Engine Components Overview

The engine system comprises various essential elements that work together to ensure the smooth functioning of the machine. Understanding the main components is crucial for proper maintenance and troubleshooting. These parts are designed to support the power generation and transfer processes, allowing the equipment to perform its tasks effectively.

Core Elements of the Engine

The central components of the engine include mechanisms responsible for air and fuel intake, combustion, and exhaust. These systems work in tandem to convert energy efficiently. The air filter ensures clean airflow, while the carburetor regulates fuel mixture. The exhaust system safely removes combustion by-products, maintaining engine health.

Supporting Mechanisms

Apart from the core systems, several other elements contribute to the overall engine efficiency. The cooling system prevents overheating, while the ignition system ensures reliable starts. Additionally, lubrication mechanisms reduce friction, promoting longer component life and smoother operation.

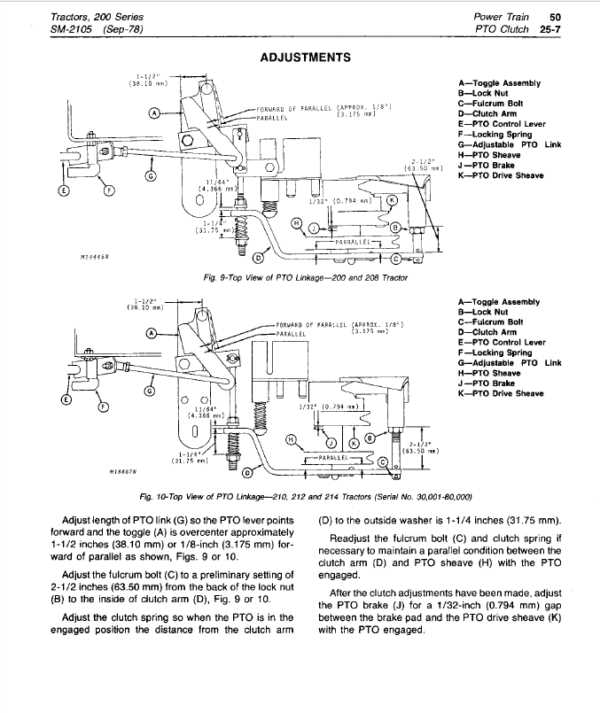

Transmission and Drive System

The transmission and drive system is crucial for ensuring smooth movement and control. It is responsible for transferring power from the engine to the wheels, allowing the equipment to navigate various terrains. This system plays a key role in determining speed, maneuverability, and efficiency during operation.

Components of the Transmission

The transmission consists of several interconnected elements that work together to regulate the machine’s motion. Key components include the gearbox, which adjusts speed and torque, and the drive belts, which help transfer power effectively. Proper maintenance of these elements ensures optimal performance.

Drive Mechanism and Maintenance

The drive mechanism is designed to engage the wheels efficiently, allowing for smooth acceleration and deceleration. It is essential to regularly inspect and maintain the drive system to prevent wear and ensure longevity. Lubrication and timely replacement of worn parts are important steps in maintaining functionality.

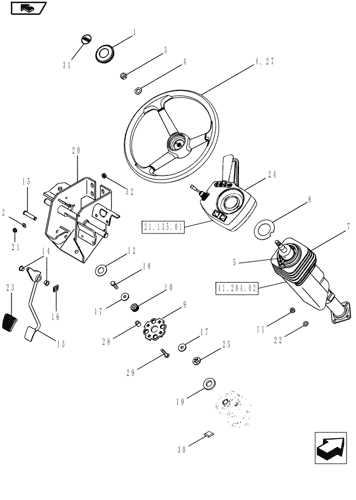

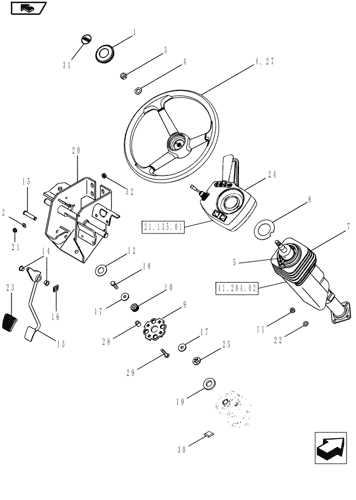

Steering Mechanism and Linkages

The steering system is a crucial component responsible for guiding the machine effectively in various directions. It consists of interconnected elements that ensure smooth control, providing stability and precision during operation. These components work together, allowing the operator to direct movement effortlessly.

