In the realm of heavy-duty transportation, it is essential to comprehend the various elements that contribute to the functionality and safety of these vehicles. Each component plays a significant role in ensuring smooth operation and reliability on the road. By familiarizing oneself with these intricate structures, one can appreciate the engineering that supports the movement of substantial loads.

Recognizing the interplay between different systems is crucial for both operators and maintenance personnel. These systems encompass various mechanisms, each designed for specific tasks, from supporting weight to enhancing maneuverability. Grasping the layout and function of these systems can facilitate better handling and troubleshooting, leading to improved performance.

By delving into the specifics of each element, individuals can gain insights into their importance in maintaining operational efficiency. Understanding these essential components empowers users to make informed decisions regarding maintenance and repairs, ultimately prolonging the lifespan of the vehicle and ensuring safe journeys.

This section aims to provide a comprehensive overview of the essential elements that make up the structure and functionality of a hauling vehicle. Understanding these components is crucial for anyone involved in the maintenance, operation, or design of such vehicles. Each component plays a vital role in ensuring safety and efficiency on the road.

The following list outlines the key elements associated with these vehicles:

- Chassis: The framework that supports the entire structure, providing stability and strength.

- Axles: Crucial for load distribution, they connect the wheels and facilitate movement.

- Suspension: This system absorbs shocks and maintains balance during travel.

- Braking System: Vital for safety, it allows the driver to control the speed and stop the vehicle effectively.

- Lighting: Ensures visibility and signals intentions to other drivers, enhancing safety.

- Coupling Mechanism: The interface that connects the hauling unit to the load-carrying unit.

- Wheels and Tires: Designed for traction and stability, they are critical for safe navigation.

Each of these components contributes to the overall performance and safety of the vehicle, making it essential for operators to be familiar with their functions and maintenance needs.

Essential Parts of a Truck Trailer

Understanding the fundamental components of a heavy-duty hauling vehicle is crucial for ensuring optimal performance and safety on the road. These crucial elements work in harmony to support the overall functionality and reliability of the transport system, making it essential for operators to be familiar with them.

Key Components for Stability

One of the primary elements that contribute to stability is the framework, which serves as the backbone of the vehicle. This sturdy structure is designed to withstand significant loads and adverse conditions. Additionally, the suspension system plays a vital role in maintaining balance, allowing for smooth rides even when carrying heavy cargo.

Mechanisms for Control and Efficiency

Effective steering mechanisms are indispensable for maneuverability, enabling precise control during transit. Furthermore, braking systems are critical for ensuring safe stops, particularly when handling substantial weights. Regular maintenance of these vital systems is essential to avoid accidents and enhance operational efficiency.

Common Types of Trailer Attachments

Understanding the various types of connections used for transporting goods is essential for optimizing functionality and safety. These connections facilitate the seamless transfer of loads, ensuring stability and ease of use. Each type serves a specific purpose and is designed to accommodate different hauling needs.

Standard Couplings

Standard couplings are widely utilized for their simplicity and reliability. They allow for quick attachment and detachment, making them ideal for frequent loading and unloading scenarios. This category includes both ball hitches and pin-style connections, which provide a secure fit for various hauling applications.

Specialized Mounts

Specialized mounts cater to specific requirements, enhancing the versatility of the hauling system. Examples include adjustable couplers that can accommodate different height requirements, as well as hydraulic connections for heavy-duty applications. These mounts ensure that diverse cargo types can be transported efficiently and securely.

Functionality of Trailer Axles

The axles play a crucial role in ensuring the stability and performance of the vehicle’s load-bearing system. They serve as the primary connection point between the body and the ground, facilitating movement while supporting the weight of the cargo. Their design and function significantly impact the overall efficiency and safety of transportation.

Weight Distribution and Balance

One of the main functions of these essential components is to evenly distribute the weight of the load. Proper weight distribution enhances balance and reduces the risk of swaying during transit. This stability is vital for maintaining control, especially when navigating turns or uneven surfaces.

Support and Movement

Additionally, these components provide the necessary support for wheels, allowing for smooth rotation and efficient movement. Their design accommodates various road conditions, ensuring that the vehicle can handle bumps and dips without compromising the integrity of the load. This adaptability contributes to a safer driving experience.

Role of Suspension Systems

The suspension system plays a crucial role in ensuring stability and comfort during transportation. It serves to absorb shocks and vibrations from the road, providing a smoother ride for the vehicle’s cargo and its occupants. By maintaining proper alignment and support, this system significantly contributes to the overall performance and safety of the vehicle.

