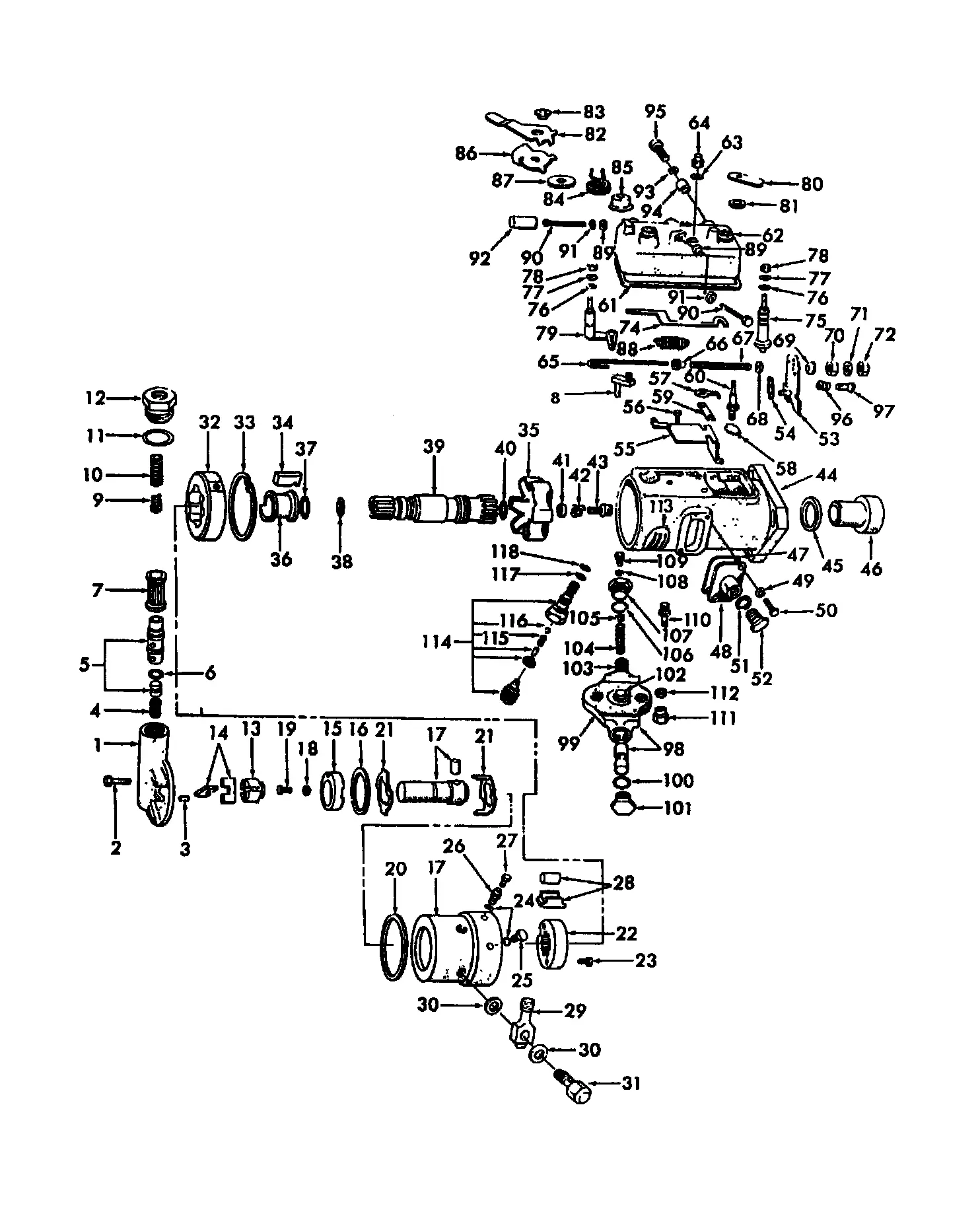

Understanding the individual elements of a machine is crucial for maintaining its functionality and ensuring its longevity. A well-structured visual breakdown of the components offers valuable insights, helping users identify key elements and their relationships within the system.