Main Components of the Steering System

The key elements of the steering setup include a wheel, linkages, and rods that transmit motion to the wheels. The proper alignment and maintenance of these parts are essential for achieving reliable and consistent handling. Ensuring that all elements function properly helps avoid unexpected issues during use.

Common Issues and Maintenance Tips

Over time, the steering system can become less responsive due to wear and tear. Regular inspection of joints and linkages can help identify early signs of wear, such as looseness or difficulty in turning. Lubrication and adjustments should be performed periodically to maintain the system’s efficiency and extend its lifespan.

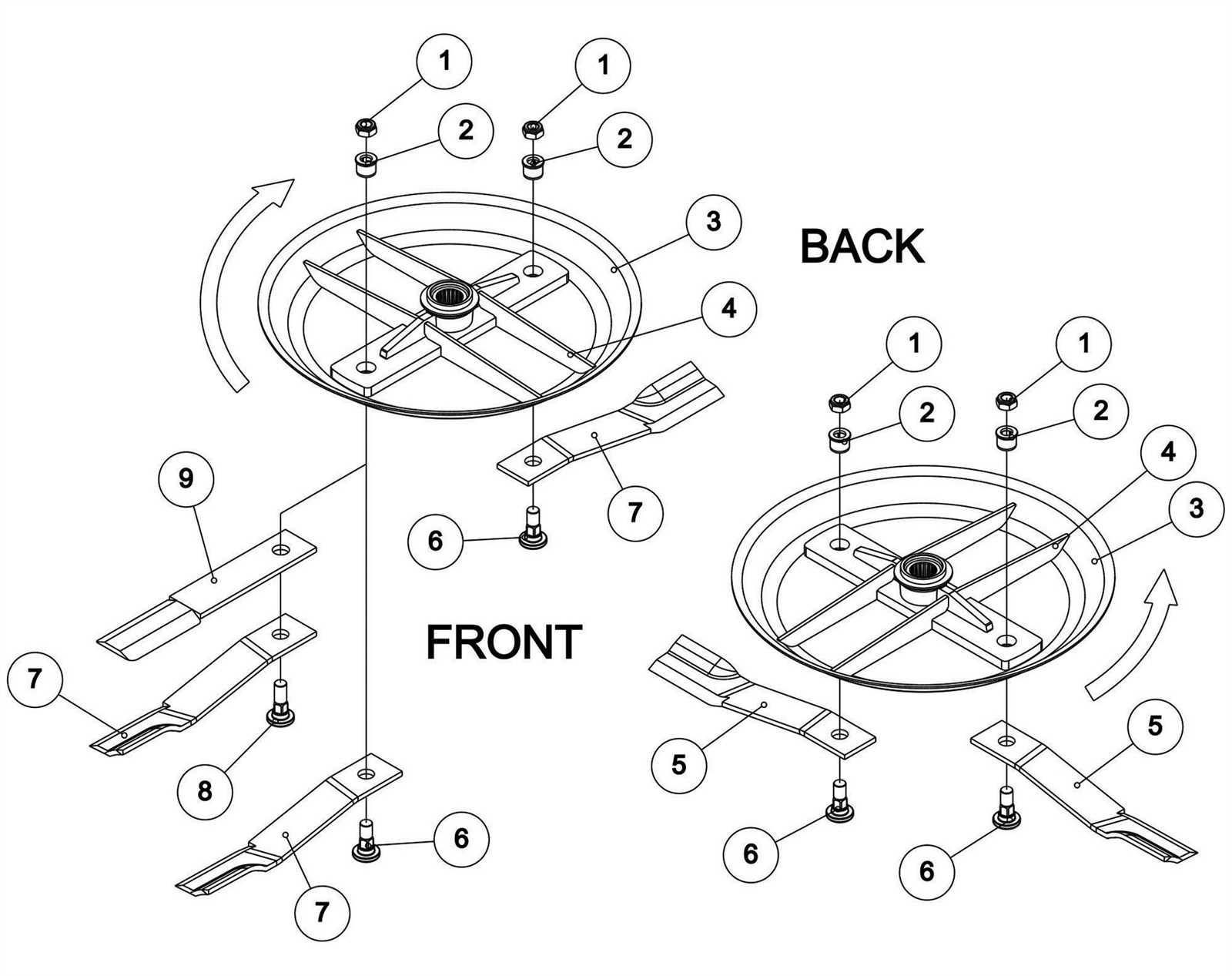

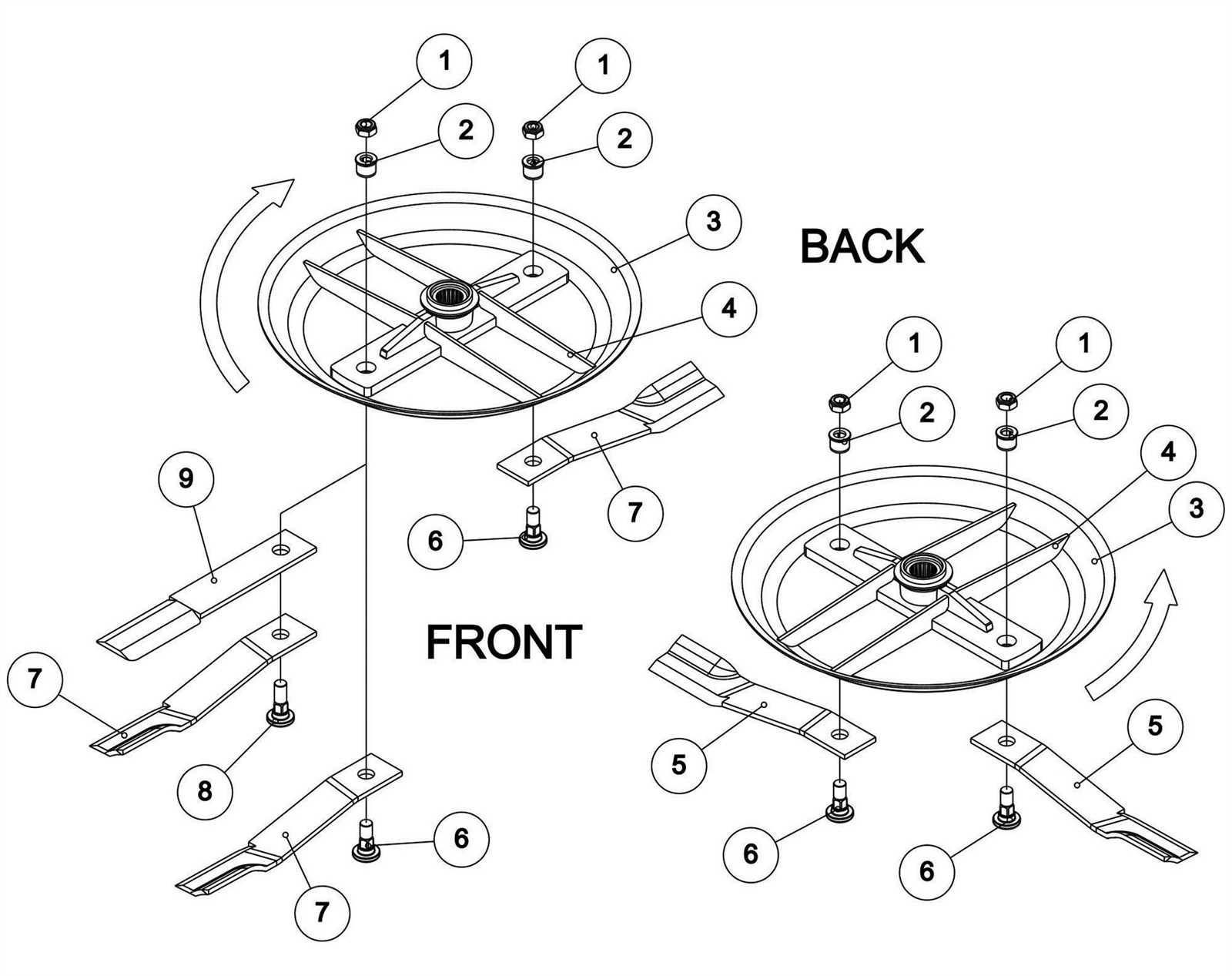

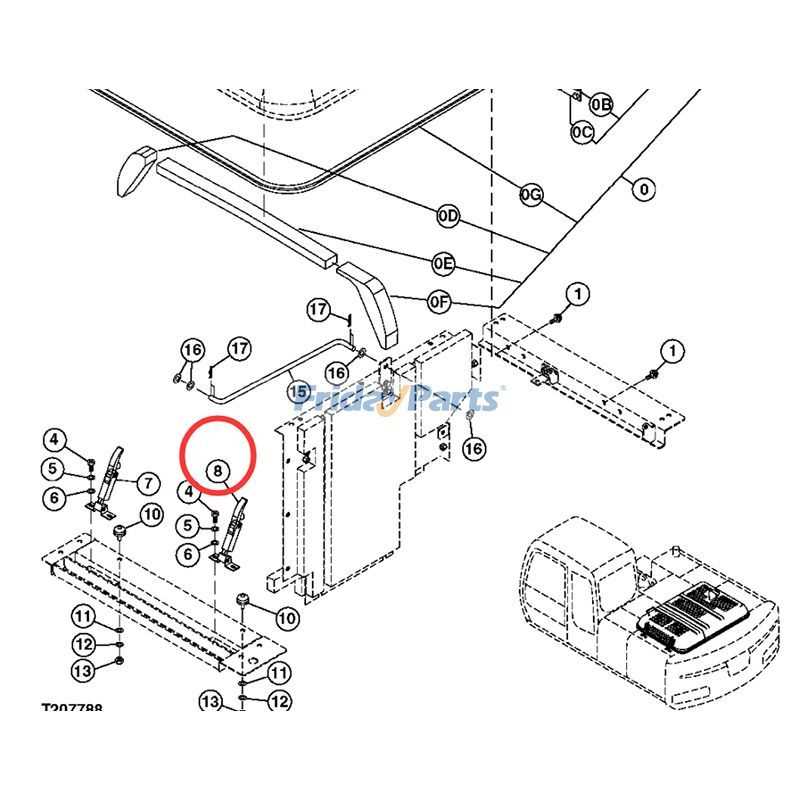

Blade and Cutting Deck Assembly