Functionality and Benefits

One of the primary functions of a suspension system is to manage the interaction between the vehicle and the road surface. It helps to distribute the load evenly, which not only enhances handling but also prolongs the lifespan of the vehicle. Moreover, an efficient suspension system minimizes wear and tear on other components, ensuring a more reliable operation.

Types of Suspension Systems

There are various types of suspension systems designed to meet different needs. For example, air suspension systems offer adjustable ride height and improved comfort, while leaf spring systems provide robustness for heavy loads. Understanding the specific advantages of each type can help in selecting the most suitable option for various applications.

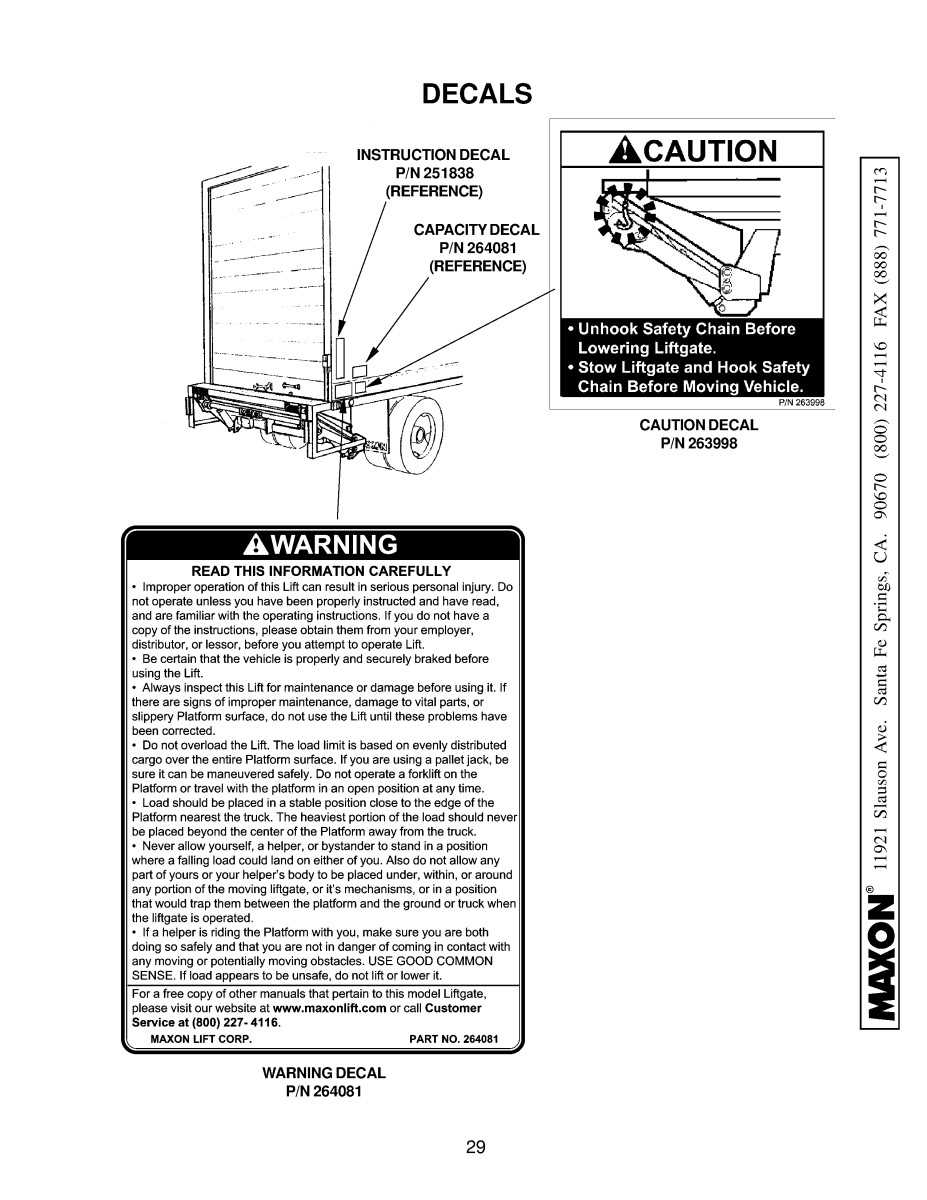

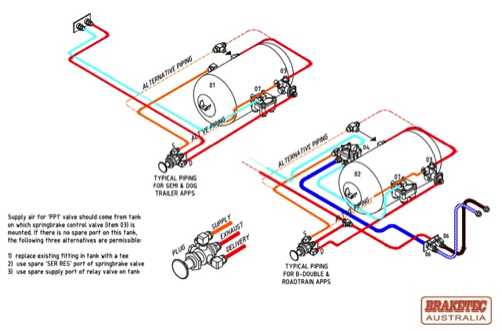

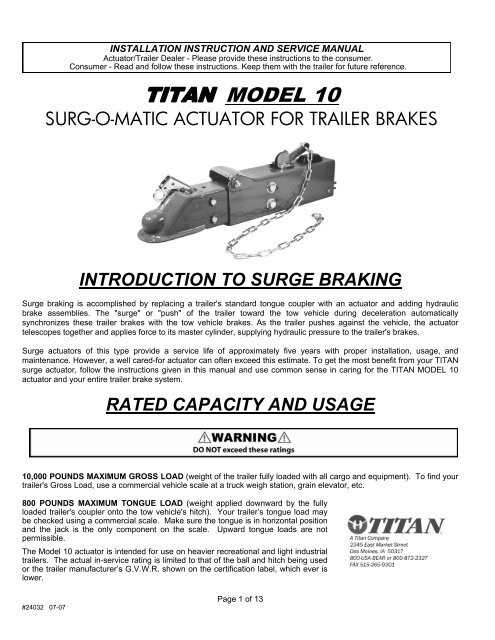

Brake Mechanisms Explained

The braking system is a crucial component that ensures the safety and control of large vehicles. Understanding how these mechanisms operate is essential for proper maintenance and efficient performance. This section delves into the different types of braking systems, their functionalities, and the significance of each component in achieving reliable deceleration.

Types of Braking Systems

- Hydraulic Brakes: These systems utilize fluid pressure to engage the brake pads, providing powerful stopping force.

- Pneumatic Brakes: Commonly found in larger vehicles, they use compressed air to activate the braking process, allowing for rapid engagement.

- Mechanical Brakes: These rely on physical components such as cables and levers to apply pressure, often used as backup systems.

Key Components of Braking Systems

- Brake Pads: Friction materials that press against the wheel to slow down or stop motion.

- Rotors: Discs that rotate with the wheels; brake pads clamp onto them to create friction.

- Calipers: Devices that house the brake pads and provide the necessary pressure to engage them against the rotors.

- Master Cylinder: A component that converts the force from the brake pedal into hydraulic pressure.

- Brake Lines: Tubes that transport brake fluid from the master cylinder to the calipers.

Regular inspections and maintenance of these systems are vital to ensure optimal functionality and safety on the road. Understanding how each element contributes to the overall performance allows for better handling and control of larger vehicles.

Importance of Trailer Lighting

