In the realm of modern farming, the efficiency of machinery plays a crucial role in enhancing productivity. A comprehensive grasp of the various elements that constitute these machines is essential for optimal operation and maintenance. Each component serves a specific purpose, contributing to the overall functionality of the equipment.

Recognizing the significance of each piece allows operators to troubleshoot issues effectively and ensure longevity. Familiarity with the arrangement and interplay of these elements aids in the timely identification of potential malfunctions, ultimately safeguarding against costly repairs.

Moreover, understanding the assembly and connection of these components fosters better communication among operators, technicians, and suppliers. This knowledge empowers users to make informed decisions regarding repairs and upgrades, ensuring that their equipment remains reliable and efficient in the field.

Understanding Foton Tractor Components

In the realm of agricultural machinery, a comprehensive grasp of various elements is essential for optimal functionality. Each unit plays a critical role, contributing to the overall efficiency and effectiveness of the equipment. Familiarity with these components not only aids in maintenance but also enhances operational performance.

Key Functional Elements

Central to any machinery are its operational elements, which include engines, transmission systems, and control mechanisms. These crucial features work in harmony to ensure seamless performance. Regular inspection and maintenance of these components are vital for sustaining longevity and reliability in various conditions.

Importance of Accessory Components

In addition to the primary units, accessory features such as hydraulic systems, electrical connections, and structural frameworks significantly impact overall functionality. Understanding the interplay between these elements can lead to improved maintenance practices and enhanced operational effectiveness in diverse tasks.

Key Parts of Foton Tractors

The efficiency and functionality of agricultural machines rely heavily on their essential components. Each element plays a vital role in ensuring smooth operations and optimal performance, contributing to the overall effectiveness of these machines in various tasks.

| Component | Function |

|---|---|

| Engine | Generates power to drive the machine and perform agricultural tasks. |

| Transmission | Transfers power from the engine to the wheels, allowing for different speeds and torque. |

| Chassis | Provides structural support and stability, housing essential systems and components. |

| Hydraulic System | Facilitates lifting and controlling implements through pressurized fluid. |

| Fuel System | Stores and delivers fuel to the engine for combustion. |

| Electrical System | Powers lighting, starting mechanisms, and other electrical components. |

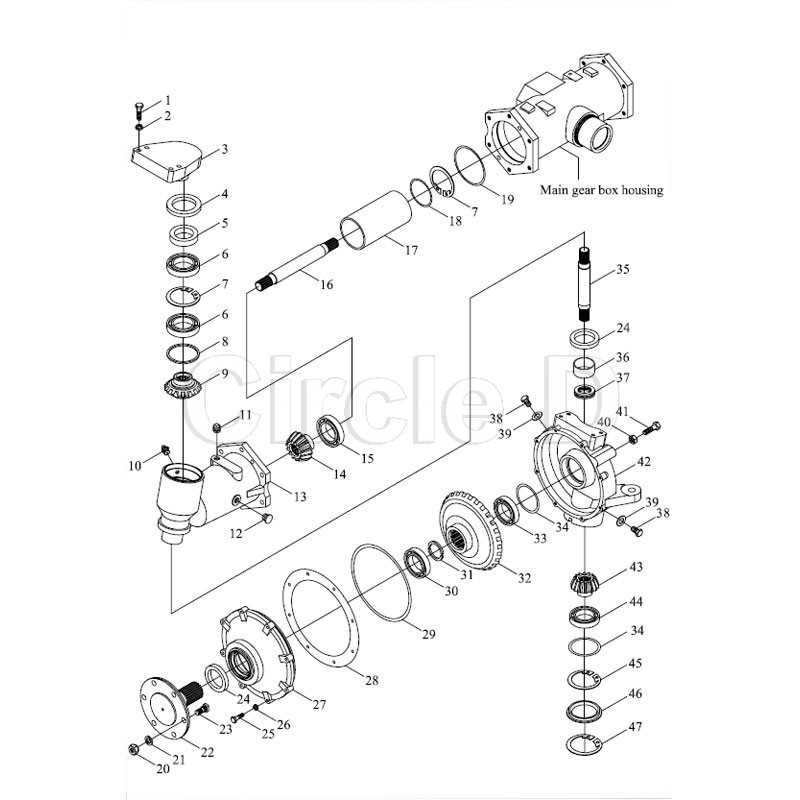

Importance of Accurate Diagrams

Having precise illustrations is essential for ensuring the effective functioning of complex machinery. These visual representations play a crucial role in guiding users through the assembly, maintenance, and troubleshooting processes, making them indispensable in the realm of equipment management.

