| Front Panel |

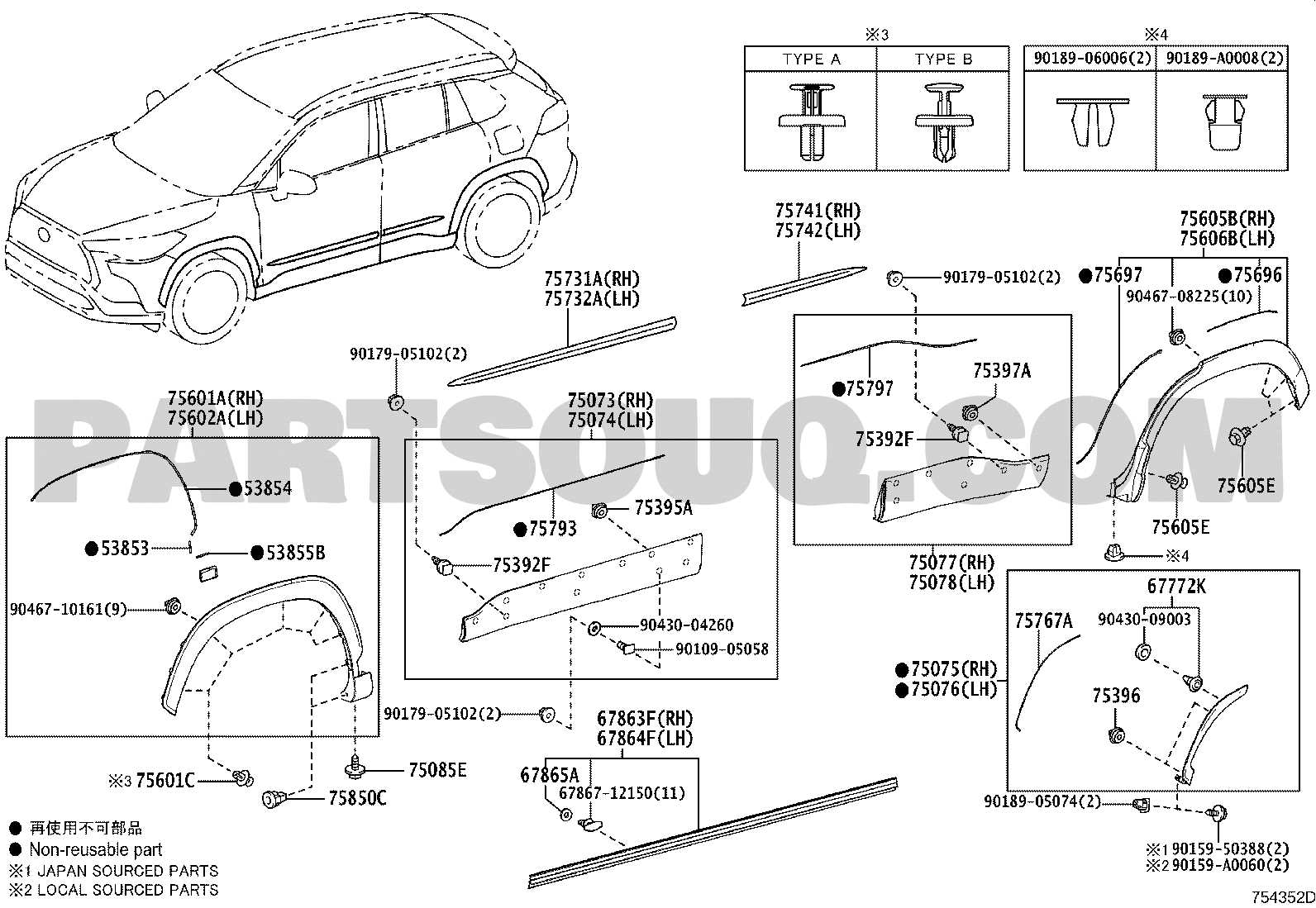

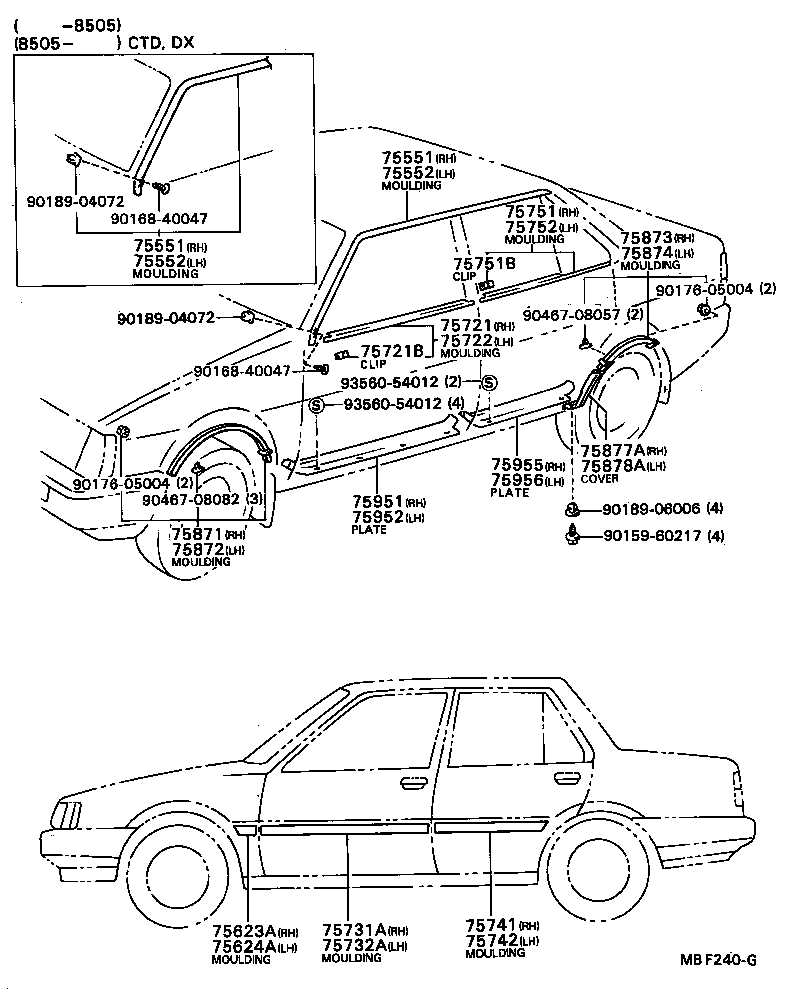

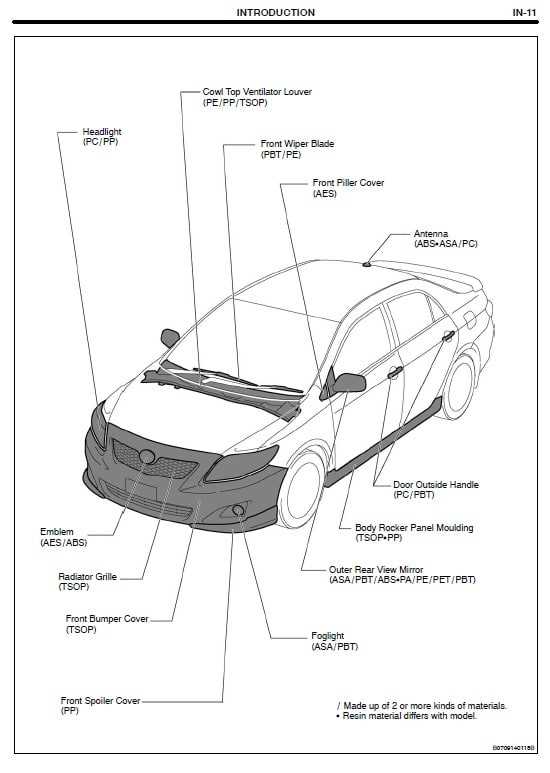

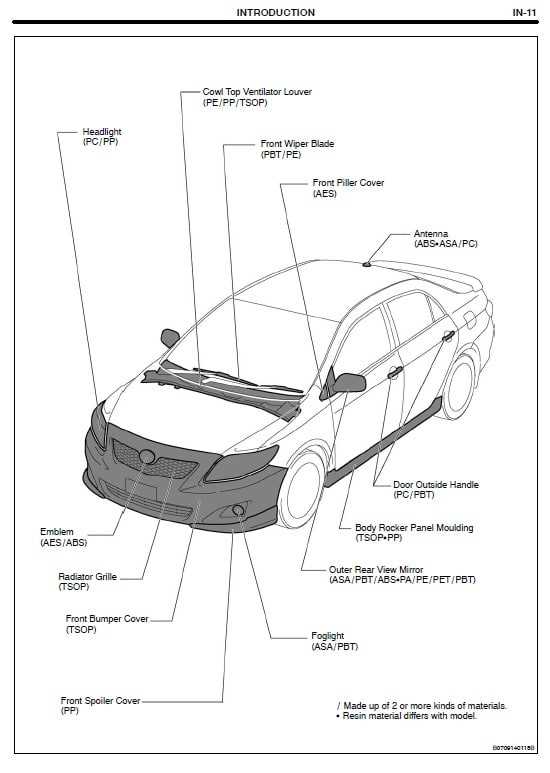

Identifying Outer Body Components

Understanding the exterior layout of a vehicle is essential for maintenance, customization, or repairs. Each element serves a specific function, contributing to both the aesthetic appeal and overall performance. In this section, we’ll explore the primary outer structures and their roles in the vehicle’s design.

