Maintaining and optimizing your outdoor equipment is essential for achieving the best results in your garden or yard. This section will provide a comprehensive overview of the various components that make up these tools, enabling you to enhance their performance and longevity.

Familiarizing yourself with the individual elements is crucial, as each piece plays a significant role in the overall functionality. By exploring the structure and design of these devices, you can better understand how to troubleshoot issues and conduct necessary repairs.

In this guide, we will delve into the intricate workings of your gardening tools, highlighting the relationships between the various components. This knowledge will empower you to take proactive steps in maintaining your equipment, ensuring that your outdoor tasks are completed efficiently and effectively.

Understanding Honda Trimmer Components

In the realm of garden maintenance tools, a comprehensive grasp of the various elements that contribute to the functionality of these machines is essential. Each component plays a vital role, ensuring efficiency and reliability during use. Familiarity with these integral parts can greatly enhance the user experience and prolong the lifespan of the equipment.

Key elements include the power unit, which serves as the engine behind the operation, and the cutting mechanism, designed to handle different types of vegetation. Additionally, the ergonomic design of handles and harnesses provides comfort and reduces fatigue during extended use. Understanding how these components interact can aid in troubleshooting and maintenance, leading to improved performance.

| Component | Function |

|---|---|

| Power Unit | Drives the entire system and provides necessary energy. |

| Cutting Mechanism | Responsible for trimming and shaping various plants. |

| Handle | Offers control and maneuverability while in use. |

| Harness | Distributes weight for comfort during operation. |

| Fuel Tank | Stores fuel required for the power unit. |

By delving into the specifics of these components, users can not only enhance their understanding but also ensure their equipment operates at peak performance, ultimately leading to a more enjoyable gardening experience.