In this section, we provide a detailed look at the internal and external elements of a robust piece of machinery, highlighting the various connections and mechanisms that contribute to its performance. This overview will serve as a helpful guide for anyone looking to enhance their knowledge of the equipment’s structure and operational features.

Each component plays a specific role in the overall operation, and having a clear understanding of how these pieces fit together allows for easier troubleshooting and maintenance. This guide emphasizes the importance of recognizing and understanding the key elements that keep the machine running smoothly.

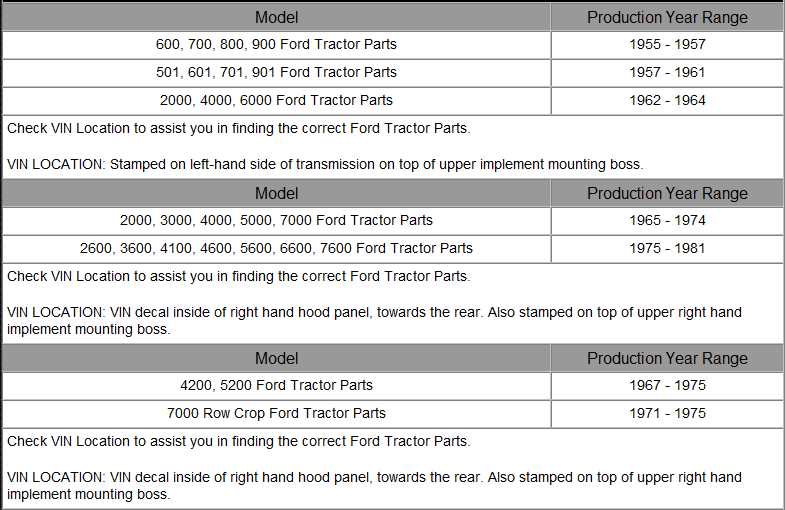

Ford 4610 Tractor Components Overview

In this section, we will explore the essential mechanisms and assemblies that contribute to the functionality of a typical agricultural machine. These components ensure efficient performance, durability, and adaptability across various tasks in the field.

Engine and Transmission System

The core of the vehicle’s operation lies in its engine, providing the necessary power to drive multiple systems. Combined with a robust transmission, this unit ensures smooth power distribution and flexible speed control, enabling the machine to perform a wide range of agricultural duties.

Hydraulic and Electrical Systems

Hydraulics play a vital role in maneuverability and tool attachment, while the electrical systems maintain operational efficiency and manage essential controls. Together, these systems enhance the versatility of the equipment, allowing it to adapt to different working conditions and tools.

Essential Engine Parts for Agricultural Machinery

The engine is the heart of any agricultural machine, and understanding its critical components is key to ensuring smooth operation and longevity. Each of these essential elements works in harmony to provide the power and efficiency needed for various tasks on the field.

- Cylinder Block: The foundation that holds major components and channels coolant for temperature control.

- Pistons: Convert energy from combustion into mechanical force, driving the machine’s movement.

- Crankshaft: Transfers the linear motion of the pistons into rotational energy, essential for generating power.

- Camshaft: Controls the opening and closing of valves, crucial for air and fuel management in the engine cycle.

- Fuel Injectors: Ensure the precise delivery of fuel into the combustion chamber for optimal performance.

Transmission and Gearbox Components

The transmission system plays a crucial role in ensuring smooth power delivery from the engine to the wheels. Its internal structure is designed to adjust the speed and torque, providing flexibility in various working conditions. A well-functioning gearbox enables effective control over movement and performance, allowing for optimal adaptation to different terrains and loads.

Main Shafts and Bearings

The central shafts in the transmission are responsible for transferring energy between different gears. They are supported by bearings that ensure smooth rotation and reduce friction, thus prolonging the lifespan of the system. Proper alignment of these components is essential for maintaining efficiency and preventing premature wear.

