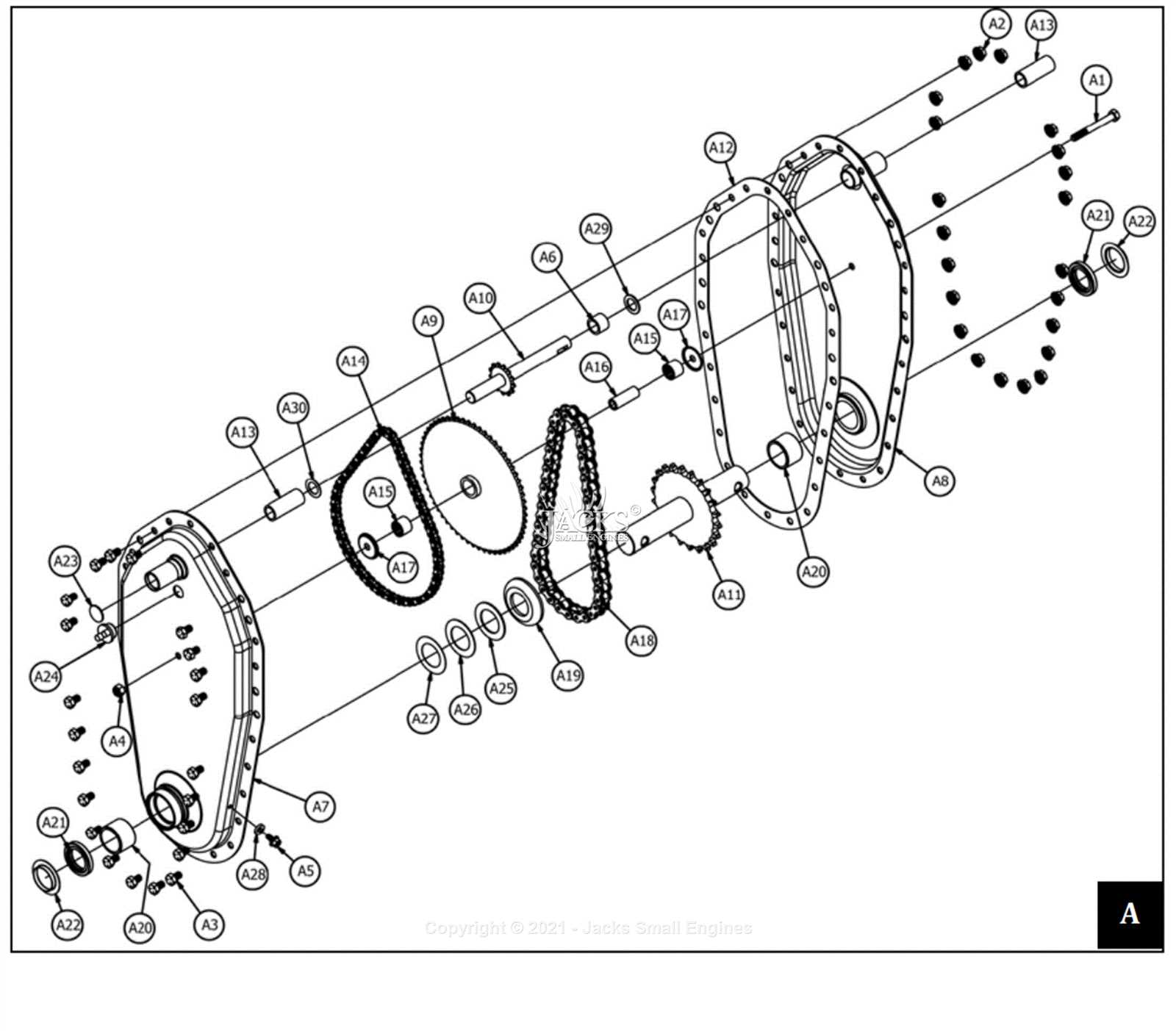

The structure of complex mechanical systems requires a deep understanding of how various elements interact. This section provides an insight into the critical elements responsible for ensuring smooth operation within intricate mechanisms. Each element plays a vital role in maintaining efficiency and reliability.

From controlling power distribution to managing seamless movement, the individual components within these systems are essential for optimal performance. Understanding the function and interplay of these elements is crucial for anyone looking to enhance their technical knowledge or perform necessary maintenance.

Precise adjustments and careful alignments of these elements ensure longevity and proper functioning of the entire system, which is vital for avoiding breakdowns and costly repairs.

