Exploring the complexities of automatic gear mechanisms reveals the intricate interplay of components that contribute to smooth vehicle operation. Each element plays a crucial role, ensuring efficiency and reliability on the road. This section delves into the various segments involved in these sophisticated systems, highlighting their significance in overall performance.

By breaking down the assembly, one can appreciate how each piece functions in harmony with others. This examination not only aids in better understanding but also enhances maintenance practices. Knowledge of these assemblies is essential for anyone looking to optimize their vehicle’s functionality and longevity.

In this guide, we will provide a detailed visual representation, allowing enthusiasts and professionals alike to familiarize themselves with the configuration and arrangement of these essential components. Understanding the layout and relationships among these elements is key to troubleshooting and repairs, ultimately leading to a more informed approach to vehicle care.

Understanding 4t65e Transmission Basics

Familiarizing oneself with the core elements of an automatic gearbox is crucial for anyone interested in vehicle mechanics. This complex assembly plays a vital role in transferring power from the engine to the wheels, allowing for smooth acceleration and deceleration. A clear grasp of its components and their functions can enhance maintenance and troubleshooting efforts.

The following table outlines the essential components typically found within such a system, along with their primary roles:

| Component | Function |

|---|---|

| Planetary Gear Set | Responsible for gear ratios and speed control. |

| Torque Converter | Facilitates smooth power transfer and provides torque multiplication. |

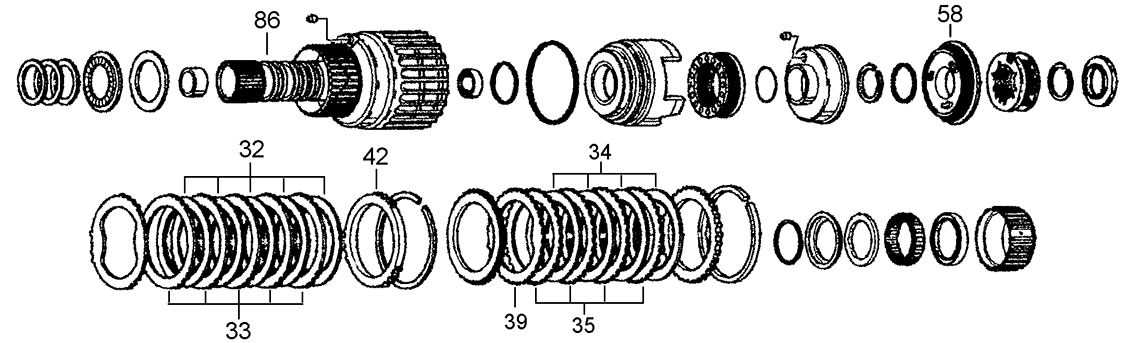

| Clutch Packs | Engage and disengage various gear sets for optimal performance. |