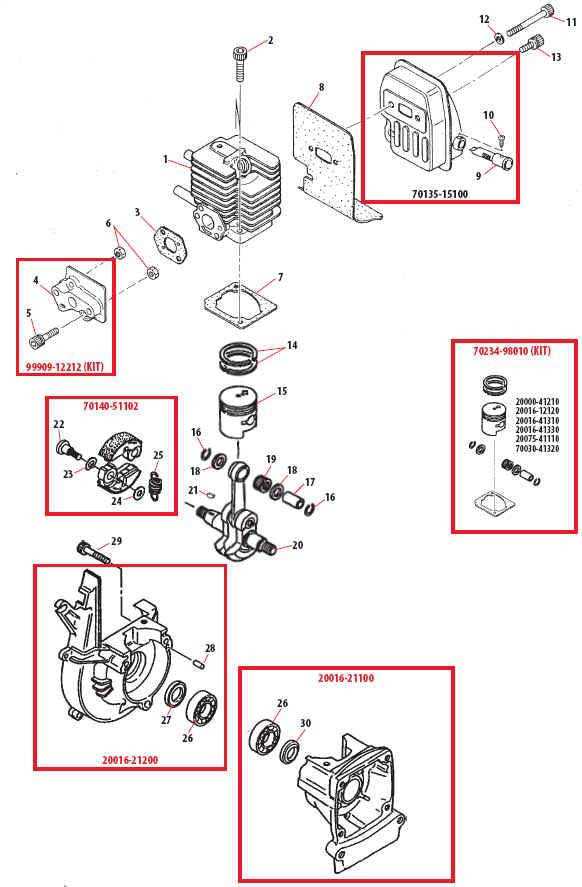

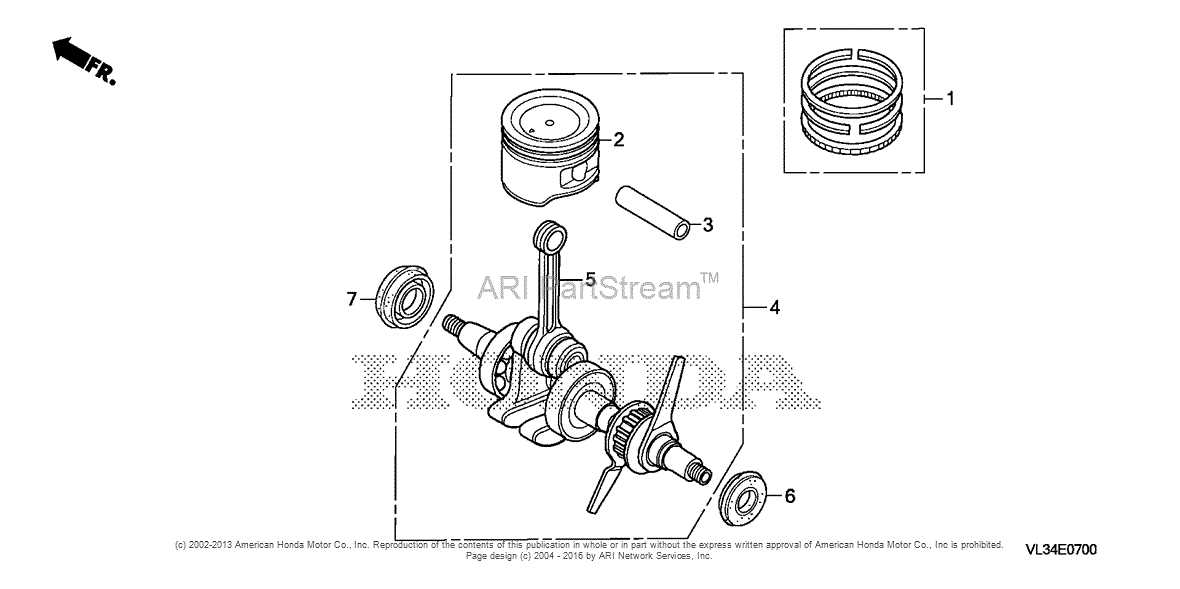

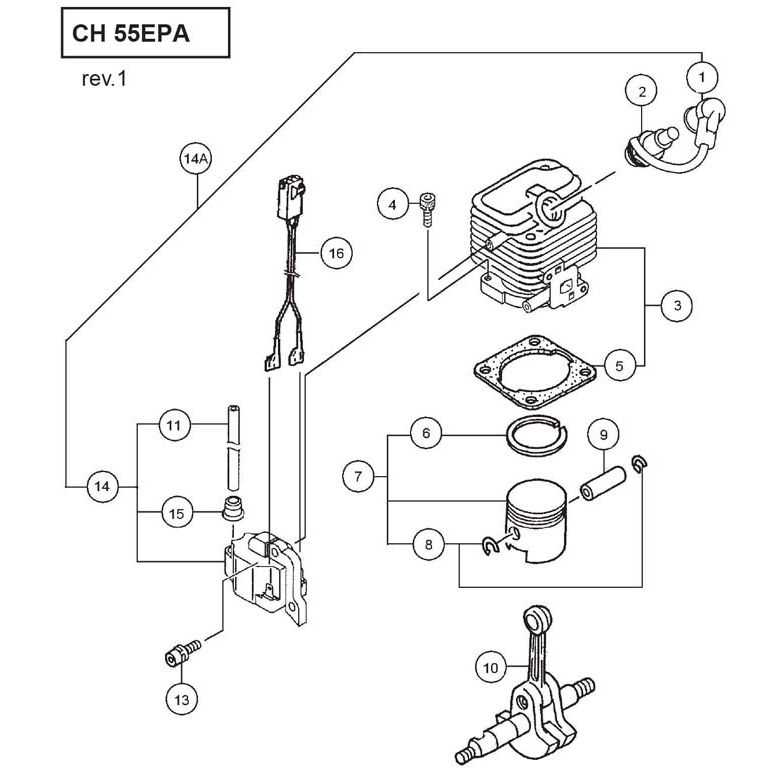

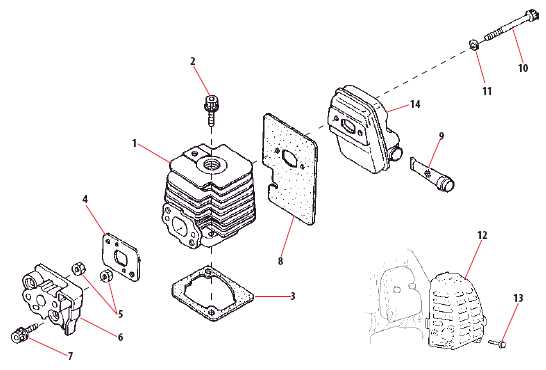

Importance of Parts Diagrams

Understanding the components and their interrelations is crucial for effective maintenance and repair. Visual representations serve as a valuable resource for both professionals and enthusiasts, enabling a clear grasp of the structure and function of various elements.

Here are several reasons why these visual aids are essential:

- Enhanced Clarity: Illustrations provide a straightforward view of complex assemblies, making it easier to identify each element.

- Efficient Repairs: Knowing the exact location and function of each component accelerates the troubleshooting process.