Understanding Key Transmission Components

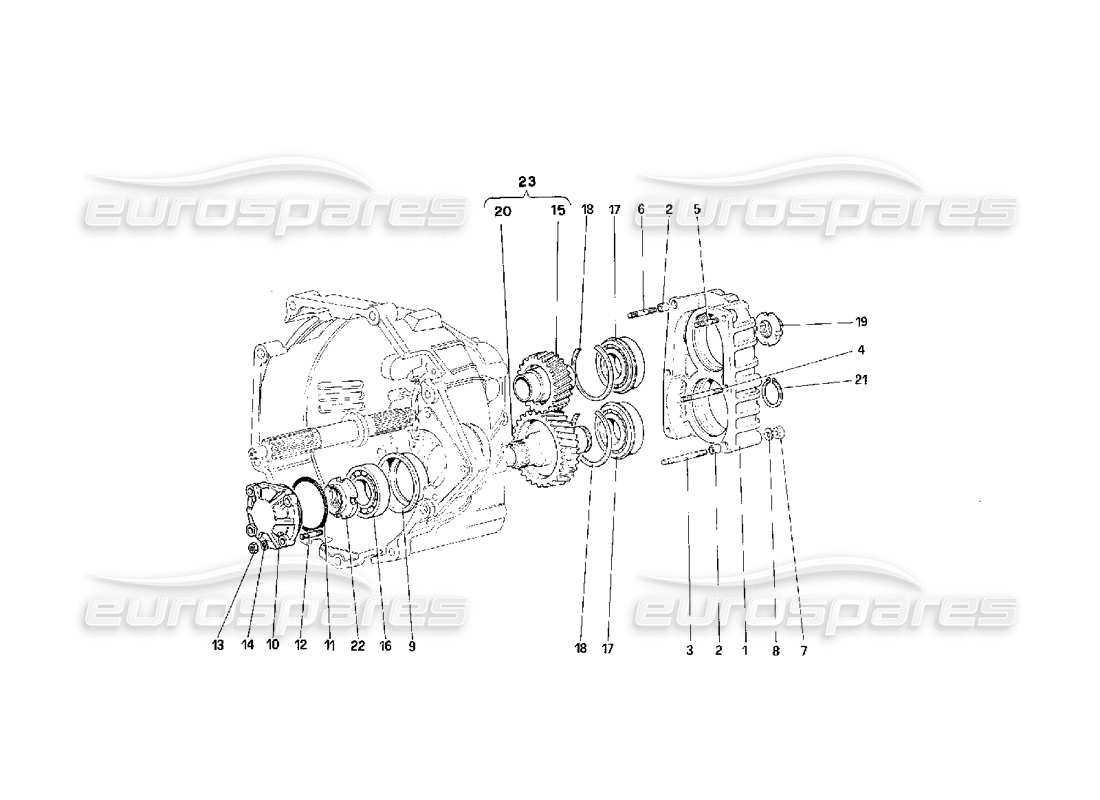

The essential system responsible for transferring motion within vehicles relies on several interconnected elements. Each of these plays a crucial role in ensuring smooth operation and optimal performance. Understanding how these components interact can help in recognizing potential issues and maintaining the system’s efficiency.

- Gear Mechanism: Facilitates changes in speed and force, adapting to various driving conditions.