Effective illumination plays a crucial role in ensuring safety and visibility on the road. Properly functioning lights enhance the ability of surrounding drivers to perceive the dimensions and movements of the vehicle, reducing the likelihood of accidents during both day and night.

Moreover, regulatory compliance mandates the use of appropriate lighting systems to meet safety standards. Bright and clearly visible lights not only provide necessary signals but also contribute to the overall awareness of other road users. This aspect is particularly vital when navigating in adverse weather conditions or low-light environments.

In addition to safety, well-maintained illumination systems can enhance the aesthetic appeal of the vehicle. Customized lighting can reflect personal style while also ensuring functionality. Regular checks and maintenance of these systems are essential for optimal performance and to prevent potential hazards associated with faulty lighting.

Evaluating Load Distribution

Understanding the balance of weight across a transport system is crucial for ensuring stability and safety during operation. Proper evaluation helps in preventing issues such as uneven wear, tipping, and compromised handling.

When assessing the allocation of weight, several factors should be considered:

- Weight Placement: The location of the load significantly impacts the center of gravity. Ideally, the heaviest items should be positioned closer to the axle for optimal balance.

- Axle Capacity: Each axle has a specific weight limit. Distributing weight evenly across axles prevents overloading and enhances performance.

- Load Shape: Irregularly shaped cargo may require special attention to ensure that weight is distributed evenly. Use supportive structures to stabilize odd shapes.

- Environmental Conditions: Factors such as terrain and weather can affect handling. Assessing load distribution in varying conditions is vital for safety.

To effectively analyze the distribution, follow these steps:

- Conduct a thorough inspection of the loaded structure.

- Measure the distance from the load’s center of mass to the axles.

- Calculate the total weight and compare it with the recommended limits.

- Make adjustments as necessary to achieve an even distribution.

Regular evaluation of weight distribution not only enhances safety but also extends the lifespan of the entire system. Adopting best practices in load placement will lead to improved operational efficiency.