- Accurate Replacements: A clear depiction helps ensure that the correct parts are sourced and fitted, reducing errors.

- Educational Value: Visual aids serve as an excellent learning tool for those new to equipment maintenance, fostering better understanding.

- Organizational Aid: By showing how components fit together, these resources assist in organizing tasks and workflows during repairs.

In summary, visual representations of equipment components significantly enhance the efficiency and accuracy of maintenance activities, making them indispensable tools for anyone involved in repair and upkeep.

Common Issues with Trimmer Parts

Maintaining garden equipment is crucial for optimal performance. Various components may encounter problems over time, affecting the overall functionality. Understanding these common issues can help in identifying and addressing them efficiently.

Worn-Out Components: Frequent use can lead to wear and tear. Key elements may become less effective, resulting in reduced cutting efficiency. Regular inspections can help catch these issues early.

Fuel System Problems: Blockages or leaks in the fuel delivery system can cause the engine to stall or run poorly. Ensuring that all connections are secure and free from debris is essential for smooth operation.

Electrical Failures: Malfunctions in the ignition system can prevent the engine from starting. Checking the spark plug and wiring can often resolve these issues, restoring functionality.

Excessive Vibration: Unbalanced or damaged blades can lead to increased vibration, making the equipment difficult to handle. Regular maintenance and blade inspection can help prevent this problem.

Overheating: Lack of proper lubrication or airflow can cause overheating, risking permanent damage. Keeping the equipment clean and ensuring adequate oil levels can mitigate this risk.

By being aware of these common concerns, users can maintain their equipment more effectively, ensuring a longer lifespan and better performance.

How to Read a Parts Diagram

Understanding an assembly illustration is essential for anyone looking to maintain or repair equipment. These visuals provide a comprehensive overview of the components involved, allowing users to identify, locate, and order the necessary elements for effective servicing. Grasping the layout and symbols used in these illustrations can significantly enhance your repair experience.

Identifying Components

The first step in deciphering an assembly illustration is recognizing the various elements depicted. Each part is typically labeled with a unique identifier, which corresponds to a list that provides detailed information such as descriptions, quantities, and specifications. Familiarizing yourself with these labels can streamline the process of pinpointing the exact components you need.

Understanding Relationships

Next, pay attention to how the components are interconnected. Lines and arrows often illustrate how parts fit together or how they function in relation to one another. By following these connections, you can better understand the assembly’s overall mechanics, which is crucial for effective troubleshooting and repairs.

Maintenance Tips for Honda Trimmers

Proper upkeep of your outdoor equipment is essential for ensuring optimal performance and longevity. Regular attention to details can make a significant difference in efficiency and reliability, allowing you to tackle your gardening tasks with ease.

Here are some key maintenance tips to keep your equipment running smoothly:

- Regular Cleaning: Remove dirt, grass clippings, and debris after each use to prevent buildup that can affect performance.

- Check the Blades: Inspect and sharpen the cutting blades periodically to maintain effectiveness. Dull blades can lead to uneven cuts and increased strain on the motor.

- Inspect the Fuel System: Ensure that the fuel is fresh and the lines are free from cracks or leaks. Old fuel can cause starting issues and reduced power.

- Monitor the Air Filter: Clean or replace the air filter regularly to ensure optimal airflow and engine efficiency.

- Examine the Spark Plug: Check the spark plug for wear and replace it if necessary to ensure smooth ignition and engine performance.

By following these simple maintenance steps, you can enhance the lifespan of your equipment and ensure it operates at its best, ready for any task at hand.

Finding Replacement Parts Easily

Locating the necessary components for your equipment can be a straightforward process with the right approach. Ensuring that you have access to quality replacements will help maintain the performance and longevity of your machine. Here are some effective strategies to simplify your search.

- Online Retailers: Many websites specialize in offering a wide range of components. Check for reputable suppliers with good customer reviews.

- Manufacturer’s Website: Visit the official site to find specific models and compatible items. Often, they provide detailed resources and links to authorized dealers.

- Local Stores: Don’t overlook nearby hardware or gardening stores. They might stock essential items or be able to order them for you.

- Forums and Communities: Join online groups related to your equipment. Members often share valuable information about where to find replacements.

Utilizing these resources can significantly enhance your search efficiency, ensuring you find what you need without unnecessary delays.

Comparing OEM and Aftermarket Parts

When it comes to maintaining outdoor equipment, choosing between original components and alternatives can significantly impact performance and durability. Understanding the differences between these options is essential for making informed decisions.

