Regular upkeep of outdoor power tools is essential to ensure their long-lasting performance and reliability. When it comes to these machines, knowing how to replace and maintain individual elements can significantly extend their lifespan and improve efficiency. This guide focuses on the critical aspects of keeping such equipment in optimal condition by identifying and understanding its core elements.

Whether you’re a seasoned user or new to maintaining outdoor devices, having a clear understanding of the essential components is invaluable. This not only aids in troubleshooting but also allows for more informed decisions when it comes to replacements and repairs. In this guide, we will explore the key sections of various devices, helping you navigate through their internal structures.

By familiarizing yourself with the crucial elements that make up your equipment, you’ll be able to maintain smooth operation and tackle any potential issues with confidence. This knowledge is vital in preserving functionality and ensuring that your outdoor tasks are carried out efficiently.

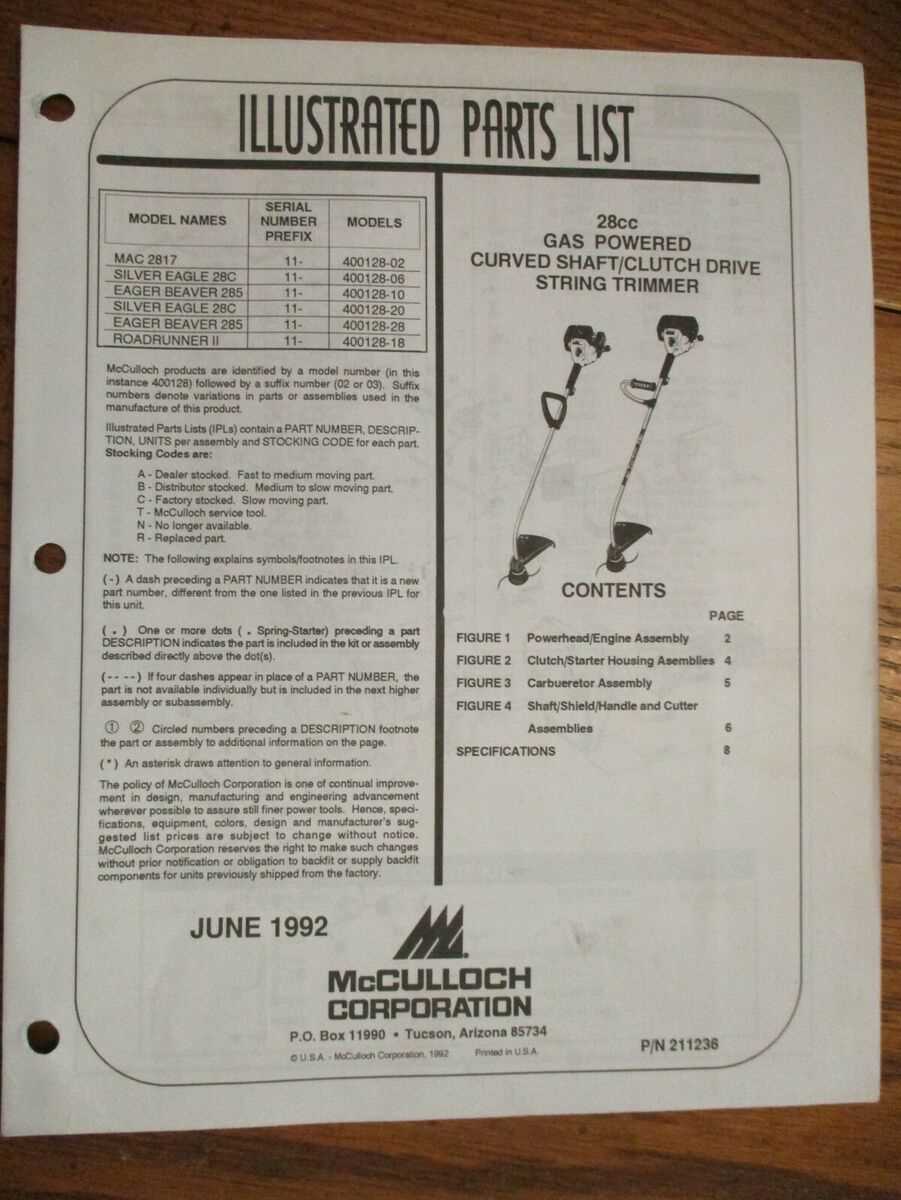

Mcculloch Trimmer Parts: Comprehensive Overview

Maintaining the efficiency and durability of garden equipment requires a clear understanding of its components. Each piece works together to ensure smooth operation, and knowing how they interact can significantly enhance the lifespan of your machine. From key mechanical elements to finer details, these elements play an essential role in keeping the tool functioning optimally. Understanding the importance of each part, as well as its role in the overall system, can make repairs and maintenance much simpler.

