Exploring the intricate layouts of vehicle assemblies reveals a complex world where precision and engineering excellence converge. Each element plays a crucial role in ensuring optimal performance and reliability. Gaining insights into these configurations can greatly enhance one’s comprehension of automotive mechanics.

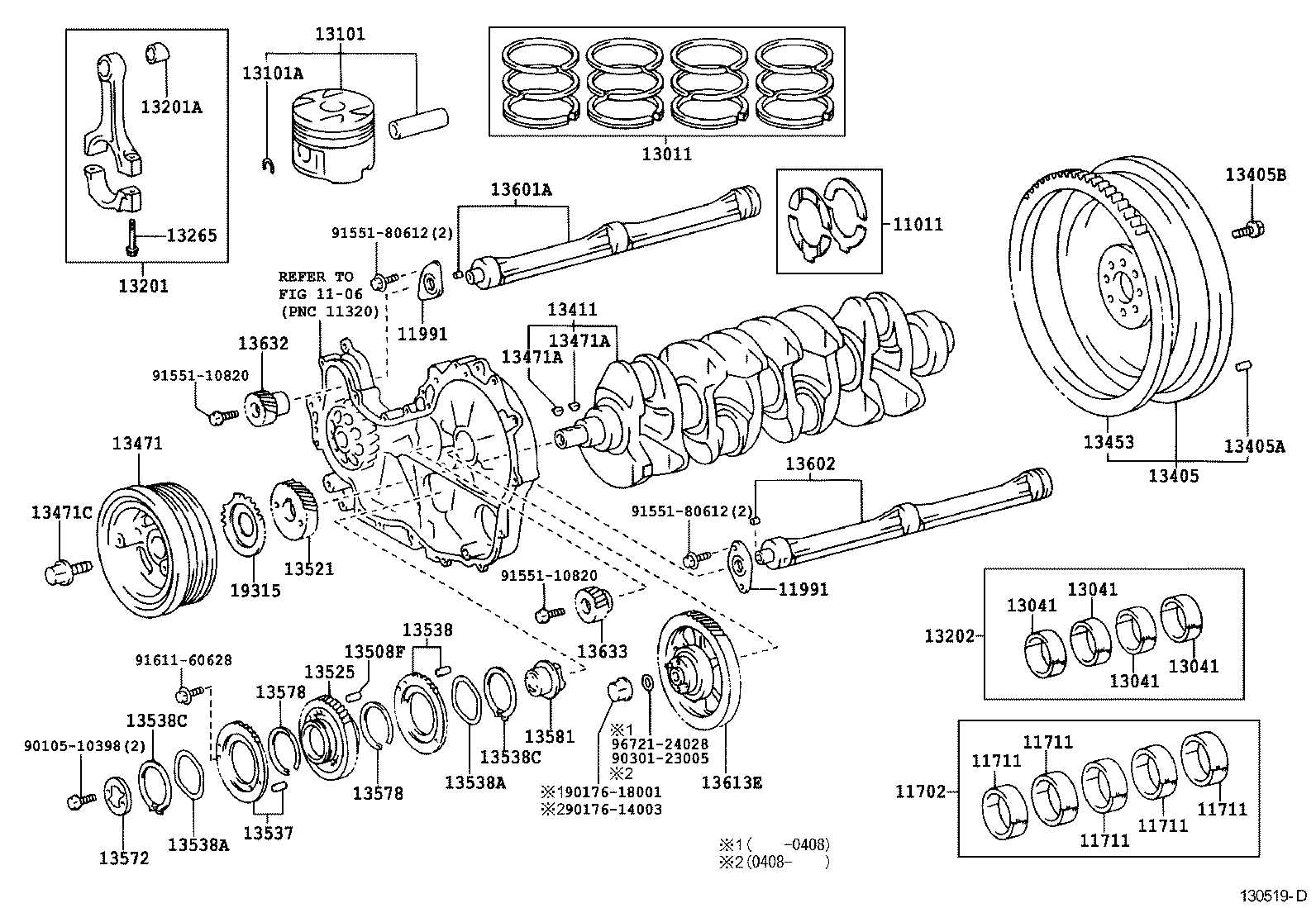

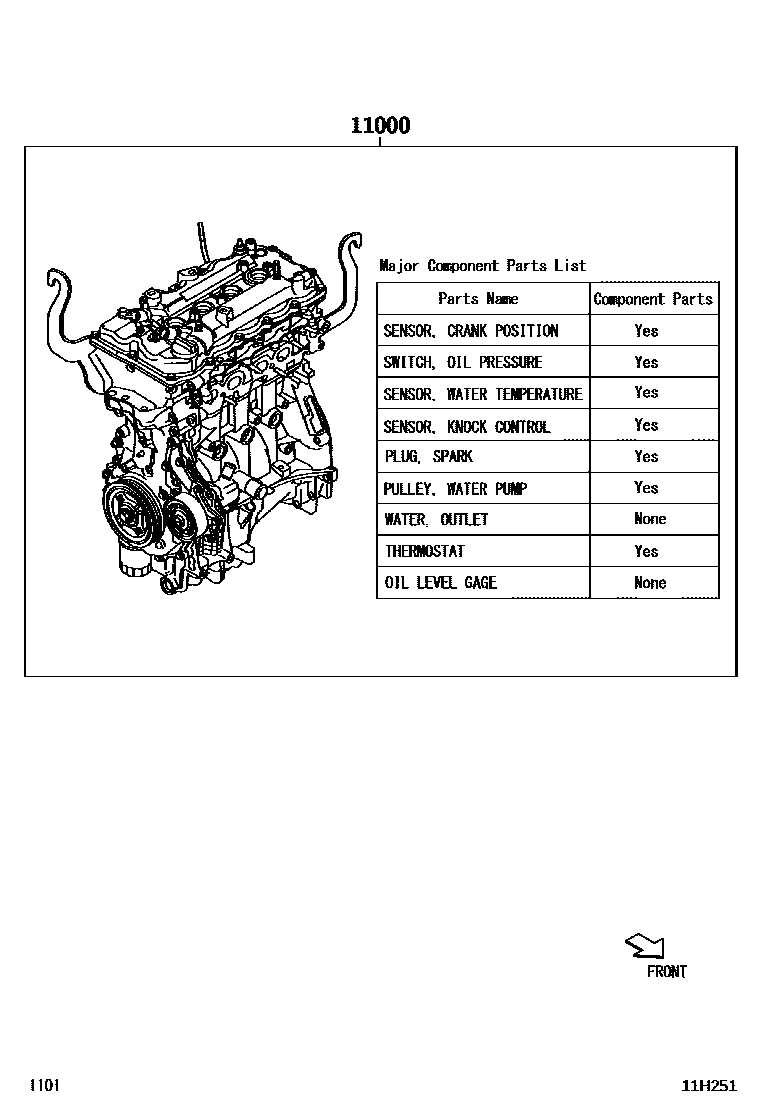

Visual representations of these assemblies provide clarity and facilitate a deeper understanding of how various elements interact. By studying these illustrations, enthusiasts and professionals alike can unravel the relationships between components, leading to informed decisions during maintenance or upgrades.

Furthermore, familiarity with these schematic representations empowers individuals to tackle repairs with confidence. Armed with the right knowledge, one can navigate the intricacies of vehicle systems, ensuring longevity and efficiency. Whether for educational purposes or hands-on applications, mastering these layouts is essential for anyone involved in automotive care.

Automotive Components Overview

This section provides a comprehensive look at the essential elements that contribute to the functionality and performance of a vehicle’s power system. Understanding these components is crucial for both maintenance and enhancements, ensuring optimal operation and longevity.

Main Functional Elements

- Combustion Chamber

- Fuel Delivery System

- Ignition System

- Cooling Mechanism

- Lubrication System

Supporting Components

- Crankshaft

- Camshaft

- Valves and Springs

- Piston Assembly

- Exhaust System

Each of these elements plays a vital role in ensuring that the vehicle operates efficiently and meets performance standards. Regular inspection and understanding of these systems can help in troubleshooting and improving overall vehicle health.

Understanding Engine Part Functions

In any mechanical system, the individual components work together to achieve optimal performance. Each element plays a vital role, contributing to the overall efficiency and functionality. Understanding how these components interact is crucial for maintenance and troubleshooting, ensuring that the entire assembly operates smoothly.