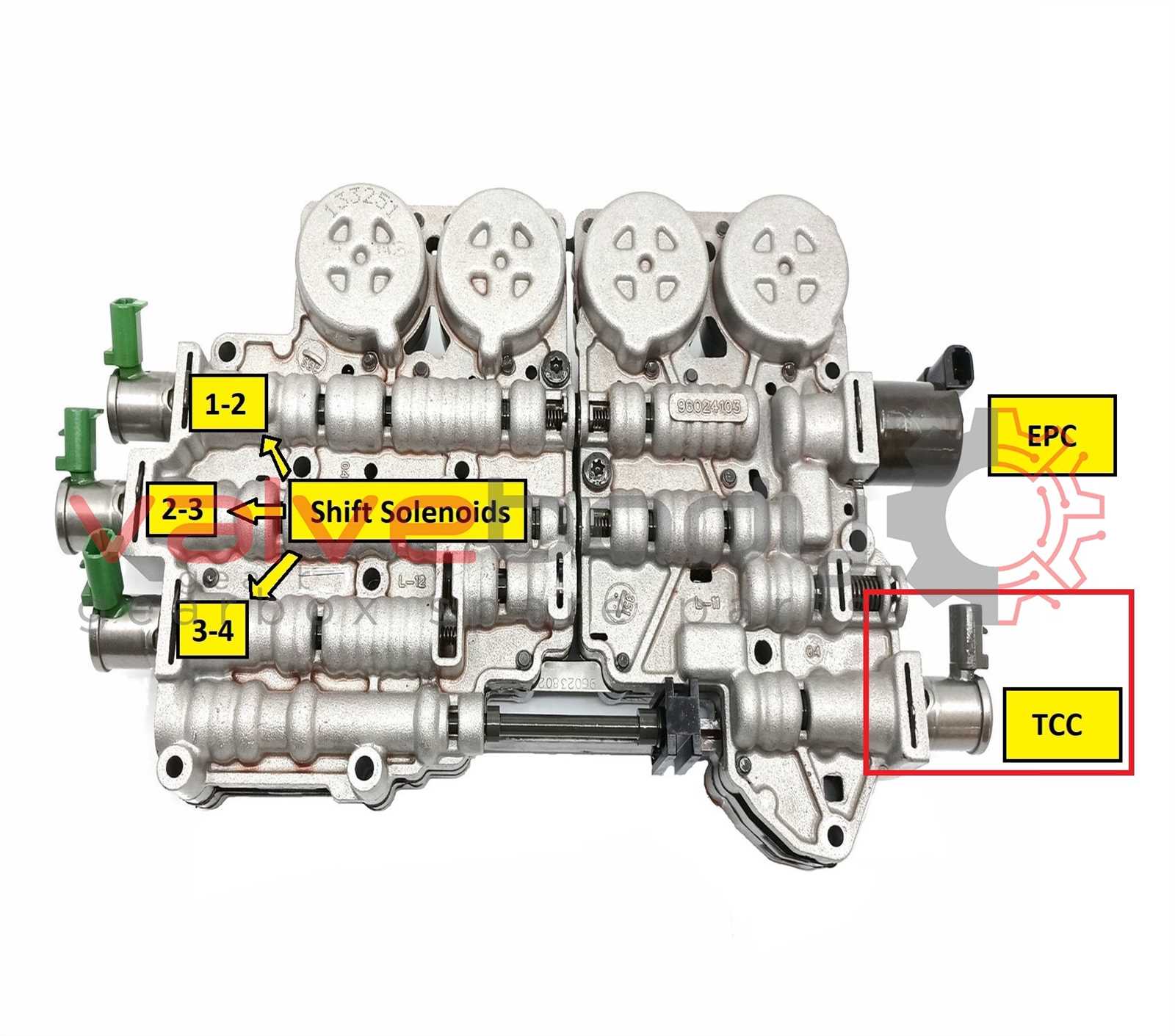

| Valve Body | Controls fluid flow and regulates shifting patterns. |

| Oil Pump | Maintains hydraulic pressure essential for operation. |

Understanding these key components allows for a better insight into how the system operates as a whole, ensuring that vehicle enthusiasts can address issues effectively and maintain optimal performance.

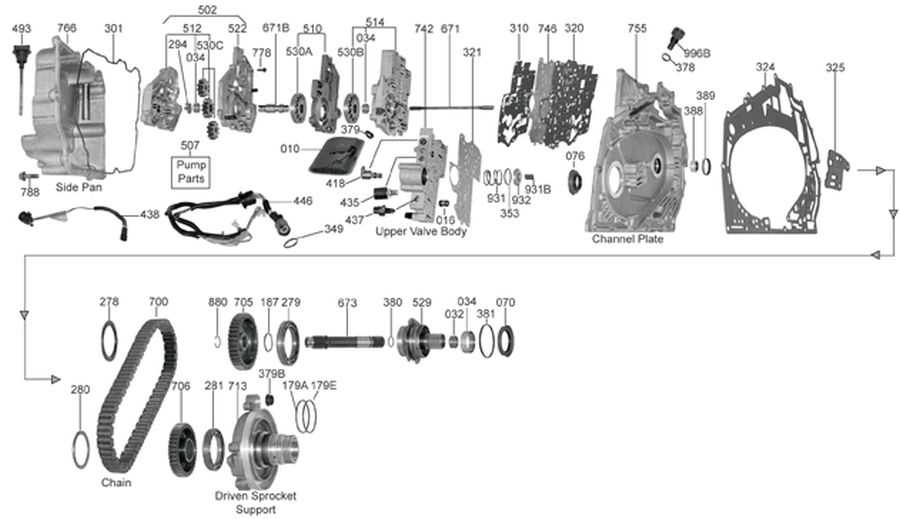

Key Components of the 4t65e System

Understanding the essential elements of this complex assembly is crucial for effective maintenance and repair. Each component plays a vital role in ensuring smooth operation and longevity, contributing to the overall performance of the vehicle’s drivetrain. Familiarity with these individual parts enables technicians and enthusiasts alike to troubleshoot issues and enhance vehicle functionality.

