In the realm of construction machinery, the functionality of equipment hinges on the intricate arrangement of its internal systems. A comprehensive grasp of how these systems operate is vital for effective maintenance and troubleshooting. This section delves into the key elements that contribute to the seamless performance of heavy machinery, particularly focusing on the essential mechanisms that facilitate movement and power transfer.

By examining the configuration and relationship of various components, operators and technicians can enhance their understanding of how to optimize equipment efficiency. Each segment plays a crucial role, influencing not only the performance but also the longevity of the machine. This exploration serves as a valuable resource for anyone looking to deepen their knowledge of construction machinery operations.

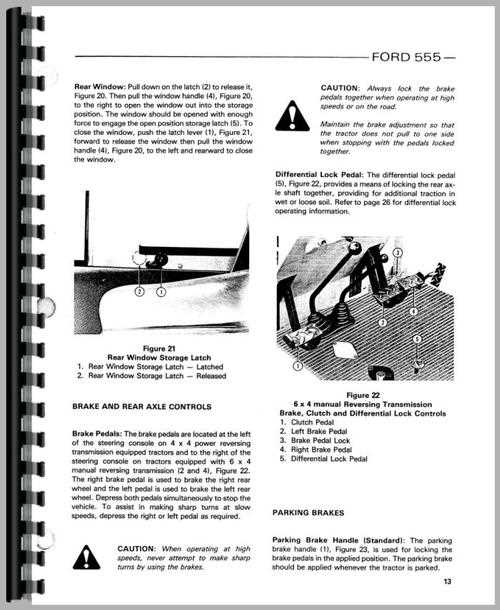

Detailed visual representations serve as practical tools for identifying and comprehending the intricate assembly of machinery systems. These illustrations aid in recognizing how individual components interact, allowing for more informed decisions regarding repairs and replacements. Gaining insights into these configurations empowers users to maintain their equipment effectively and ensure its operational reliability.

This section will provide a comprehensive understanding of a specific model of an excavating machine, renowned for its efficiency and versatility. The focus will be on its mechanical layout, including the critical systems that enable its operation. Understanding these components is essential for maintenance and troubleshooting, ensuring optimal performance in various applications.

Key Features of the Excavator

The machine is designed with multiple functionalities, making it ideal for construction and landscaping tasks. It is equipped with a robust engine, advanced hydraulics, and user-friendly controls, which contribute to its effectiveness in digging, lifting, and moving materials. The integration of these systems ensures seamless operation, enhancing productivity on job sites.

Understanding the Mechanical Layout

To gain insight into the functionality of this equipment, examining its mechanical arrangement is crucial. Below is a summary of the significant components involved:

| Component | Description |

|---|---|

| Engine | Provides power to operate the machinery. |

| Hydraulic System | Controls the movement and operation of various attachments. |

| Frame | Supports the entire structure and provides stability. |

| Control System | Enables the operator to manage all functions efficiently. |

| Attachment Interface | Allows the connection of various tools for different tasks. |

Importance of Transmission Systems

The efficiency of any vehicle largely relies on its ability to effectively transfer power from the engine to the wheels. This crucial mechanism ensures that the vehicle can perform optimally under varying conditions, providing the necessary torque and speed for different tasks. A well-functioning power transfer system enhances productivity, prolongs the lifespan of the machinery, and ensures safety during operation.

Role in Performance

Power transfer mechanisms are integral to the overall performance of construction machinery. They regulate the distribution of energy, allowing operators to maneuver with precision and control. By optimizing the gear ratios, these systems enable vehicles to operate smoothly across diverse terrains and workloads, thereby improving efficiency and reducing fuel consumption.

Maintenance Considerations

Regular upkeep of the power transfer assembly is essential for maintaining optimal performance. Neglecting maintenance can lead to premature wear and tear, resulting in costly repairs and downtime. Routine inspections and timely replacements of worn components can significantly enhance reliability and reduce the risk of unexpected failures.

