The operational efficiency of a utility vehicle significantly relies on its internal mechanisms. Understanding the structure and functionality of its core elements is essential for effective maintenance and troubleshooting. In this section, we will explore the intricate arrangement of key components, highlighting their roles in ensuring seamless performance.

Analyzing the configuration of these essential assemblies can provide valuable insights into the vehicle’s operation. By delving into the specific functions of each segment, users can enhance their knowledge and proficiency in handling various issues that may arise during use. This information is particularly beneficial for those engaged in repair and upkeep, as it facilitates informed decision-making.

Ultimately, grasping the layout of these vital systems empowers operators to maintain their equipment in optimal condition. Whether for professional tasks or recreational activities, a well-informed user can ensure longevity and reliability in their machinery.

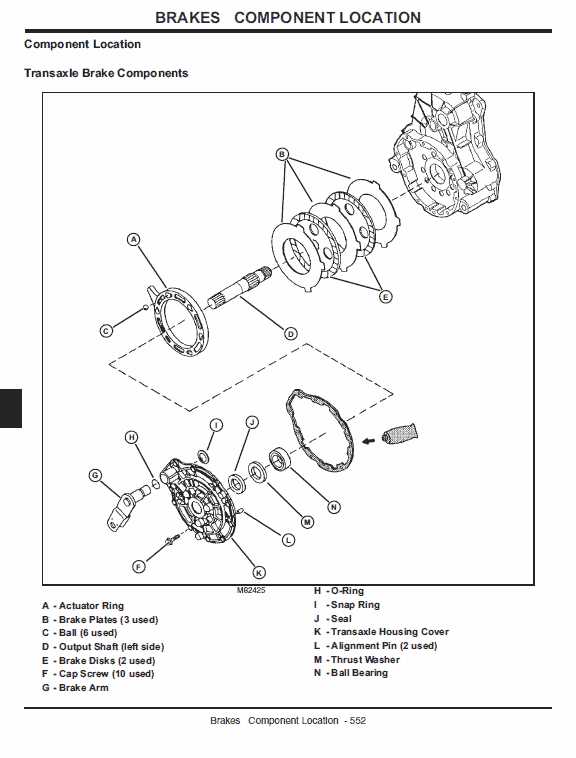

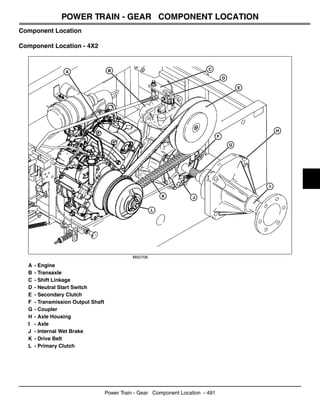

Overview of Utility Vehicle Transmission Components

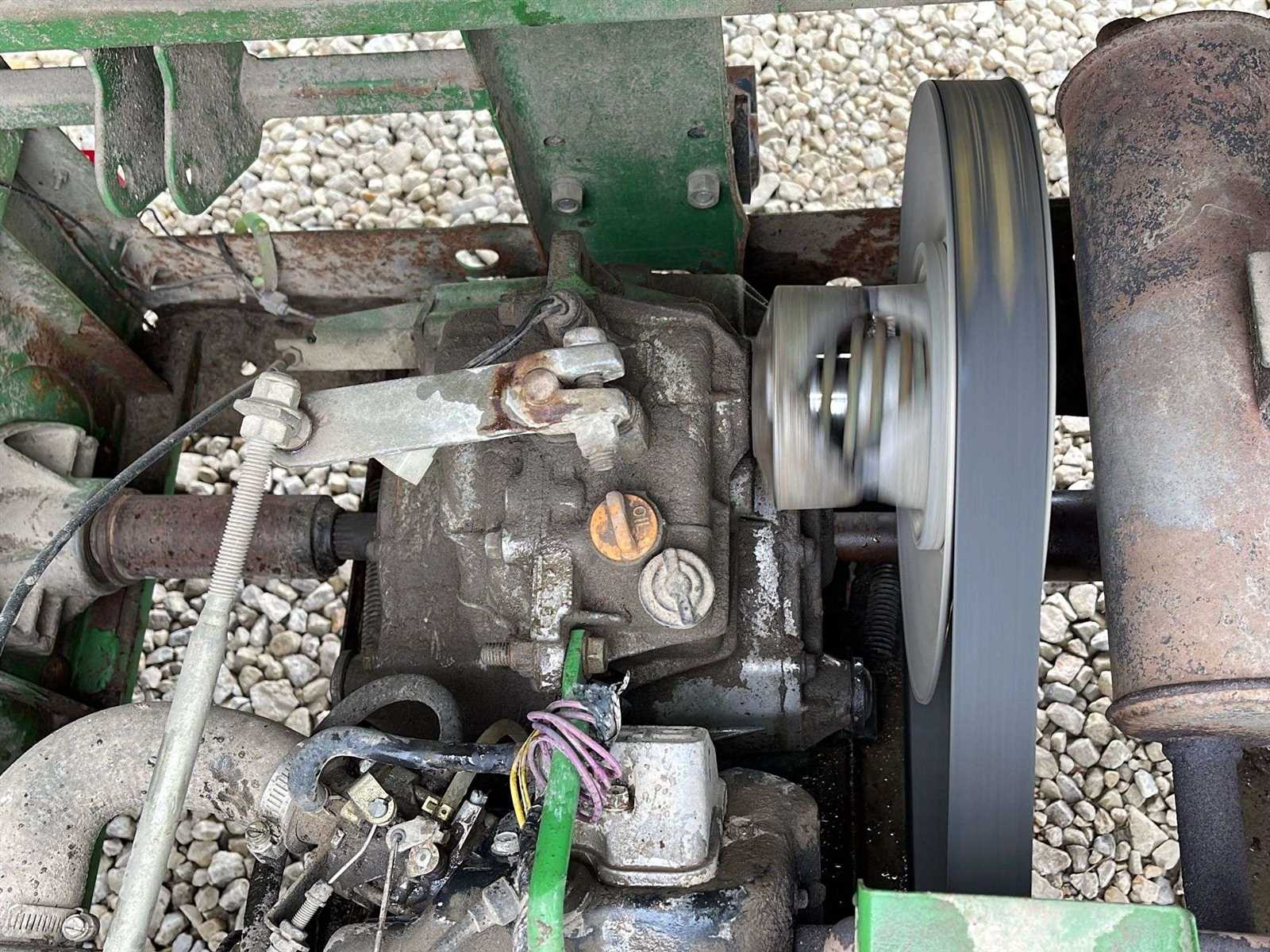

This section provides a comprehensive look at the essential elements that make up the drivetrain of a specific utility vehicle model. Understanding these components is crucial for effective maintenance and repairs. The drivetrain plays a vital role in the overall performance and efficiency of the vehicle, influencing factors such as power delivery, speed control, and durability.

Key Components of the Drivetrain

