The intricate machinery of a vehicle’s drivetrain plays a crucial role in delivering power to the wheels. This section delves into the essential elements that enable effective torque distribution, ensuring smooth operation under various conditions. By exploring these fundamental components, one gains insights into the complexities involved in vehicle performance and reliability.

Each element within this system has a specific function, contributing to the overall efficiency and responsiveness of the vehicle. Understanding these individual components enhances awareness of how they interact and affect driving dynamics. The interplay between various mechanisms is vital for maintaining optimal functionality, especially in challenging environments.

As we examine the assembly of these crucial mechanisms, it becomes clear how each piece contributes to the system’s integrity. This exploration will provide a comprehensive view of how these elements work together to ensure stability and power delivery, paving the way for a deeper appreciation of automotive engineering.

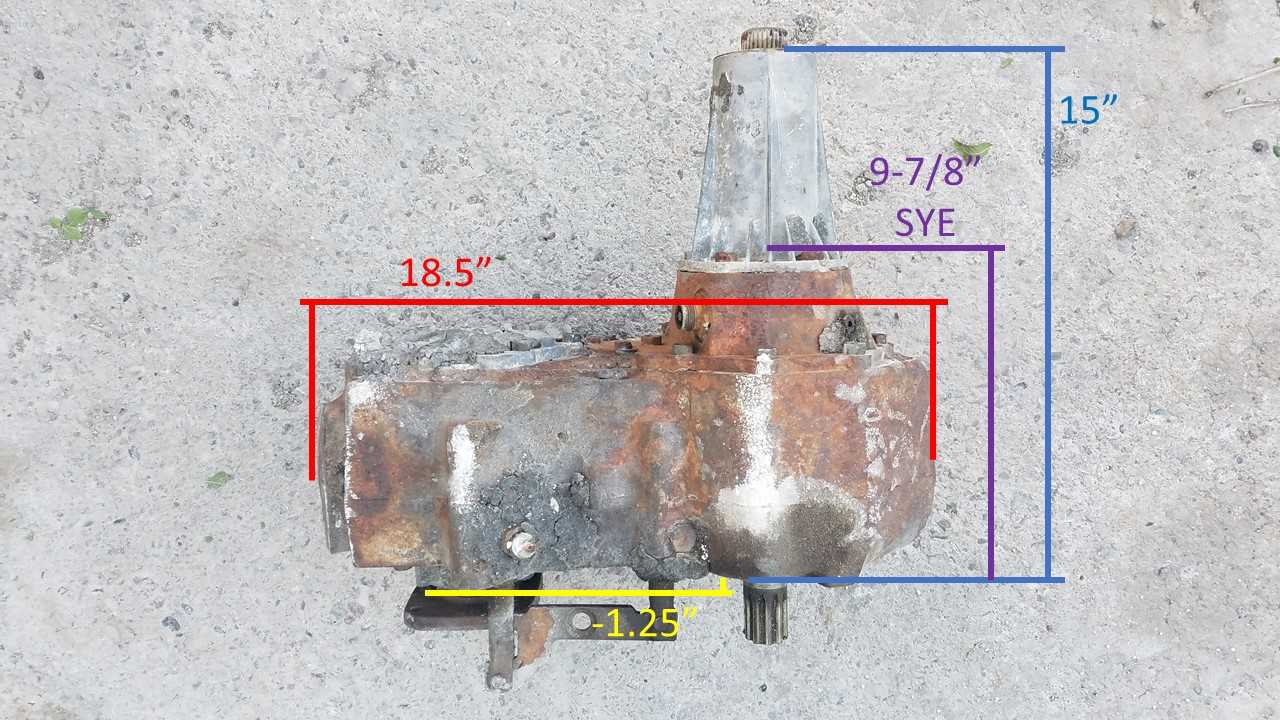

Key Components of NP205 Design

The design of this rugged system encompasses several crucial elements that contribute to its robust performance and reliability. Each component plays a significant role in ensuring seamless operation and optimal functionality in demanding conditions.

Housing is the outer structure that encases all internal mechanisms, providing durability and protection against external elements. Its robust construction helps maintain structural integrity under high stress.

