When maintaining outdoor machinery, comprehending the intricate network of its components is essential for optimal performance. A clear illustration of each element can significantly aid users in identifying and troubleshooting potential issues, ensuring their equipment operates smoothly throughout the seasons. This section aims to provide valuable insights into the structure and function of various elements involved in these versatile devices.

Efficient upkeep of lawn care apparatus not only prolongs their lifespan but also enhances user experience. By familiarizing oneself with the assembly of individual elements, operators can tackle repairs confidently and select the appropriate replacements when necessary. With a focus on clarity, the forthcoming visuals will facilitate a deeper understanding of how these components interconnect and function cohesively.

In addition, recognizing the role of each part empowers users to implement preventive measures, minimizing the likelihood of malfunction. Knowledge of how to properly care for these devices ensures that they remain reliable tools for maintaining landscapes and gardens, providing a sense of satisfaction and accomplishment for every user.

This section will provide a comprehensive examination of the essential elements found in a common landscaping tool. Understanding these components is crucial for effective maintenance, troubleshooting, and repair of the equipment. By familiarizing yourself with these parts, you can enhance the performance and longevity of your device.

Key Components of the Equipment

Each tool is made up of several fundamental parts that work together to ensure smooth operation. Here are some of the primary components:

- Power Source: The mechanism that provides energy for operation, which can be electric or fuel-powered.

- Cutting Head: The part responsible for trimming, typically equipped with a line or blade.

- Shaft: The connecting structure that links the power source to the cutting head.

- Handle: The area where the user grips the equipment for control and maneuverability.

- Guard: A safety feature that protects the user from debris and injury during operation.

Maintenance and Replacement Considerations

Regular inspection and maintenance of these components are vital for optimal functionality. Consider the following:

- Check the power source for signs of wear or damage.

- Inspect the cutting head for dullness or breakage, and replace as necessary.

- Ensure the shaft is securely attached and free from corrosion.

- Examine the handle for cracks or instability, which can affect control.

- Make sure the guard is intact to ensure user safety.

Common Issues with Trimmer Parts

Maintaining lawn care equipment is essential for optimal performance, yet users often encounter various challenges that can hinder functionality. Understanding these common problems can help in troubleshooting and ensuring that the equipment operates smoothly. Many issues arise from wear and tear, improper usage, or lack of regular maintenance.

Frequent Mechanical Failures

One of the most prevalent challenges is mechanical failure, which can stem from components wearing out over time. Common signs include unusual noises, vibration, or decreased efficiency. Regular inspection and timely replacement of worn parts can significantly extend the lifespan of the device.

Fuel and Electrical Issues

Another common problem involves fuel delivery or electrical components. Blockages in fuel lines or dirty filters can impede performance, while electrical failures may result from faulty connections or worn batteries. Keeping these systems clean and ensuring proper connectivity can prevent many operational issues.

Identifying Essential Replacement Parts

When maintaining outdoor power equipment, recognizing key components for replacement is vital for ensuring optimal functionality and performance. Understanding which elements may require attention can save both time and effort during repairs, allowing for seamless operation and longevity.

To effectively identify necessary components, consider the following:

- Wear and Tear: Regular use can lead to deterioration. Inspect components for signs of damage, such as cracks, fraying, or excessive wear.

- Performance Issues: If your equipment is underperforming, certain elements may be malfunctioning. Look for signs of poor performance like reduced power or efficiency.

- Manufacturer Recommendations: Consult the user manual or manufacturer guidelines to understand suggested replacement schedules for crucial components.

Some of the most common elements to assess include:

- Cutting implements

- Fuel filters

- Air filters

- Starter mechanisms

- Drive belts

Regular maintenance checks and timely replacements of these essential components will not only enhance performance but also prolong the life of your equipment.