The blade and deck assembly is essential for ensuring optimal cutting performance. The structure is designed to maintain efficiency during grass trimming, with the blade rotating beneath the deck to slice vegetation cleanly. This system is integral to delivering a smooth, even cut across varying terrains.

The cutting deck houses the blade and helps guide grass clippings during the mowing process. Regular maintenance, including blade sharpening and checking for wear, is necessary to keep the system operating at peak performance. A well-functioning deck and blade setup prevents uneven cutting and ensures a healthier lawn.

Proper alignment and securing of the blade within the deck are crucial for smooth operation. Regular inspection for any signs of damage or misalignment will help avoid potential issues and maintain the effectiveness of the assembly.

Fuel System and Related Parts

The fuel system plays a crucial role in ensuring the engine operates smoothly and efficiently. A well-maintained system ensures optimal fuel delivery and prevents issues that may arise from clogged or faulty components. Understanding how the fuel system is structured helps in both routine maintenance and troubleshooting.

- Fuel Tank: The container responsible for storing the fuel before it enters the engine. It must be regularly inspected for leaks or damage.

- Fuel Lines: These hoses transport fuel from the tank to the engine. Over time, they may wear out or crack, leading to potential fuel loss or pressure issues.

- Fuel Filter: A filter that removes impurities from the fuel to prevent them from entering the engine. Regular replacement of the filter ensures clean fuel supply.

- Fuel Pump: The mechanism that moves fuel from the tank to the engine at the correct pressure. Faults in the pump can lead to poor performance or engine stalling.

- Carburetor/Injector: These components are responsible for mixing the fuel with air in the proper ratio before it enters the combustion chamber. Proper tuning is essential for efficient engine operation.