The drivetrain consists of various critical components that work in unison to ensure smooth operation. These elements typically include gears, belts, and housing assemblies, each designed to withstand significant stress while providing reliable functionality. Familiarity with these components can aid in troubleshooting common issues and implementing appropriate solutions.

Maintenance Tips for Optimal Performance

Regular inspection and maintenance of the drivetrain components are essential for longevity and peak performance. Checking for wear and tear, ensuring proper lubrication, and replacing damaged parts promptly can help maintain efficiency. Staying proactive in vehicle upkeep not only enhances performance but also prolongs the life of the machine.

Transmission Functionality and Design

The efficient movement of power within a vehicle is essential for optimal performance and reliability. The design of such mechanisms involves various components that work in unison to ensure smooth operation. This section explores the essential aspects of these systems, focusing on their functionality and structural design.

At its core, the mechanism is responsible for directing engine output to the wheels, allowing for effective propulsion. This process includes the conversion of rotational motion into usable torque, facilitating the vehicle’s movement across different terrains. Key elements include gear systems that provide varying levels of torque and speed, ensuring adaptability to various driving conditions.

Moreover, the configuration of these components plays a significant role in overall efficiency. Materials used in construction are chosen for their durability and weight properties, influencing the overall performance and longevity of the system. Regular maintenance is crucial to uphold functionality and prevent wear, highlighting the importance of design in facilitating ease of access to components for service and repair.