- Front Section: This area includes key elements that influence the vehicle’s aerodynamics and first impressions. It often features components like grilles, light assemblies, and protective structures that ensure safety and style.

- Side Panels: The lateral parts of the vehicle provide structural integrity and support. These sections often house important details like door handles, windows, and mirror attachments, all crucial for functionality and access.

- Rear Segment: The back section of the vehicle plays a significant role in design and utility. It typically incorporates items like lighting clusters, trunk or hatch features, and mechanisms for ease of loading and visibility.

Each segment of the exterior is designed with both form and function in mind, making it vital to recognize their individual characteristics when assessing any changes or upgrades.

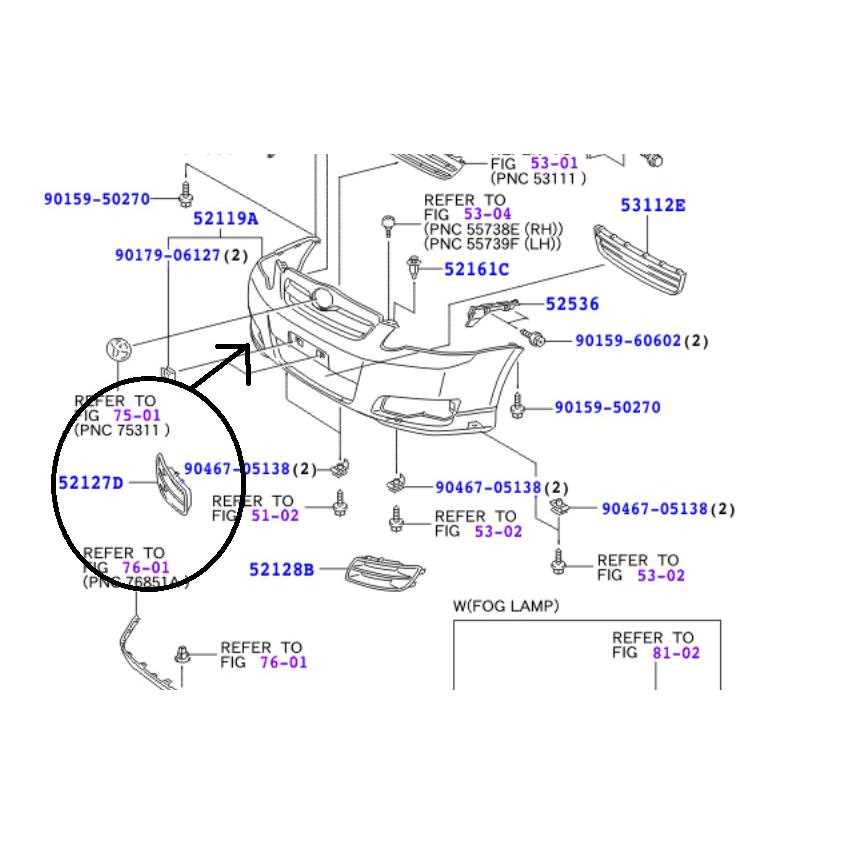

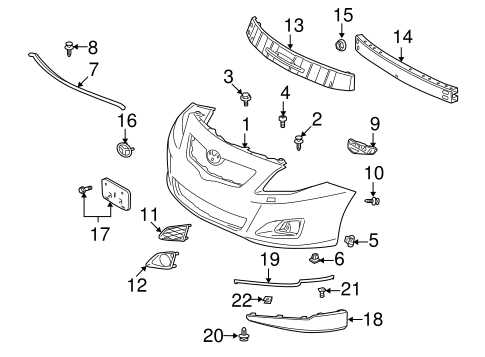

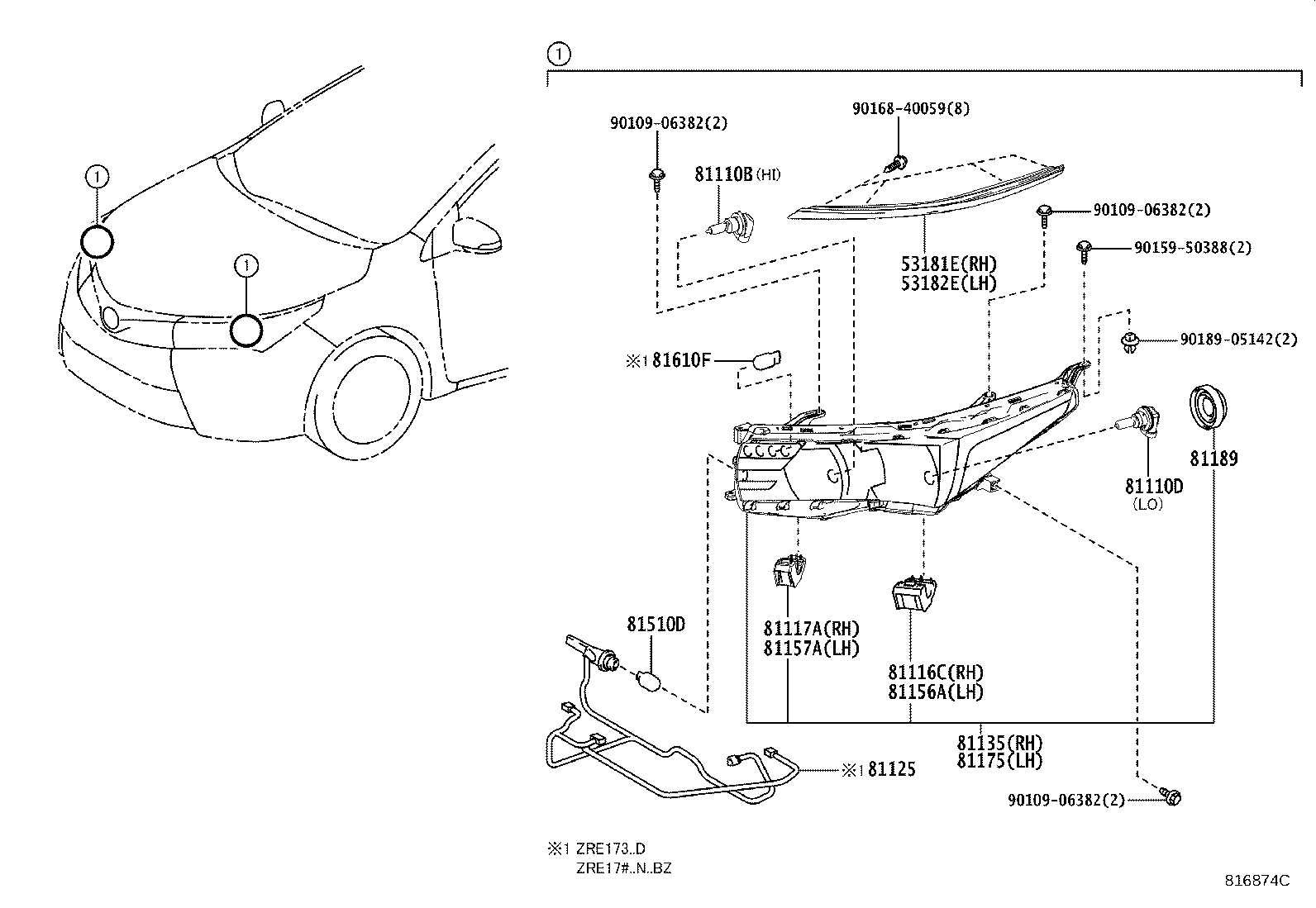

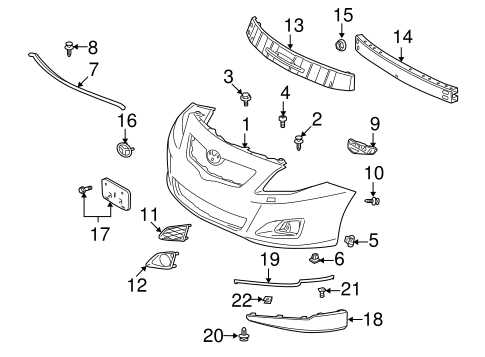

Front Bumper Assembly Details

The frontal protective structure plays a crucial role in both aesthetics and functionality. Its components are designed to absorb impact, enhance the vehicle’s appearance, and provide mounting points for other elements. Understanding the layout of this assembly can help with repairs or upgrades, ensuring all elements fit seamlessly.