Input Shaft serves as the primary connection point for power from the engine, translating rotational energy into the system. This component is engineered to withstand significant torque loads, ensuring efficient power transfer.

Output Shaft directs the power to the wheels, enabling movement. It is designed for durability and precision to maintain synchronization with the driving mechanisms.

Gear Set consists of various gears that facilitate the desired gear ratios, allowing for both high and low ranges of operation. Their arrangement is critical for achieving efficient performance across different terrains.

Shift Mechanism enables the user to switch between operating modes. Its design ensures ease of use while maintaining a secure connection during transitions, providing flexibility in various driving situations.

Understanding these essential elements enhances the appreciation of the overall system’s efficiency and functionality. The interplay between these components exemplifies engineering excellence, contributing to the trusted reputation of the assembly in the automotive field.

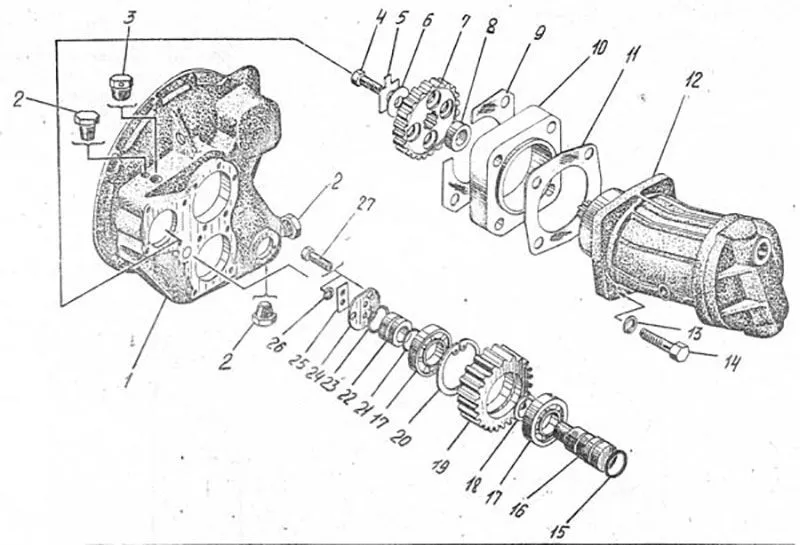

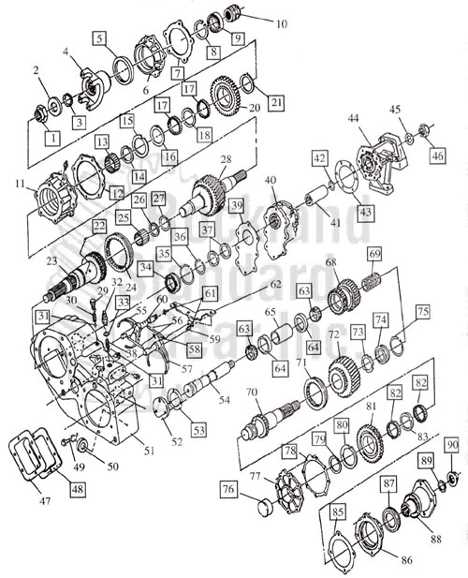

Diagram Overview of NP205 Parts

This section provides a comprehensive examination of the essential components found within the specified mechanism, highlighting their functions and interconnections. Understanding these elements is crucial for effective maintenance and troubleshooting.

Key Elements

The primary components include various gears, shafts, and housings that work in unison to ensure proper operation. Each element plays a vital role in the overall performance, contributing to the system’s reliability and efficiency.

Functional Relationships

Examining how these components interact reveals the intricate design of the assembly. For instance, the synchronization between the gears and the shafts is critical for smooth transitions and optimal power distribution. A thorough grasp of these relationships aids in diagnosing potential issues and improving performance.

Common Issues with NP205 Cases

When it comes to four-wheel drive systems, certain challenges frequently arise, impacting performance and reliability. Understanding these common complications can help owners address issues proactively, ensuring optimal functionality and longevity.

