The intricate assembly of mechanisms within a vehicle plays a crucial role in its overall performance and efficiency. A comprehensive grasp of these elements allows for enhanced maintenance and optimization, ensuring smoother operation and longevity. Each component is designed to fulfill specific functions, contributing to the seamless transfer of power and control.

In this section, we will delve into the various elements that constitute the drive system, exploring their interconnections and functionalities. By visualizing the arrangement of these essential mechanisms, one can better appreciate how they work in harmony to achieve the desired results. Understanding this arrangement not only aids in troubleshooting but also enhances one’s knowledge for potential upgrades or modifications.

Equipped with this insight, enthusiasts and professionals alike can make informed decisions regarding repairs and enhancements. Whether for routine maintenance or performance improvements, recognizing how these components fit together is invaluable. Join us as we uncover the detailed layout and relationships of these vital systems.

This section aims to provide a comprehensive understanding of a specific assembly responsible for power transfer within vehicles. By exploring its components, functions, and significance, readers will gain insight into how this mechanism operates and contributes to overall performance.

The following headings will guide the exploration:

- Introduction to the Power Delivery System

This section will introduce the concept of power delivery and its relevance in modern vehicles.

- Key Components of the Assembly

An overview of the main components that comprise this intricate system.

- Functionality Explained

A detailed look at how each component works together to facilitate power transfer.

- Importance in Vehicle Performance

Discussion on how this assembly affects vehicle efficiency and performance metrics.

- Common Issues and Solutions

Identifying typical problems associated with the assembly and potential fixes.

- Maintenance Tips

Best practices for keeping the system in optimal condition.

- Upgrades and Modifications

Options for enhancing the performance of this mechanism.

- Future Trends in Design

Exploring emerging technologies and their potential impact on the assembly.

- Real-world Applications

Examples of how this system is utilized across different vehicle models.

- Expert Opinions

Insights from industry professionals regarding best practices and innovations.

- Conclusion and Summary

A recap of the key points discussed throughout the article.

- Additional Resources

References and further reading materials for interested readers.