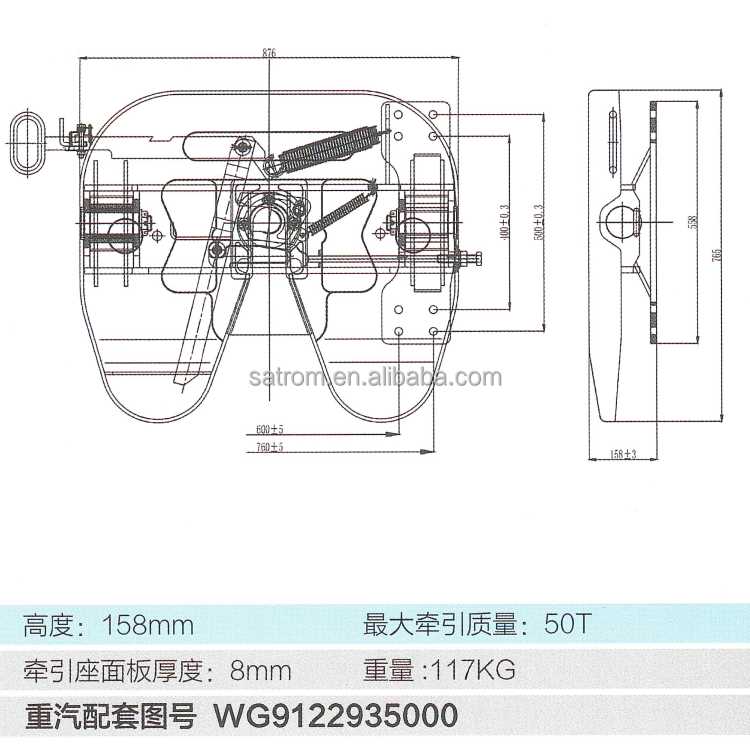

Overview of Coupling Devices

Coupling devices play a crucial role in establishing secure connections between various vehicles and their associated equipment. These mechanisms ensure stability and reliability during transport, enabling smooth operations on diverse terrains. Understanding the functionality and types of these devices is essential for maintaining efficiency and safety in hauling activities.

Types of Coupling Mechanisms

There are several categories of coupling mechanisms, each designed to meet specific needs and applications. The most common types include:

| Type | Description |

|---|---|

| Ball Coupling | A rounded connector that allows for a pivoting motion, facilitating easy attachment and detachment. |

| Pintle Hook | A heavy-duty option, providing robust connections suitable for rough terrains and heavy loads. |

| Gooseneck Coupling | Offers a higher connection point, enhancing maneuverability and stability, particularly for larger setups. |

Importance of Proper Selection

Selecting the appropriate coupling device is vital for ensuring optimal performance and safety. Factors such as load capacity, vehicle compatibility, and environmental conditions must be considered to achieve a secure and efficient connection.

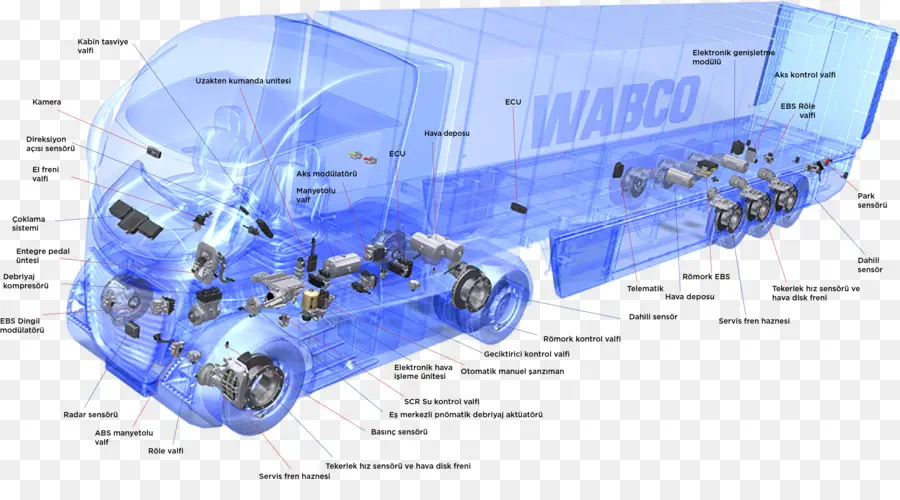

Safety Features in Truck Trailers

Ensuring the protection of both the cargo and the surrounding environment is paramount in the design of heavy-duty transport vehicles. Various mechanisms are implemented to enhance security and mitigate risks during transit. These features not only safeguard the load but also promote safer interactions on the road.