| Key Components | Function |

|---|---|

| Gearbox | Modulates the engine’s power output to the wheels |

| Clutch | Allows for smooth engagement and disengagement of power |

| Drive Shafts | Transmits power from the gearbox to the wheels |

| Linkages | Connects various components for coordinated movement |

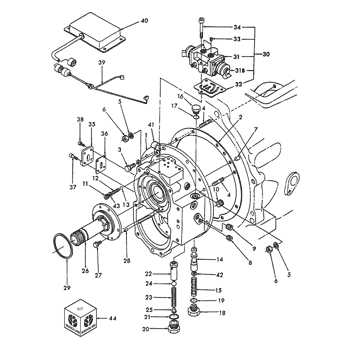

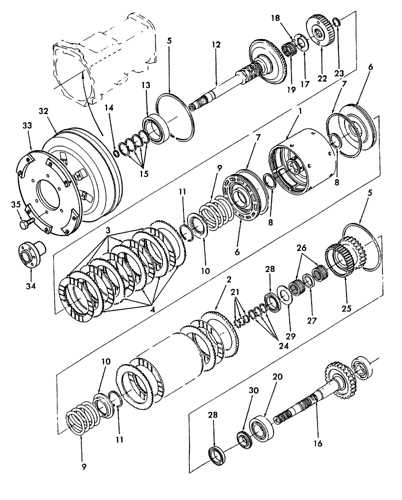

Key Components of the Transmission

The effective functioning of a vehicle’s drive system relies on a variety of essential elements that facilitate the transfer of power from the engine to the wheels. Understanding these fundamental components is crucial for maintenance and troubleshooting. Each part plays a unique role in ensuring smooth operation and optimal performance.

Main Elements

- Gearbox: This mechanism houses the gears that adjust the torque and speed delivered to the wheels.

- Clutch: A critical component that engages and disengages the engine from the drive system, allowing for smooth gear changes.

- Input Shaft: This shaft connects the engine to the gearbox, transmitting power directly into the gearing system.

- Output Shaft: Responsible for delivering the power to the differential, leading to the wheels.

Additional Components

- Bearings: These support various rotating elements, reducing friction and wear.

- Synchronizers: Used to match the speeds of gears during shifting, ensuring seamless transitions.

- Fluid Pump: This component circulates lubricating fluid, which is vital for cooling and protecting internal parts.

- Torque Converter: A type of fluid coupling that transfers power by using hydraulic fluid to amplify torque.

Understanding the Transmission Diagram

This section delves into the intricacies of the gear mechanism utilized in heavy machinery. By grasping the layout and functionality of each component, operators can enhance performance and ensure longevity of the equipment. A clear visualization aids in identifying the essential elements involved in power transfer and control.

Key Components

- Gear Set: Transfers power from the engine to the wheels.

- Hydraulic Pumps: Facilitate movement through fluid pressure.

- Clutch Mechanism: Engages and disengages the drive system.

- Bearings: Support rotating parts and reduce friction.

- Linkage: Connects various components for coordinated operation.

Importance of Understanding

Comprehending the arrangement of these elements is crucial for effective maintenance and troubleshooting. Familiarity with the layout allows operators to:

- Identify potential issues before they escalate.

- Implement timely repairs to minimize downtime.

- Optimize machine performance through informed adjustments.

Functionality of Transmission Parts

The effective operation of heavy machinery relies on the seamless interaction of its components, particularly those involved in power transfer. Understanding the roles these elements play is crucial for ensuring optimal performance and longevity of the equipment.

Key functionalities include:

- Power Conversion: This involves transforming the engine’s output into usable power for movement and hydraulic systems.

- Speed Regulation: Components are designed to adjust the vehicle’s speed, allowing for smooth operation in various terrains.

- Torque Distribution: Effective distribution of force is essential for maximizing efficiency and minimizing wear on the system.

In summary, each element contributes to the overall functionality, enhancing the machine’s capabilities while ensuring reliability during operation.

