In the realm of modern agriculture, the efficient functioning of machinery is paramount. A comprehensive grasp of the various elements that contribute to these machines enhances their performance and longevity. This section aims to explore the intricate relationships between the components, shedding light on their roles and interactions.

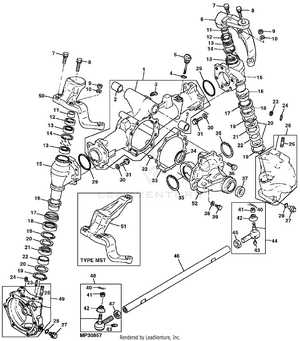

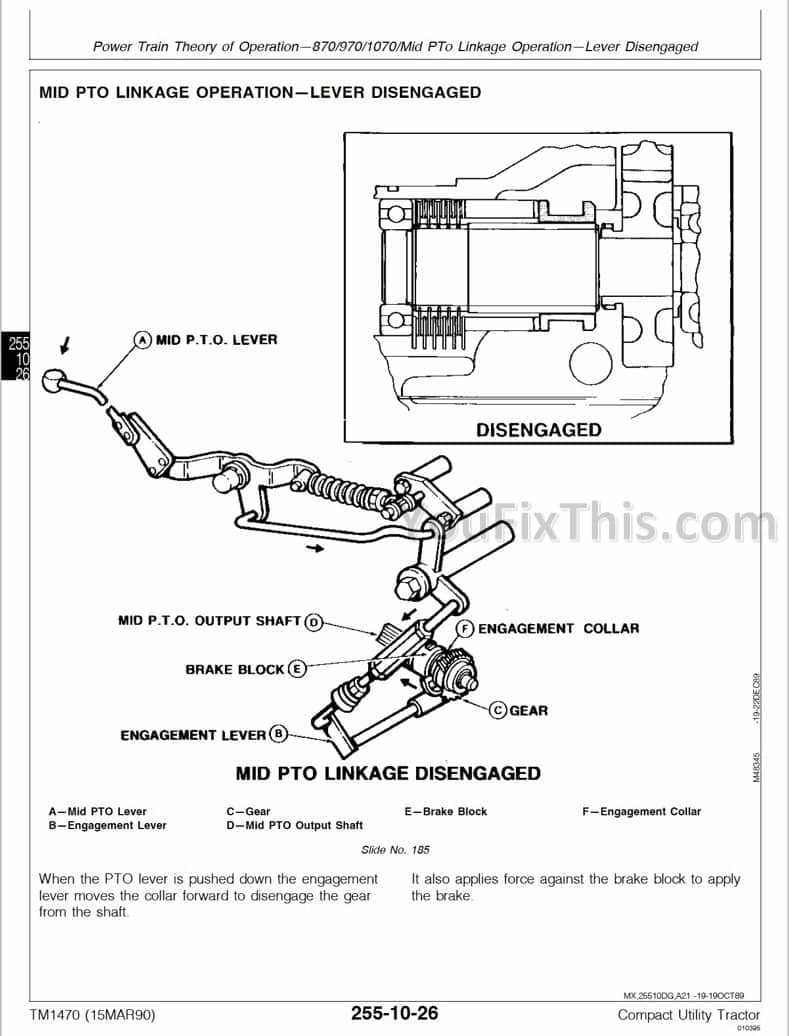

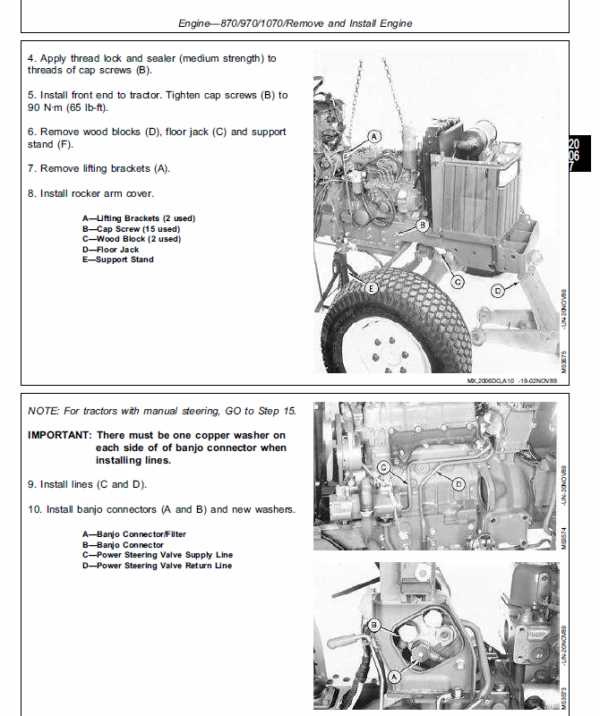

Visual aids play a crucial role in grasping complex systems, enabling operators and enthusiasts to identify and understand each element’s function. By dissecting the intricate assembly of these machines, one can uncover the ultimate mechanics that drive agricultural success.

Furthermore, familiarizing oneself with the structure and layout of essential components not only aids in maintenance but also fosters a deeper appreciation for the engineering behind these powerful tools. Join us as we delve into the fascinating world of machinery components, equipping you with the knowledge to optimize their usage.

Understanding the John Deere 770 Tractor

This section explores the intricacies of a renowned agricultural vehicle, highlighting its essential features and components. The focus lies on how various elements contribute to its efficiency and performance in diverse farming tasks.

| Component | Function |

|---|---|

| Engine | Provides power for operations and movement. |

| Transmission | Controls speed and torque delivery to the wheels. |

| Hydraulics | Enables lifting and controlling attachments. |

| Chassis | Serves as the structural foundation and support. |

Key Features of the 770 Model

This model stands out in the agricultural machinery landscape due to its impressive combination of performance, efficiency, and user-friendly design. Its robust engineering ensures reliability and ease of operation, making it a preferred choice among professionals in the field.

Performance Characteristics

- Powerful engine delivers exceptional torque for demanding tasks.

- Advanced transmission system allows for smooth gear shifts and enhanced control.