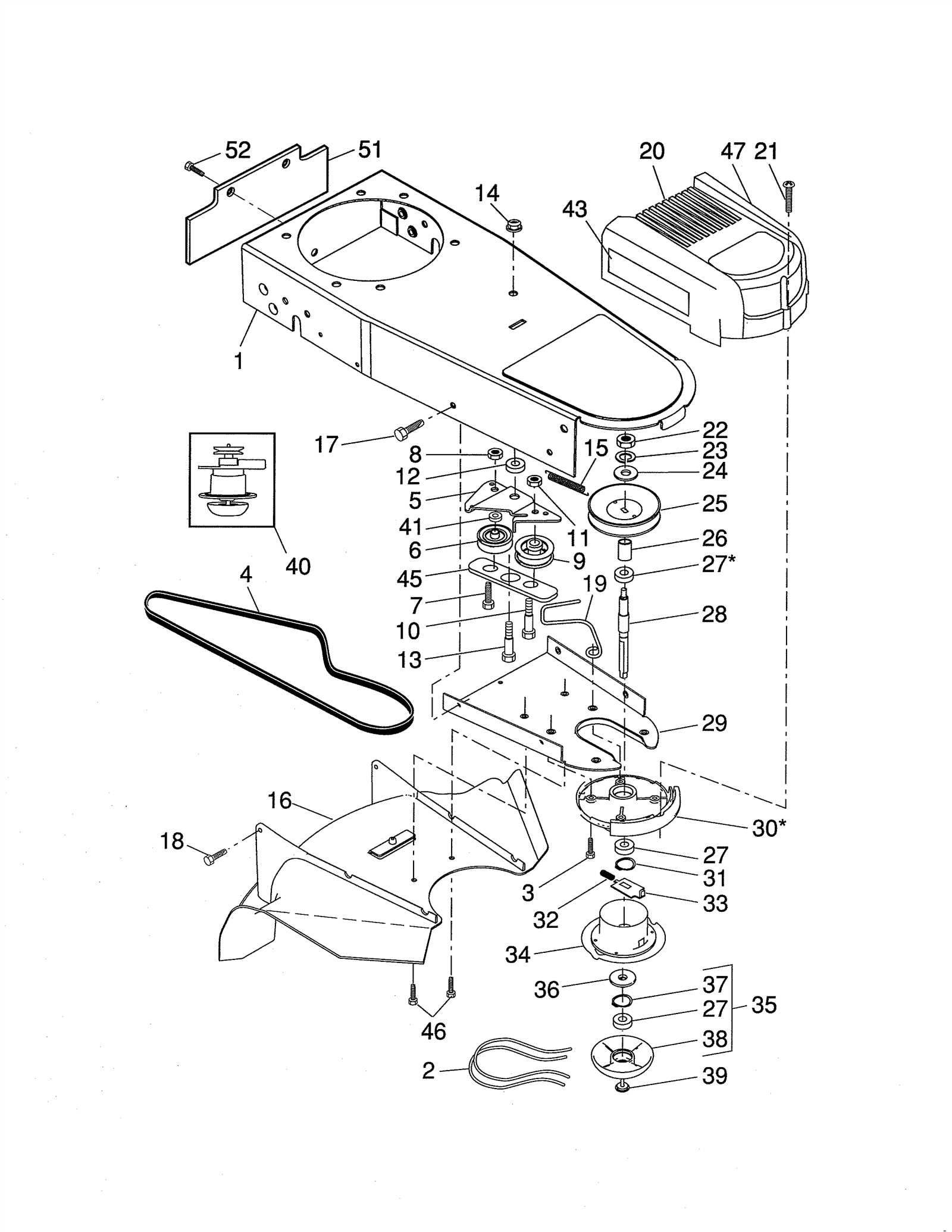

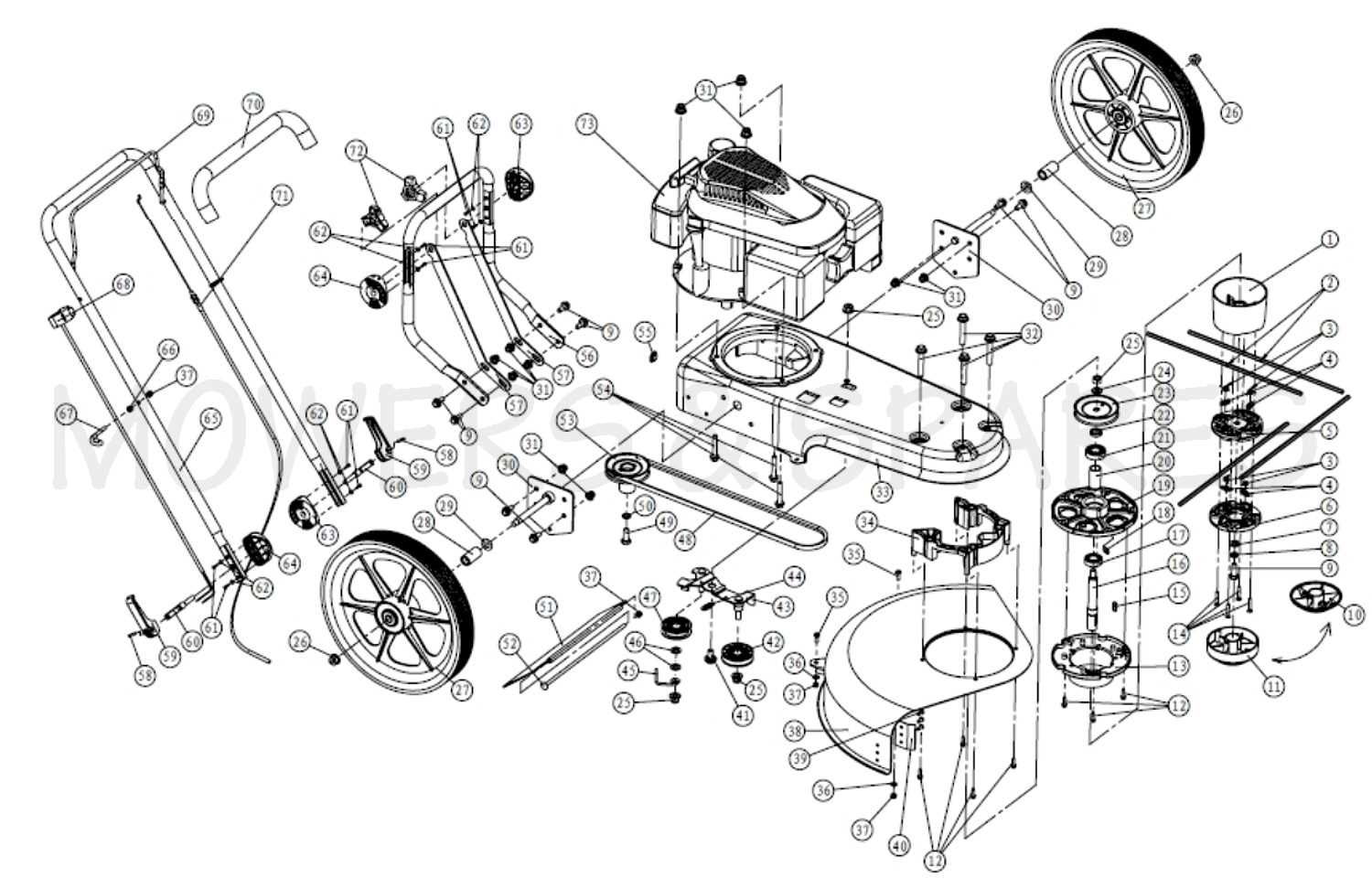

Understanding Trimmer Assembly Layout

The configuration of a cutting device is essential for its effective operation and longevity. Familiarizing oneself with the arrangement of its components can enhance maintenance practices and ensure optimal performance. Each section of the equipment plays a critical role in the overall functionality, and recognizing how these elements interact is key to troubleshooting and repairs.