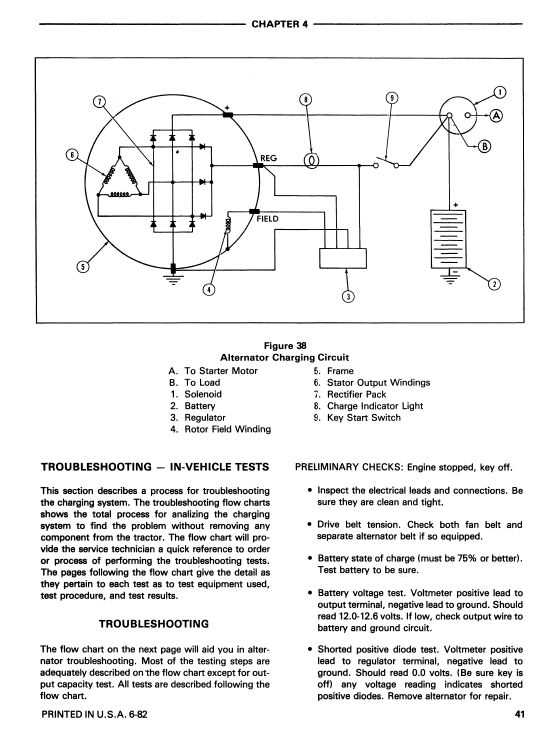

Common Issues in Transmission Systems

Mechanical systems designed for power transfer can encounter a variety of challenges that affect their efficiency and performance. Identifying these issues early is crucial for maintaining functionality and prolonging the lifespan of the equipment. Understanding the common complications can help in proactive maintenance and timely repairs.

One prevalent issue involves fluid leaks, which can lead to insufficient lubrication and ultimately result in overheating. This can cause significant damage if not addressed promptly. Additionally, worn or damaged seals often contribute to these leaks, highlighting the importance of regular inspections.

Another frequent concern is the improper engagement of gears. This may stem from misaligned components or inadequate adjustment, leading to grinding noises and difficulty shifting. Such symptoms can indicate that the system requires realignment or component replacement to restore smooth operation.

Moreover, overheating is a common problem that can be attributed to several factors, including low fluid levels or a failing cooling system. Overheating not only reduces performance but can also lead to catastrophic failure if not managed effectively.

Lastly, electrical issues, such as faulty sensors or wiring problems, can disrupt the operation of the mechanical system. These electrical malfunctions can prevent proper function, leading to erratic behavior and necessitating thorough diagnostic checks.

How to Identify Transmission Problems

Recognizing issues within the shifting mechanism of a vehicle is essential for ensuring optimal performance and longevity. Various signs can indicate malfunctions, allowing for timely interventions to prevent further damage. Understanding these indicators is crucial for maintaining the machinery’s efficiency.

Common Symptoms of Malfunction

- Unusual noises such as grinding or clunking during gear changes

- Difficulty in shifting gears, including slipping or sticking

- Unresponsive controls or delayed reactions when changing gears

- Fluid leaks under the vehicle, particularly oily substances

- Warning lights illuminated on the dashboard

Diagnostic Steps to Follow

- Check fluid levels and conditions regularly.

- Inspect for any visible leaks around the mechanism.

- Listen for unusual sounds while operating the equipment.

- Test the responsiveness of the shifting controls.

- Consult the user manual for specific troubleshooting guidelines.

Maintenance Tips for Transmission Parts

Ensuring the longevity and performance of essential mechanical components requires regular upkeep and attention. Proper care not only enhances functionality but also prevents unexpected breakdowns. Adopting a systematic approach to maintenance can significantly extend the lifespan of your equipment.

Regular Inspections

Conducting frequent checks on critical components is vital. Look for signs of wear, leaks, or unusual noises during operation. Early detection of issues can save time and resources, preventing more extensive repairs later. Make it a habit to document your observations for better tracking of any recurring problems.

Fluid Management

Maintaining the correct levels of operating fluids is essential for optimal performance. Ensure that fluids are clean and free from contaminants. Regularly replacing fluids according to the manufacturer’s recommendations can enhance the efficiency of mechanical functions. Consider using high-quality fluids to maximize protection against wear and overheating.

Replacement Parts for Ford 555

When maintaining heavy machinery, ensuring the availability of high-quality components is essential for optimal performance. This section focuses on the critical replacements necessary for effective operation and longevity of the equipment. Understanding the various alternatives can aid in making informed decisions for upkeep and repairs.

Essential replacement components may include:

- Hydraulic seals and gaskets

- Drive belts and pulleys

- Filters (oil, air, hydraulic)

- Engine components (pistons, rings)

- Electrical connectors and wiring harnesses

Utilizing OEM and aftermarket options can provide flexibility in budgeting and availability. It’s crucial to select reliable suppliers to ensure that each component meets the necessary specifications for durability and compatibility.