Clear and detailed visuals contribute significantly to various aspects of machinery handling:

- Enhanced Understanding: Comprehensive visuals simplify the comprehension of intricate systems, allowing users to grasp the relationships between components easily.

- Streamlined Repairs: Accurate illustrations expedite the repair process by clearly showing the locations and orientations of different elements.

- Minimized Errors: When users have access to reliable visuals, the likelihood of misinterpretation and mistakes is reduced, leading to better outcomes.

- Time Efficiency: Well-structured representations save time by providing quick references during assembly and maintenance tasks.

In conclusion, investing in high-quality illustrations enhances the overall experience for users, ensuring that machinery operates smoothly and efficiently while minimizing complications.

Exploring the Engine System

This segment delves into the crucial components that contribute to the functionality and efficiency of the power unit. Understanding how these elements work together can enhance overall performance and reliability.

Key Components of the Power Unit

The heart of the machinery consists of several essential parts that play distinct roles. Each component, from the combustion chamber to the ignition system, works in unison to ensure optimal operation. Maintaining these elements is vital for achieving peak efficiency and longevity.

Importance of Regular Maintenance

Routine checks and upkeep are necessary to prevent potential failures. Proper care not only extends the life of the engine but also enhances its performance. Staying informed about maintenance practices can significantly impact the overall functionality of the unit.

Hydraulic Systems in Foton Models

Hydraulic systems play a crucial role in the functionality of modern agricultural machinery, facilitating efficient operation and enhancing productivity. These systems utilize fluid power to perform various tasks, from lifting implements to steering and braking, ensuring smooth and effective handling of equipment in diverse working environments.

Components of Hydraulic Systems

The essential elements of hydraulic systems include pumps, cylinders, and valves. The pump generates the necessary pressure to move hydraulic fluid, while cylinders convert hydraulic energy into mechanical force. Valves control the flow and direction of the fluid, allowing operators to manage the machinery’s movements precisely.

Advantages of Hydraulic Technology

Utilizing hydraulic technology provides numerous benefits, such as increased force output and superior control over machinery operations. This technology enables the implementation of compact designs, reducing the overall size and weight of equipment while maintaining high performance. Additionally, hydraulic systems offer adaptability, allowing for customization to meet specific operational requirements.

Electrical Components Overview

This section provides a comprehensive examination of the electrical elements found within heavy machinery, emphasizing their roles and interconnections. Understanding these components is crucial for effective maintenance and troubleshooting.

Key components include:

- Batteries: Essential for storing electrical energy, providing power for starting and operating the engine.

- Alternators: These devices generate electricity while the engine runs, supplying power to various systems.

- Relays: Used to control the flow of electricity to different circuits, enhancing functionality and safety.

- Sensors: Vital for monitoring parameters such as temperature and pressure, ensuring optimal performance.

- Wiring Harnesses: Bundles of wires that connect various electrical components, facilitating communication between them.

Proper understanding of these components not only aids in diagnosing issues but also contributes to the efficient operation of the machinery. Regular inspection and maintenance can prevent failures and extend the lifespan of the equipment.

Transmission System Insights

The transmission system plays a crucial role in the overall functionality of machinery, enabling the effective transfer of power from the engine to the wheels. Understanding its components and mechanisms is essential for maintaining optimal performance and ensuring smooth operation. This section delves into the intricacies of this vital system, highlighting key elements that contribute to its efficiency.

| Component | Function |

|---|---|

| Gearbox | Facilitates the selection of gear ratios, allowing for speed adjustment and torque management. |

| Clutch | Enables engagement and disengagement of the engine from the transmission, providing control over power transfer. |

| Driveshaft | Transmits rotational force from the transmission to the wheels, playing a key role in mobility. |

| Differential | Allows for the variation of wheel speeds during turns, enhancing stability and maneuverability. |

Maintenance of Foton Equipment

Regular upkeep of agricultural machinery is essential for ensuring optimal performance and longevity. A well-maintained machine not only enhances productivity but also reduces the risk of unexpected breakdowns. Proper care involves routine checks, timely servicing, and replacing worn-out components as needed.