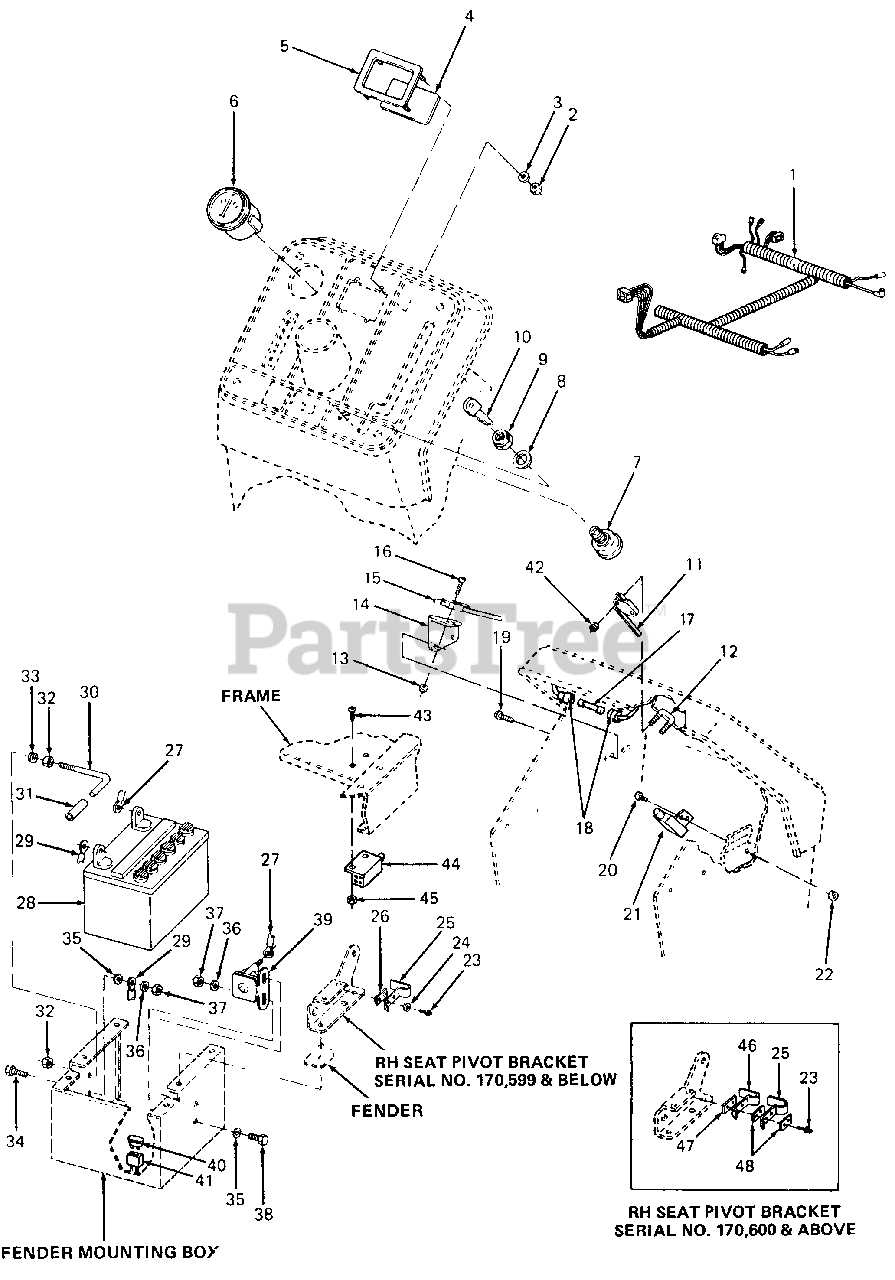

Electrical System Components

The electrical system of a garden machine plays a crucial role in ensuring its proper functionality. It encompasses various elements that work together to power essential features and enhance overall performance. Understanding these components is vital for effective maintenance and troubleshooting.

Other notable components are the solenoid, which engages the starter motor, and fuses, which protect the system from overloads. The alternator generates electrical energy while the machine is in operation, helping to recharge the battery. Familiarity with these elements can aid in diagnosing issues and ensuring optimal performance.

