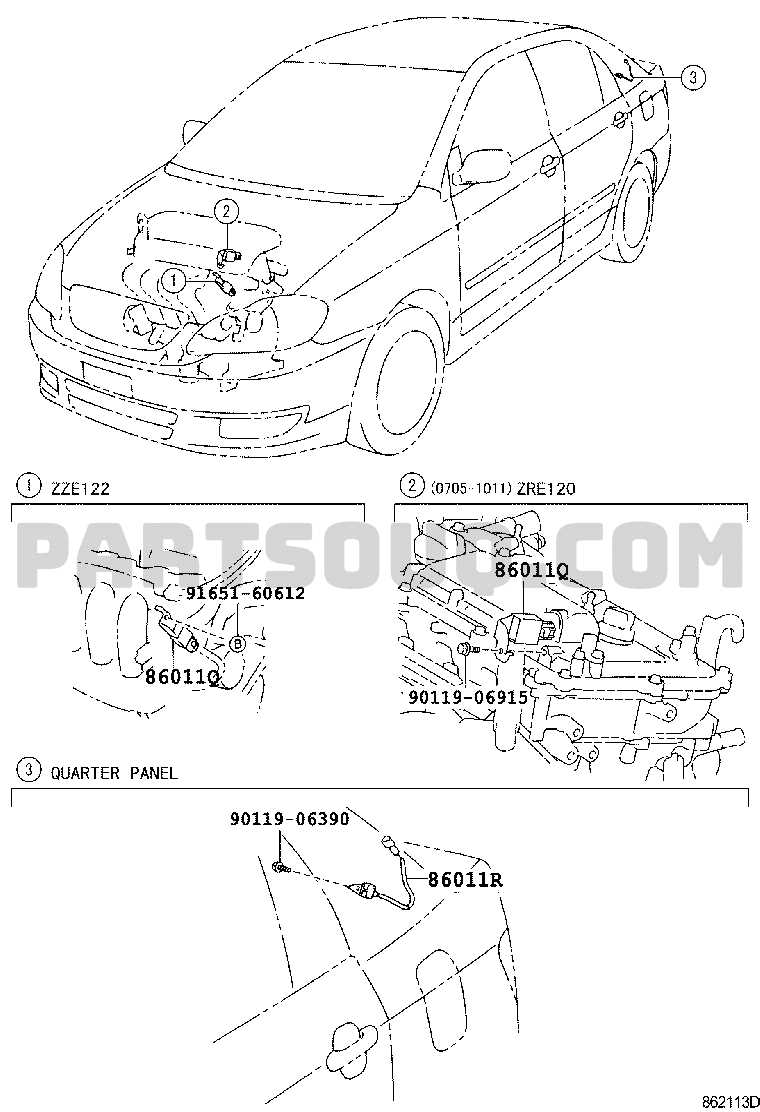

Where to Find Replacement Diagrams

Locating accurate visual references for automotive components can greatly enhance repair and maintenance efforts. Various sources provide reliable information that can guide individuals through their projects, ensuring the right elements are identified and replaced effectively.

Online Resources

The internet offers a plethora of websites dedicated to automotive repair. Websites like forums, manufacturer sites, and specialized automotive platforms are excellent starting points for finding detailed illustrations and manuals.

Printed Manuals

Hardcopy manuals often include comprehensive visuals that can be beneficial for hands-on work. These resources may be available at bookstores, libraries, or through automotive retailers.

| Source Type | Description |

|---|---|

| Online Forums | Community-driven platforms where users share diagrams and advice. |

| Manufacturer Websites | Official sites offering detailed technical documentation. |

| Repair Manuals | Printed guides with illustrations specific to various models. |