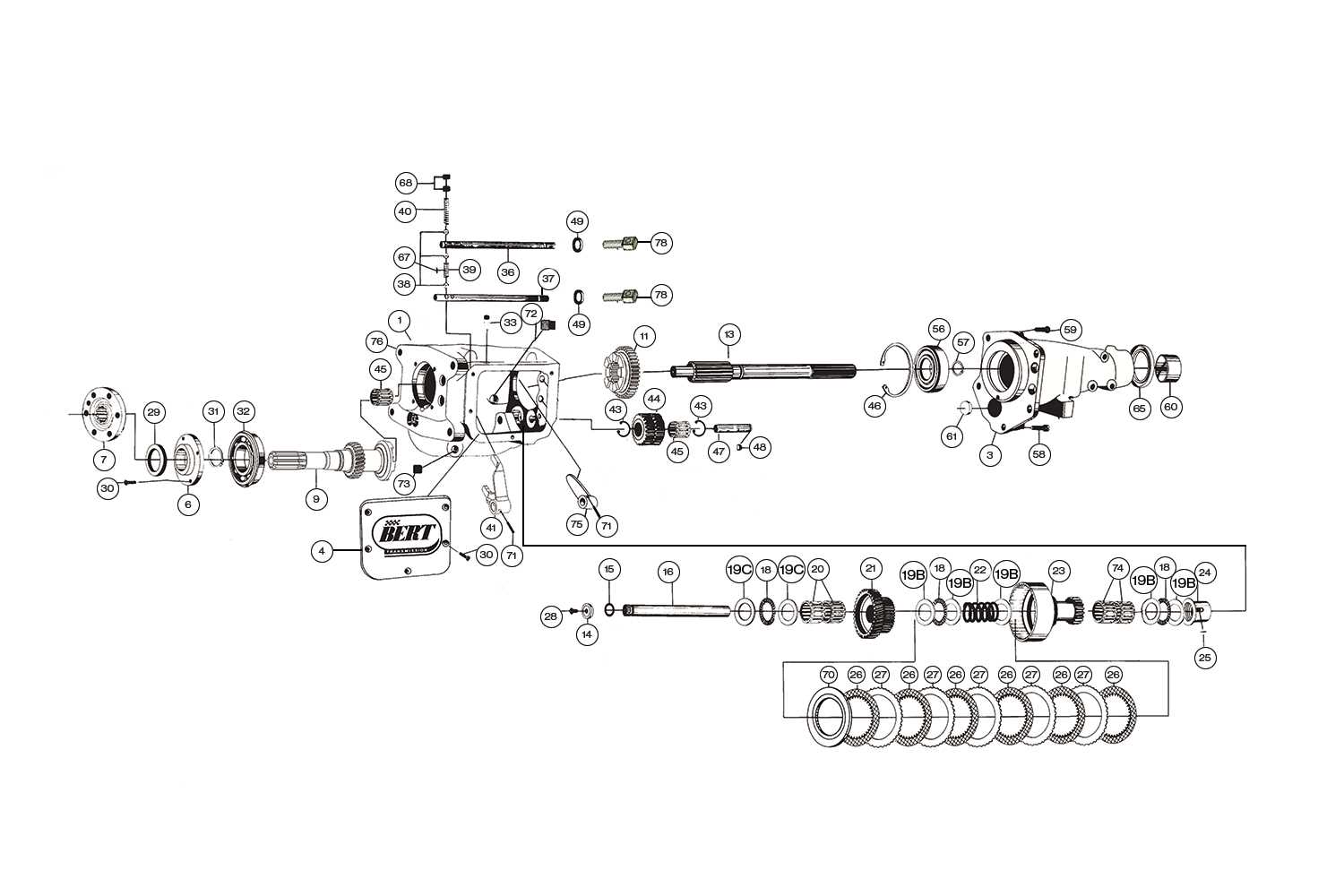

- Clutch Assembly: Connects and disconnects the engine’s power, enabling smooth shifts between gears.

- Drive Shafts: Transmit the rotational force from the engine to the wheels, ensuring effective power distribution.

- Differential Unit: Balances the rotation between the wheels, crucial for turns and maintaining control.

- Control System: Man

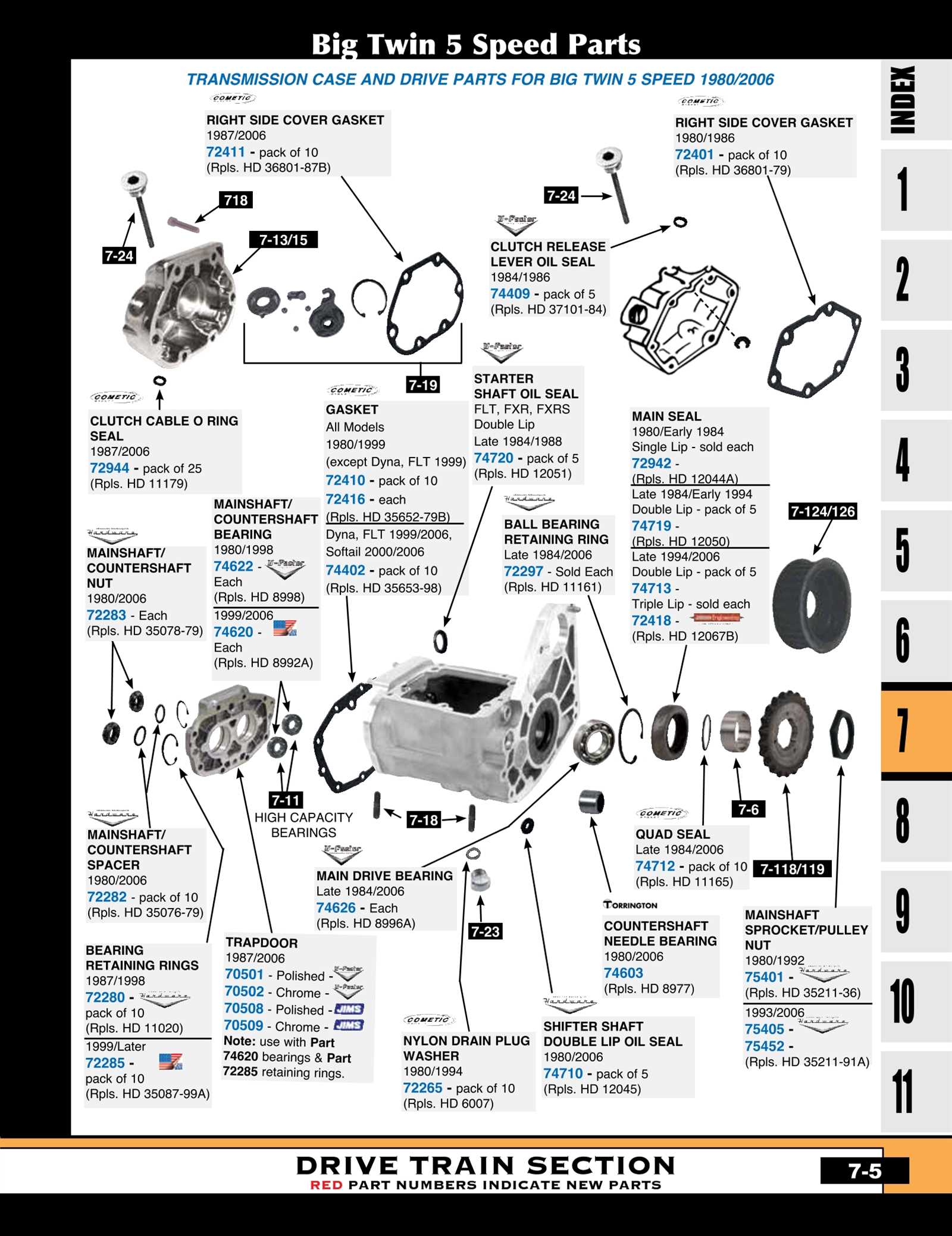

Common Issues in Transmission Systems

Various challenges frequently arise in the operation of mechanisms responsible for transferring power within automotive vehicles. These difficulties can lead to impaired performance, increased wear and tear, and in some cases, complete system failure. Understanding and addressing these issues promptly is crucial for maintaining vehicle reliability and safety.

- Operational inefficiencies often manifest as erratic gear shifting or delays in response to driver input.