Brake System and Controls

The braking mechanism is a crucial component in ensuring the safety and functionality of any outdoor machinery. It provides the operator with the ability to halt movement effectively, allowing for precise control during operation. Understanding the various elements that comprise this system can enhance overall maintenance and efficiency.

Typically, the braking system consists of several key components, including the pedal, cables, and various linkages. Regular inspection of these elements is essential to ensure proper functioning. Additionally, operators should be aware of any adjustments needed to maintain optimal performance. Proper care can extend the life of the braking system and contribute to safer usage.

Control mechanisms, often integrated into the machine’s design, allow users to engage the brakes smoothly and intuitively. Familiarity with these controls can improve responsiveness, especially in challenging terrains. Overall, maintaining a well-functioning brake system is vital for safe and effective operation.

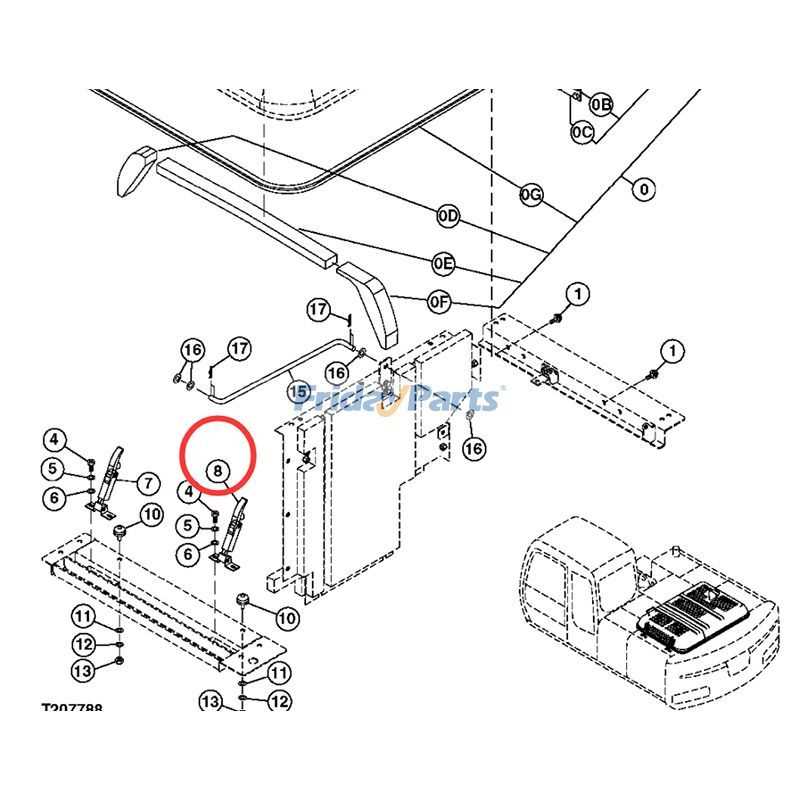

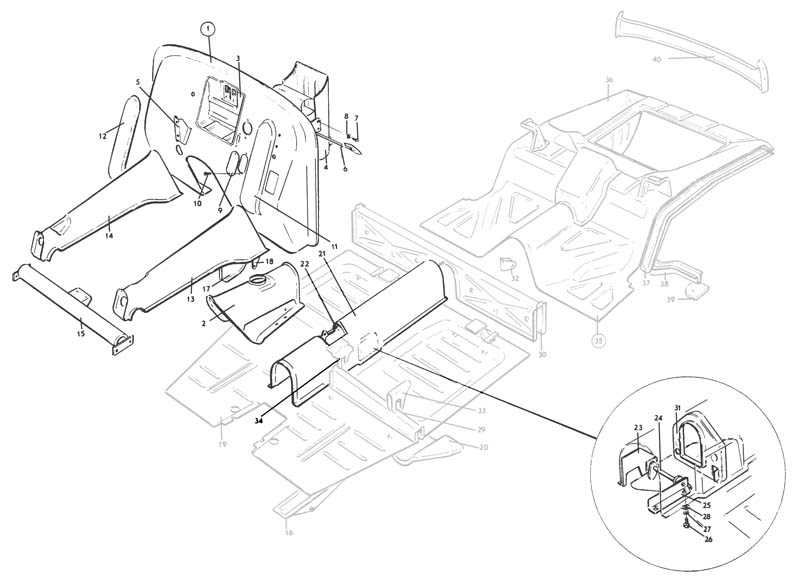

Chassis and Frame Structure

The framework of any outdoor machinery serves as its backbone, providing essential support and stability. A well-designed chassis ensures proper weight distribution, enhances maneuverability, and contributes to the overall durability of the equipment. Understanding the structural components involved is crucial for maintenance and repair, as each element plays a vital role in the machine’s functionality.

Key Components of the Chassis

The main elements that make up the chassis include various supports, brackets, and reinforcements. These parts work together to create a robust foundation capable of withstanding the stresses encountered during operation. Regular inspection and maintenance of these components are important to prevent premature wear and ensure optimal performance.

Importance of Structural Integrity

The integrity of the frame is paramount for safe operation. Any compromise in the structure can lead to mechanical failures, affecting both performance and safety. Therefore, it’s essential to pay attention to signs of wear and tear, such as cracks or deformation, which may indicate the need for immediate repairs or replacements.