Fluid Leaks: One prevalent problem is the occurrence of fluid leaks. These leaks can stem from worn seals or gaskets, leading to inadequate lubrication and potential overheating. Regular inspections and timely replacements can mitigate this issue.

Gear Noise: Unusual noises during operation often indicate underlying issues. Grinding or clunking sounds may suggest worn gears or misalignment, which should be diagnosed and repaired to prevent further damage.

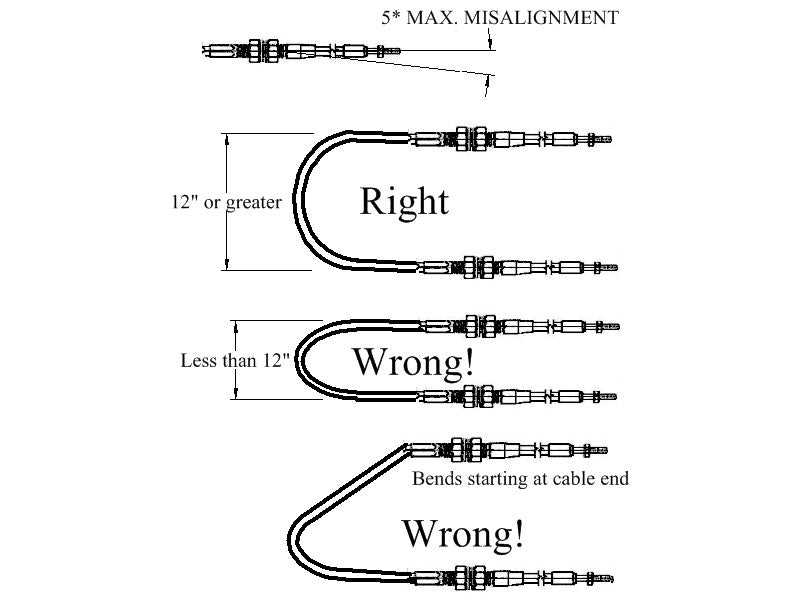

Engagement Difficulties: Another frequent concern involves difficulties in engaging or disengaging the system. This may result from cable or linkage problems, requiring adjustments or replacements to restore smooth operation.

Overheating: Overheating can significantly affect performance, often caused by inadequate fluid levels or contamination. Regular maintenance and monitoring of fluid quality can help prevent this issue.

Being aware of these challenges allows owners to take preventive measures, ensuring their four-wheel drive systems operate efficiently and reliably.

Maintenance Tips for NP205 Parts

Proper upkeep of your vehicle’s components is crucial for ensuring smooth operation and longevity. Regular attention to various elements can prevent costly repairs and enhance performance. Below are some essential maintenance practices to keep in mind.

- Regular Inspections: Check the system for signs of wear, leaks, or damage. Early detection of issues can save time and money.

- Fluid Changes: Ensure that lubricants are replaced according to the manufacturer’s schedule. Clean fluids reduce friction and wear.

- Component Cleaning: Remove dirt and debris from external surfaces to prevent corrosion. This is especially important for areas prone to moisture accumulation.

- Secure Fastenings: Routinely verify that all bolts and connections are tight. Vibration can lead to loosening over time, which may affect performance.

- Monitor Performance: Pay attention to any unusual sounds or changes in operation. Addressing these concerns promptly can prevent further complications.

Implementing these maintenance practices will help keep your vehicle’s mechanisms functioning optimally, ultimately leading to a more reliable and enjoyable driving experience.