- Hydraulic capabilities ensure efficient operation of various implements.

User-Focused Design

- Ergonomically designed operator station for increased comfort during long hours.

- Intuitive controls simplify operation, even for inexperienced users.

- Excellent visibility enhances safety and precision during work.

Overall, this model exemplifies the perfect blend of power and practicality, making it a valuable asset for any agricultural operation.

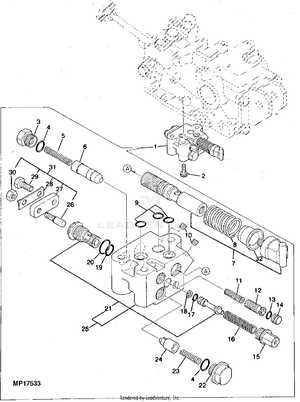

Importance of Accurate Parts Diagrams

Precision in schematics is crucial for effective maintenance and repair of machinery. These visual representations serve as vital references, ensuring that every component is correctly identified and understood. When technicians and mechanics have access to clear and accurate illustrations, the risk of errors during assembly or replacement significantly diminishes.

Enhancing Efficiency

Accurate schematics streamline the repair process, allowing professionals to quickly locate and replace faulty elements. This not only saves time but also reduces downtime, which is essential for operational efficiency. Clear visuals help to minimize confusion, enabling smoother workflows.

Promoting Safety

Inaccurate representations can lead to hazardous situations, as improper handling of machinery components may result in malfunctions or accidents. By providing reliable and precise information, quality schematics enhance safety standards. Attention to detail in these illustrations is vital for protecting both equipment and personnel.

Common Issues with John Deere Tractors

Owners often encounter various challenges with their machinery, impacting performance and efficiency. Understanding these frequent problems can help in timely maintenance and repairs, ensuring optimal functionality.

| Issue | Description |

|---|---|

| Engine Overheating | Insufficient coolant levels or clogged radiators can lead to excessive temperatures. |

| Hydraulic Failures | Poor fluid quality or leaks in the system may result in compromised hydraulic functions. |

