Maintaining a reliable and efficient system for vehicles requires attention to the individual mechanisms that support their operation. Every vehicle relies on a combination of elements designed to provide stability, balance, and durability over various terrains. These elements work together, ensuring a steady and secure motion while adapting to different conditions.

To fully grasp how these elements function, it’s important to recognize the intricate roles of various connectors, structures, and devices. Each of them is designed to reduce impact and wear, enhancing the overall lifespan and performance of the vehicle. A well-maintained system not only offers a smooth ride but also helps prevent long-term damage.

Understanding the proper arrangement and function of these components is essential for ensuring both safety and efficiency. With regular inspection and upkeep, you can significantly extend the operational lifespan, while minimizing the risk of costly repairs or breakdowns. Ensuring everything is correctly aligned and functioning optimally is crucial to maintaining balance and control.

Understanding Key Components in Trailer Suspension

The efficiency and stability of a load-carrying vehicle depend significantly on the system that absorbs road impact and ensures a smooth ride. This system comprises several interconnected elements that work together to distribute weight evenly and reduce the effects of uneven terrain. Understanding how these elements function collectively can help improve performance and extend the life of the vehicle.

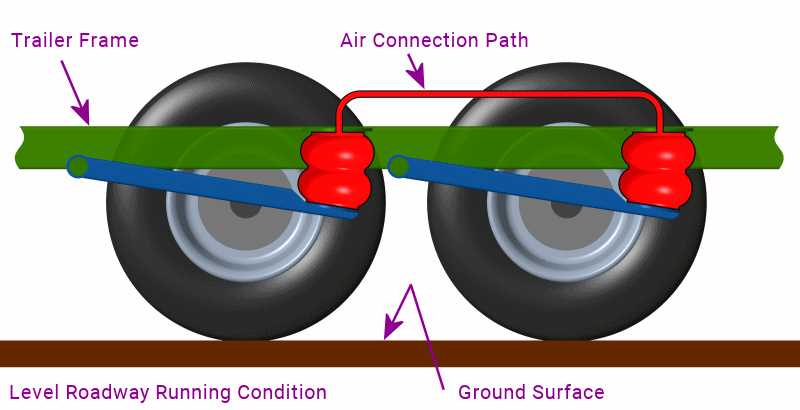

Shock Absorbers and Their Role

Shock absorbers play a crucial role in controlling the rebound of the vehicle after encountering bumps. They help maintain control by dampening vibrations, ensuring that the load remains stable even on rough surfaces. Without them, the ride would be significantly harsher, and the risk of damage to other components increases.

Axle and Linkage Functions

The axle and linkages are essential in maintaining the structure’s balance. They connect the wheels to the main body and allow for controlled movement while supporting weight distribution. Proper alignment and maintenance of these elements ensure smooth operation and prevent uneven wear on the tires.

How Leaf Springs Support Your Trailer

Leaf springs play a crucial role in distributing the load evenly across the vehicle, ensuring a smoother and more stable ride. They are designed to absorb shocks from uneven surfaces, preventing excessive bounce and sway. By flexing and returning to their original shape, these components maintain balance and protect the frame from damage.

Durability and Flexibility

One of the key advantages of leaf springs is their robust construction, allowing them to handle heavy loads without compromising performance. Their ability to flex under weight ensures a level of flexibility that enhances the overall driving experience, especially over rough terrain.

Maintaining Stability

Leaf springs are essential for maintaining control when navigating bumps or uneven ground. By adjusting to weight shifts, they keep the vehicle steady, minimizing the risk of instability during movement. This balance helps protect both the structure and the cargo.

The Role of Equalizers in Suspension Balance

The role of equalizers is crucial in maintaining even distribution of weight between axles during movement. Their main function is to balance the forces exerted on multiple points, allowing for smoother transitions and improved stability. By reducing the uneven stresses caused by varying loads, they help ensure that the entire system functions more efficiently and with less strain.