In summary, understanding the interplay between design and functionality provides valuable insights into enhancing the performance of power transfer systems. These principles are critical for achieving a reliable and efficient driving experience.

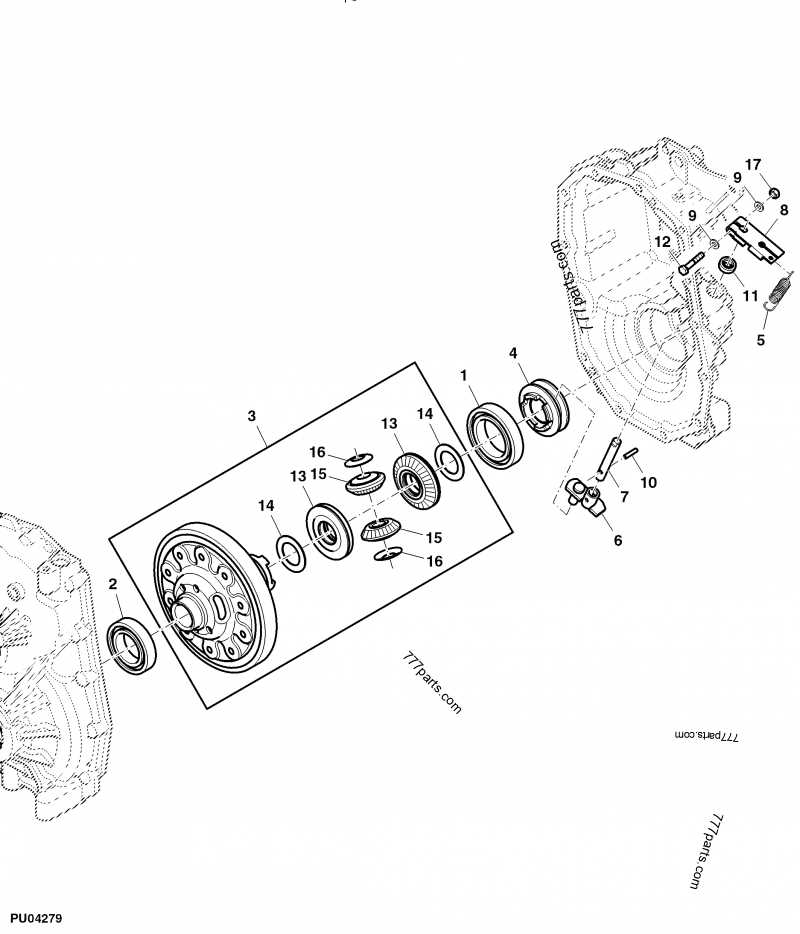

Main Components of the Transmission

The functioning of any vehicle relies heavily on its essential mechanisms, which work together to ensure smooth movement and control. Understanding these key elements is vital for effective maintenance and repair, contributing to the overall efficiency and performance of the machinery.

Key Elements Overview

Central to the movement system are various interconnected components that facilitate gear changes and power distribution. These elements are designed to handle substantial forces while providing reliable operation under varying conditions.

Importance of Each Component

Each part plays a significant role in ensuring optimal functionality. The interaction between the drive system, control levers, and supporting frameworks guarantees that the vehicle responds accurately to the operator’s commands. Regular inspection and maintenance of these components are crucial for prolonging the lifespan and enhancing the performance of the entire system.