Original equipment manufacturer (OEM) components are specifically designed to meet the standards set by the original creator of the machinery. They ensure compatibility and often come with warranties that provide peace of mind. On the other hand, aftermarket options can offer a cost-effective solution with varying levels of quality and compatibility. While some alternatives are produced by reputable companies, others may lack the same rigorous testing and specifications.

One of the main advantages of OEM components is their reliability. Since they are made to fit perfectly and function seamlessly, users often find fewer issues over time. However, this comes at a higher price point. In contrast, aftermarket choices can be more budget-friendly, allowing for savings, but they may require careful selection to avoid potential complications during installation or use.

Ultimately, the decision between these two types hinges on individual preferences and specific needs. Assessing the importance of quality, price, and long-term reliability will guide users in choosing the best route for their equipment maintenance.

Identifying Model-Specific Components

Understanding the unique elements that make up your equipment is essential for effective maintenance and repair. Each model comes with its own set of features and specifications, which can affect performance and compatibility with various accessories. By recognizing these individual characteristics, users can ensure optimal functionality and longevity of their device.

Start by consulting the manufacturer’s documentation, which typically includes detailed information about model variations. This documentation may contain lists of unique identifiers and features specific to each version, aiding in accurate identification.

Additionally, familiarizing yourself with the visual layout can significantly simplify the process. Many models showcase distinguishing marks or configurations that help differentiate between similar designs. Paying attention to these details can save time and prevent errors when sourcing replacements or upgrades.

Finally, engaging with online communities or forums dedicated to your specific equipment can provide invaluable insights. Experienced users often share their knowledge about model-specific components, helping newcomers navigate potential challenges more effectively.

Tools Required for Trimmer Repairs

When it comes to maintaining and fixing your gardening equipment, having the right instruments is essential for effective and efficient repairs. This section will outline the necessary tools that will help you tackle various issues, ensuring your machine operates smoothly and reliably.

Essential Tools

- Wrench Set

- Socket Set

- Screwdriver Set

- Plier Set

- Hex Key Set

Additional Accessories

- Cleaning Brush

- Lubricating Oil

- Replacement Blades

- Protective Gloves

- Safety Goggles

Equipped with these tools, you will be well-prepared to address any maintenance challenges that arise, helping to extend the life of your equipment and improve its performance.

Preventative Measures for Longevity

Ensuring the extended lifespan of your gardening equipment requires a proactive approach. Regular maintenance and careful usage can significantly enhance performance and durability. By following specific practices, you can prevent common issues that lead to premature wear and tear.

| Preventative Measure | Description |

|---|---|

| Regular Cleaning | Remove debris and dirt after each use to prevent buildup that can affect functionality. |

| Check Fuel Quality | Use fresh fuel and store it properly to avoid deterioration and engine problems. |

| Inspect Components | Periodically examine all elements for signs of wear and replace any damaged parts promptly. |

| Proper Storage | Store equipment in a dry, sheltered location to protect it from moisture and temperature extremes. |

| Follow Manufacturer’s Guidelines | Adhere to the recommended maintenance schedule to ensure optimal performance and longevity. |

Resources for Trimmer Parts Information

Accessing accurate resources for equipment components is crucial for effective maintenance and repair. Whether you are seeking specific details or general guidance, a variety of platforms can enhance your understanding and streamline your search. This section aims to provide valuable information sources that cater to diverse needs.

Manufacturer Websites: The official sites of manufacturers often offer comprehensive resources, including user manuals, component catalogs, and troubleshooting guides. These can serve as a primary reference for identifying and ordering necessary components.

Online Forums and Communities: Engaging with online communities allows users to share experiences and solutions. Forums dedicated to equipment enthusiasts often provide insights, tips, and recommendations that may not be found elsewhere.

Retailer Support: Many retailers provide dedicated support for their products. They can assist with inquiries regarding component compatibility, installation instructions, and even replacement options. Checking with your local dealer or authorized distributor can yield useful information.

Video Tutorials: Platforms like YouTube host a wealth of instructional videos that cover various maintenance and repair topics. Visual aids can simplify complex tasks and help users better understand the assembly and disassembly processes.

Repair Guides: Numerous websites offer detailed repair guides tailored to specific models. These guides often include step-by-step instructions, tools needed, and troubleshooting tips, making them invaluable resources for users looking to perform their own repairs.

By utilizing these resources, individuals can enhance their knowledge and improve the longevity and performance of their equipment, ensuring that it remains in optimal working condition.