Key Functions of Major Components

The various elements within a mechanical assembly serve distinct purposes that enhance operational effectiveness. Here’s a brief overview of some critical functions:

| Component | Function |

|---|---|

| Piston | Converts pressure into mechanical work. |

| Crankshaft | Transforms linear motion into rotational motion. |

| Camshaft | Controls the timing of valve openings and closings. |

| Fuel Injector | Delivers fuel into the combustion chamber. |

| Ignition Coil | Provides the spark needed for combustion. |

Interconnected Roles

The synergy among these components is essential for peak performance. Any malfunction in one area can lead to a cascade of issues affecting the entire system. Regular inspections and understanding the functionality of each part can significantly enhance longevity and reliability.

Common Toyota Engine Models Explained

This section provides an overview of widely recognized powertrain types produced by a leading automotive manufacturer. These configurations are known for their reliability and performance, catering to various vehicle categories, from compact cars to larger SUVs.

Overview of Popular Configurations

Different variations of internal combustion setups are designed to meet specific needs. Each configuration typically features unique characteristics that influence efficiency, power output, and emissions.

| Model | Type | Displacement | Power Output |

|---|---|---|---|

| 2ZR-FE | Inline-4 | 1.8L | 132 hp |

| 1NZ-FE | Inline-4 | 1.5L | 109 hp |

| 3MZ-FE | V6 | 3.3L | 225 hp |

Key Features and Applications

These distinct types are engineered to deliver specific benefits. For instance, smaller configurations excel in fuel efficiency, making them ideal for urban driving, while larger setups often provide enhanced torque for towing capabilities in larger vehicles.

Key Differences in Engine Designs

The evolution of mechanical power sources has led to various configurations, each tailored to specific performance characteristics and efficiency standards. These variations impact everything from torque delivery to fuel consumption, shaping the driving experience.

Configurations can range from inline setups to V-shaped arrangements, influencing overall size and weight distribution. For instance, inline designs often offer simplicity and compactness, while V-configurations can provide enhanced power output in a more condensed form.

Materials used in construction also play a crucial role, with advancements in composites and alloys leading to lighter and stronger structures. This innovation contributes to better thermal management and durability under stress.

Furthermore, valve mechanisms vary significantly; some systems utilize overhead cam designs for efficiency, while others may employ pushrod arrangements, each with its own advantages in terms of responsiveness and complexity.

Ultimately, understanding these distinctions is essential for enthusiasts and professionals alike, as they delve into the intricacies of performance and reliability in modern mechanical designs.

How to Read Engine Diagrams

Understanding technical illustrations is crucial for anyone involved in automotive maintenance or repair. These visual representations convey complex information in a simplified format, helping individuals grasp the relationships and functions of various components within a system. By familiarizing oneself with the symbols and layout, one can effectively troubleshoot and service the machinery.

Familiarizing with Symbols

Every schematic utilizes specific symbols to denote different elements. Learning these representations is essential, as they vary across different systems. Refer to a legend or key that accompanies the illustration to decode what each symbol signifies.

Analyzing the Layout

The arrangement of components in these illustrations often reflects their physical connections and interactions. Observing the flow of connections and the positioning of parts will enhance your understanding of how they work together to achieve optimal performance.

Essential Tools for Engine Repair

When tackling any mechanical restoration, having the right instruments at your disposal is crucial for a successful outcome. Each tool plays a vital role in ensuring precision and efficiency throughout the process.

- Wrenches: Adjustable and socket types are fundamental for loosening or tightening components.

- Ratchet and Socket Set: Provides versatility for various fastener sizes and hard-to-reach areas.

- Screwdrivers: Both flathead and Phillips are necessary for removing and securing screws.

- Pliers: Essential for gripping, twisting, and cutting wires and small parts.

- Torque Wrench: Ensures that fasteners are tightened to the manufacturer’s specifications.

Utilizing these tools will enhance your ability to perform effective repairs, ultimately leading to better performance and longevity of the machinery.

Finding Genuine Toyota Parts

When it comes to maintaining your vehicle, ensuring the use of authentic components is crucial for performance and longevity. These original elements are designed to meet specific standards, providing reliability and enhancing overall functionality. Choosing genuine replacements helps avoid issues often associated with substandard alternatives.