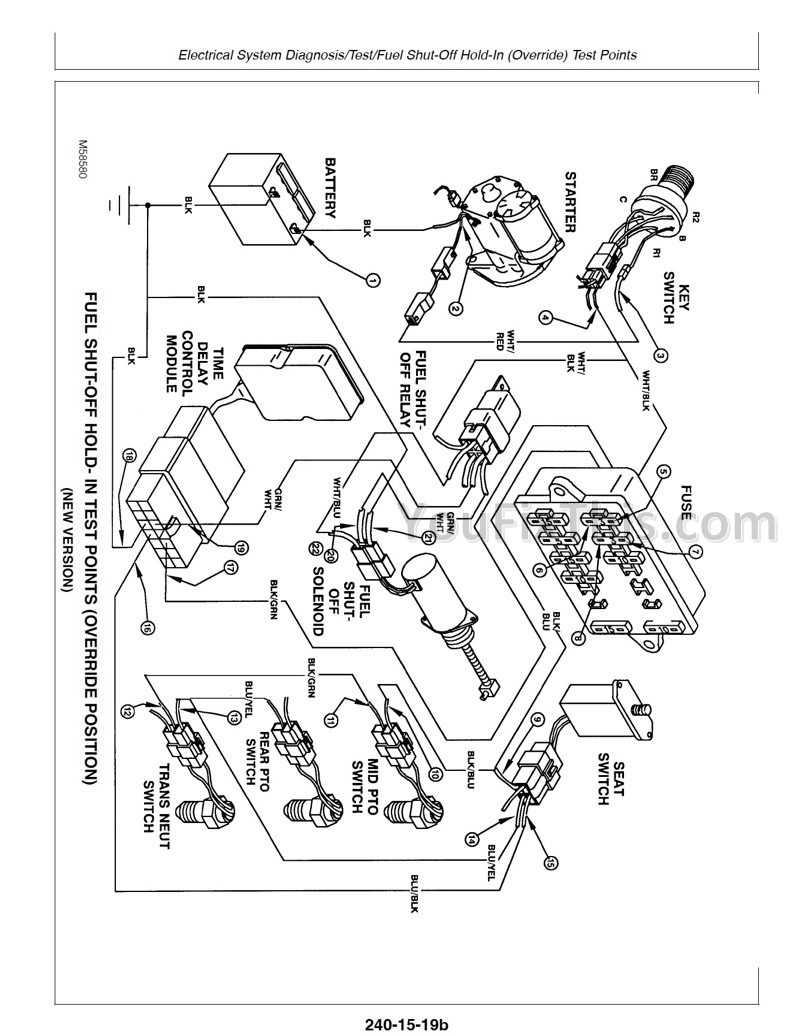

| Electrical Problems | Faulty wiring or battery issues often cause starting difficulties or erratic performance. |

| Transmission Issues | Worn gears or low fluid levels can lead to shifting difficulties and reduced power transfer. |

How to Use Parts Diagrams Effectively

Understanding assembly blueprints is essential for efficient maintenance and repair of machinery. These illustrations serve as visual guides, enabling users to identify components and their interconnections. By mastering their use, operators can streamline repairs, enhance their knowledge of the equipment, and ensure proper functioning over time.

Interpreting Visual Guides

To effectively utilize these visual representations, start by familiarizing yourself with the symbols and notations used within them. Each element corresponds to a specific component, which can vary between different models. Pay attention to labels and numbering, as they often indicate the order of assembly or the sequence of operations necessary for maintenance. Taking time to study these features will enhance your ability to navigate through the information seamlessly.

Applying Knowledge in Practice

Once comfortable with the visual aids, apply the insights gained to your maintenance routine. Referencing these illustrations during disassembly and reassembly will minimize errors and prevent damage to the equipment. Additionally, keeping a printed copy or a digital version accessible can facilitate quick references during urgent repairs. Regularly consulting these guides not only boosts efficiency but also builds confidence in handling machinery tasks independently.

Identifying Components of the 770 Tractor

Understanding the various elements of this agricultural machine is essential for effective maintenance and operation. Each component plays a crucial role in ensuring optimal performance and longevity.

- Engine: The heart of the machine, responsible for power generation.

- Transmission: Facilitates gear changes and enhances control.

- Hydraulics: Provides the necessary force for attachments and implements.

- Chassis: The framework that supports all components and maintains stability.

- Electrical System: Powers lights, ignition, and various controls.