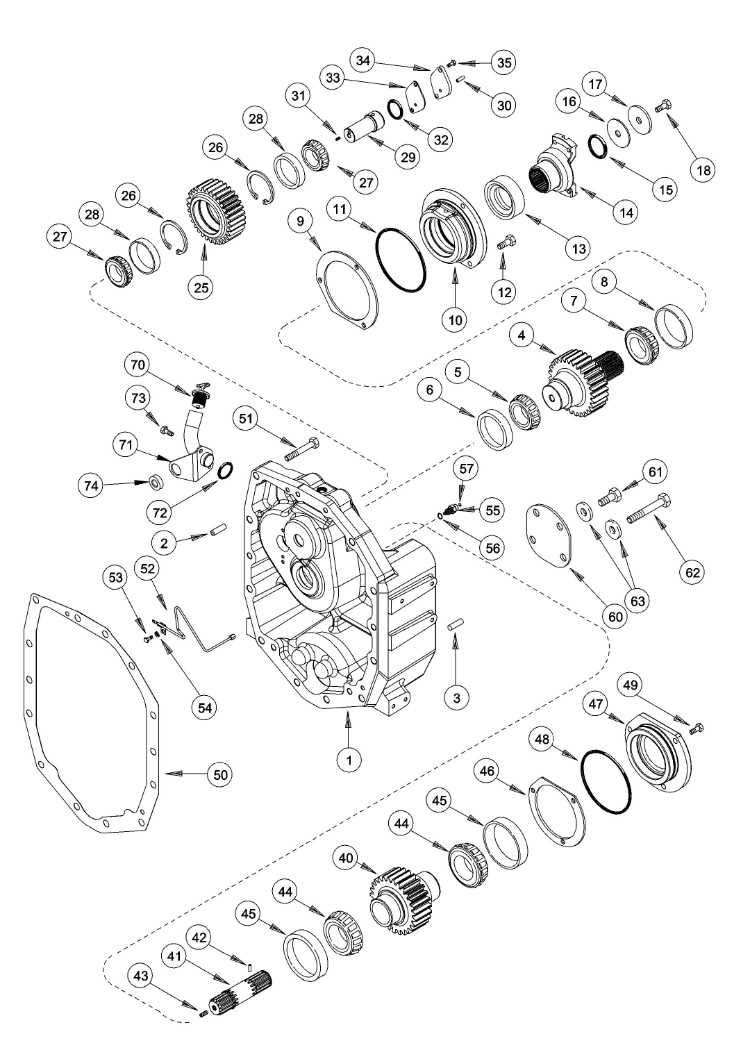

Transmission Parts Identification Guide

This section aims to assist users in recognizing and understanding the various components involved in the power transfer system of utility vehicles. Having a clear grasp of these elements is essential for effective maintenance and troubleshooting.

Below are the key components commonly found in the power transfer mechanism:

- Gearbox: The central unit responsible for altering the vehicle’s speed and torque.

- Drive Shafts: These rods transmit power from the gearbox to the wheels.

- Clutch Assembly: Engages and disengages power flow between the engine and the drive system.

- Input Shaft: The component that receives power from the engine.

- Output Shaft: Transfers power to the drive shafts leading to the wheels.

- Bearings: Support rotating components, reducing friction and wear.

- Seals: Prevent fluid leaks and protect internal components from dirt and debris.

Identifying these components can significantly enhance the ability to conduct repairs or upgrades effectively. Familiarizing oneself with each element’s function and location will lead to a more efficient understanding of the vehicle’s overall operation.

Common Issues with Transmission Components

In any vehicle, the system responsible for transferring power plays a critical role in overall functionality. Over time, certain challenges may arise, impacting efficiency and performance. Understanding these common issues is essential for effective maintenance and repair.

Frequent Problems Encountered

- Fluid Leaks: Leakage of hydraulic fluid can lead to inadequate lubrication, causing increased wear and tear on internal components.

- Overheating: Excessive heat buildup can result from various factors, including low fluid levels or blocked cooling lines.

- Noisy Operation: Unusual sounds during operation may indicate issues such as worn bearings or loose fittings.

- Difficulty Shifting: Problems with engaging or disengaging can stem from faulty linkage or worn-out components.

Preventive Measures

- Regularly inspect fluid levels and top off as necessary.

- Change the fluid and filters according to the manufacturer’s recommendations.

- Conduct routine checks for any visible leaks or signs of wear.

- Ensure that all connections and fittings are secure to prevent operational noise.

Maintenance Tips for Transmission Longevity

Ensuring the durability of your vehicle’s gear system is essential for optimal performance and reliability. Regular upkeep not only enhances efficiency but also prevents costly repairs in the long run. By following a few key practices, you can significantly extend the lifespan of this crucial component.

Regular Fluid Checks

Monitoring fluid levels and quality is vital for smooth operation. Periodically inspect the lubricant for any signs of contamination or degradation. If the fluid appears dark or has a burnt odor, it may need replacing. Always use the recommended type of lubricant to maintain optimal performance.