- Noise and vibrations, indicative of misaligned or worn-out components, can undermine driving comfort and signal potential mechanical failures.

- Fluid leaks, typically originating from damaged seals or gaskets, pose a risk of fluid loss that compromises lubrication and cooling functions.

- Overheating due to inadequate cooling mechanisms or prolonged stress on transmission components can accelerate wear and lead to irreversible damage.

- Electrical malfunctions, such as faulty sensors or wiring issues, disrupt transmission control module operations and trigger error codes.

Addressing these issues promptly through regular maintenance, timely repairs, and adherence to manufacturer-recommended service intervals can significantly extend the lifespan of transmission systems and enhance vehicle performance.

How Gears Affect Vehicle Performance

Gears play a critical role in optimizing how efficiently a vehicle operates. By adjusting the speed and force, they enable the engine to function in different conditions. The way gears are structured and designed influences the vehicle’s overall performance, especially in terms of acceleration, fuel consumption, and top speed.

Lower gears are typically used for increasing power during situations such as climbing steep hills or accelerating from a stop. On the other hand, higher gears allow for smoother driving at high speeds, reducing engine effort and improving fuel efficiency. The balance between these settings ensures that a vehicle can operate effectively across different terrains and driving scenarios.

The interaction between engine power and gear selection determines how the vehicle responds to changes in speed and load. Choosing the right gear at the right time helps in maintaining a smooth driving experience while preventing unnecessary strain on the engine.

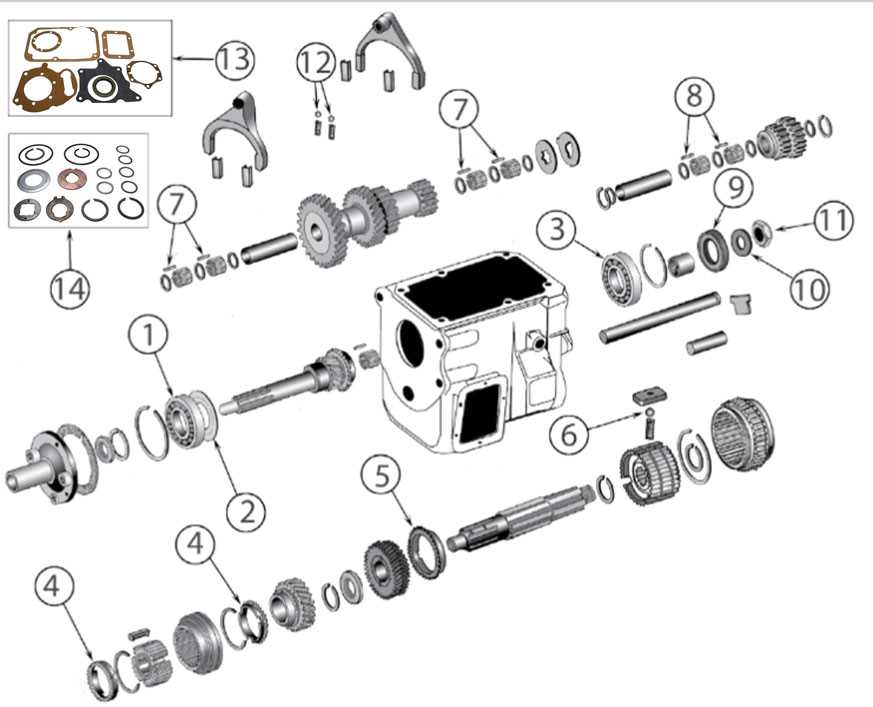

Clutch Mechanisms and Their Role

The clutch system serves a critical function in enabling smooth control over power delivery between the engine and the drivetrain. This mechanism allows for the temporary disconnection of power, ensuring smooth gear changes and preventing excessive strain on the components during operation.

Various types of clutch designs cater to different driving needs, each contributing to improved efficiency and responsiveness. The core function remains the same: to regulate power flow and maintain seamless operation of the vehicle.

Without a well-functioning clutch, handling a vehicle becomes increasingly difficult. Its importance lies in the ability to smoothly engage or disengage power, preventing wear and damage to connected systems.