Gears and Synchronizers

The gears are fundamental for adjusting the output speed and torque, while synchronizers assist in smooth gear changes. Their precise interaction ensures seamless transitions between speed ranges, minimizing wear on the internal components and contributing to overall driving comfort and safety

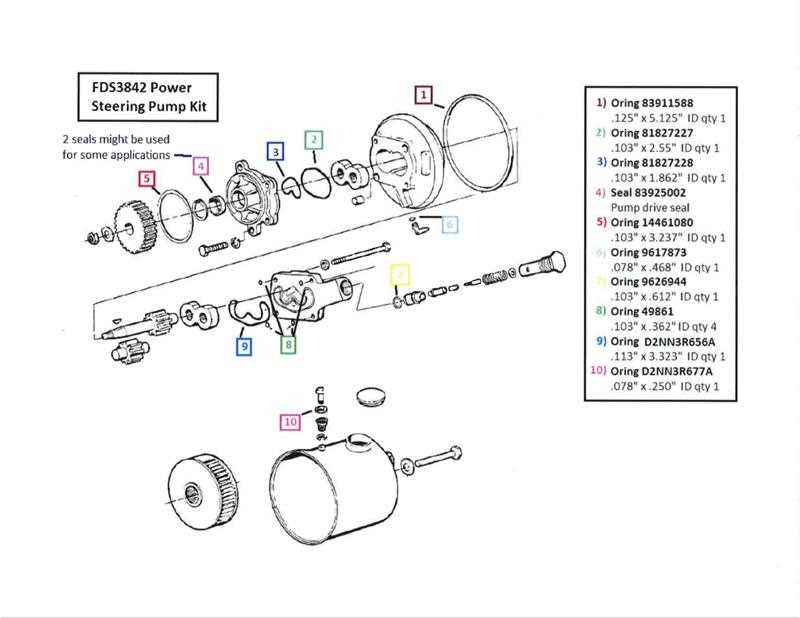

Hydraulic System Components for Agricultural Machinery

The hydraulic setup in agricultural machines plays a crucial role in operating various equipment functions. This section delves into the key elements of this system, ensuring smooth operation and efficient power transfer. Whether it’s lifting, lowering, or tilting, the system relies on a combination of specialized components to perform essential tasks. Understanding these elements is vital for maintenance and repair.

Main Elements of the Hydraulic Setup

At the heart of the hydraulic mechanism lies the pump, responsible for circulating fluid through the system. This component generates the pressure required to move various machine parts. Alongside the pump, the control valves direct the flow of fluid, allowing the operator to manage different functions. Hoses and connectors link these parts, ensuring the smooth flow of hydraulic fluid.

Additional Components for Optimal Function

Other crucial parts include the hydraulic cylinder, which converts fluid power into mechanical force. The reservoir holds

Steering Mechanism and Linkage Components

The steering system plays a crucial role in ensuring smooth and precise control, allowing operators to easily navigate in various conditions. It consists of multiple interconnected elements, each contributing to the responsiveness and accuracy of steering movements. These components work together to transfer the operator’s input into turning motion efficiently.

Main Components of the Steering System

- Steering Wheel: The primary interface for directing movement, it converts rotational input into mechanical force.

- Steering Shaft: This element connects the wheel to the rest of the system, transmitting the force further down the assembly.

- Brake System Elements of Ford 4610

The braking mechanism is crucial for ensuring safety and control in agricultural machinery. This section delves into the components that contribute to the effective functioning of the braking system, highlighting their roles and interconnections.

Main Components

The primary elements of the braking system include various parts that work together to create the necessary friction and stopping power. Understanding these components is essential for maintaining and troubleshooting the braking system.

Component Function Brake Pedal Initiates the braking action when pressed. Brake Cylinder Converts the pedal pressure into hydraulic force. Brake Shoes Provide friction against the drum to slow down the machinery. Brake Drum Houses the shoes and works with them to halt movement. Maintenance Considerations

Regular inspections and servicing of the braking components are vital for optimal performance. Ensuring that each element is functioning correctly can prevent potential failures and enhance safety during operation.

Fuel System Components and Their Functions

The fuel system is a crucial aspect of any machinery, ensuring the effective delivery and management of fuel to the engine. Understanding the various elements within this system is essential for optimal performance and maintenance.

- Fuel Tank: This component stores fuel until it is needed by the engine. It is typically designed to minimize evaporation and prevent contamination.