Benefits of Authentic Components

Using original components guarantees compatibility with your vehicle’s systems. Quality is paramount; authentic elements undergo rigorous testing to meet manufacturer specifications. This means you can trust their durability and effectiveness, reducing the risk of future complications.

Where to Find Authentic Options

To acquire genuine components, consider visiting authorized dealers or certified retailers. They typically offer a wide selection of original products, ensuring that what you purchase aligns with your vehicle’s needs. Online platforms can also provide access to trusted sellers, but always verify their credibility before making a purchase.

Aftermarket vs. OEM Components

The choice between alternative and original components can significantly impact performance, durability, and cost. Understanding the nuances of each option is crucial for making informed decisions that align with both personal preferences and vehicle needs.

Benefits of OEM Components

Original parts are designed specifically for a particular vehicle, ensuring a precise fit and adherence to manufacturer specifications. This often results in better reliability and peace of mind, as they come with warranties and are subject to rigorous quality control standards.

Advantages of Aftermarket Options

On the other hand, alternative components can offer competitive pricing and a wider selection. Many brands focus on enhancing performance and durability, appealing to enthusiasts looking to customize their vehicles. However, it’s essential to research the manufacturer’s reputation to ensure quality and compatibility.

Maintenance Tips for Engine Longevity

Ensuring the durability of your vehicle’s core components is essential for optimal performance and efficiency. Adopting a proactive approach to upkeep can significantly enhance the lifespan of crucial machinery. Here are some effective strategies to consider.

Regular Checks

- Inspect fluid levels frequently, including oil and coolant.

- Look for leaks or unusual noises that may indicate underlying issues.

- Monitor temperature gauges to prevent overheating.

Scheduled Maintenance

- Follow the manufacturer’s recommended service intervals.

- Replace filters regularly to ensure clean operation.

- Keep belts and hoses in good condition to avoid failures.

Diagnosing Engine Problems Easily

Identifying issues within a vehicle’s machinery can often seem daunting, but with the right approach, it becomes a manageable task. Understanding the common signs of trouble and employing systematic methods can help in pinpointing the root cause. This section will provide you with essential techniques to simplify the troubleshooting process and enhance your confidence in handling mechanical complications.

Common Symptoms to Watch For

Start by observing unusual sounds, vibrations, or changes in performance. Anomalies like knocking, sputtering, or difficulty in starting are indicators that something might be amiss. Additionally, pay attention to warning lights on the dashboard; these often serve as an initial alert to underlying issues that require immediate attention.

Steps for Effective Troubleshooting

Begin with a thorough visual inspection of accessible components. Look for signs of wear, leaks, or loose connections. Next, utilize diagnostic tools to retrieve error codes that can provide insights into the specific area needing attention. Finally, consider consulting repair manuals or online resources for detailed guidance on the identified problems, which will facilitate a more accurate and efficient resolution.

Performance Upgrades for Toyota Engines

Enhancing the capabilities of your vehicle’s mechanical heart can significantly improve driving experience and overall power. Various modifications can be made to optimize efficiency, increase horsepower, and achieve better handling. This section explores popular enhancements that enthusiasts often consider for maximum performance.

| Upgrade Type | Description |

|---|---|

| Cold Air Intake | Increases airflow to improve combustion efficiency. |

| High-Performance Exhaust | Reduces back pressure and enhances sound while boosting power. |

| ECU Tuning | Optimizes fuel and ignition settings for improved performance. |

| Turbocharger/Supercharger | Forces more air into the combustion chamber, significantly increasing power. |

| Upgraded Fuel Injectors | Allows for more precise fuel delivery, supporting higher power outputs. |

Resources for Further Learning

To deepen your understanding of mechanical components and their functions, exploring various resources can provide invaluable insights. From books and online courses to forums and videos, numerous avenues exist to enhance your knowledge and skills in this field.

Books and Publications

Consider seeking out specialized literature that covers the intricacies of mechanical systems. These texts often include detailed explanations, illustrations, and case studies, making complex concepts more accessible.

Online Learning Platforms

Platforms offering courses on mechanical technology can be particularly beneficial. They often provide interactive content and practical exercises, allowing for a hands-on approach to learning about different systems and their maintenance.