- Main Structure: The core frame provides stability and serves as the base for attaching other components.

- Reinforcement Bar: Located behind the outer shell, this bar increases durability and helps to absorb collision forces.

- Cover Panel: This outer layer is typically made from lightweight materials and is designed to blend with the vehicle’s overall look.

- Mounting Brackets: These fixtures secure the assembly to the chassis, ensuring a stable attachment.

- Air Vents: Openings integrated into the assembly aid in cooling the engine by allowing airflow.

- Fasteners and Clips: Various clips and screws hold the parts together, maintaining the assembly’s integrity during operation.

- Inspect for Damage: Regularly check the assembly for cracks or loose parts to ensure safety and longevity.

- Replace Damaged Elements: Promptly swap out any worn or broken components to maintain the structure’s efficiency.

- Ensure Proper Alignment: During reassembly, verify that each piece is correctly positioned for optimal performance.

Exploring the Bumper’s Key Elements

The front and rear impact protectors of a vehicle play a crucial role in both aesthetics and functionality. Their design is focused on enhancing the appearance while providing an essential safeguard during minor collisions. Understanding these components helps to appreciate how they contribute to the vehicle’s durability and overall safety.

One of the primary elements includes the protective cover, which not only acts as a shield but also integrates seamlessly with the vehicle’s structure. This outer layer is often designed to absorb impact, reducing potential damage. Additionally, the support brackets are engineered to maintain the protector’s position, ensuring that it stays securely in place during movement.

Another significant feature involves the energy absorbers, situated behind the cover. These units are constructed to disperse force efficiently, minimizing the risk of structural harm. The inclusion of reinforcement bars further strengthens the setup, providing added resistance against forceful impacts.