Hydraulic System

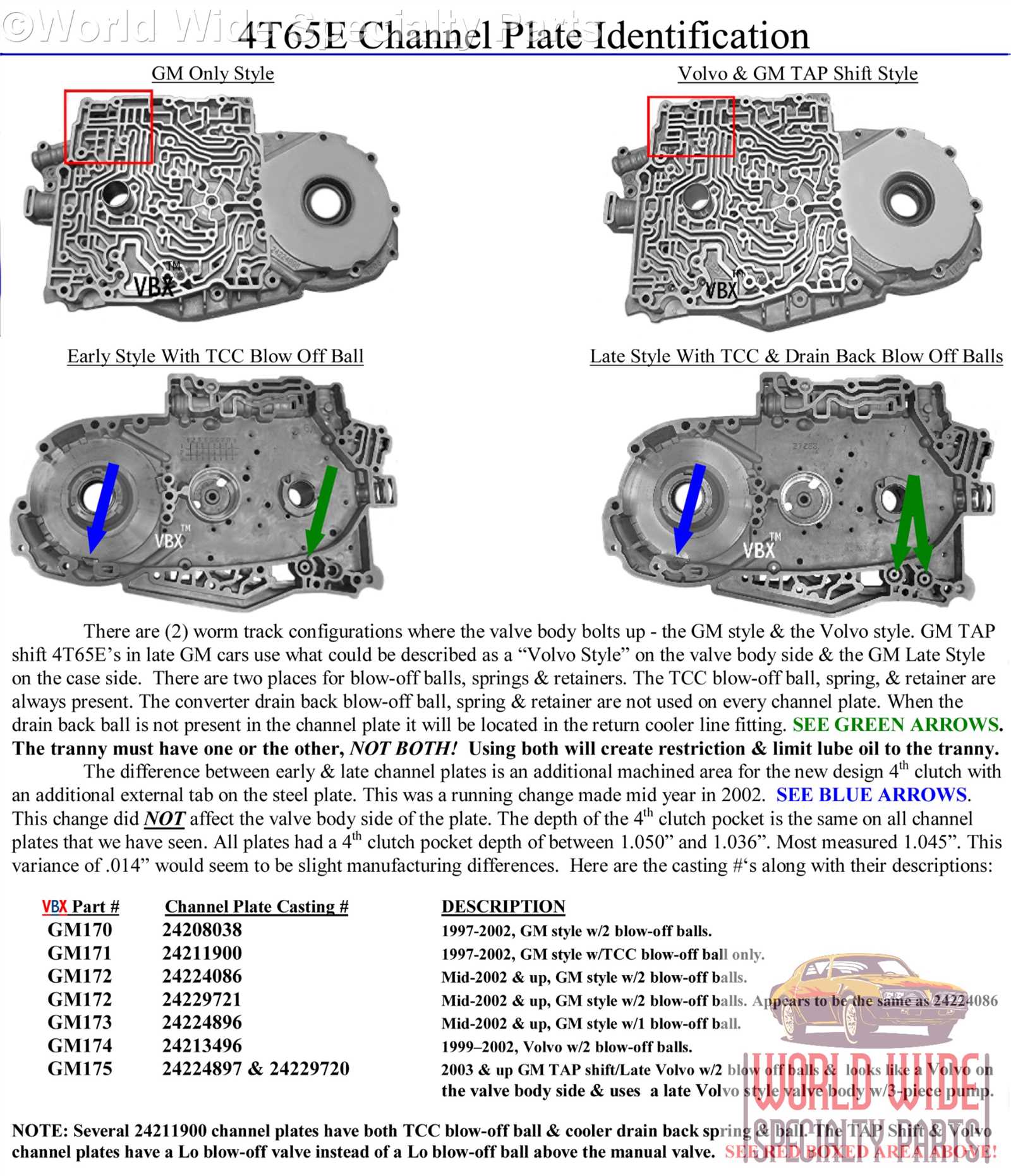

The hydraulic mechanism is central to the operation, utilizing fluid pressure to facilitate gear shifts and engage various functions. This system includes several crucial elements, such as pumps, valves, and filters. Each component works in harmony to manage fluid flow and maintain optimal pressure levels, allowing for seamless transitions between gears.