Familiarity with these parts allows operators to diagnose issues quickly and maintain efficiency in their agricultural tasks.

Where to Find Replacement Parts

Locating suitable components for machinery can be a daunting task, but there are various avenues to explore that can simplify the process. Understanding where to search for high-quality replacements ensures optimal performance and longevity of your equipment.

Online Retailers

Many users prefer the convenience of shopping online. Here are some key platforms:

- Dedicated Equipment Websites: Specialized retailers often carry a wide range of items tailored for specific models.

- Marketplaces: Websites like eBay or Amazon provide options from various sellers, often at competitive prices.

- Manufacturer’s Website: Official websites can be a reliable source for original components and detailed specifications.

Local Suppliers

For those who prefer to see items in person, local suppliers can be invaluable. Consider the following:

- Dealerships: Authorized dealerships may have a selection of parts along with expert advice.

- Local Hardware Stores: Smaller retailers sometimes stock essential components or can order them for you.

- Salvage Yards: These can be treasure troves for finding used parts at a fraction of the cost.

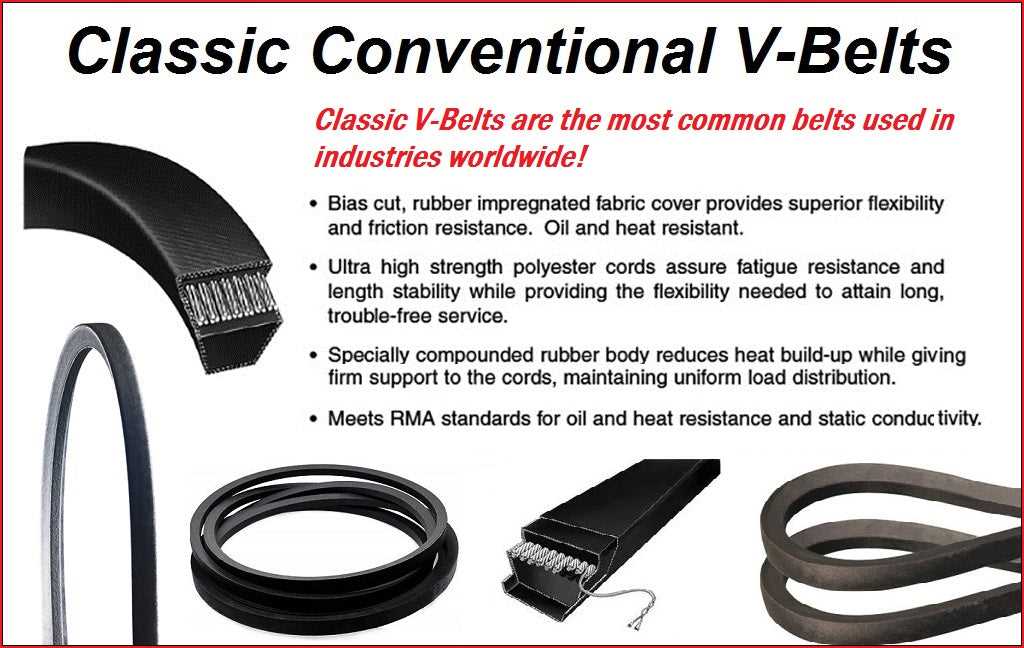

Benefits of Genuine John Deere Parts

Utilizing authentic components for machinery maintenance offers numerous advantages that enhance performance and longevity. These original elements ensure compatibility and reliability, ultimately contributing to smoother operation and reduced downtime.

Quality Assurance

Original components are manufactured to stringent standards, providing superior durability and efficiency compared to aftermarket alternatives. This quality assurance leads to enhanced machine performance and fewer repair needs.

Optimal Performance

By choosing genuine components, operators can expect their equipment to function at its best, maximizing productivity. These elements are designed to work seamlessly together, ensuring that every part operates harmoniously for optimal results.