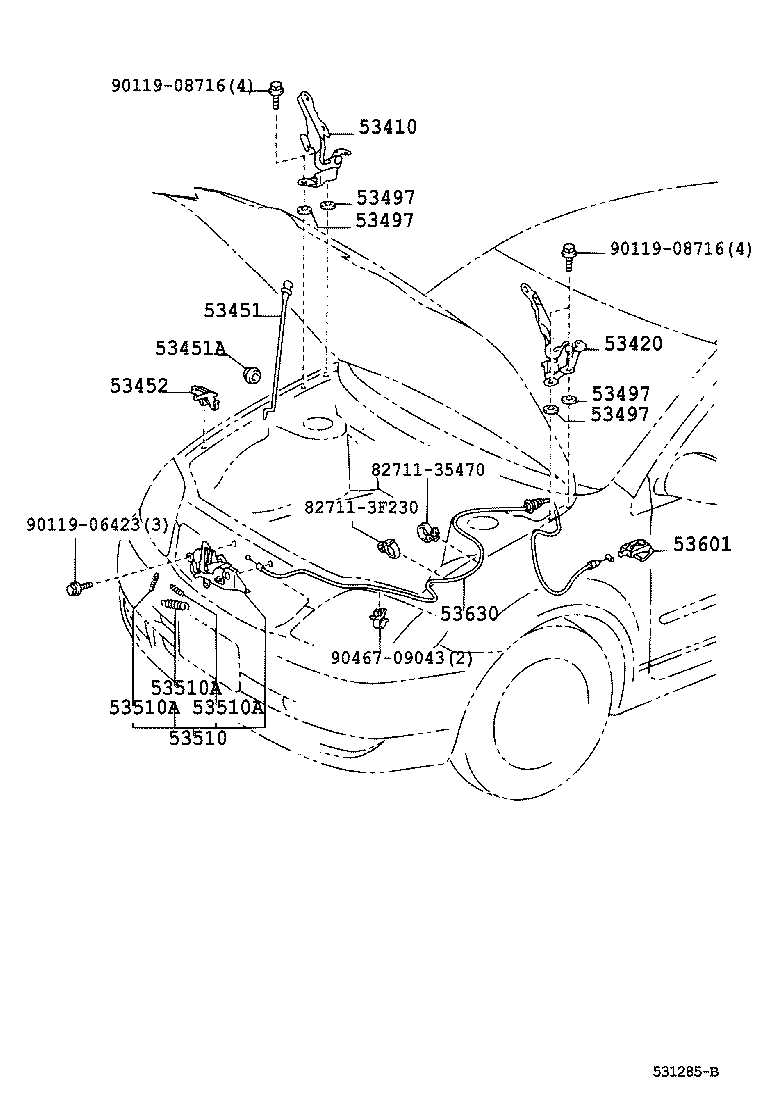

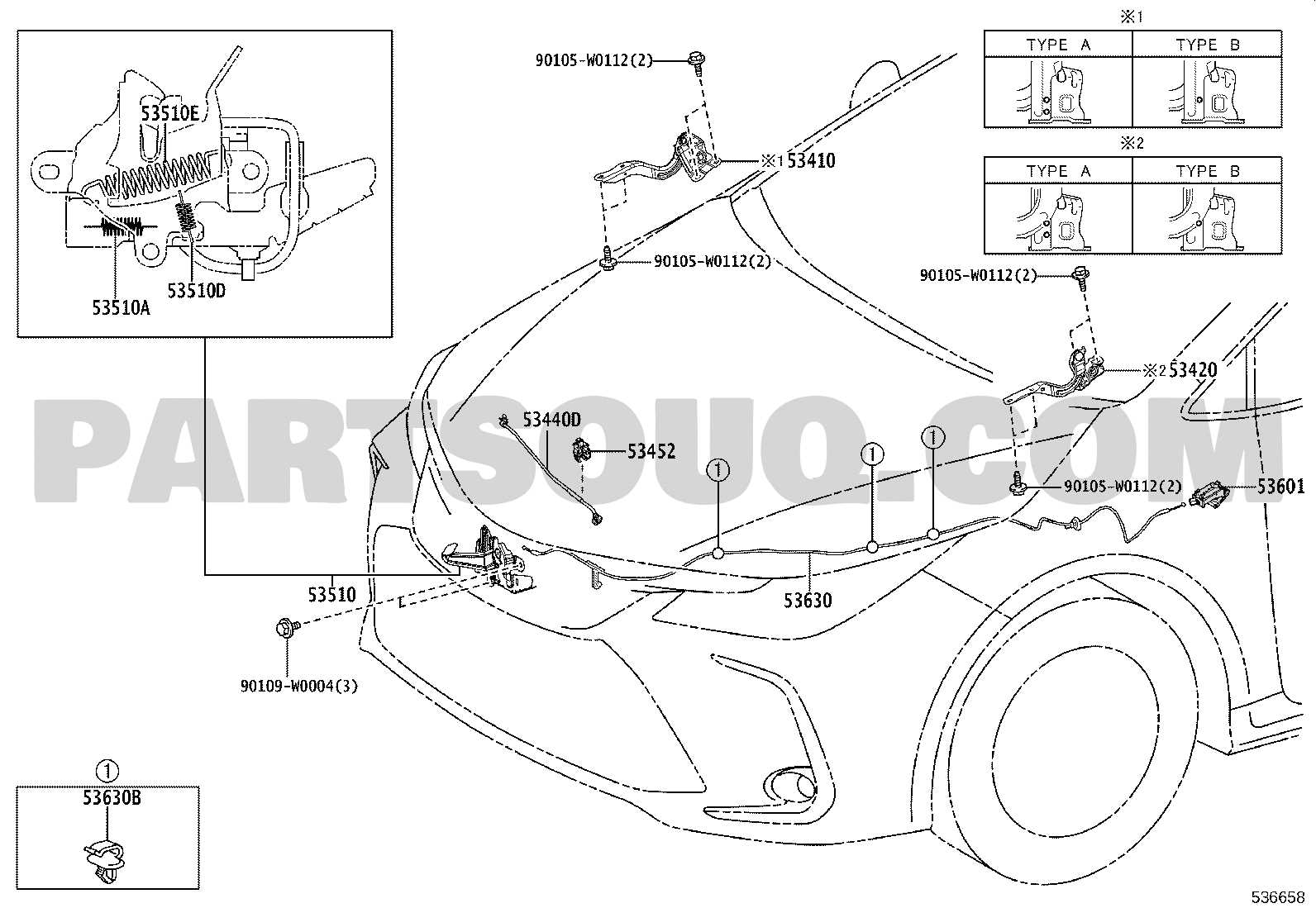

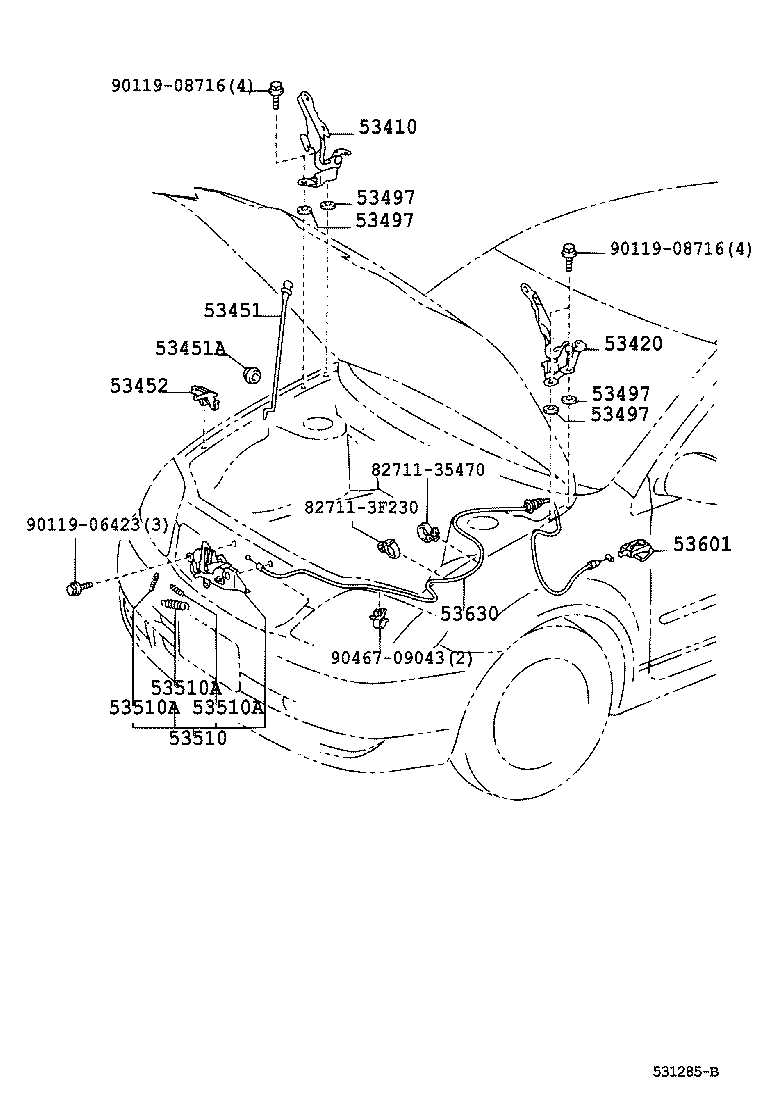

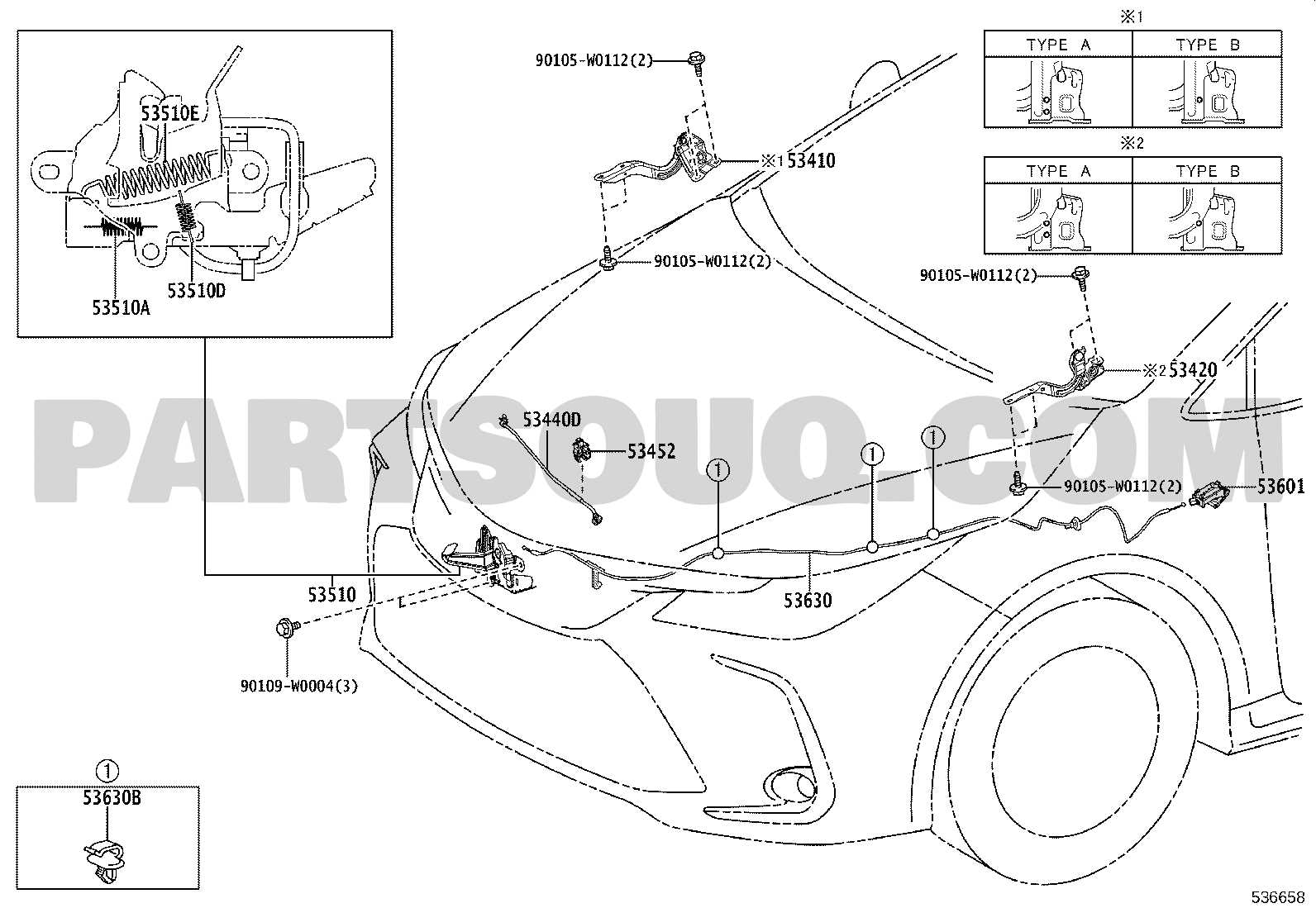

Hood Structure Breakdown

The hood is a crucial element in a vehicle’s exterior assembly, designed to provide protection and facilitate maintenance. This section explores the layout and construction of this component, highlighting its key features and materials used for durability and safety.

- Frame Design: The framework of the hood is crafted to ensure both rigidity and flexibility. Reinforced sections contribute to impact resistance, while the overall shape helps maintain aerodynamic efficiency.

- Outer Layer Composition: Typically, the outer surface consists of materials that balance strength and weight, such as aluminum or composite blends, enhancing both performance and fuel efficiency.

- Inner Support Structure: Beneath the visible layer, a network of support beams distributes force and maintains the panel’s shape, reducing the chances of deformation under stress.

- Insulation and Noise Reduction: Specialized insulation is often added to the underside to minimize engine noise and manage heat, contributing to a quieter cabin experience.

- Impact Zones: Strategic areas are designed to absorb energy in case of a collision, providing an additional layer of safety for the occupants.

- Latch and Hinge Mechanisms: The secure closing and easy opening of the hood rely on precisely engineered latch systems and robust hinge components, ensuring stability even during high-speed travel.