When considering a replacement, evaluating the following factors can significantly impact the selection process:

- Quality assurance standards

- Warranty offerings

- Customer reviews and feedback

- Availability of support and assistance

By prioritizing the right replacements, users can enhance the efficiency and reliability of their machinery, minimizing downtime and maximizing productivity.

Tools Needed for Transmission Repair

Repairing a vehicle’s power transfer system requires a specific set of instruments to ensure the process is efficient and effective. Properly equipped technicians can diagnose issues, replace components, and reassemble systems with precision, minimizing the risk of errors and enhancing overall performance.

Essential Instruments

Here is a list of essential tools that are commonly required during the repair of a vehicle’s power transfer system:

| Tool | Description |

|---|---|

| Socket Set | A collection of sockets in various sizes to fit different fasteners. |

| Torque Wrench | Ensures fasteners are tightened to the manufacturer’s specifications. |

| Puller | Used to remove gears and bearings without damaging components. |

| Fluid Pump | Facilitates the transfer of fluids during maintenance or replacement. |

| Diagnostic Scanner | Helps identify electronic issues and trouble codes. |

Additional Tools

Depending on the specific requirements of the repair, additional instruments may include specialized wrenches, pry bars, and cleaning supplies to ensure all surfaces are free of debris before reassembly.

Step-by-Step Repair Process

This section outlines a comprehensive approach to fixing the essential components of a construction vehicle, ensuring optimal functionality and performance. Following a systematic method can enhance efficiency and reduce downtime during repairs.

-

Assessment of the Issue: Begin by identifying the specific malfunction. Carefully inspect the equipment for any visible damage or wear.

-

Gather Necessary Tools: Collect all required tools and replacement elements needed for the task. This may include wrenches, screwdrivers, and other specialized implements.

-

Disassembly: Follow the guidelines to disassemble the affected area methodically. Ensure that each component is labeled and stored safely to avoid confusion during reassembly.

-

Inspection: Examine the disassembled components for signs of damage, corrosion, or wear. Identify which elements require replacement or repair.

-

Replacement of Components: Install new or refurbished parts as necessary. Ensure that all replacements meet the required specifications for compatibility.

-

Reassembly: Carefully reassemble the components, following the reverse order of disassembly. Double-check all connections and fasteners to ensure they are secure.

-

Testing: Once reassembly is complete, conduct thorough testing to confirm that the repairs were successful. Monitor the performance to ensure everything operates smoothly.

-

Final Inspection: After testing, perform a final inspection to ensure that all parts are functioning correctly and that no issues remain.

By adhering to these structured steps, one can efficiently address malfunctions, prolonging the lifespan of the machinery and enhancing its reliability.

Upgrades for Enhanced Performance

Improving machinery efficiency often involves integrating advanced components that can significantly boost operational capabilities. By focusing on key enhancements, users can achieve better productivity and longevity from their equipment.

One effective approach is to replace standard elements with high-performance alternatives. Upgrading the hydraulic system can lead to improved lifting capacity and faster cycle times, enabling operators to complete tasks more efficiently. Additionally, incorporating precision-engineered gears and clutches can enhance the overall drive mechanism, providing smoother transitions and better power distribution.

Regular maintenance paired with these enhancements is crucial for maximizing performance. Implementing a routine inspection schedule and utilizing quality lubricants can reduce wear and tear on upgraded components, ensuring they operate at peak efficiency for an extended period.

Investing in training for operators on how to effectively use upgraded systems is equally important. Knowledgeable operators can leverage the full potential of new components, resulting in improved handling and operational success.

Resources for Further Learning

Enhancing your understanding of heavy machinery maintenance and repair is essential for both professionals and enthusiasts. This section provides valuable resources to deepen your knowledge and skills related to construction equipment mechanics. Explore various materials, including books, online courses, and forums that cater to different levels of expertise.

Books and Manuals

Technical literature is a great starting point for anyone looking to grasp the complexities of machinery systems. Comprehensive manuals often offer insights into operational guidelines and troubleshooting techniques. Consider looking for publications focused on mechanical systems and hydraulic operations that can provide a solid foundation.

Online Learning Platforms

Many online resources are available to expand your expertise. Platforms offering courses on machinery operation and maintenance can be particularly beneficial. Engaging with interactive content, such as videos and quizzes, enhances retention and understanding. Additionally, community forums allow for discussions with experienced technicians and fellow learners, fostering a collaborative learning environment.