To facilitate effective maintenance, it is crucial to follow a systematic approach. Below is a table outlining key maintenance tasks along with their recommended frequency:

| Maintenance Task | Frequency |

|---|---|

| Oil Change | Every 100 hours of operation |

| Filter Replacement | Every 200 hours of operation |

| Tire Inspection | Monthly |

| Battery Check | Every 3 months |

| Hydraulic Fluid Check | Monthly |

Implementing these maintenance practices will ensure the machinery operates efficiently and can withstand the demands of agricultural work. Regular inspections and servicing can also prevent costly repairs and enhance safety during operation.

Common Replacement Parts

Maintenance of heavy machinery often necessitates the replacement of certain components to ensure optimal performance and longevity. Understanding the frequently substituted elements can aid operators in making informed decisions regarding upkeep and repairs.

Essential Components

Regularly replaced items include elements that wear down due to prolonged usage or exposure to harsh conditions. These components are critical for the effective operation of machinery and should be monitored closely for signs of wear.

| Component Type | Description |

|---|---|

| Belts | These flexible loops transmit power between rotating shafts and are crucial for driving various mechanisms. |

| Filters | Used to remove impurities from fluids, ensuring that the machinery operates smoothly and efficiently. |

| Hydraulic Hoses | These tubes carry hydraulic fluid and are essential for the operation of lifting and steering systems. |

Recommendations for Replacement

It is advisable to regularly check and replace worn components to prevent potential failures. Keeping a stock of commonly needed items can significantly reduce downtime during maintenance activities.

Identifying Operational Issues

Recognizing challenges in machinery performance is crucial for maintaining efficiency and reliability. Operational difficulties can arise from various sources, including mechanical failures, improper adjustments, or wear and tear over time. Addressing these issues promptly ensures optimal functionality and prolongs the lifespan of the equipment.

Common Signs of Trouble

When a machine experiences problems, specific indicators may become apparent. Unusual noises, vibrations, or changes in performance are often the first signs of underlying issues. Observing these symptoms closely can help pinpoint the root causes, leading to timely interventions.

Importance of Regular Maintenance

Routine inspections and preventive measures play a vital role in identifying potential operational challenges before they escalate. By establishing a maintenance schedule and adhering to it, operators can ensure that all components function smoothly, thus reducing the likelihood of unexpected breakdowns and costly repairs.

Upgrading Your Tractor’s Performance

Enhancing the functionality of your agricultural machinery can lead to significant improvements in efficiency and productivity. By implementing various modifications, you can optimize engine output, fuel efficiency, and overall operational capabilities. These upgrades can range from simple adjustments to comprehensive enhancements.

Consider the following approaches to elevate your equipment’s performance:

- Engine Tuning: Fine-tuning the engine parameters can result in better fuel consumption and increased power output.

- Exhaust System Enhancement: Upgrading the exhaust system can facilitate improved airflow, reducing back pressure and boosting engine efficiency.

- Transmission Modifications: Altering the transmission settings can enhance responsiveness and control, making operations smoother.

- Tire Selection: Choosing the right tires for your specific tasks can optimize traction and reduce soil compaction.

- Weight Distribution: Adjusting the weight distribution on your equipment can improve stability and handling, especially during challenging tasks.

By focusing on these areas, you can achieve a remarkable increase in the effectiveness of your machinery, ultimately leading to enhanced performance and productivity in the field.

Safety Features in Foton Tractors

Modern agricultural machinery is equipped with various safety mechanisms to ensure the protection of operators and bystanders. These enhancements are crucial for minimizing risks during operation and maintenance, providing peace of mind while working in demanding environments.

Operator Protection

The design of contemporary farming equipment prioritizes the safety of the operator. Key features include:

- Cabs: Enclosed areas shield users from external elements and potential hazards.

- Seat Belts: Secure seating arrangements to prevent movement during unexpected incidents.

- Rollover Protection Structures (ROPS): Frameworks designed to maintain structural integrity in case of overturning.

Emergency Systems

In addition to physical safeguards, various emergency systems enhance operational safety:

- Safety Switches: Automatic shut-off features that engage during critical malfunctions.

- Warning Lights and Alarms: Visual and auditory signals alert operators to potential issues.

- Fire Extinguishers: Easily accessible fire suppression devices to address emergencies quickly.