Analyzing the Hood’s Main Sections

Understanding the primary components of a vehicle’s front cover is essential for effective maintenance and repair. Each section plays a crucial role in both functionality and aesthetics, contributing to the overall performance and appearance of the automobile.

Structural Framework: The framework provides the necessary support, ensuring that the cover remains secure during operation. It must be robust enough to withstand external forces while maintaining its integrity.

Insulation Layer: This section serves to minimize noise and heat transfer, enhancing the comfort of the interior space. Proper insulation is vital for improving the driving experience and ensuring efficient engine operation.

Release Mechanism: The mechanism enables easy access to the engine compartment for maintenance tasks. A reliable release system is crucial for ensuring user convenience and safety during inspections.

Exterior Finish: The outer layer not only protects the underlying components from environmental damage but also contributes to the vehicle’s overall aesthetics. A well-maintained finish enhances the visual appeal and resale value.

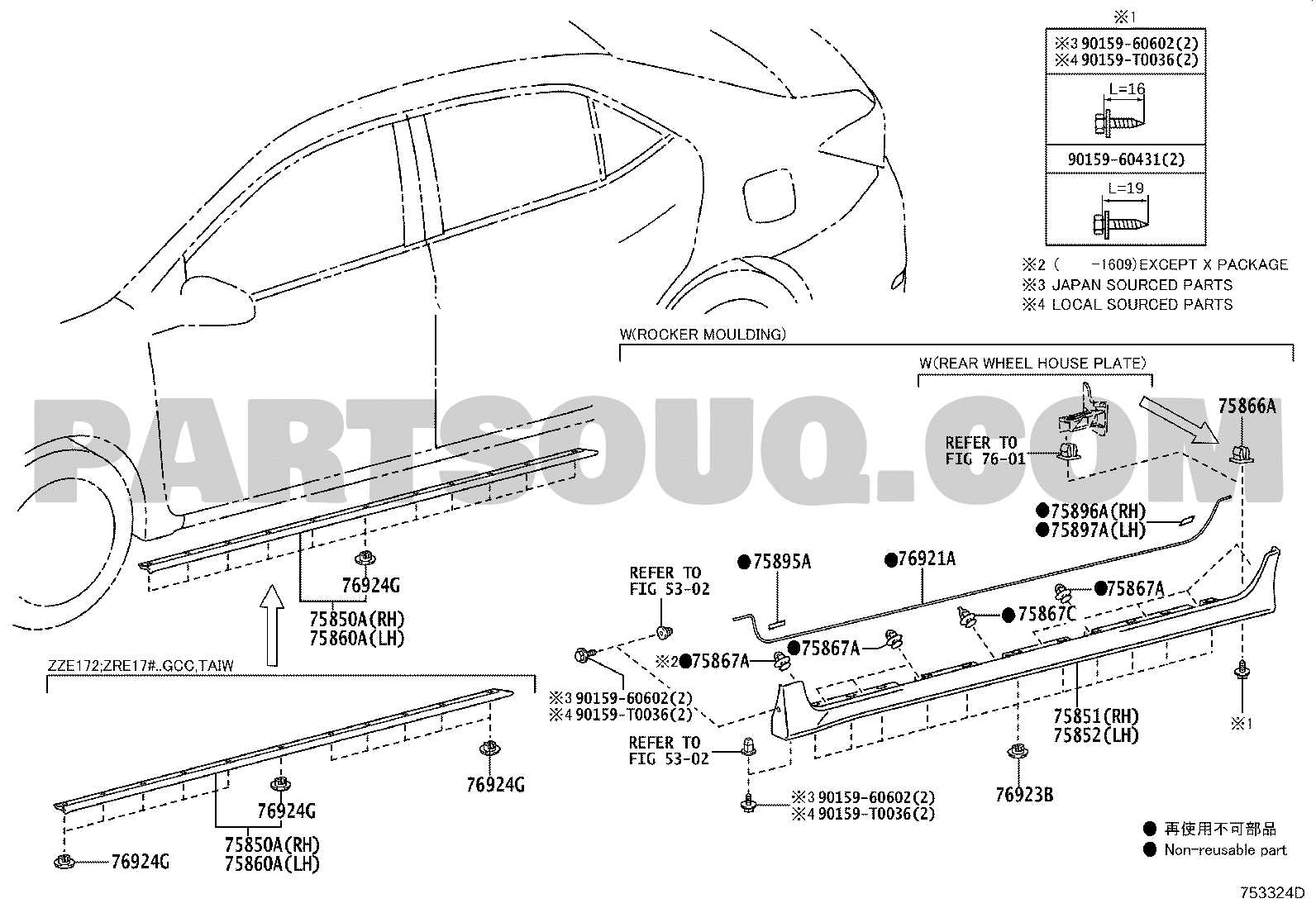

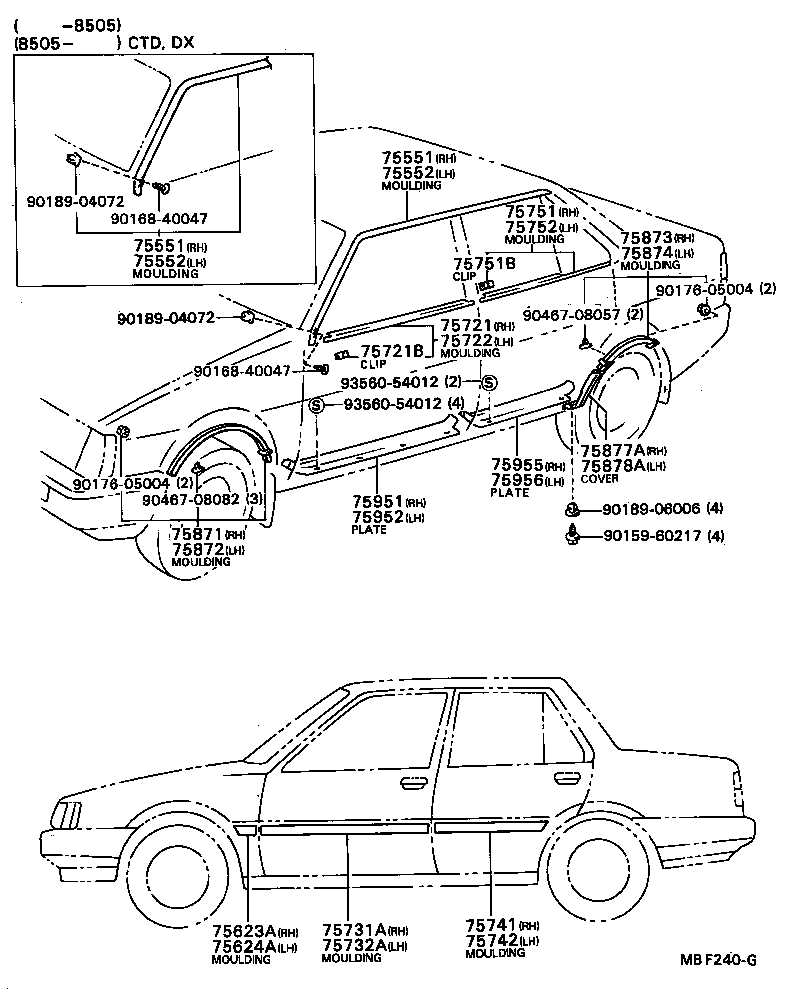

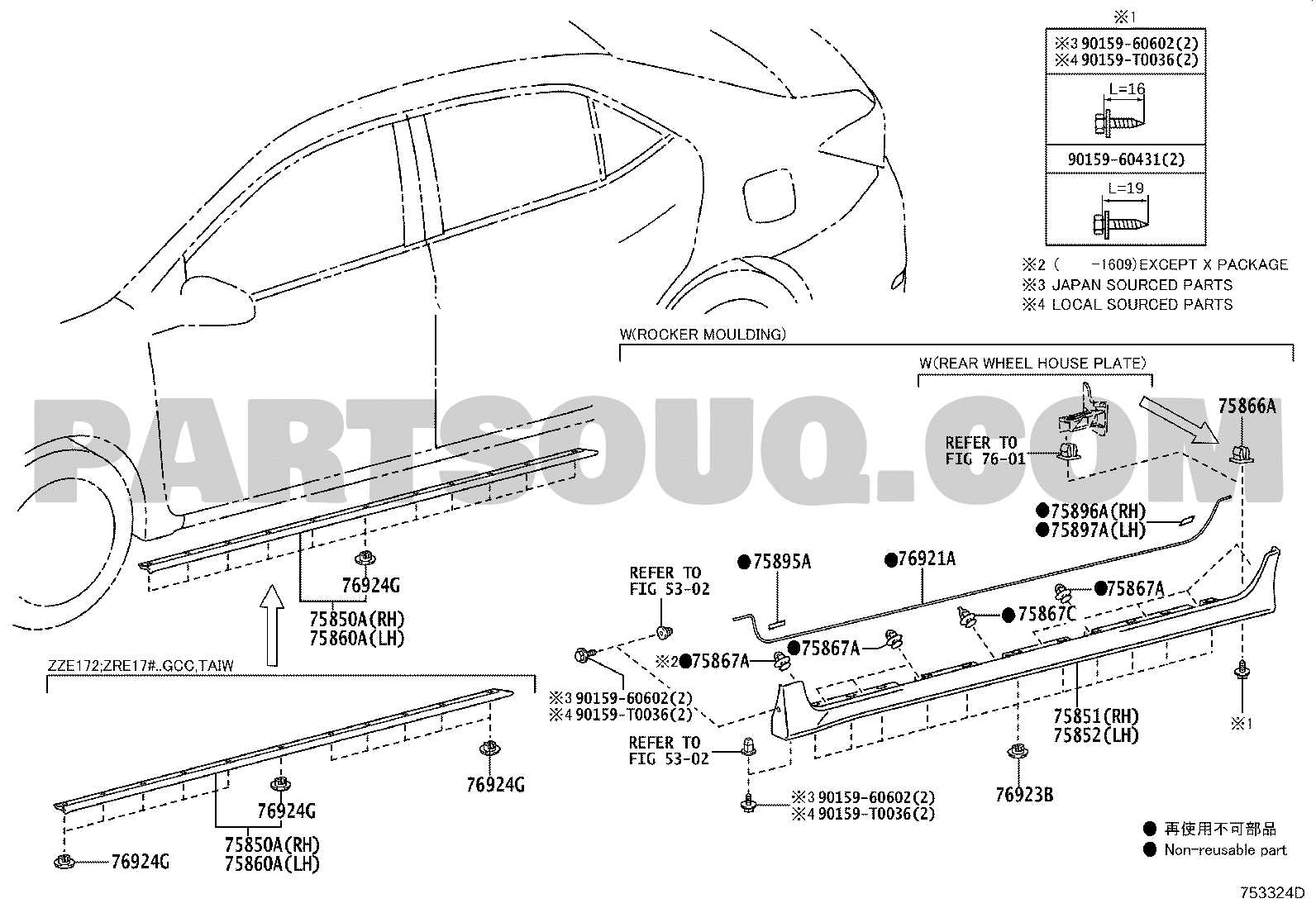

Door Frame Components

The structure surrounding the entryway plays a vital role in ensuring both safety and functionality. This framework is composed of various elements that work together to support the door and enhance its performance. Understanding these components can provide valuable insights into maintenance and repair processes.

Key elements of the door frame include:

- Vertical Posts: These sturdy components run along the sides, providing essential support and stability.

- Header: Positioned at the top, this element adds strength to the overall structure, helping to distribute weight evenly.

- Sill Plate: Found at the bottom, it serves as a base for the door and helps to prevent water intrusion.

- Jambs: These side sections are critical for holding the door in place, allowing it to swing smoothly.

- Weather Stripping: This material lines the edges to keep out drafts, moisture, and noise, enhancing comfort inside the vehicle.

By familiarizing oneself with these components, one can better appreciate their functions and significance in the overall design.

Understanding Door Assembly Parts

The components of a door assembly play a crucial role in ensuring the functionality and security of a vehicle. Each element contributes to the overall performance and user experience, affecting how the door operates, seals, and interacts with other systems. A comprehensive grasp of these elements aids in maintenance and repair, allowing for informed decisions regarding replacements or upgrades.

Main Components of a Door Assembly

The primary elements include the outer shell, inner panel, window mechanism, and locking system. The outer shell provides structural integrity and aesthetic appeal, while the inner panel houses essential components such as wiring and insulation. The window mechanism enables smooth operation of the glass, and the locking system enhances security, preventing unauthorized access.

Correct installation of each component is vital for the door’s performance. Misalignment can lead to issues such as rattling, water leaks, or difficulty in closing. Regular inspection of these components ensures longevity and proper functionality, making it essential for vehicle upkeep.