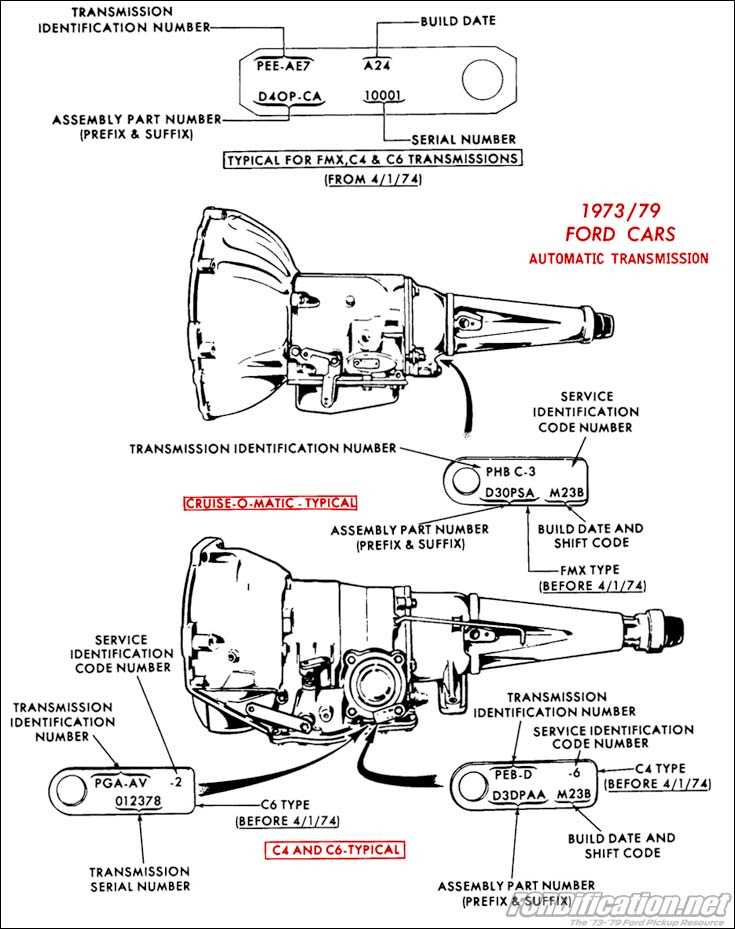

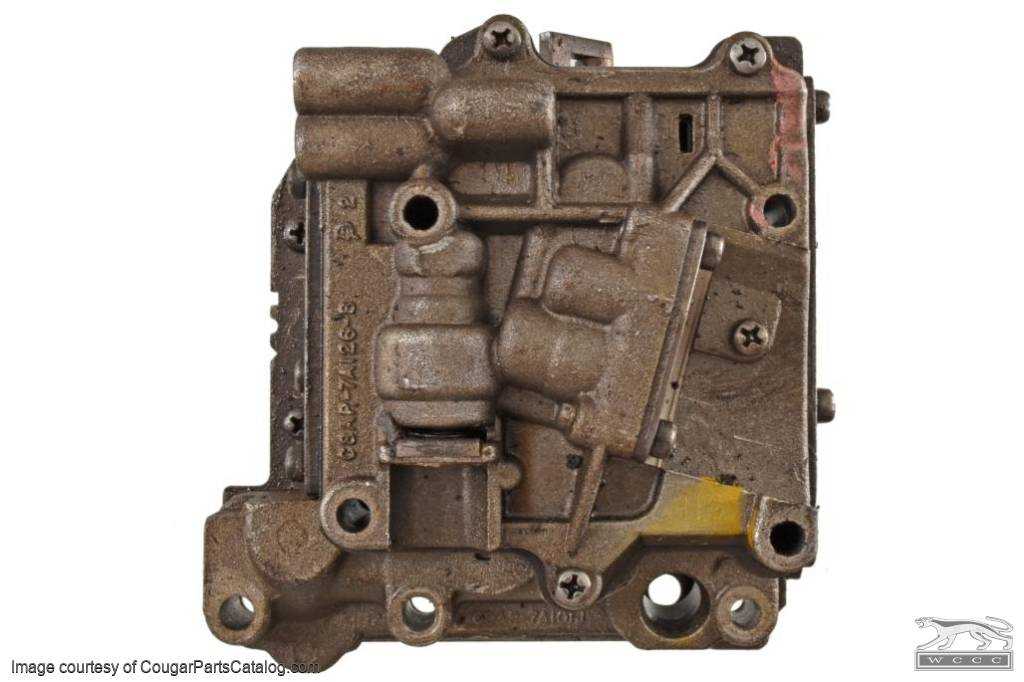

Key Components of FMX System

The system comprises several vital elements that work together to ensure optimal performance and efficiency. Each component plays a significant role in facilitating smooth operation, contributing to the overall functionality of the machinery.

Among the primary constituents are the control units, which govern the system’s operations, ensuring that all functions occur in a coordinated manner. Additionally, various sensors monitor critical parameters, providing real-time feedback to maintain efficiency and safety. The hydraulic assembly is also crucial, as it enables the movement and control of various mechanisms within the system.

Moreover, the integration of electronic control modules enhances precision and responsiveness, allowing for adjustments based on operational demands. Each of these elements must be properly maintained and synchronized to achieve the desired outcomes, reflecting the complexity and sophistication of the entire system.