| Component |

Function |

| Chassis Frame |

Provides overall support and structure |

| Mounting Brackets |

Secure various parts to the frame |

| Reinforcements |

Enhance strength and durability |

| Suspension Supports |

Absorb shocks and improve stability |

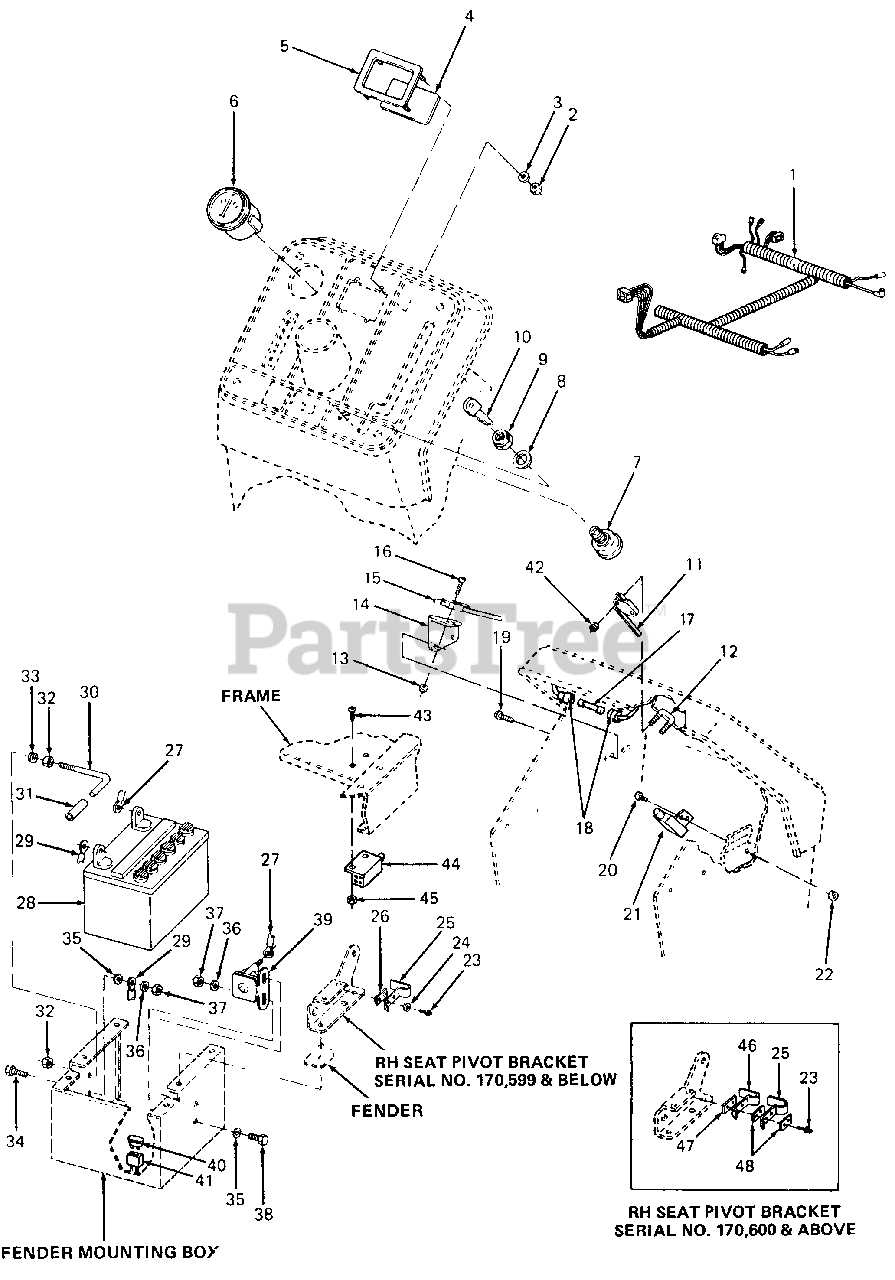

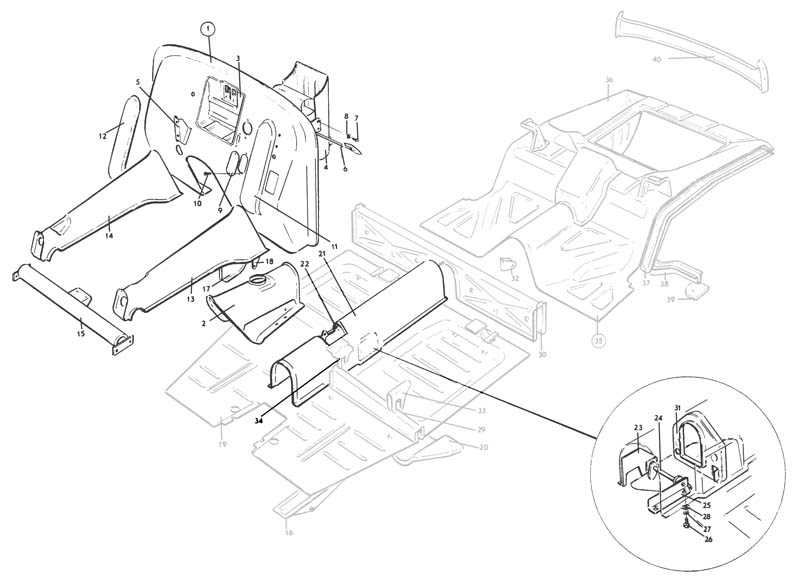

Seat, Control Levers, and Pedals

This section focuses on the essential components that enhance the user’s experience during operation. The seating arrangement, along with various control mechanisms, plays a crucial role in ensuring comfort and ease of use. Each element is designed to facilitate optimal performance while navigating different terrains.

| Component |

Description |

| Seat |

The seat is designed for comfort and support, allowing the operator to maintain focus over extended periods. Adjustable features ensure a personalized fit for different users. |

| Control Levers |

These levers are strategically placed for easy access, enabling quick adjustments to various functions. Their ergonomic design enhances operational efficiency. |

| Pedals |

Pedals provide control over speed and direction, ensuring smooth transitions while operating. Their layout is optimized for intuitive use, allowing for precise maneuvering. |

Tires and Wheel Assembly Diagram

The tire and wheel assembly is a crucial component that directly affects the overall performance and stability of the machine. Understanding the layout and function of each element within this assembly helps in maintaining optimal functionality and ensuring a smooth operation on various terrains.

This section provides a visual representation of the various parts involved in the wheel setup, including the tires, rims, and attachment mechanisms. Each component plays a vital role in supporting the weight of the equipment, providing traction, and absorbing shocks while in motion. A well-maintained tire assembly contributes to better maneuverability and efficiency during use.

Regular inspections of the tire condition, air pressure, and alignment are essential for safe and effective operation. Any signs of wear or damage should be addressed promptly to avoid potential issues that could hinder performance. Familiarizing oneself with the structure and arrangement of the wheel components can aid in troubleshooting and making informed maintenance decisions.