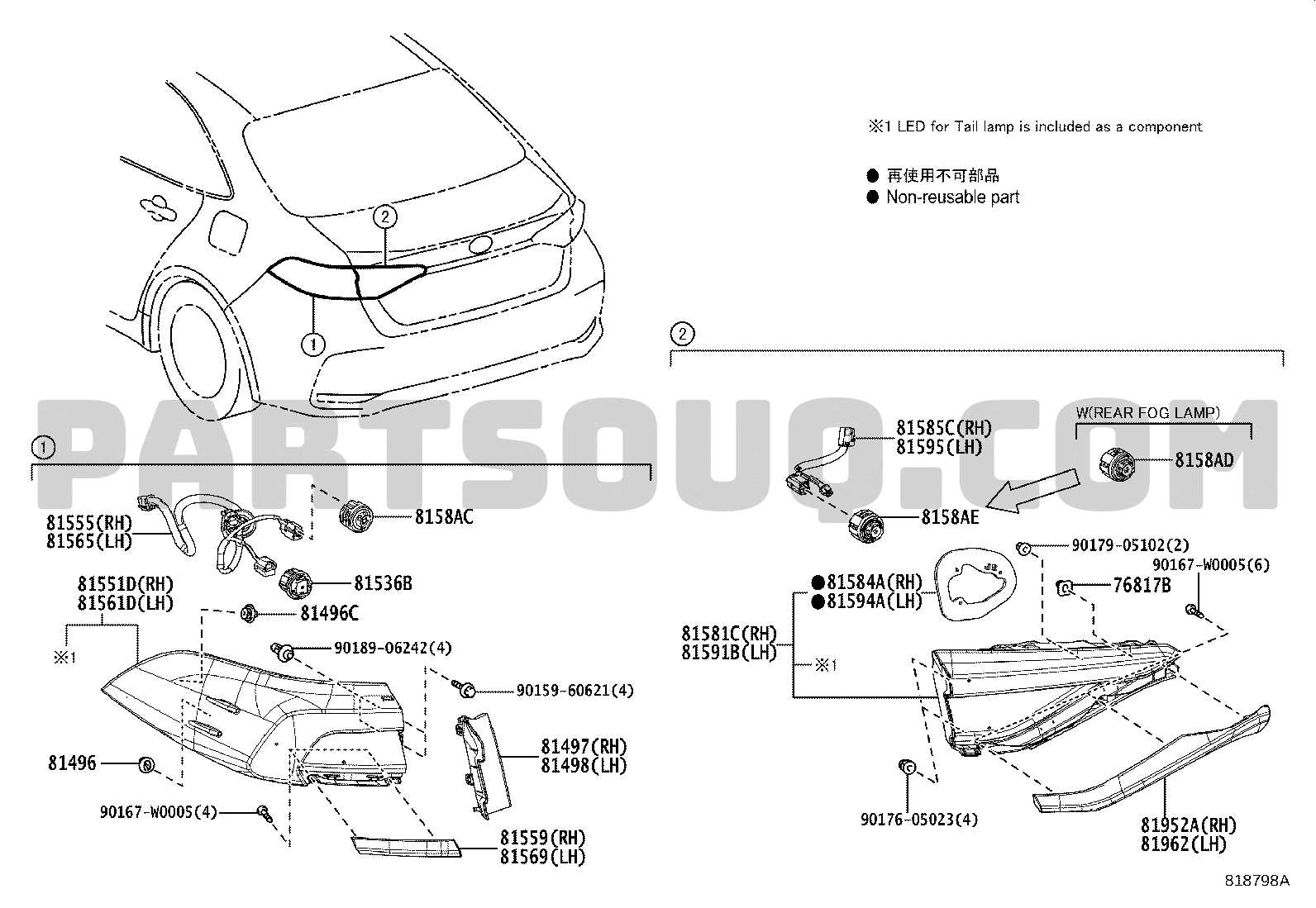

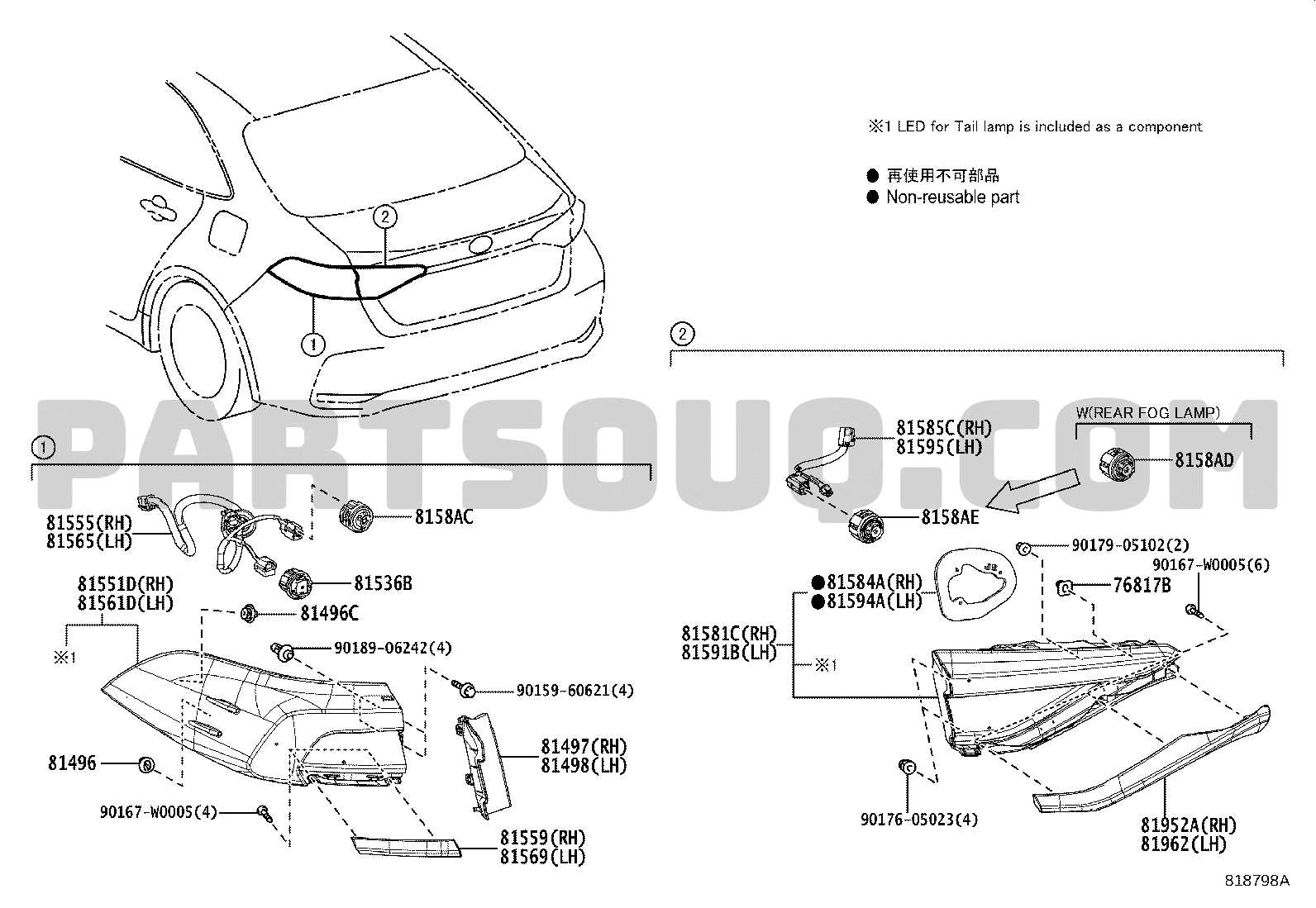

Rear Bumper Configuration

The rear protective structure plays a crucial role in the overall functionality and aesthetics of a vehicle. It is designed to absorb impact and safeguard the rear section, contributing to safety and style. Understanding the various components involved in this assembly can enhance maintenance and repair efforts.

Key Components

- Impact Absorber

- Reinforcement Bar

- Outer Cover

- Mounting Brackets

- Reflectors

Installation Considerations

- Ensure proper alignment of the protective assembly with the chassis.

- Check for compatibility with the mounting hardware.

- Verify that all electrical connections for lighting are secure.

- Use appropriate tools for fastening to avoid damage.

Regular inspections of this rear structure are essential to identify any signs of wear or damage, ensuring optimal performance and appearance.