- Fuel Pump: Responsible for transporting fuel from the tank to the engine, this device generates the necessary pressure to maintain a steady flow.

- Fuel Filter: This part cleans the fuel before it reaches the engine, removing impurities and particles that could cause damage or inefficiency.

- Fuel Injectors: These components atomize the fuel, delivering it in a fine mist directly into the combustion chamber for efficient ignition and combustion.

- Fuel Lines: These are the conduits through which fuel flows from the tank to the engine, designed to withstand pressure and prevent leaks.

Each of these elements plays a significant role in the overall functionality of the fuel system, contributing to the efficiency and reliability of the engine’s operation.

Cooling System Components of the Ford 4610

The cooling system plays a crucial role in maintaining optimal operating temperatures for agricultural machinery. It prevents overheating and ensures efficient performance during prolonged use. Understanding the various elements that comprise this system is essential for proper maintenance and troubleshooting.

Main Elements of the Cooling System

This system typically consists of several key components. The radiator serves as a heat exchanger, dissipating heat from the coolant as it circulates. Additionally, the water pump facilitates the movement of coolant through the system, ensuring consistent flow and temperature regulation.

Regular inspection and maintenance of these components are vital to prevent malfunctions. Issues such as leaks or blockages can lead to severe overheating, resulting in costly repairs. Keeping the cooling system in top condition not only prolongs the lifespan of the equipment but also enhances its overall efficiency.

Electrical System Elements and Wiring

The electrical system of a vehicle encompasses various components that work together to ensure efficient operation and functionality. Understanding these elements is essential for troubleshooting and maintaining optimal performance.

At the heart of the electrical setup are the battery, which stores energy, and the alternator, responsible for generating electricity while the engine is running. These components supply power to various systems, including lighting, ignition, and control modules.

Wiring harnesses connect these elements, facilitating the flow of electricity throughout the vehicle. Properly routed and secured wires are crucial for preventing short circuits and ensuring reliable operation. Additionally, fuses and relays serve as protective devices, preventing overloads and allowing for the safe management of electrical currents.

Regular inspection of the electrical connections and components can help identify potential issues before they escalate. Maintaining clean terminals and checking for frayed wires are vital practices in preserving the integrity of the electrical system.

Rear Axle and Differential Components

The rear axle and differential assembly plays a crucial role in the overall functionality of agricultural machinery. These components work together to ensure smooth power transfer to the rear wheels while allowing for necessary turning and maneuverability. Understanding the structure and function of these elements is essential for effective maintenance and operation.

Components Overview

The assembly includes various key elements, such as the axle housing, differential gears, and wheel bearings. Each component serves a distinct purpose, contributing to the efficient distribution of power and torque to the wheels. Regular inspection of these elements can prevent potential issues, ensuring optimal performance and longevity of the equipment.

Maintenance Tips

Proper care of the rear axle and differential is vital for sustained efficiency. Regular lubrication of moving parts, timely replacement of worn-out gears, and ensuring proper alignment can significantly enhance the operational lifespan. Neglecting maintenance may lead to serious complications, emphasizing the need for routine checks and servicing.

Body and Frame Components for Ford 4610

The structural elements of agricultural machinery play a crucial role in ensuring durability and functionality. A well-designed chassis supports various components, providing stability and resilience during operation. Understanding these elements is essential for maintenance and optimization of performance.

The primary framework consists of robust materials designed to withstand the rigors of farming tasks. Key components include the main frame, which serves as the backbone, and the subframe, offering additional support for attached implements. Proper alignment and integrity of these sections are vital for overall efficiency.

Moreover, the body panels not only contribute to the aesthetic appeal but also protect the internal mechanisms from environmental factors. Features such as side shields and engine covers play an important role in safeguarding sensitive areas from debris and moisture.

In addition, the suspension system enhances stability during movement across uneven terrains. Components like axles and spring assemblies absorb shocks, ensuring a smoother operation and prolonging the lifespan of the machinery.

Overall, a thorough understanding of the body and frame components is essential for effective maintenance and repair, ensuring that the equipment remains reliable and efficient in demanding agricultural environments.