Equalizers are essential in improving handling and minimizing wear on individual components. They evenly spread out pressure, preventing excessive force from concentrating in one area, which helps to enhance durability and ensure a more controlled ride.

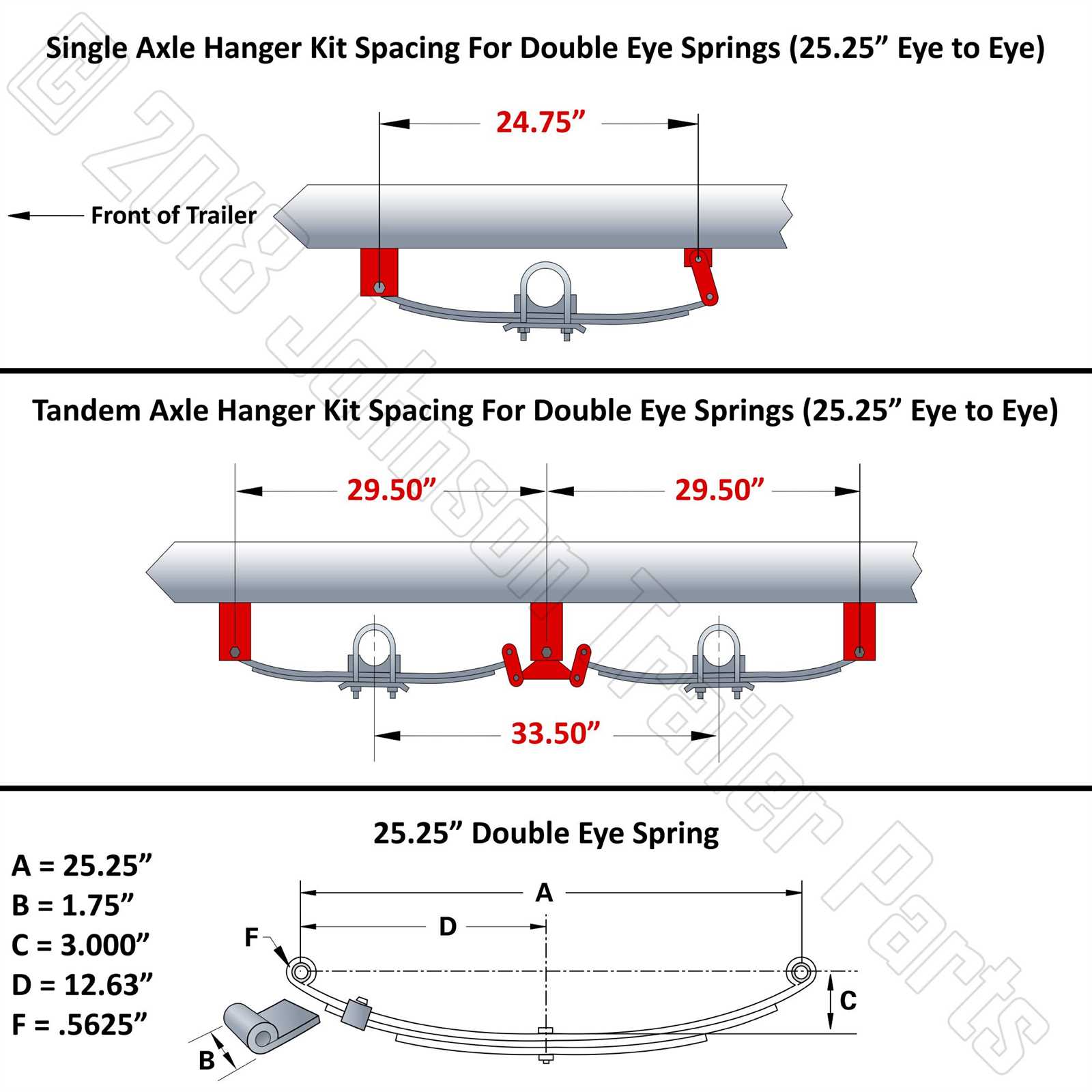

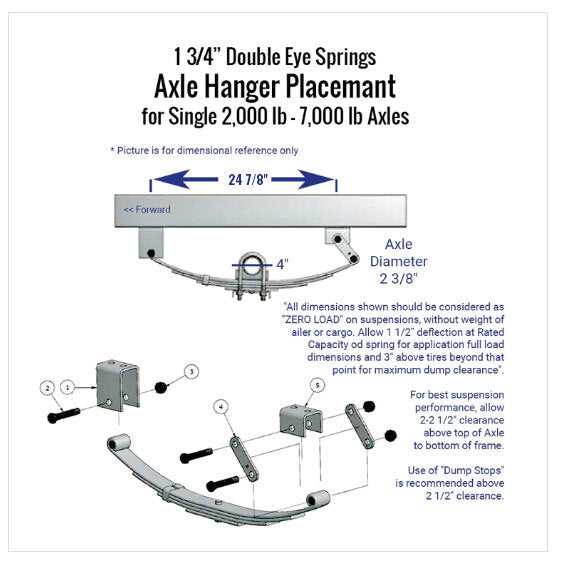

Shackles and Hangers: Their Function Explained

Shackles and hangers play a crucial role in ensuring the stability and flexibility of a vehicle’s movement. They work together to manage the movement of components, allowing smooth operation and weight distribution. Understanding their roles helps maintain proper performance and extend the lifespan of the system.

- Shackles: These are essential for providing flexibility. By connecting different elements, shackles allow controlled movement, ensuring that components can move efficiently without causing excess strain.

- Hangers: Hangers serve as secure attachment points. They hold the structure in place, maintaining balance and supporting the overall framework during operation.

Both shackles and hangers work together to ensure that forces are properly distributed, reducing wear and maintaining efficient functionality under various conditions.

Axles in Trailer Suspension: A Breakdown

Axles play a crucial role in distributing the load evenly and ensuring smooth movement. By supporting the weight, they allow the vehicle to handle different road conditions and maintain balance. Understanding the different types and how they function is key to optimizing performance.

| Type of Axle | Key Features |

|---|---|

| Solid Axle | Offers high durability and can support heavier loads. Typically used in more rugged applications. |

| Independent Axle | Provides better handling and smoother ride, especially on uneven terrain. Each wheel moves independently, improving comfort. |

| Tandem Axle | Used to distribute weight across multiple points, increasing load capacity and stability on the road. |

U-Bolts and Their Importance in Suspension

U-bolts play a crucial role in securing various components of a vehicle’s framework, ensuring stability and safety during operation. These fasteners are uniquely designed to accommodate the shapes of different assemblies, providing necessary support to keep everything in place. Their shape allows them to evenly distribute weight and reduce stress on critical areas, contributing to the overall integrity of the structure.

The significance of U-bolts cannot be overstated. They facilitate effective load management, allowing for smooth handling and control. By connecting essential elements securely, these fasteners help maintain alignment and prevent potential issues caused by excessive movement. Regular inspection of U-bolts is vital, as wear and tear can compromise their function, leading to adverse effects on performance and safety.

In summary, U-bolts are integral components that enhance the durability and efficiency of various systems. Their reliable design and robust functionality make them indispensable in maintaining a vehicle’s operational efficiency.