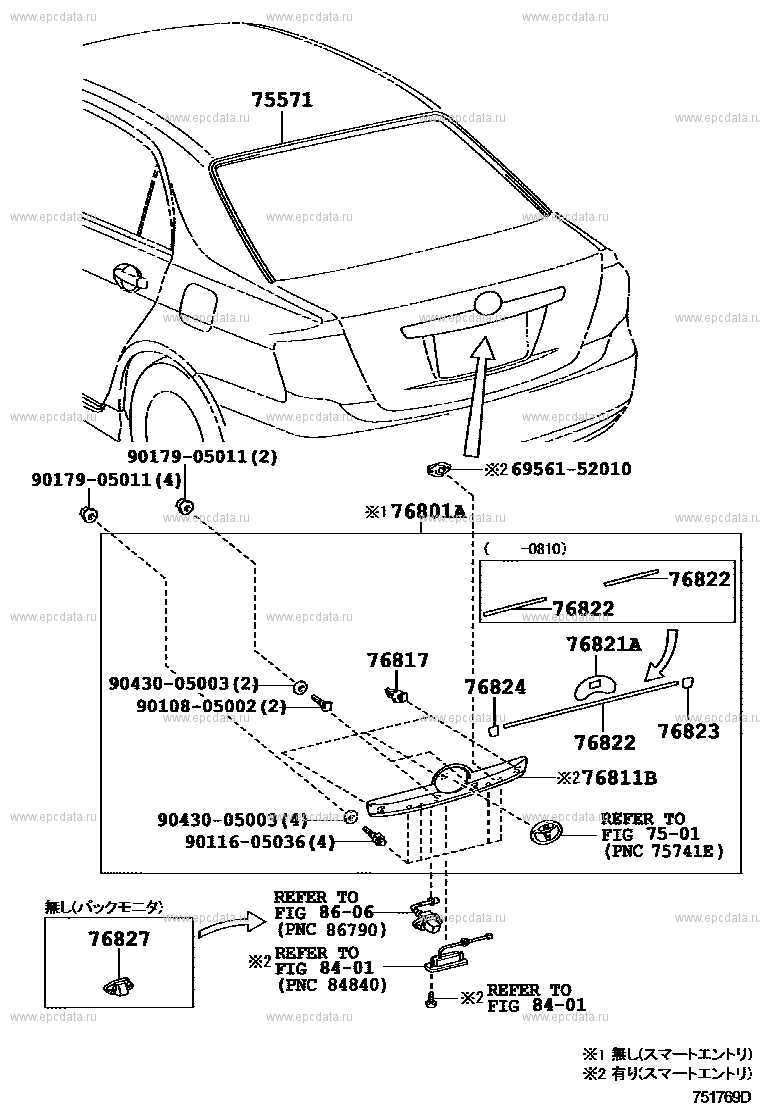

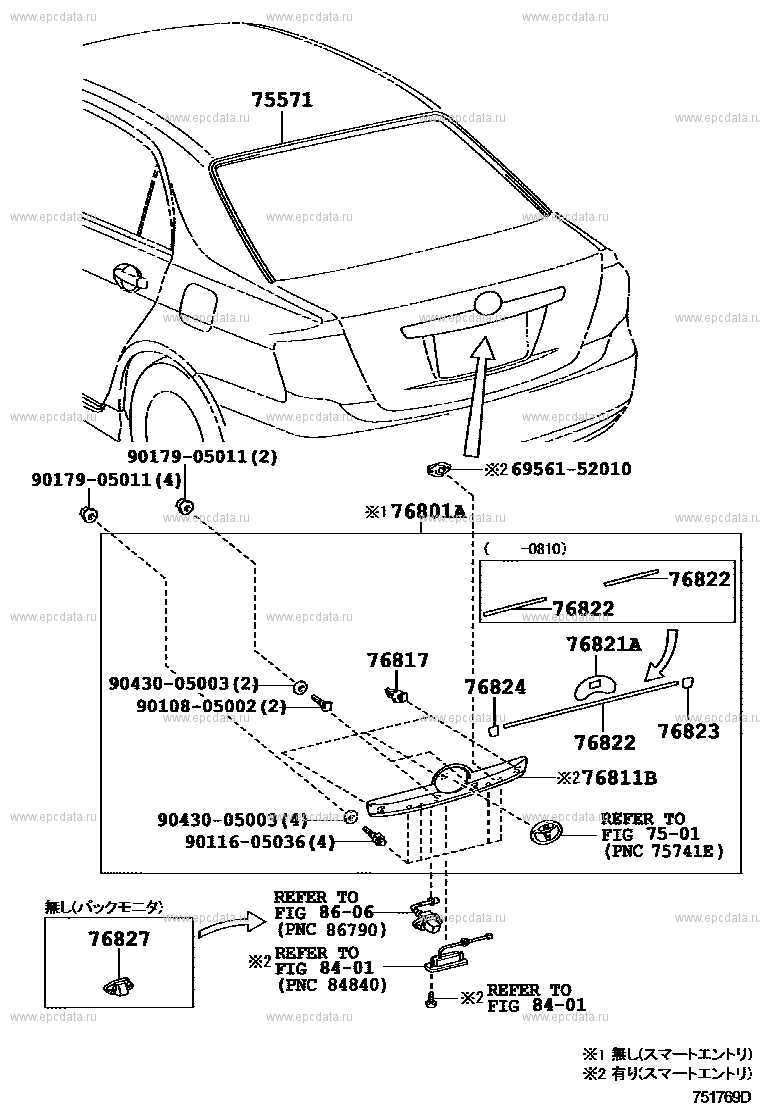

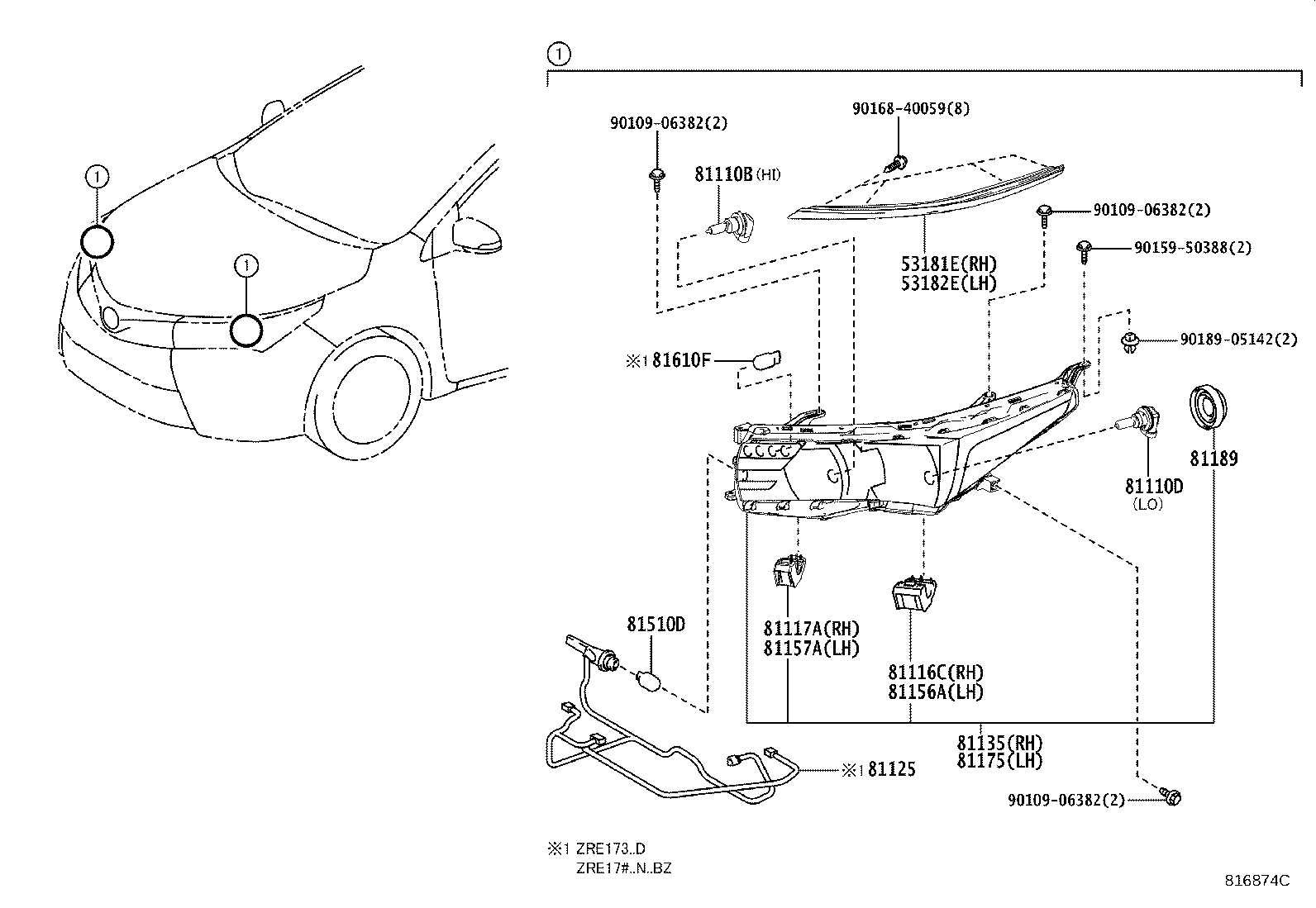

Mapping Rear-End Body Elements

Understanding the various components located at the rear section of a vehicle is essential for both maintenance and repair. Each element plays a significant role in the overall functionality and aesthetics, contributing to safety and performance. Analyzing these components allows for effective troubleshooting and enhances the overall driving experience.

Key Components Overview

The rear section consists of several crucial elements, including the trunk lid, bumper assembly, and tail lights. Each of these elements serves specific functions, from protecting the interior space to providing visibility to other drivers. Recognizing their layout and interconnections is vital for any repair process.

Importance of Proper Identification

Accurate identification of these elements can streamline the repair process, ensuring that all components are compatible and functioning correctly. Understanding the arrangement not only aids in repairs but also assists in upgrades or modifications, enhancing the vehicle’s performance and appearance.

Trunk Lid Composition

The rear closure element plays a vital role in the overall structure and functionality of a vehicle. Its design incorporates various materials and components that ensure durability, aesthetics, and efficiency. Understanding the composition of this essential part helps in recognizing its contribution to both safety and performance.

Material Selection

This closure is typically crafted from a combination of lightweight metals and robust polymers. The choice of materials aims to balance strength and weight, enhancing fuel efficiency while providing adequate protection for the cargo area. Advanced manufacturing techniques often lead to improved resistance to environmental factors, such as corrosion and impact.

Functional Elements

In addition to the primary structure, this component features several functional elements, including sealing systems and locking mechanisms. These features are designed to ensure a secure closure while preventing water intrusion and enhancing user convenience. Proper functioning of these elements is crucial for maintaining the integrity of the enclosed space.

Details of the Rear Hatch Structure

The rear hatch assembly plays a crucial role in providing accessibility and security to the storage area of a vehicle. Its design encompasses various components that contribute to both functionality and aesthetics. Understanding these elements is essential for maintenance and repairs.

Components Overview

This section outlines the main elements that constitute the rear hatch assembly, including their functions and interconnections. These components work together to ensure proper operation and durability.

| Component |

Description |

Function |

| Hatch Frame |

The structural outline that supports the hatch. |

Provides rigidity and shapes the hatch design. |

| Glass Panel |

Transparent covering that allows visibility. |

Facilitates rear visibility and aesthetics. |

| Locking Mechanism |

System that secures the hatch in place. |

Ensures the hatch remains closed during operation. |

| Weather Seals |

Rubber or foam strips along the edges. |

Prevents water and dust ingress into the storage area. |

| Struts |

Gas-filled supports that assist in lifting the hatch. |

Enables easy opening and closing of the hatch. |

Maintenance Considerations

Regular inspections of the rear hatch assembly are essential for ensuring longevity and performance. Key areas to check include the locking mechanism for smooth operation, weather seals for wear, and struts for adequate support. Proper care can prevent costly repairs and enhance overall vehicle safety.

Side Mirror Elements

The external reflective units are crucial components of a vehicle, enhancing both safety and functionality. These structures provide drivers with a clear view of the surroundings, aiding in effective navigation and maneuvering.

Typically, the assembly consists of several key components. The reflective surface plays a pivotal role in visibility, allowing the driver to observe approaching vehicles and obstacles. This surface is often adjustable, providing customizable angles for optimal viewing.

Additionally, the housing protects the reflective surface and internal mechanisms from environmental factors. It is designed to withstand impacts and resist weathering, ensuring longevity. Furthermore, many units include integrated features such as turn signal indicators and heating elements to enhance functionality and safety during adverse conditions.