Routine Inspections

Conducting systematic inspections can help identify potential issues before they escalate. Look for any signs of wear, such as leaks or unusual noises. Pay attention to the seals and connections, ensuring they remain intact. Addressing minor problems promptly can prevent more significant complications down the road.

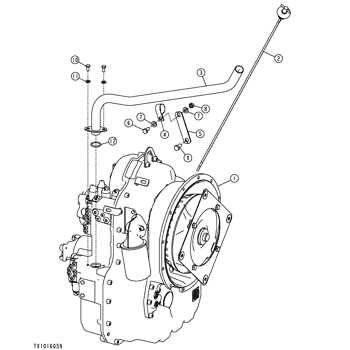

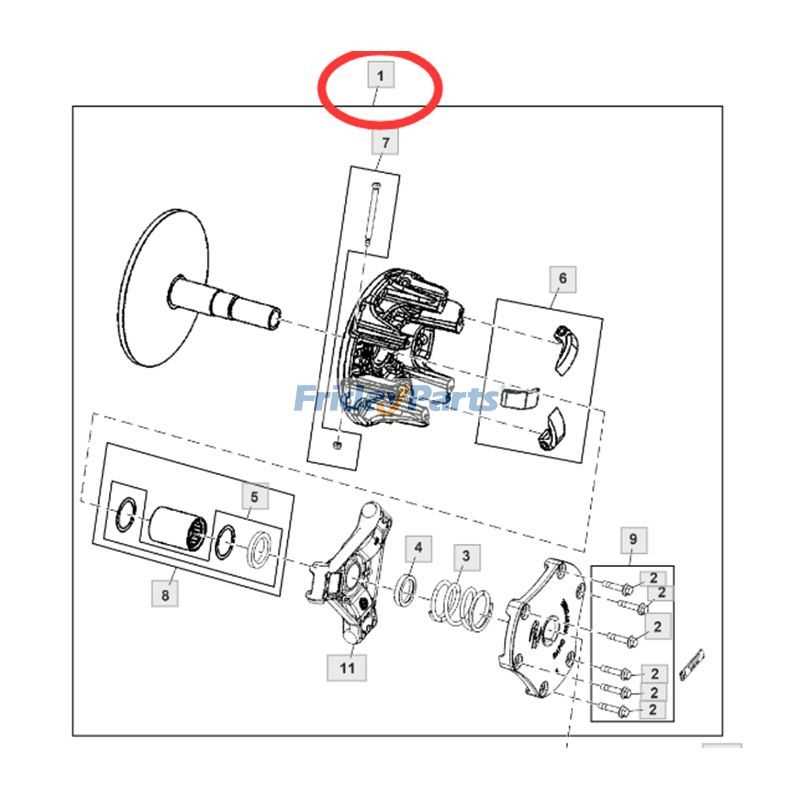

Understanding the Transmission Diagram

Grasping the intricacies of vehicle power systems is essential for effective maintenance and repair. A visual representation of the mechanisms involved allows for a clearer understanding of how different components interact. This section will delve into the various elements involved in the operation of these systems, emphasizing their roles and relationships.

Key features to consider include:

- Components that transfer power from the engine to the wheels

- Gear arrangements that influence speed and torque

- Connection points that facilitate the flow of motion

- Indicators that help diagnose potential issues

Analyzing this visual representation can enhance comprehension of the entire system. By recognizing how each element functions and connects, users can identify maintenance needs and troubleshoot problems more effectively.

Overall, a thorough understanding of this schematic serves as a foundation for both novice and experienced operators. Familiarity with the specific components leads to improved performance and longevity of the vehicle.

How to Replace Transmission Components

Replacing components within a drive system is essential for maintaining optimal performance and ensuring longevity. Properly executed replacements can enhance functionality and prevent further issues. This section provides a comprehensive guide on the process of swapping out these critical elements.

Preparation Steps

- Gather necessary tools and replacement components.

- Refer to the maintenance manual for specifications and guidelines.

- Ensure that the vehicle is on a flat surface and securely elevated.

- Disconnect the battery to prevent any electrical accidents.

Replacement Process

- Begin by removing any protective covers or shields that obstruct access to the components.

- Carefully detach the old components, taking note of their arrangement and connections.