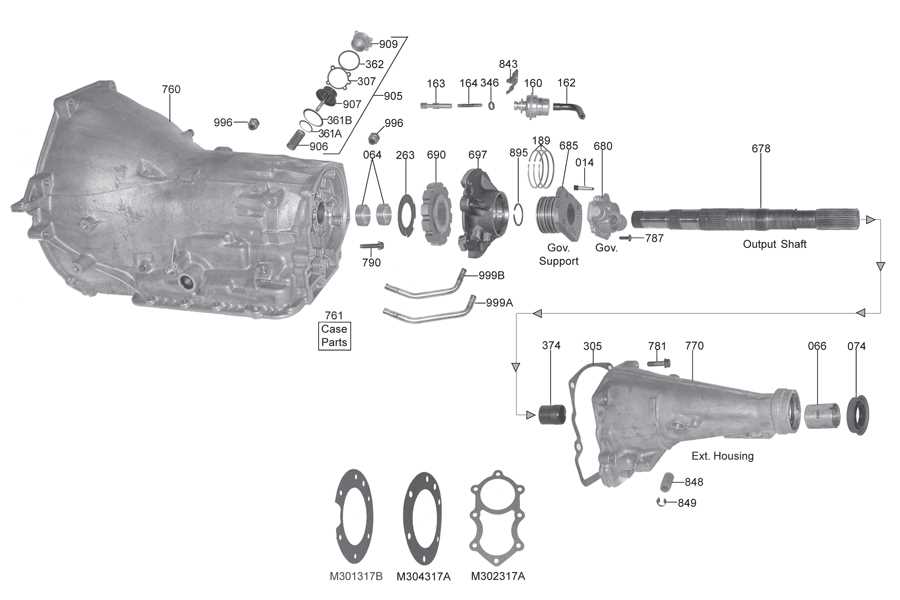

Functionality of Transmission Parts

The mechanisms involved in the transfer of power within a vehicle play a crucial role in its overall performance. Each component contributes uniquely to ensuring that energy generated by the engine is effectively harnessed and directed to the wheels. Understanding the functions of these elements can enhance maintenance practices and improve operational efficiency.

Firstly, the components responsible for energy transfer act as intermediaries between the engine and the wheels, facilitating smooth acceleration and deceleration. They are designed to manage torque and enable various speed settings, which is essential for adapting to different driving conditions.

Additionally, the systems involved in this process include mechanisms that enhance durability and reliability. Regular monitoring and maintenance of these elements are vital for preventing wear and tear, ultimately extending the lifespan of the vehicle.

Moreover, understanding the interplay between these components can aid in diagnosing issues early on. By recognizing how each element functions within the broader context, operators can ensure optimal performance and mitigate potential problems before they escalate.

Common Issues in FMX Transmissions

Understanding the frequent complications that arise in automatic systems is essential for maintaining optimal performance. Many operators encounter challenges that can affect efficiency and reliability. Awareness of these issues can lead to timely interventions and minimize downtime.

- Fluid Leaks: One of the most common concerns is fluid loss, which can result from worn seals or damaged components.

- Overheating: Excessive heat can compromise the functionality of the system, often due to inadequate cooling or low fluid levels.

- Slipping Gears: Inconsistent shifting can signal underlying problems, often related to the control system or hydraulic pressure.

- Noises: Unusual sounds, such as grinding or whining, may indicate mechanical wear or damage within the assembly.

- Warning Lights: Dashboard alerts can provide early warnings of malfunctions, necessitating immediate attention to avoid further damage.

Proactive maintenance and timely diagnosis are key in addressing these challenges. Regular checks and servicing can extend the lifespan and improve the reliability of the entire mechanism.

Maintenance Tips for Longevity

Ensuring the extended lifespan of your machinery involves a series of proactive measures. Regular upkeep not only enhances performance but also minimizes the risk of unexpected failures. By adopting a few essential practices, you can maintain optimal functionality and reliability.

Regular Inspection

Conducting routine checks is vital to identify potential issues before they escalate. Focus on the following areas:

- Inspect seals and gaskets for wear and tear.

- Check fluid levels and replace them as necessary.

- Monitor for unusual noises during operation.

Scheduled Maintenance

Establishing a consistent maintenance schedule helps ensure that all components are functioning correctly. Consider these steps:

- Follow the manufacturer’s guidelines for service intervals.

- Replace filters and fluids as recommended.

- Lubricate moving parts to reduce friction.

By implementing these practices, you can significantly enhance the durability and reliability of your equipment.

Tools Needed for Repair

Successful maintenance and restoration of mechanical systems require a specific set of tools to ensure efficiency and accuracy. Having the right equipment on hand can significantly simplify the repair process and enhance overall effectiveness. Below is a detailed overview of essential tools necessary for these tasks.

Essential Hand Tools

- Socket Wrenches: Useful for loosening and tightening various fasteners.

- Torque Wrench: Ensures components are fastened to the manufacturer’s specifications.