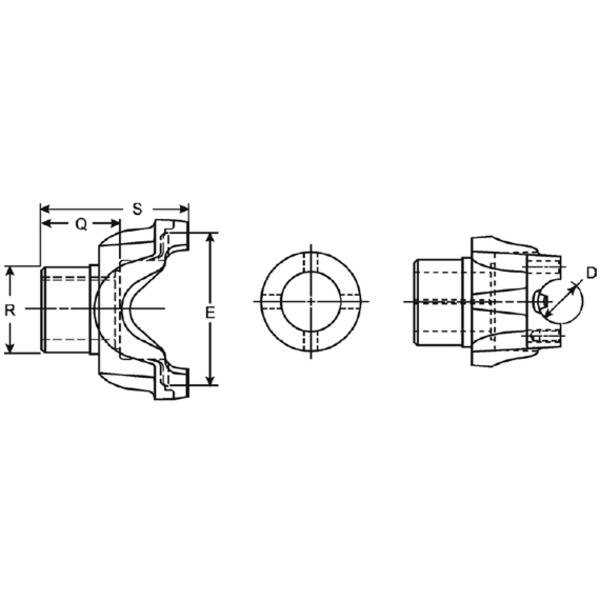

Replacement Parts for NP205 Transfer Case

Maintaining the efficiency of a specific mechanical assembly is essential for optimal vehicle performance. Over time, components within this system may wear out or become damaged, necessitating the use of suitable substitutes to ensure seamless operation. Understanding the available options for restoration can significantly enhance longevity and functionality.

Common Components: When considering replacements, it is vital to identify the various elements that may require attention. Key items include seals, bearings, and gears, each playing a crucial role in the overall function of the assembly. Utilizing high-quality alternatives can prevent future issues and ensure reliable performance.

Quality Assurance: When sourcing replacements, opt for reputable suppliers known for their durability and compatibility. Investing in superior materials will reduce the likelihood of premature failure, providing peace of mind and efficiency. Furthermore, proper installation techniques are critical in maximizing the lifespan of new components.

Conclusion: Ensuring the availability of appropriate substitutes for essential mechanical elements is crucial for any vehicle owner. By prioritizing quality and compatibility, one can maintain optimal operation and enhance the longevity of the system.

Upgrades for NP205 Performance

Enhancing the capabilities of your vehicle’s drive system can lead to improved handling, power distribution, and overall efficiency. By implementing various upgrades, you can ensure that your setup performs at its best under diverse conditions. This section will explore several modifications that can significantly boost performance and reliability.

Essential Modifications

- High-Performance Gears: Upgrading to stronger gear sets can withstand higher torque loads and enhance power transfer.

- Enhanced Seals and Bearings: Using premium seals and bearings can reduce friction and extend the lifespan of components.

- Improved Fluid Choices: Selecting specialized lubricants can optimize thermal stability and reduce wear on internal parts.

Advanced Solutions

- Electronic Control Systems: Installing a modern electronic control unit can allow for better adaptability in various driving conditions.

- Upgraded Input and Output Shafts: Reinforcing these shafts can prevent failure during extreme torque situations, enhancing durability.

- Custom Fabricated Skid Plates: Adding robust skid plates can provide additional protection for the assembly, especially during off-road adventures.

Implementing these upgrades will not only enhance performance but also ensure that your vehicle is prepared for a range of driving challenges.

Comparison with Other Transfer Cases

This section examines the distinctions and similarities between various mechanisms utilized for power distribution in vehicles. By evaluating different designs, users can better understand the advantages and drawbacks inherent in each system.

Key Features to Consider

- Gear Ratios: Different systems offer varying gear ratios that can affect torque distribution and speed.

- Durability: Construction materials and engineering quality influence longevity and reliability under stress.

- Weight: The mass of the mechanism can impact overall vehicle performance and fuel efficiency.

- Complexity: Some designs have more intricate components, which may require specialized knowledge for maintenance.

Common Alternatives

- All-Wheel Drive Systems: Often provide seamless engagement, but can be less robust than other options.

- Manual Locking Mechanisms: Offer direct control over power allocation, appealing to off-road enthusiasts.

- Electronic Control Units: Allow for automated adjustments but can introduce additional failure points.

Each type of system has its unique set of characteristics that cater to different driving conditions and preferences. By understanding these variations, vehicle owners can make informed decisions based on their specific needs and usage scenarios.

Installation Guidelines for NP205 Components

When working with the assembly of drivetrain components, it is essential to follow precise procedures to ensure optimal performance and reliability. Each element plays a crucial role in the overall function, and proper installation can prevent future issues.