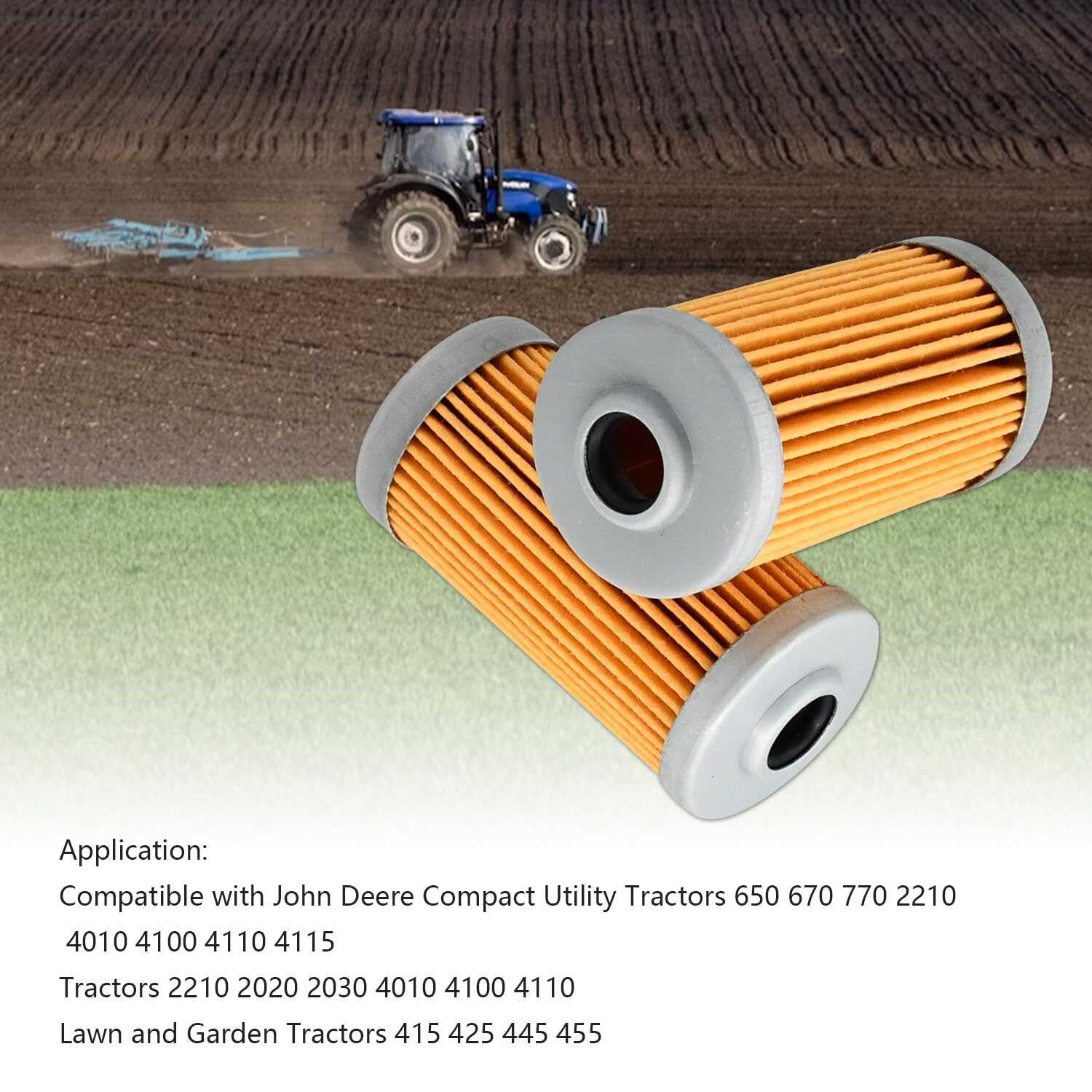

Maintenance Tips for the 770 Tractor

Regular upkeep is essential for ensuring optimal performance and longevity of your equipment. By implementing a structured maintenance routine, you can prevent potential issues and enhance efficiency. This section offers practical advice to help you keep your machinery in top shape.

1. Routine Inspections: Conduct frequent checks on key components to identify wear and tear. Focus on areas such as the engine, hydraulic system, and electrical connections. Addressing minor issues promptly can save you from costly repairs later.

2. Fluid Levels: Regularly monitor and maintain fluid levels, including engine oil, coolant, and hydraulic fluids. Clean and replace filters as needed to ensure smooth operation and to prevent contamination.