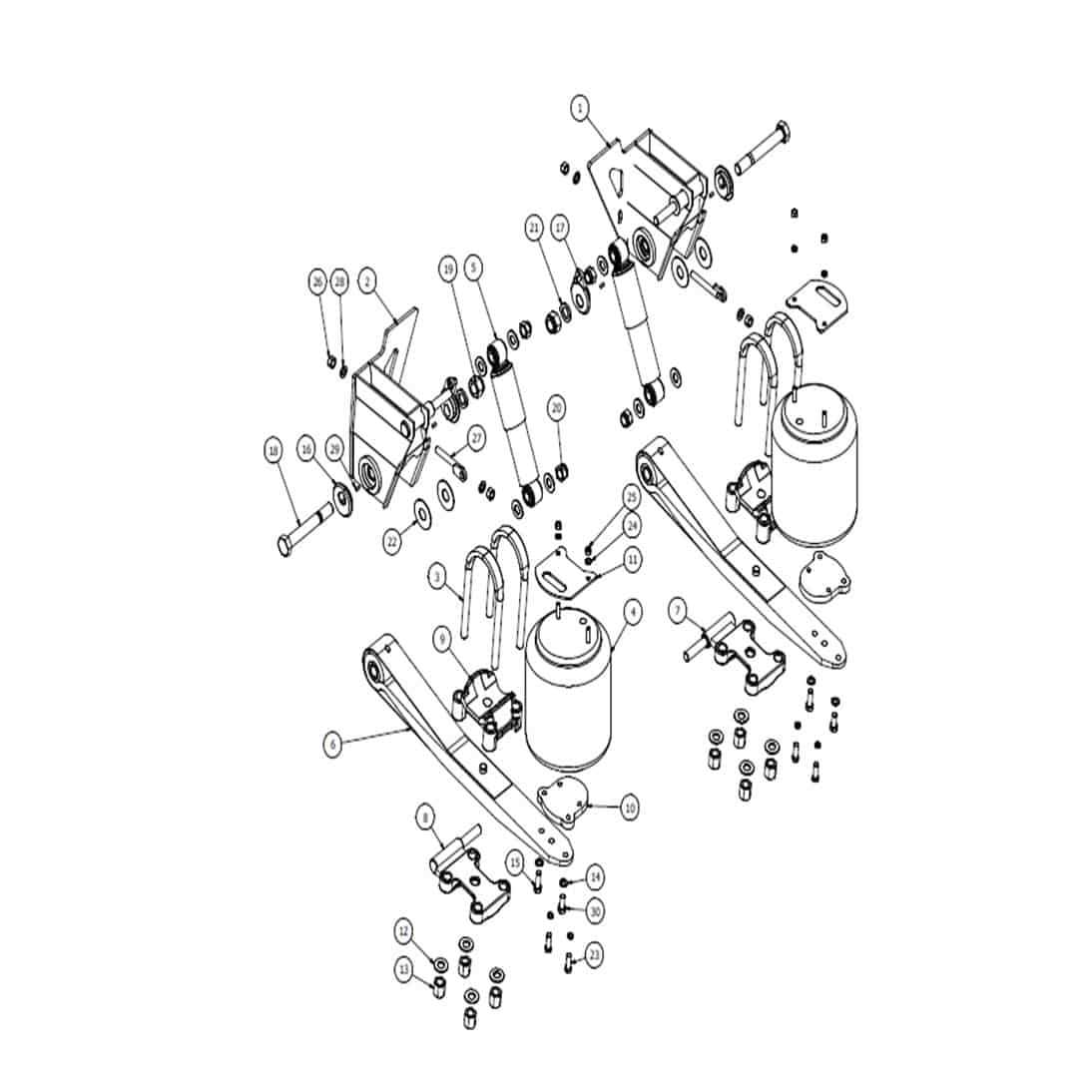

Understanding the Use of Torque Arms

Torque arms play a vital role in the stability and control of vehicles that carry heavy loads. These components are designed to manage the forces that act on the frame, ensuring that the vehicle maintains its intended path while navigating various terrains. Their primary function is to absorb and distribute the stress generated during operation, contributing to overall safety and performance.

The design of torque arms allows them to withstand significant lateral and longitudinal forces. By connecting different elements of the system, they effectively limit unwanted movement and enhance rigidity. This not only improves handling but also prolongs the lifespan of associated components by minimizing wear and tear caused by excessive motion.