How to Identify Key Trimmer Components

Understanding the essential components of your lawn maintenance tool is crucial for efficient operation and upkeep. By learning to recognize these core parts, you can ensure smoother functionality, troubleshoot common issues, and replace worn elements as needed. This knowledge also helps when consulting manuals or ordering replacement pieces.

Main Structural Elements

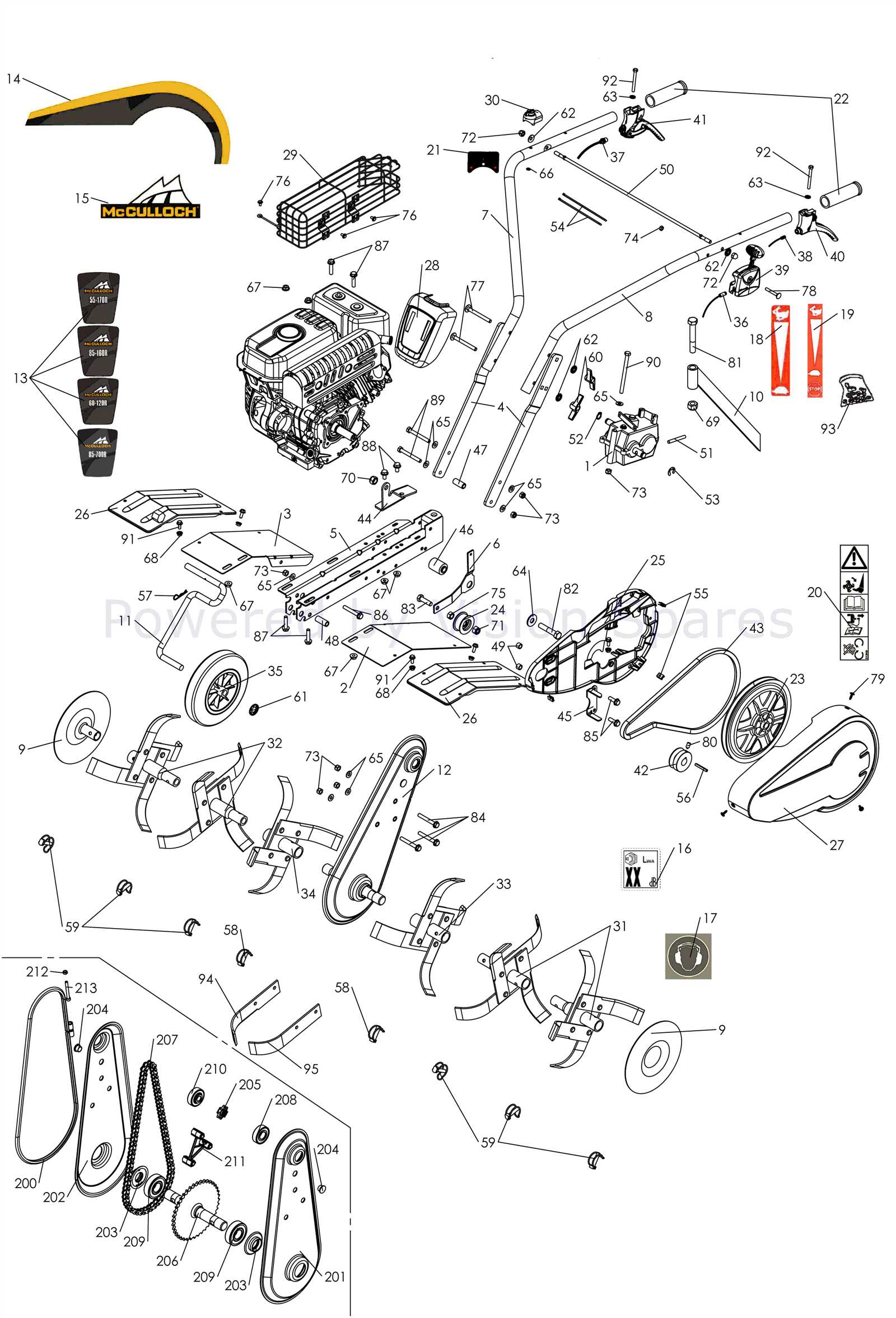

The primary structural elements include the engine housing, the handle, and the cutting mechanism. Each part plays a significant role in ensuring the tool operates effectively, from power generation to user control. Familiarity with these components allows for more precise handling and better performance.