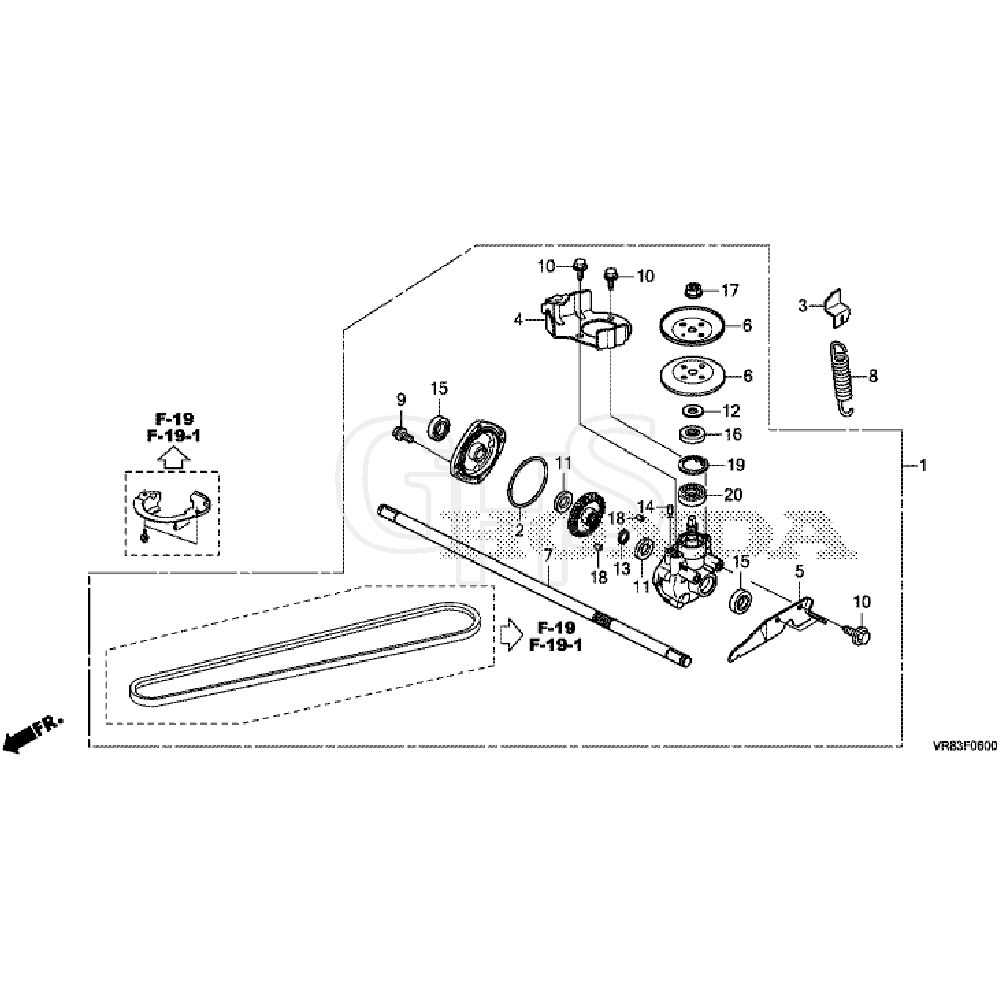

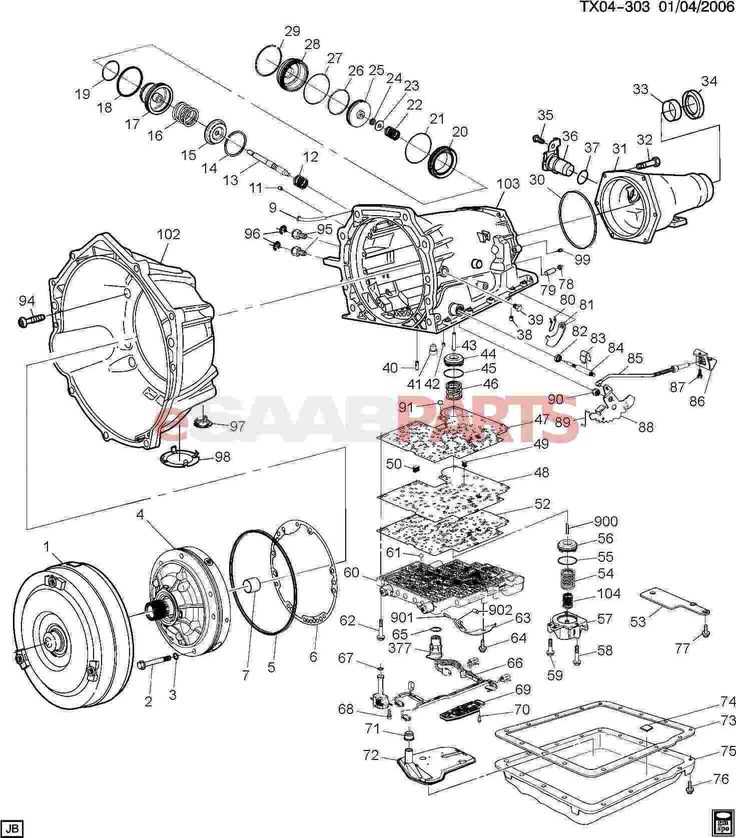

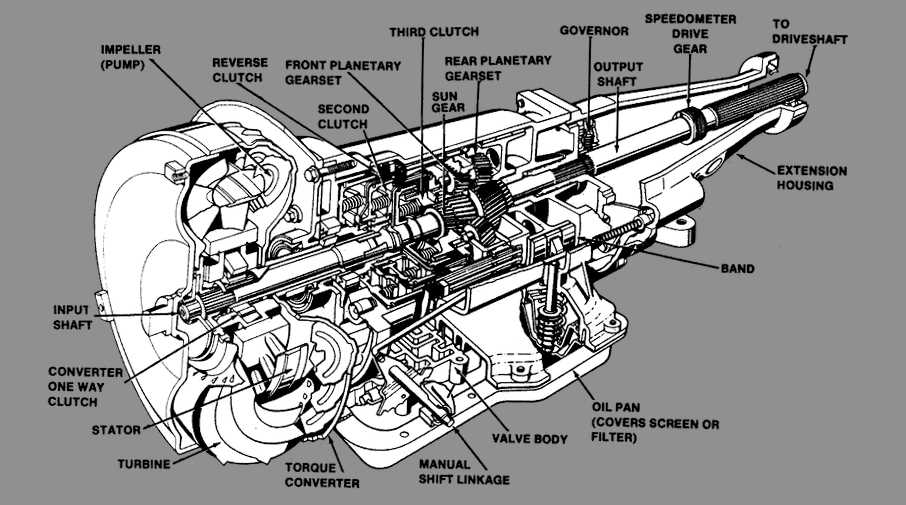

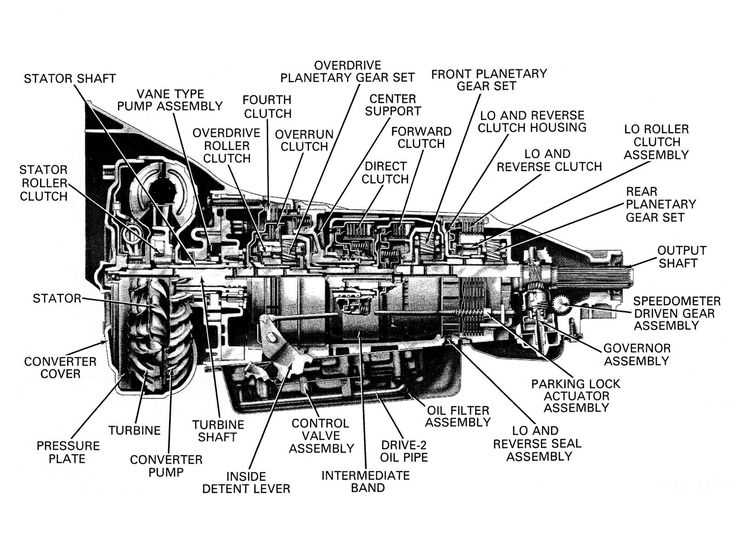

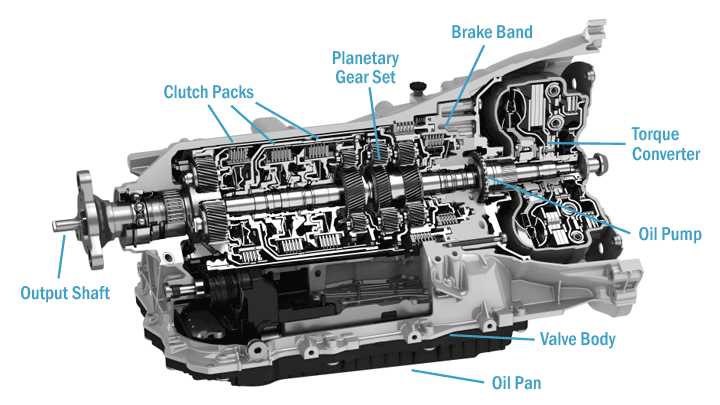

Exploring the Function of Torque Converters

A key component in modern machinery, torque converters play a vital role in ensuring efficient power transfer between the engine and other mechanical systems. Their unique design allows them to handle variations in speed and output, providing smooth and controlled performance without direct contact between moving parts. Understanding how these mechanisms operate can offer insights into the efficiency and functionality of various motorized equipment.

Feature Purpose Pump Moves fluid to generate rotational force Turbine Receives the fluid and transmits power to the output system Stator Redirects the flow of fluid for optimal efficiency Maintenance Tips for a Smooth Transmission

Proper upkeep of essential vehicle systems is crucial for long-term performance and efficiency. Regular care not only prevents breakdowns but also ensures that components function optimally, providing a seamless driving experience.

- Ensure regular fluid checks and replacements as needed. Clean, fresh fluid is key for reducing wear and tear on key components.

- Monitor for unusual noises or vibrations during operation, which can indicate issues that require immediate attention.

- Keep an eye on any leaks. Even small drips can lead to significant problems if left unchecked.