Preparation and Tools

Before commencing the installation, gather all necessary tools and components. A clean workspace is vital to avoid contamination. Make sure you have the following items ready:

- Socket set

- Torque wrench

- Sealant

- Lubricants

Step-by-Step Installation

Begin by securely positioning the assembly on a stable surface. Carefully align all connection points, ensuring they fit correctly. It is recommended to apply lubricant to moving parts for smoother operation. Follow the manufacturer’s specifications for torque settings during the tightening process to prevent damage.

Once the installation is complete, perform a thorough inspection to verify that all components are correctly secured and functioning. A test run is advisable to identify any potential issues before putting the vehicle into regular use.

Identifying NP205 Part Numbers

Understanding the components of your vehicle’s drivetrain is essential for effective maintenance and repairs. Recognizing the specific identifiers associated with each element is crucial for sourcing the correct replacements and ensuring compatibility with your system.

Importance of Accurate Identification

Accurate identification of these identifiers not only streamlines the replacement process but also minimizes the risk of errors that could lead to mechanical failures. Each identifier typically corresponds to a unique function or feature of the component, making it imperative to have this knowledge at hand when making purchases or seeking repairs.

Common Identifiers Table

| Identifier Type | Description | Common Uses |

|---|---|---|

| Part Number | Specific code for each individual component | Used for ordering replacements and verifying compatibility |

| Model Number | Code representing the design or version of the assembly | Helps identify the appropriate series or generation |

| Manufacturer Code | Unique identifier assigned by the manufacturer | Assists in ensuring authenticity and quality of the part |

Tools Needed for NP205 Repairs

Performing repairs on this essential component requires a specific set of tools to ensure the process is efficient and effective. Having the right equipment on hand not only simplifies the job but also enhances the overall quality of the repair. Below is a list of essential tools that every mechanic should consider for these maintenance tasks.

| Tool | Description |

|---|---|

| Socket Set | A comprehensive socket set is crucial for removing and tightening bolts of various sizes. |

| Torque Wrench | This tool is necessary for applying the correct amount of force when fastening components, preventing damage. |

| Wrench Set | A set of wrenches, including adjustable and standard sizes, is needed for versatile applications. |

| Screwdriver Set | Both flathead and Phillips screwdrivers are required for various screws encountered during repairs. |

| Pry Bar | Useful for removing stuck components or providing leverage in tight spaces. |

| Drain Pan | This tool collects fluids during maintenance, helping to keep the workspace clean. |

| Flashlight | A reliable light source is essential for visibility in dark or cramped areas. |

| Shop Manual | This reference guide provides essential specifications and procedures for repairs. |

Safety Precautions When Working on NP205

Ensuring safety during mechanical work is essential for preventing injuries and accidents. When handling heavy machinery and complex assemblies, following proper guidelines is crucial. This section outlines necessary measures to take when performing maintenance or repairs on specific vehicle components.

1. Personal Protective Equipment (PPE): Always wear appropriate safety gear, including gloves, goggles, and steel-toed boots. This protective equipment helps safeguard against potential hazards, such as sharp edges and heavy items.

2. Work Area Organization: Maintain a clean and organized workspace. Clear any clutter that may cause slips or falls. Ensure tools and materials are stored correctly to avoid accidents.

3. Use Proper Tools: Employ the right tools for each task. Using incorrect or damaged equipment can lead to injuries or damage to components. Inspect tools regularly to ensure they are in good condition.

4. Read the Manual: Familiarize yourself with the relevant manuals and guidelines. Understanding the specifications and procedures reduces the risk of errors and enhances safety during repairs.

5. Avoid Working Alone: Whenever possible, have a partner present while working. In case of an emergency, having someone nearby can provide immediate assistance and support.

6. Secure Components: Before starting work, ensure that all components are securely fastened. This precaution prevents unintended movement or shifting, which could result in accidents.

7. Proper Lifting Techniques: Use correct lifting techniques when handling heavy items. Bend your knees and keep your back straight to avoid strains or injuries.

By adhering to these precautions, individuals can significantly reduce risks and ensure a safer working environment while performing tasks related to vehicle systems.