3. Tire Maintenance: Proper tire inflation is critical for stability and fuel efficiency. Inspect for signs of wear and damage, and rotate tires periodically to promote even wear.

4. Cleaning: Keep your machinery clean by removing dirt and debris. This not only improves performance but also helps prevent rust and corrosion, extending the life of various components.

5. Follow the Manual: Always refer to the manufacturer’s guidelines for specific maintenance tasks and intervals. Adhering to these recommendations ensures that you are performing necessary upkeep correctly.

6. Professional Assistance: Consider scheduling regular check-ups with a qualified technician. Professional assessments can uncover hidden issues and provide peace of mind regarding your equipment’s condition.

By following these tips, you can ensure that your equipment remains reliable and efficient, allowing you to focus on your work with confidence.

Comparing 770 with Other Models

When evaluating machinery in the agricultural sector, it’s essential to consider how different models stack up against each other in terms of functionality, efficiency, and user experience. This section delves into the strengths and weaknesses of one specific model in relation to its peers, highlighting key features that set it apart.

Performance is often a critical factor. The machine in focus excels in heavy-duty tasks, making it suitable for larger operations. In contrast, some alternatives may offer enhanced fuel efficiency or lighter builds, catering to smaller farms or specific tasks. Comparing these performance metrics allows users to make informed choices based on their unique requirements.

Durability is another vital aspect. While this model is built for longevity under rigorous conditions, other units might use different materials or designs that provide varying levels of resilience. Understanding these differences can help potential buyers assess which machine will withstand the test of time in their particular environment.

Finally, accessibility of support and availability of components are crucial considerations. Some alternatives might have a more extensive network for service and repair, offering peace of mind for owners. Conversely, the model under discussion may feature a straightforward approach to maintenance, simplifying the upkeep process for users. These factors combined offer a comprehensive view, enabling informed decisions tailored to individual needs.

Resources for John Deere Enthusiasts

For those passionate about agricultural machinery, having access to valuable materials and information can enhance understanding and maintenance. This section presents various sources that offer insights, community support, and technical knowledge for enthusiasts looking to deepen their expertise.

Online Communities

Engaging with fellow fans through online forums and social media platforms can provide invaluable advice and shared experiences. Participating in discussions can lead to new discoveries and practical solutions.

Technical Manuals and Guides

Comprehensive manuals are essential for anyone wanting to explore the intricacies of machinery. These documents typically include detailed instructions, troubleshooting tips, and maintenance schedules.

| Resource Type | Examples |

|---|---|

| Online Forums | Reddit, TractorByNet |

| Technical Manuals | OEM Manuals, Repair Guides |

| YouTube Channels | How-To Videos, Repair Tutorials |

| Parts Suppliers | Online Retailers, Local Dealers |

DIY Repairs Using Parts Diagrams

Engaging in repairs can be a rewarding experience, especially when utilizing visual aids to guide the process. These illustrations serve as invaluable tools, allowing enthusiasts to identify components and understand their assembly. By following these visuals, anyone can enhance their repair skills and maintain equipment more effectively.

| Component | Description | Common Issues |

|---|---|---|

| Engine | The powerhouse of the machine. | Overheating, oil leaks |

| Hydraulic System | Responsible for lifting and movement. | Leaks, low pressure |

| Transmission | Transfers power from the engine. | Slipping, strange noises |

| Electrical System | Controls starting and lighting. | Battery failure, wiring issues |

Utilizing these visuals, DIY enthusiasts can delve deeper into maintenance, ensuring longevity and optimal performance. Empower yourself by understanding the essentials of your machinery, turning repairs into an ultimate opportunity for learning and growth.

Frequently Asked Questions about the 770

This section addresses common inquiries regarding the specific model, focusing on its components and functionality. Understanding these aspects can enhance user experience and maintenance efficiency.

Common Inquiries

| Question | Answer |

|---|---|

| What are the main features of this model? | This model boasts robust performance, versatility, and user-friendly controls, making it suitable for various tasks. |

| How can I improve its lifespan? | Regular maintenance, including oil changes and timely inspections, will significantly extend its longevity. |

Maintenance Tips

Staying proactive with upkeep is crucial. Regular checks on fluids and components can prevent larger issues down the line.