- Follow the manufacturer’s service schedule for periodic inspections and adjustments, which can prevent costly repairs down the road.

- Avoid overloading your vehicle, as this puts additional strain on the system and may lead to overheating or failure.

By following these simple steps, you can significantly extend the lifespan of your vehicle’s system and ensure reliable operation for years to come.

Recognizing Signs of Transmission Wear

Identifying indicators of deterioration in mechanical systems is essential for maintaining optimal performance and longevity. Awareness of specific symptoms can aid in early detection, allowing for timely interventions and repairs. Recognizing these signs ensures that functionality remains intact and prevents more extensive damage.

Common Symptoms to Monitor

- Unusual Noises: Listen for grinding, whining, or clunking sounds that may signal internal issues.

- Shifting Difficulties: Experience hesitations or jerking motions during gear changes.

- Fluid Leaks: Notice any spots of oily fluid beneath the vehicle, indicating potential leaks.

Visual Inspection Techniques

- Check for discoloration or burnt odor in the fluid.

- Examine the condition of seals and gaskets for signs of wear.

- Inspect the housing for cracks or corrosion.

Regular monitoring and inspection are crucial in ensuring the efficiency of mechanical systems. By being vigilant and responsive to these signs, one can maintain reliability and extend the lifespan of the equipment.