When considering the installation and maintenance of torque arms, it is essential to pay attention to proper alignment and tension. Ensuring these components are correctly positioned can significantly affect their efficiency and effectiveness. Regular inspections and adjustments help maintain optimal performance and can prevent potential issues before they escalate.

In summary, torque arms are crucial for ensuring that vehicles remain stable under load. Their ability to manage forces and enhance control is indispensable for safe and effective operation. Understanding their function and maintaining them properly is key to achieving reliable performance in demanding conditions.

Shock Absorbers: Enhancing Ride Comfort

Shock absorbers play a crucial role in improving the overall experience during travel by effectively managing the forces exerted on a vehicle. These components significantly influence how well a vehicle responds to various surfaces, ensuring stability and minimizing disturbances. A well-functioning system contributes to smoother rides, which is essential for both comfort and safety.

By absorbing and dissipating energy from bumps and irregularities in the road, these mechanisms help maintain optimal contact between the wheels and the surface. This capability not only enhances ride quality but also extends the life of the vehicle by reducing wear on other components.

| Function | Benefits |

|---|---|

| Absorb shocks from uneven surfaces | Improves comfort and handling |

| Stabilize the vehicle during motion | Enhances safety and control |

| Reduce wear on tires and other elements | Prolongs lifespan of components |

Incorporating high-quality shock absorbers into a vehicle’s setup is essential for optimizing performance and ensuring a pleasant journey. Whether traversing rough terrains or cruising on smooth highways, these devices are integral to achieving a balanced and enjoyable driving experience.

Why Suspension Bushings Are Crucial

Rubber or polyurethane components play a vital role in the overall performance of a vehicle’s framework. These elements are designed to absorb shocks, minimize vibrations, and enhance the overall stability of the system. Their functionality directly impacts the comfort and safety of the ride.

Enhanced Comfort and Stability

These components provide a buffer between various moving parts, allowing for smoother transitions during operation. By reducing friction and wear, they help maintain the integrity of the structure, which leads to a more comfortable experience for passengers.

Durability and Maintenance

Using high-quality materials in these components can significantly extend their lifespan. Regular inspection and timely replacement of worn-out elements prevent more extensive damage to the overall framework, ensuring that the vehicle remains in optimal condition for longer periods.

Choosing the Right Trailer Suspension Kit

Selecting the appropriate system for load support is crucial for ensuring smooth transport and stability. The right choice enhances performance, increases safety, and prolongs the lifespan of your equipment. Various options are available, and understanding their features can help in making an informed decision.

Understanding Load Capacity

Load capacity is a key factor in the selection process. It refers to the maximum weight that the system can handle effectively. Evaluating the weight of the cargo and the overall requirements will help in determining the ideal setup for your specific needs.

Types of Load Support Systems

There are different configurations designed for various applications. Leaf spring systems provide durability and are often used for heavier loads, while torsion axles offer better ride quality for lighter loads. Assessing the advantages of each type will guide you to the most suitable option for your situation.

Maintenance Tips for Trailer Suspension Parts

Proper upkeep of critical components is essential for ensuring optimal performance and longevity. Regular care can prevent wear and tear, contributing to safer and smoother operation. Here are some valuable suggestions to help you maintain these vital elements effectively.

Regular Inspections

Routine examinations can help identify potential issues before they escalate. Consider the following:

- Check for visible signs of wear, such as cracks or rust.

- Inspect all connections and fasteners to ensure they are secure.

- Look for any abnormal noises during operation, which may indicate underlying problems.

Lubrication Practices

Keeping moving components well-lubricated is crucial for reducing friction and wear. Follow these guidelines:

- Use high-quality lubricant suitable for your specific application.

- Apply lubricant to pivot points, bushings, and other moving areas as needed.

- Reapply regularly, especially after heavy use or exposure to harsh conditions.