Typically, the assembly consists of several integral components, each with specific functions. The main body serves as the foundation, while the motor unit drives the cutting mechanism. Additionally, the handle provides support for maneuverability, and various protective features enhance user safety.

| Component | Description | Function |

|---|---|---|

| Main Housing | The central structure that houses other components. | Provides support and protection for internal elements. |

| Motor | The power source that drives the cutting mechanism. | Generates motion for efficient cutting action. |

| Cutting Head | The area where the cutting line or blade is installed. | Engages with the material for trimming or cutting. |

| Handle | The part designed for user control. | Allows for maneuverability and comfort during operation. |

| Safety Guard | A protective barrier around the cutting area. | Prevents accidental contact with the cutting elements. |

Tools for Repairing Your Trimmer

Maintaining and fixing your gardening equipment requires the right set of tools to ensure efficiency and effectiveness. A well-equipped toolbox can make all the difference when it comes to performing repairs and enhancing the longevity of your devices. Below are essential instruments that every DIY enthusiast should consider for tackling maintenance tasks.

Basic Hand Tools

Having a selection of hand tools is crucial for any repair job. Screwdrivers, wrenches, and pliers are foundational tools that allow you to disassemble components with ease. A multi-tool can be particularly handy for accessing hard-to-reach areas or dealing with multiple fasteners.

Specialized Repair Equipment

For more complex repairs, specialized tools such as torque wrenches and wire strippers become necessary. These instruments facilitate precise adjustments and modifications, ensuring that your equipment operates at peak performance. Additionally, a good quality lubricant can aid in maintaining moving parts, prolonging their lifespan.

Maintenance Tips for Longevity

Regular upkeep is essential for ensuring the durability and optimal performance of any outdoor equipment. Implementing effective maintenance practices not only enhances functionality but also extends the lifespan of your tools, allowing for a more satisfying experience during use.

1. Keep It Clean: After each session, remove any debris, grass, or dirt from the machine. This helps prevent build-up that can lead to operational issues over time. Use a soft brush or cloth to wipe down surfaces and ensure that air vents remain unobstructed.

2. Regular Inspections: Periodically check all components for wear and tear. Look for signs of damage or corrosion that may affect performance. Early detection of issues can save time and costs associated with extensive repairs.

3. Lubricate Moving Parts: Apply the appropriate lubricant to moving components to reduce friction and wear. This simple step helps maintain efficiency and prevents unnecessary strain on the machinery.

4. Store Properly: When not in use, store your equipment in a dry, sheltered place. Avoid leaving it exposed to harsh weather conditions, as moisture can lead to rust and other damage.

5. Follow Manufacturer Guidelines: Always adhere to the manufacturer’s recommendations for maintenance intervals and procedures. This ensures that you are performing necessary tasks correctly and at the right times.

By incorporating these practices into your routine, you can enhance the reliability and longevity of your outdoor equipment, ensuring it remains in excellent working condition for years to come.

Safety Precautions During Repairs

When undertaking maintenance or fixing equipment, it is crucial to prioritize safety to prevent accidents and injuries. Understanding the necessary precautions ensures a secure working environment, enabling individuals to focus on the task at hand without unnecessary risks.

Personal Protective Equipment

Wearing appropriate personal protective gear is essential when conducting repairs. This includes safety goggles to shield your eyes from debris, gloves to protect your hands from sharp edges or hazardous materials, and sturdy footwear to minimize the risk of foot injuries. Additionally, using ear protection can help prevent hearing damage in noisy environments.

Work Area Organization

Maintaining a clean and organized workspace is vital for safety. Remove any clutter that could obstruct movement or create tripping hazards. Ensure that all tools are in good condition and easily accessible, reducing the likelihood of accidents caused by reaching for equipment. Proper lighting is also important to clearly see the work area and avoid potential hazards.

How to Access Parts Diagrams

Locating the schematics for your equipment can enhance your understanding of its components and facilitate repairs. These visual guides illustrate the arrangement of each piece, making it easier to identify and order replacements when needed.

To obtain these visual representations, start by visiting the manufacturer’s official website. They often provide a dedicated section for service manuals and schematics. If you cannot find the information online, consider reaching out to customer support for assistance in obtaining the necessary resources.