- Screwdrivers: A variety of sizes and types are needed for different screws.

- Pliers: Helpful for gripping, twisting, and cutting wires or small parts.

- Hammers: Ideal for tapping and adjusting components into place.

Specialized Equipment

- Fluid Pump: Necessary for transferring lubricants or other fluids.

- Diagnostic Tools: Electronic testers or scanners help identify issues in the system.

- Jacks and Stands: Provide safe support for lifting heavy components during repairs.

- Cleaning Supplies: Solvents and brushes are crucial for removing debris and contaminants.

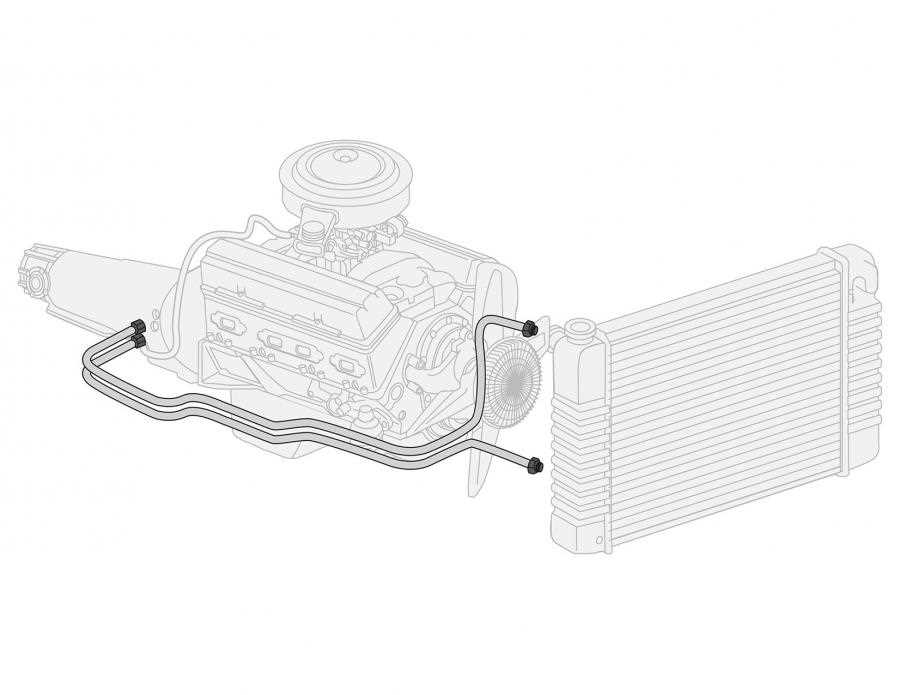

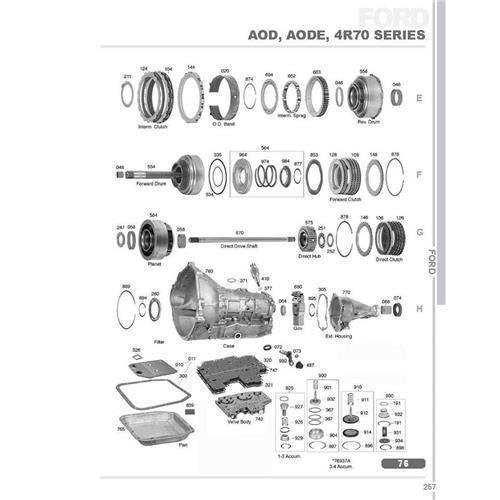

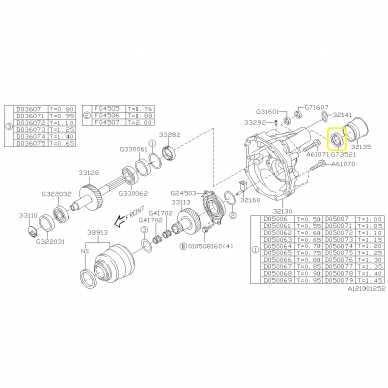

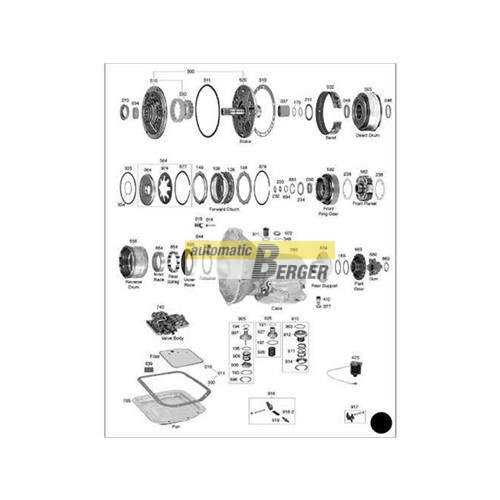

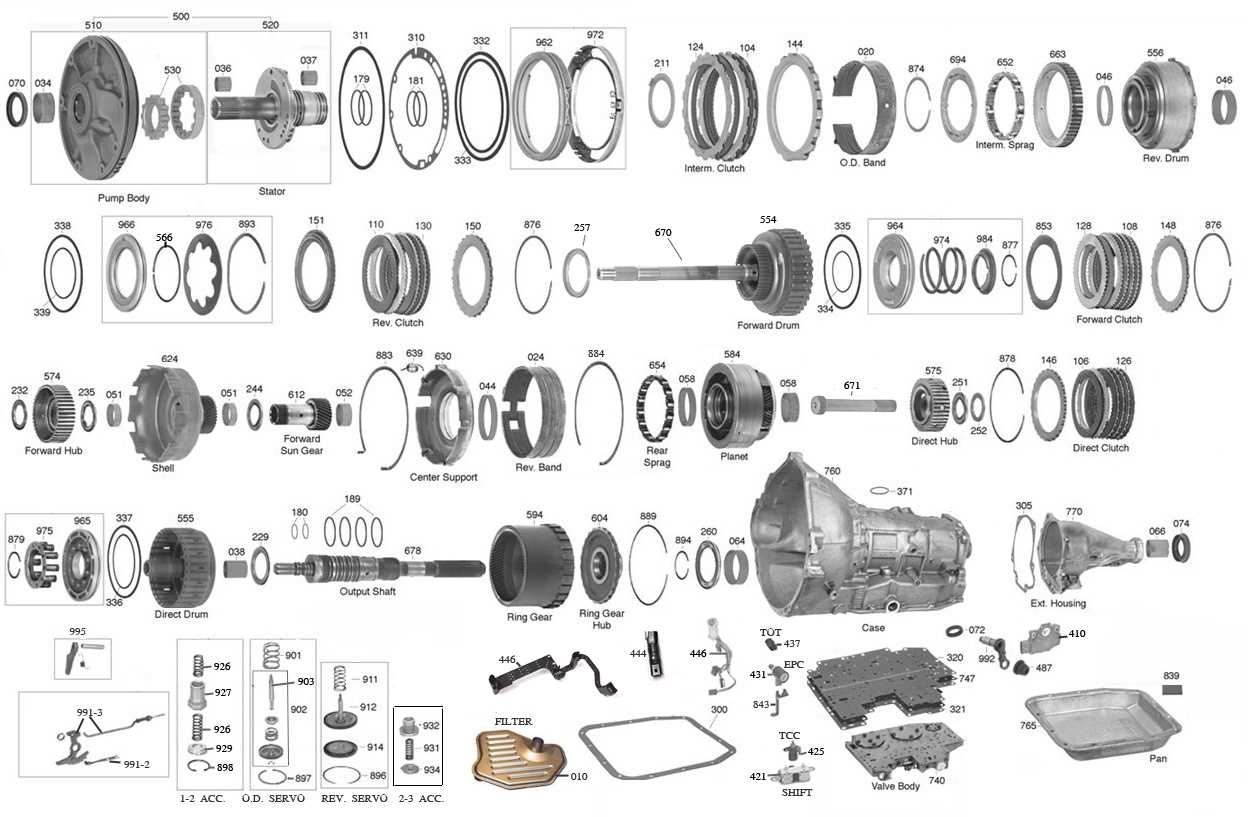

Understanding the Parts Diagram

This section provides insights into the various components that make up a complex mechanism, emphasizing their interrelationships and functions. By examining the visual representation of these elements, one can better grasp how they work together to ensure smooth operation.