Key Mechanisms for Enhanced Protection

A range of essential systems contributes to the overall safety of these vehicles. From braking technology to visibility enhancements, each element plays a crucial role in preventing accidents and ensuring compliance with safety regulations.

| Feature | Description |

|---|---|

| Anti-lock Braking System (ABS) | Prevents wheel lock-up during braking, improving steering control and reducing stopping distances. |

| Electronic Stability Control (ESC) | Detects and reduces loss of traction, helping to maintain directional control in slippery conditions. |

| Reflective Markings | Enhances visibility, especially in low-light conditions, making the vehicle more recognizable to other road users. |

| Load Securing Systems | Ensures that the cargo remains stable and secure during transit, reducing the risk of shifting or falling. |

Importance of Regular Maintenance

To maintain optimal functionality of these safety features, regular inspections and maintenance are vital. Ensuring that all systems are in working order not only enhances performance but also contributes to the overall safety of road transportation.

Maintenance Tips for Trailer Parts

Regular upkeep of your vehicle’s components is essential for ensuring optimal performance and longevity. Neglecting maintenance can lead to unnecessary wear and tear, affecting both safety and efficiency. By following a few straightforward practices, you can enhance the reliability and functionality of your equipment.

Routine Inspections

Conducting frequent checks is crucial. Look for signs of wear, rust, or any other abnormalities that may indicate potential issues. Pay attention to the following elements:

| Component | What to Check |

|---|---|

| Braking System | Inspect pads and discs for wear; check fluid levels. |

| Suspension | Look for leaks and ensure all components are secure. |

| Tires | Monitor tread depth and check for uneven wear. |

| Lights | Test all lights for functionality; replace any burnt-out bulbs. |

Cleaning and Lubrication

Maintaining cleanliness is vital for preventing corrosion and ensuring smooth operation. Regularly clean the surfaces and apply appropriate lubricants to moving parts. This will reduce friction and prolong the life of the components.

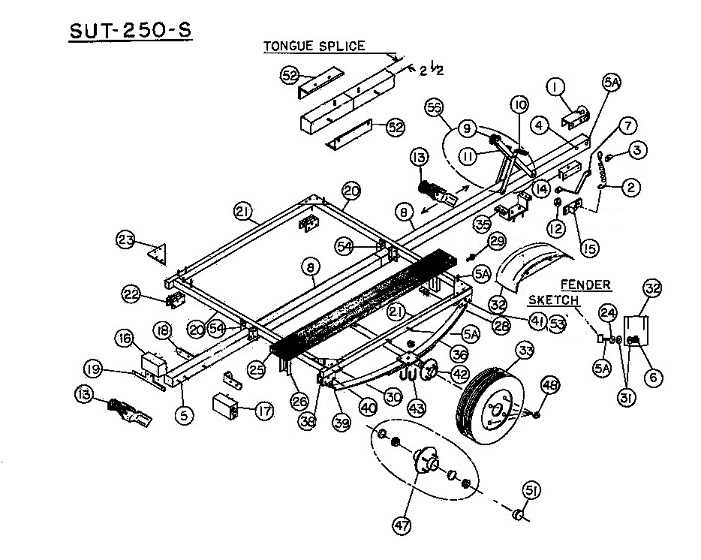

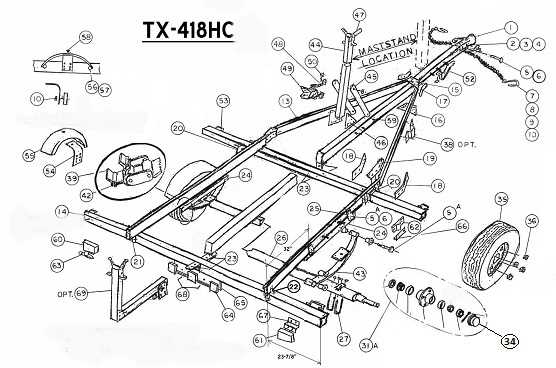

Diagram of Typical Trailer Layout

This section presents a visual representation of a common configuration found in various hauling vehicles. Understanding this arrangement is crucial for ensuring optimal functionality and efficiency in transporting goods.

The layout consists of several key components that play specific roles in the overall structure. Below are the primary elements typically included:

- Frame: The foundational structure providing stability and support.

- Axles: Components that facilitate movement by connecting the wheels.

- Wheels: Essential for mobility, allowing the vehicle to traverse different terrains.

- Coupling Mechanism: The system that links the towing unit to the structure.

- Storage Areas: Designated spaces for carrying various types of cargo.

- Braking System: Vital for safety, enabling controlled stopping.

Each of these elements is strategically placed to enhance performance and safety during transport operations. Familiarity with this configuration assists operators in maintaining and optimizing their equipment effectively.