Additionally, many third-party websites specialize in hosting manuals and guides for various brands. Utilizing search engines with specific queries related to your equipment can lead you to these valuable resources. Ensure you verify the credibility of the site to avoid inaccurate or outdated information.

Lastly, local repair shops or authorized dealers may have printed manuals available. Visiting these establishments can provide not only access to schematics but also expert advice on maintenance and repairs.

Where to Purchase Replacement Parts

Finding suitable components for your equipment can significantly enhance its functionality and lifespan. Various options are available for sourcing these essential items, ensuring that you have access to reliable solutions that meet your needs.

Online Retailers: Numerous e-commerce platforms specialize in outdoor equipment supplies. These websites offer an extensive range of components, often accompanied by detailed descriptions and customer reviews, making it easier to select the right item. Popular choices include large retailers that focus on home and garden products, as well as niche sites dedicated to tool accessories.

Local Hardware Stores: Visiting nearby hardware or home improvement stores can provide immediate access to the components you need. Knowledgeable staff can assist in identifying the correct items and offer advice on installation. It’s also an excellent opportunity to check for compatibility with your specific model.

Manufacturer’s Websites: For those seeking authenticity and quality, official manufacturer websites often have dedicated sections for replacements. Purchasing directly from the source guarantees that you receive genuine items designed specifically for your equipment.

Second-Hand Markets: Exploring platforms for used equipment can yield affordable options. While this route requires careful inspection and verification of the item’s condition, it can be a cost-effective alternative for those on a budget.

By considering these avenues, you can confidently find the components necessary to maintain and enhance your equipment’s performance.

Comparing Models for Compatibility

When selecting equipment for yard maintenance, it’s essential to evaluate the compatibility of various models available on the market. Understanding the similarities and differences between units can greatly enhance performance and ease of use. This section will explore the important factors to consider when determining which models can effectively work together.

One key aspect to assess is the engine specifications. Models equipped with similar engine sizes and types often share components that can enhance their interchangeability. This can save time and reduce costs when looking to replace or upgrade parts. Additionally, examining the accessories and attachments that can fit multiple models can further increase versatility.

Another crucial consideration is the design features. Components such as handles, fuel tanks, and cutting mechanisms may vary slightly between models but can still be compatible if the overall dimensions are aligned. It’s beneficial to consult product manuals and compatibility charts to ensure the best match.

Lastly, taking into account customer reviews and expert recommendations can provide valuable insights into how well different models perform together. Feedback from users often highlights experiences regarding compatibility, helping potential buyers make informed decisions.

Frequently Asked Questions About Trimmers

This section addresses common inquiries related to cutting tools designed for maintaining lawns and gardens. Users often seek guidance on their functionality, maintenance, and troubleshooting tips to enhance their experience and ensure longevity.

1. What are the primary uses of these cutting devices?

These implements are primarily utilized for trimming grass, weeds, and overgrown vegetation, making them essential for achieving a neat and tidy outdoor space.

2. How often should I perform maintenance on my equipment?

Regular upkeep is crucial. It is recommended to check and clean the equipment after each use, while more comprehensive maintenance, such as replacing blades or filters, should be conducted every few months depending on usage frequency.

3. What safety precautions should I take?

Always wear protective gear, including gloves and eyewear. Ensure that the area is clear of obstacles and bystanders before operation, and follow the manufacturer’s guidelines for safe usage.

4. How do I troubleshoot common issues?

If the tool is not starting or performing poorly, check the fuel levels, spark plug condition, and for any clogs in the cutting mechanism. Refer to the user manual for specific troubleshooting tips tailored to your model.

5. Can I use these devices in wet conditions?

It is generally advisable to avoid using them in wet conditions, as moisture can affect performance and increase the risk of electrical hazards. Always wait for dry weather for optimal operation.

6. What types of accessories are available?

A variety of attachments and accessories can enhance functionality, including different blade types, harnesses for improved comfort, and specialized cutting heads for various tasks.

7. Where can I find replacement components?

Replacement components can typically be sourced from authorized dealers, local hardware stores, or online retailers specializing in garden equipment. Ensure you choose parts that are compatible with your specific model.