Component Overview

Every intricate assembly consists of multiple individual units, each serving a unique role. Understanding these roles is crucial for effective maintenance and troubleshooting. Familiarity with each element facilitates quicker diagnosis of issues and enhances overall efficiency.

Visual Representation

Visual aids play a vital role in comprehending the arrangement and connectivity of each unit. A well-structured illustration can simplify the complexities involved, making it easier to identify and locate specific sections during repairs or modifications.

| Component | Description | Function |

|---|---|---|

| Unit A | Main operational component | Controls motion |

| Unit B | Power source | Supplies energy |

| Unit C | Control mechanism | Regulates function |

| Unit D | Connection interface | Links various units |

Importance of Accurate Diagrams

Precise illustrations play a crucial role in various technical fields, providing essential guidance for understanding complex systems. These visual representations enable users to comprehend intricate details, enhancing their ability to diagnose issues and perform repairs effectively.

Clarity and Efficiency: Well-constructed visuals contribute to clarity, allowing individuals to identify components quickly. This efficiency minimizes the risk of errors during maintenance, ultimately saving time and resources.

Enhanced Learning: For those new to a particular system, accurate illustrations serve as valuable educational tools. They facilitate a deeper understanding of how different elements interact, fostering confidence in troubleshooting and repair processes.

Standardization: Consistent use of detailed visuals across the industry promotes standardization. This common understanding aids professionals in collaborating effectively, ensuring everyone is on the same page when discussing specific mechanisms.

In summary, the significance of accurate illustrations cannot be overstated. They not only improve operational efficiency but also empower individuals with the knowledge necessary to tackle challenges confidently.

Comparative Analysis with Other Models

The examination of various systems reveals distinct differences in design and functionality. By analyzing these characteristics, one can appreciate the strengths and weaknesses inherent in each model. This section aims to provide insights into how alternative mechanisms compare in performance, efficiency, and overall reliability.

When evaluating similar mechanisms, key factors such as durability and serviceability often come to the forefront. Some alternatives may boast advanced features that enhance operational efficiency, while others may focus on simplified maintenance protocols. Understanding these trade-offs is crucial for users looking to make informed decisions based on their specific requirements.

Furthermore, the adaptability of these systems to various environments plays a significant role in their effectiveness. Certain designs may excel in harsh conditions, providing robust performance, while others might prioritize energy conservation in more controlled settings. This comparative analysis highlights how different approaches can cater to distinct operational needs.

Upgrading FMX Transmission Parts

Enhancing the components of a vehicle’s gear system can significantly improve its performance and efficiency. This process involves selecting high-quality replacements and implementing advanced technologies that can lead to better handling and durability. Properly executed upgrades can extend the lifespan of your vehicle and optimize its capabilities.

Key considerations for upgrading include:

- Identifying the specific components that require enhancement.

- Researching aftermarket options that provide superior performance.

- Evaluating compatibility with existing systems.

When choosing new elements, it’s essential to focus on:

- Quality: Select components made from durable materials to withstand wear and tear.

- Performance: Look for enhancements that improve efficiency and response times.

- Installation: Ensure that upgrades are easy to install or consider professional assistance for complex tasks.

In conclusion, upgrading various elements of a vehicle’s mechanism not only boosts its overall functionality but also contributes to a more enjoyable driving experience. By investing time and resources into quality enhancements, owners can achieve significant improvements in their vehicle’s performance.

Resource Links for Further Learning

Exploring in-depth information can enhance your understanding of mechanical systems. Numerous resources are available to expand your knowledge and provide insights into their components and functionalities.

- Online Tutorials: Websites offering step-by-step guides and videos can help visualize complex mechanisms.

- Technical Forums: Engage with experts and enthusiasts to share experiences and troubleshooting tips.

- Manufacturer Websites: Access detailed specifications, manuals, and product descriptions directly from producers.

- Educational Platforms: Enroll in courses focused on automotive engineering and related technologies.

Utilizing these resources will provide a comprehensive foundation for understanding mechanical assemblies and their operational principles.