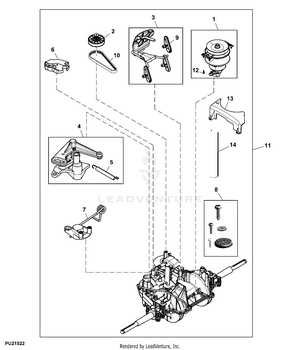

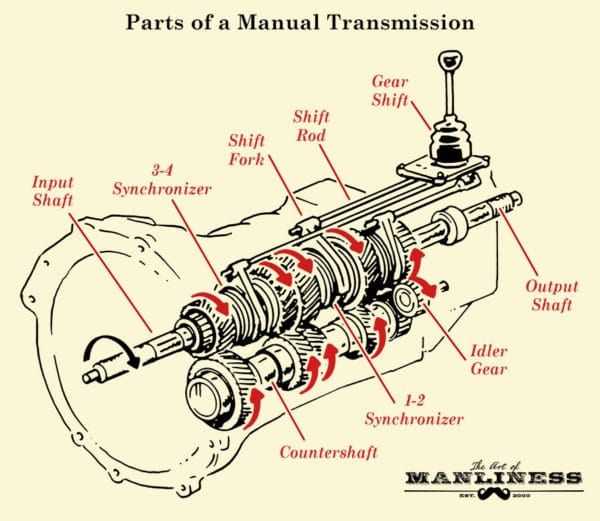

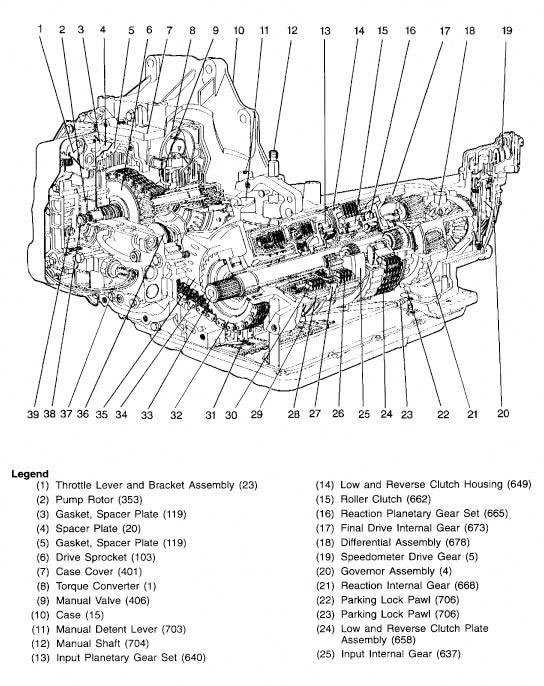

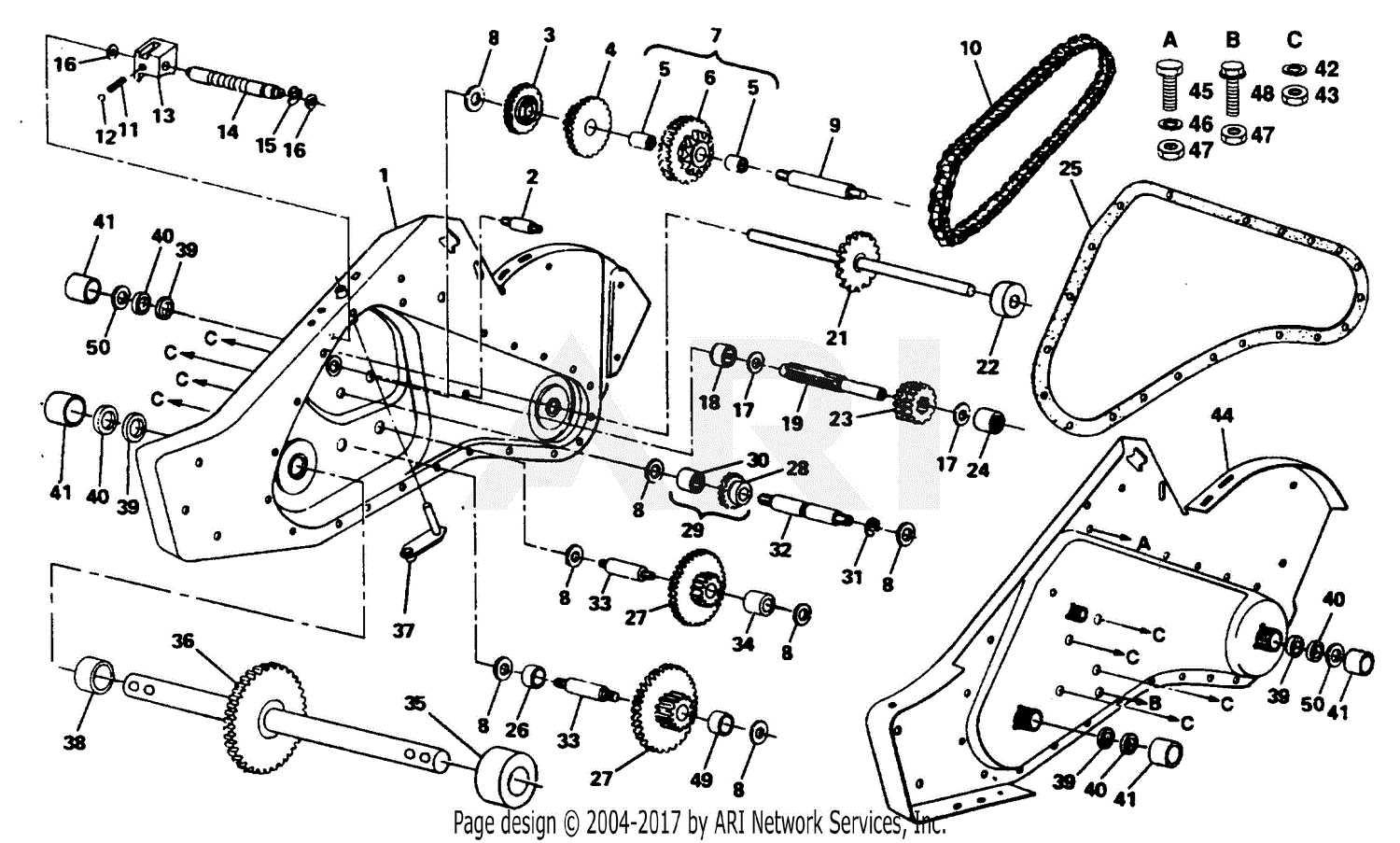

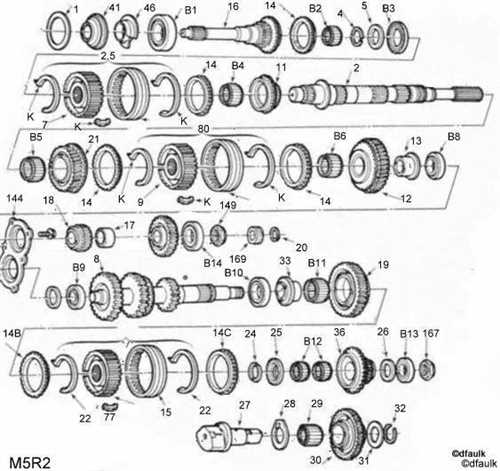

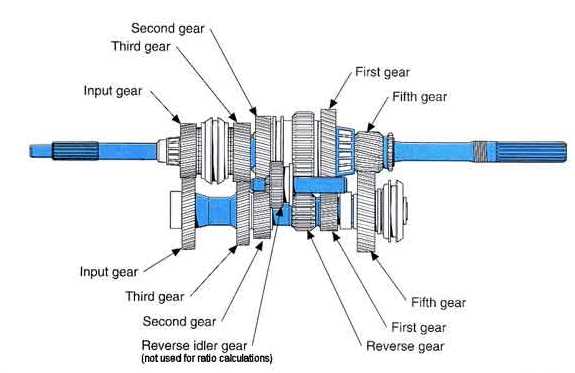

Manual vs Automatic Transmission Parts Overview

This section delves into the essential components that differentiate traditional gear systems from their modern counterparts. Understanding these crucial elements provides insight into the functionality and performance of vehicles, catering to various driving preferences and conditions.

Key Components of Manual Systems

In vehicles with traditional gear setups, the primary elements include the clutch, gear shift, and gear set. The clutch plays a vital role in engaging and disengaging the engine from the drivetrain, allowing for smooth gear changes. The gear shift enables the driver to manually select the desired ratio, offering a hands-on experience. Additionally, the gear set comprises various ratios that affect speed and torque, providing flexibility based on driving needs.

Core Elements of Automatic Systems

Conversely, modern vehicles utilize a different arrangement, characterized by components like the torque converter, automatic gear selector, and planetary gear system. The torque converter facilitates smooth acceleration by transferring power from the engine to the wheels without the need for a clutch. The automatic gear selector simplifies the driving experience, allowing for effortless gear changes. Furthermore, the planetary gear system optimizes performance by enabling multiple gear ratios within a compact design.

Benefits of Upgrading Transmission Components

Enhancing the mechanical elements of a vehicle’s power delivery system can lead to significant improvements in overall performance and efficiency. Upgrading these components not only boosts reliability but also optimizes driving experiences, ensuring that the vehicle operates smoothly and effectively under various conditions.

Improved Performance

One of the primary advantages of modernizing these components is the enhancement in performance metrics. Key benefits include:

- Increased Power Transfer: Newer components can facilitate better power transfer from the engine to the wheels.

- Smoother Shifting: Upgraded elements often result in more precise gear changes, contributing to a smoother ride.

- Enhanced Responsiveness: Improved parts lead to quicker acceleration and more dynamic handling.

Greater Durability

Investing in superior quality components contributes to the longevity of the vehicle. Benefits include:

- Resistance to Wear: High-quality materials are less prone to degradation, prolonging the life of the system.

- Less Frequent Maintenance: Upgraded parts typically require less frequent servicing, reducing overall maintenance costs.

- Improved Reliability: Enhanced components contribute to consistent performance, minimizing the risk of unexpected breakdowns.

Steps to Troubleshoot Transmission Failures

Identifying and resolving issues with your vehicle’s gear system requires a systematic approach. Begin by conducting a thorough inspection of the transmission assembly, focusing on key components that regulate power transfer within the vehicle.

1. Preliminary Inspection

- Start by checking the fluid levels and condition, as inadequate fluid or contamination can lead to transmission malfunctions.

- Inspect the external components for signs of wear, such as leaks or damaged seals, which may affect performance.

- Evaluate the transmission’s response during gear shifts to pinpoint any irregularities in operation.

2. Diagnostic Procedures

- Utilize diagnostic tools to retrieve error codes stored in the vehicle’s onboard computer system, providing insights into specific transmission-related issues.

- Conduct a road test to observe the transmission’s behavior under varying driving conditions, noting any unusual noises or vibrations.

- Perform a thorough visual inspection of electrical connections and wiring harnesses to identify potential causes of electrical failures.

By following these steps, you can effectively diagnose and address transmission failures, ensuring optimal performance and reliability of your vehicle.