Gear Sets

Integral to the assembly, the gear sets determine the vehicle’s speed and torque. These include a range of gears, such as planetary gears and ring gears, which collaborate to deliver the necessary power. The design and arrangement of these gears significantly influence the efficiency and responsiveness of the overall system, making their functionality paramount.

Common Issues with 4t65e Transmissions

Understanding frequent complications in this specific automatic gear system can help drivers identify and address concerns before they escalate. Various factors contribute to these malfunctions, often leading to noticeable performance issues.

One prevalent problem is slipping, which manifests as the vehicle hesitating to engage or a sudden loss of power during acceleration. This can stem from worn clutches or low fluid levels. Additionally, overheating is a common issue, typically caused by inadequate lubrication or a failing cooler, which may lead to severe damage if not resolved promptly.

Another concern is harsh shifting, where the gear changes feel abrupt or jerky. This can indicate problems with the valve body or solenoids. Moreover, leaks are often observed, resulting in fluid loss that can impair the system’s function. Regular checks and maintenance are essential to mitigate these issues and ensure optimal performance.

How to Read a Transmission Diagram

Understanding a schematic representation of automotive components is essential for effective maintenance and repair. These visuals provide crucial insights into the arrangement and function of various elements within the system, enabling technicians to troubleshoot and optimize performance.

To begin, familiarize yourself with the symbols used in these representations. Each symbol corresponds to a specific component, often denoting its function or connection type. Here’s a quick reference table for common symbols:

| Symbol | Description |

|---|---|

| ⚙️ | Gear or rotating element |

| Link or connector | |

| ⚡ | Electrical component |

| Fluid path or flow |

Next, trace the flow of energy or fluid through the schematic, paying attention to the connections between components. This will help you understand how they interact and the ultimate operation of the entire assembly. Finally, practice interpreting these visuals to build confidence and proficiency in automotive diagnostics.

Identifying Parts in the Diagram

Understanding the various components within a complex mechanical system is crucial for effective maintenance and repair. Each element plays a vital role in the overall functionality, and recognizing their placement can significantly enhance the troubleshooting process. By familiarizing oneself with the configuration, one can streamline both diagnostics and potential upgrades.

To successfully navigate the illustration, focus on the labeling conventions often employed, which can aid in pinpointing specific functionalities. Observing the relationships between different components provides insight into how they interact, enabling a deeper comprehension of the assembly’s operation. This knowledge is ultimately essential for anyone looking to engage in effective repair or enhancement endeavors.

Functions of Each Transmission Component

The intricacies of automotive mechanics rely on a variety of crucial elements, each playing a distinct role in ensuring smooth operation. Understanding these components can enhance appreciation for the overall system.

- Clutch: Engages and disengages the engine from the drive system, allowing for smooth gear changes.

- Gear Set: Adjusts torque and speed by changing gear ratios to optimize performance under different conditions.

- Governor: Regulates fluid pressure based on vehicle speed, influencing shift points for efficiency.

- Valve Body: Directs hydraulic fluid to various components, controlling the engagement of gears.

- Filter: Removes debris and contaminants from the fluid, ensuring longevity and efficiency.

- Pump: Circulates hydraulic fluid throughout the system, providing necessary pressure for operation.

Each element is integral, working collectively to ensure reliable functionality and performance.

Replacing Worn Out Parts Effectively

Maintaining optimal performance in machinery requires addressing components that show signs of wear. Effective replacement can extend the lifespan and enhance functionality, leading to smoother operation.

To achieve successful replacements, consider the following steps:

- Identify symptoms of wear, such as unusual noises or decreased efficiency.