- Install the new components by reversing the removal steps, ensuring a secure fit.

- Reconnect all wiring and hoses, ensuring they are correctly positioned to avoid interference.

- Replace any covers or shields removed during the process.

- Reconnect the battery and perform a thorough check to ensure everything functions as intended.

Tools Required for Transmission Repairs

Repairing the drive mechanism of utility vehicles requires a specific set of tools to ensure efficiency and accuracy. Having the right equipment at hand simplifies the process and helps avoid potential damage to components.

Essential tools include:

- Socket wrench set – Essential for loosening and tightening bolts.

- Screwdriver set – Useful for handling various types of screws.

- Torque wrench – Ensures that fasteners are tightened to the correct specifications.

- Pliers – Handy for gripping and manipulating small parts.

- Jack and jack stands – Necessary for safely lifting the vehicle for access to the undercarriage.

- Fluid transfer pump – Useful for changing out lubricants or fluids.

In addition to these tools, it is advisable to have a clean workspace and proper safety gear to ensure a safe and efficient repair process. Being well-prepared will facilitate a smoother workflow and contribute to successful outcomes.

Safety Precautions During Repairs

When undertaking maintenance tasks, ensuring personal safety and the protection of equipment is paramount. Adhering to specific guidelines can significantly reduce the risk of accidents and injuries while working on machinery.

Here are some essential safety measures to follow:

- Wear Protective Gear: Always utilize appropriate personal protective equipment, such as gloves, safety glasses, and sturdy footwear, to shield yourself from potential hazards.

- Work in a Well-Ventilated Area: Ensure that the workspace is adequately ventilated to avoid inhaling harmful fumes and chemicals.

- Disconnect Power Sources: Before starting any repair, make sure to disconnect all power sources to prevent accidental starts that could lead to injuries.

- Use Tools Properly: Familiarize yourself with the tools required for the job and ensure they are in good condition to avoid malfunctions.

- Follow Manufacturer Guidelines: Always consult the owner’s manual or technical documentation for specific safety instructions related to the equipment being repaired.

By implementing these safety practices, individuals can enhance their well-being and ensure a smoother repair process.

Frequently Asked Questions about Transmission

This section addresses common inquiries related to the system responsible for power transfer in vehicles. Understanding the intricacies of this mechanism can help users maintain and troubleshoot their machines effectively.

Here are some typical questions and answers:

-

What are the main functions of the system?

The primary roles include:

- Converting engine power into usable motion.

- Adjusting speed and torque based on driving conditions.

- Facilitating smooth gear shifts for better performance.

-

How can I identify issues?

Common symptoms of malfunction include:

- Strange noises during operation.

- Slipping or delayed engagement when accelerating.

- Unusual vibrations or overheating.

-

What maintenance practices should I follow?

To ensure longevity and proper function, consider these tips:

- Regularly check fluid levels and condition.

- Inspect for leaks or damage in the system.

- Schedule routine servicing as recommended by the manufacturer.

-

When should I seek professional help?

If you notice any of the following, it’s wise to consult an expert:

- Persistent warning lights on the dashboard.

- Significant performance drops.

- Difficulty in shifting gears or unusual sounds.

By addressing these common questions, users can better understand the function and upkeep of their vehicles, leading to improved performance and reliability.

Resources for Further Information

For those seeking additional insights and guidance on maintenance and repairs, a variety of valuable resources are available. These materials can assist enthusiasts and professionals alike in enhancing their understanding of the machinery and ensuring optimal performance.

Exploring online forums and discussion groups can provide practical tips and shared experiences from fellow users. Additionally, technical manuals and service guides offer in-depth knowledge on specific components and their functionality. Manufacturers often provide official documentation that outlines troubleshooting techniques and maintenance procedures.

| Resource Type | Details | Website/Source |

|---|---|---|

| Online Forums | Community discussions, troubleshooting tips, and user experiences | www.ownersforum.com |

| Technical Manuals | Detailed instructions and specifications for maintenance | www.manuals.com |

| Manufacturer Documentation | Official guides and service information from the manufacturer | www.manufacturer.com/support |

| Video Tutorials | Step-by-step visual guides for repairs and maintenance | www.youtube.com |