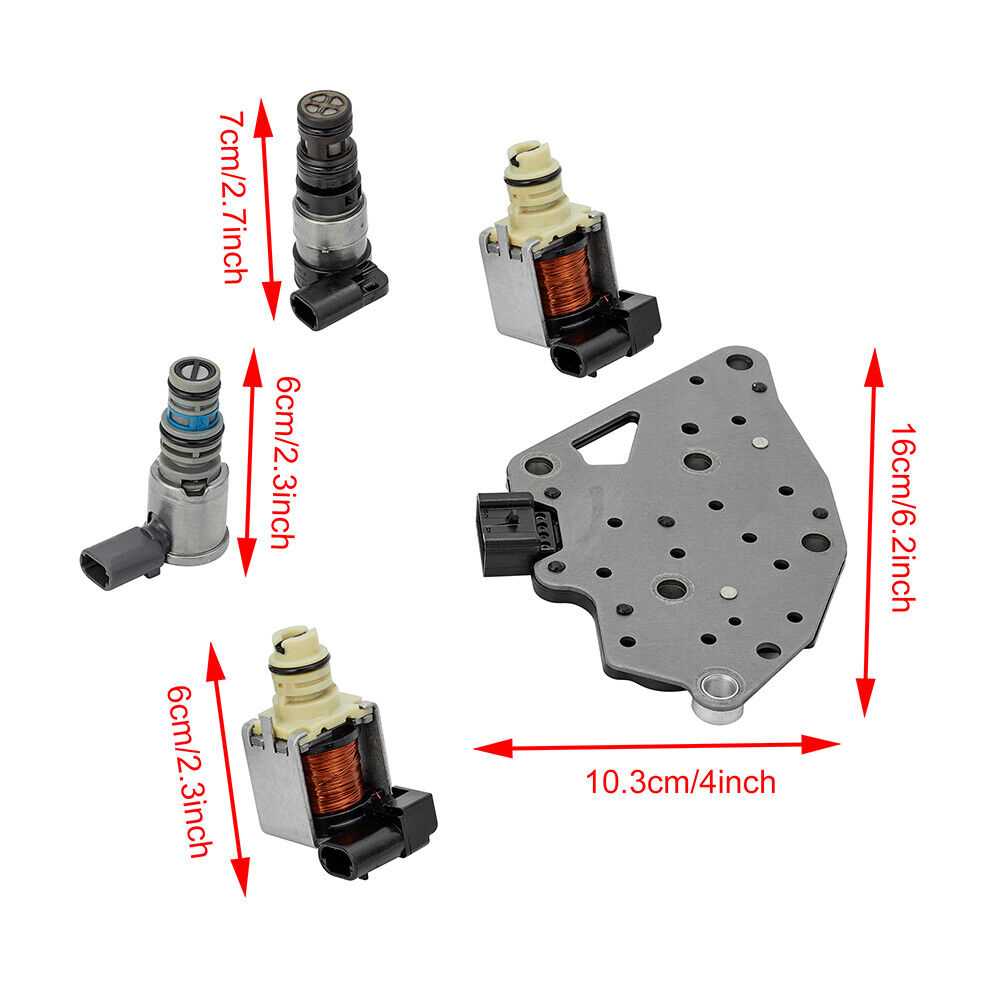

- Consult manuals or diagrams to determine specific components needing attention.

- Source high-quality replacements to ensure compatibility and durability.

- Follow proper installation procedures to prevent future issues.

- Conduct tests post-replacement to confirm successful repairs.

By following these guidelines, one can effectively rejuvenate equipment, ensuring it operates at its ultimate capacity.

Maintenance Tips for Longevity

Ensuring the durability of your vehicle’s critical systems requires consistent care and attention. By adopting a few simple practices, you can significantly enhance performance and lifespan, preventing costly repairs down the line.

Regular Fluid Checks

Maintaining optimal fluid levels is essential. Regularly inspect and replace lubricants to ensure smooth operation. Fresh fluids help reduce wear and improve efficiency, ultimately leading to better performance.

Monitor Driving Habits

Your driving style plays a crucial role in system health. Avoid aggressive starts and stops, and try to maintain steady speeds. These habits can minimize stress and prolong the life of your vehicle’s components.

Tools Needed for Transmission Work

Working on automotive gear systems requires a specific set of instruments to ensure precision and efficiency. Having the right tools not only streamlines the repair process but also enhances safety and accuracy. Below are some essential items that are commonly needed for such tasks.

Essential Hand Tools

Basic hand tools are crucial for any mechanical job. A reliable set of wrenches and sockets will help you access and secure various components. Ratchets with extensions allow for flexibility in tight spaces, while screwdrivers of various types and sizes ensure that you can handle different fasteners. Additionally, pliers and pry bars are invaluable for manipulating parts and applying leverage when necessary.

Specialized Equipment

Beyond standard hand tools, specific equipment is required to deal with the intricacies of gear systems. A torque wrench is essential for applying the correct tightness to fasteners, preventing damage to components. A gear puller can assist in the removal of tightly fitted elements, while fluid pumps are important for transferring lubricants and ensuring proper fluid levels. Lastly, having a reliable work light can significantly improve visibility in dark engine bays.

Step-by-Step Repair Guide

This guide provides a comprehensive approach to restoring a crucial component of your vehicle’s powertrain. By following a systematic method, you can ensure that every aspect is addressed, resulting in optimal performance and longevity. Preparation is key, and having the right tools at your disposal will make the process smoother and more efficient.

Preparation and Tools

Before starting the repair, gather essential tools such as wrenches, sockets, and a torque wrench. Additionally, ensure you have a clean workspace and appropriate safety gear. Reviewing the service manual specific to your model will also aid in understanding the components and procedures involved.

Step-by-Step Procedure

Begin by safely lifting the vehicle and removing any necessary coverings. Carefully disconnect the relevant connections, noting their arrangement for reassembly. Replace worn or damaged elements methodically, ensuring each part fits correctly. After completing the replacements, reassemble the unit in reverse order, double-checking all connections before lowering the vehicle and conducting a performance test.

Upgrading Your 4t65e Transmission

Enhancing your vehicle’s performance involves optimizing key components that facilitate power transfer. By focusing on upgrades, you can achieve improved efficiency, durability, and responsiveness. This guide will explore various enhancement options to elevate your driving experience.

| Upgrade Type | Description |

|---|---|

| High-Performance Fluid | Utilizing advanced fluids can reduce friction and heat, leading to smoother operation. |

| Stronger Clutches | Upgrading to heavy-duty clutches can enhance torque capacity and extend lifespan. |

| Enhanced Valve Body | Modifying the valve body allows for quicker shifts and improved responsiveness. |

| Better Torque Converter | A high-performance torque converter improves power transfer and acceleration. |

Consider these enhancements to maximize your vehicle’s potential and enjoy the ultimate driving experience.

FAQs About 4t65e Transmission Parts

This section addresses common inquiries regarding the components of a specific automotive system. Understanding these elements can significantly enhance your maintenance and repair experience, ensuring optimal vehicle performance.

| Question | Answer |

|---|---|

| What are the common symptoms of failure? | Typical indicators include slipping gears, unusual noises, and fluid leaks. |

| How often should I replace these components? | Replacement frequency varies based on driving habits and maintenance, generally recommended every 30,000 to 60,000 miles. |

| Can I use aftermarket alternatives? | Aftermarket options are available, but ensure they meet the necessary specifications for compatibility and performance. |

| What tools are required for installation? | Essential tools include basic hand tools, a torque wrench, and, in some cases, specialized equipment for alignment. |

| Is professional installation necessary? | While DIY is possible, professional assistance is recommended for those unfamiliar with complex assemblies. |

Resources for Further Learning

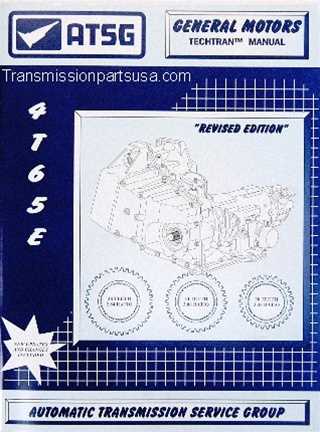

Expanding your knowledge in automotive mechanics can be both rewarding and essential for effective maintenance and repair. Numerous resources are available to help enthusiasts and professionals alike deepen their understanding of vehicle systems and components. These materials can provide insights into operation, troubleshooting, and best practices.

Online Courses: Many platforms offer structured courses covering various aspects of automotive technology. These courses often include videos, quizzes, and interactive content to enhance your learning experience.

Books and Manuals: Comprehensive texts and manuals are invaluable for anyone looking to dive deeper into vehicle mechanics. They often include detailed explanations, illustrations, and troubleshooting tips that can serve as handy references.

Forums and Online Communities: Engaging with fellow enthusiasts through forums can be incredibly beneficial. These platforms allow for the exchange of knowledge, tips, and personal experiences, fostering a collaborative learning environment.

YouTube Channels: Many creators focus on automotive repair and maintenance, providing visual guides that can simplify complex topics. Watching demonstrations can be particularly helpful for grasping practical skills.

Workshops and Seminars: Attending local workshops or seminars can offer hands-on experience and direct interaction with experts in the field. These events often provide opportunities to ask questions and gain practical insights.

Utilizing these diverse resources can significantly enhance your understanding and skills in the automotive realm, making you more proficient in handling various mechanical challenges.