Operational Mechanisms

Beyond the main structure, operational mechanisms like the fuel system, cutting line, and protective guard are equally important. These parts contribute to both the safety and efficiency of the tool. Inspecting and maintaining them regularly is key to extending the equipment’s lifespan.

| Component | Function | |||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

En

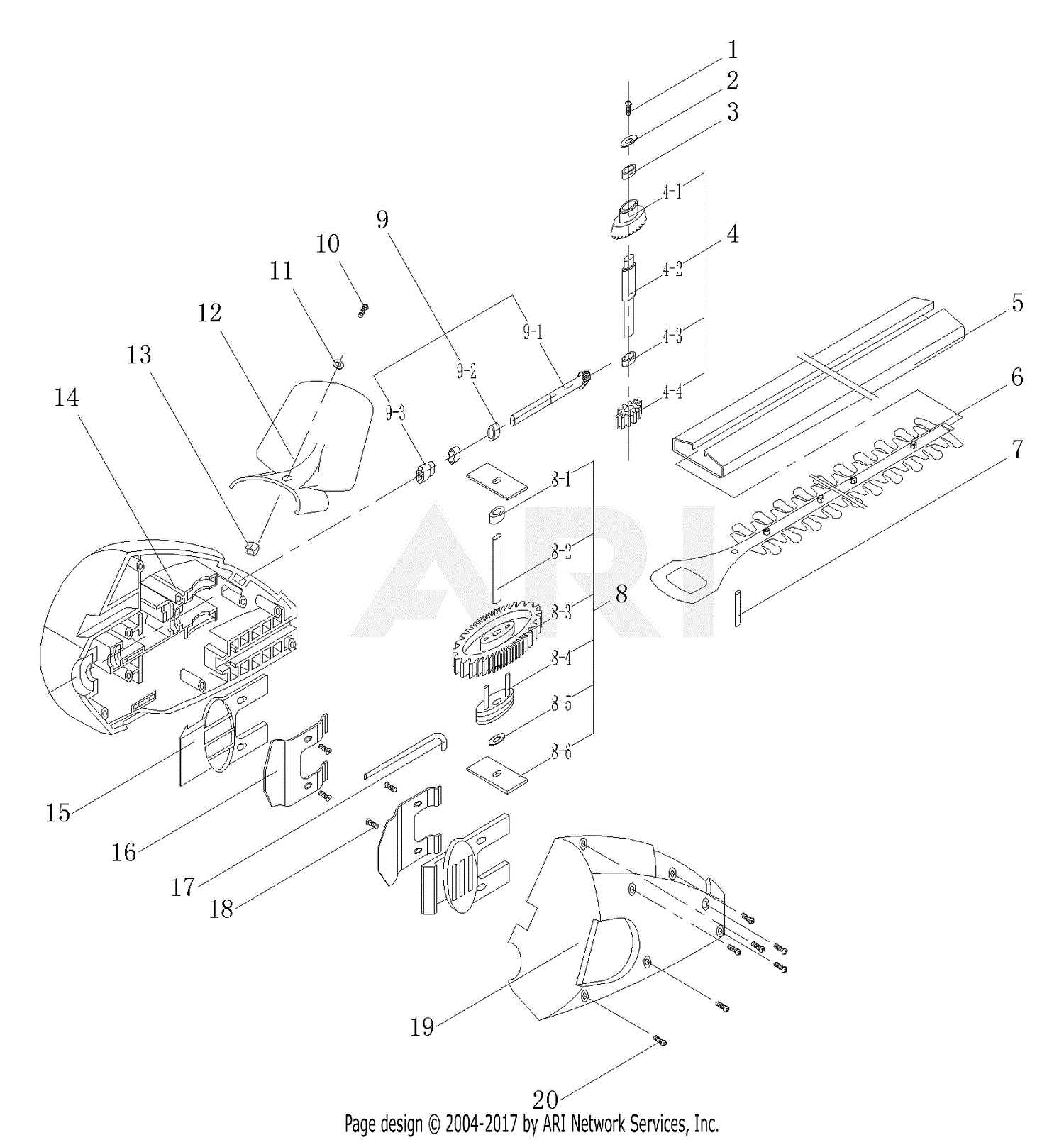

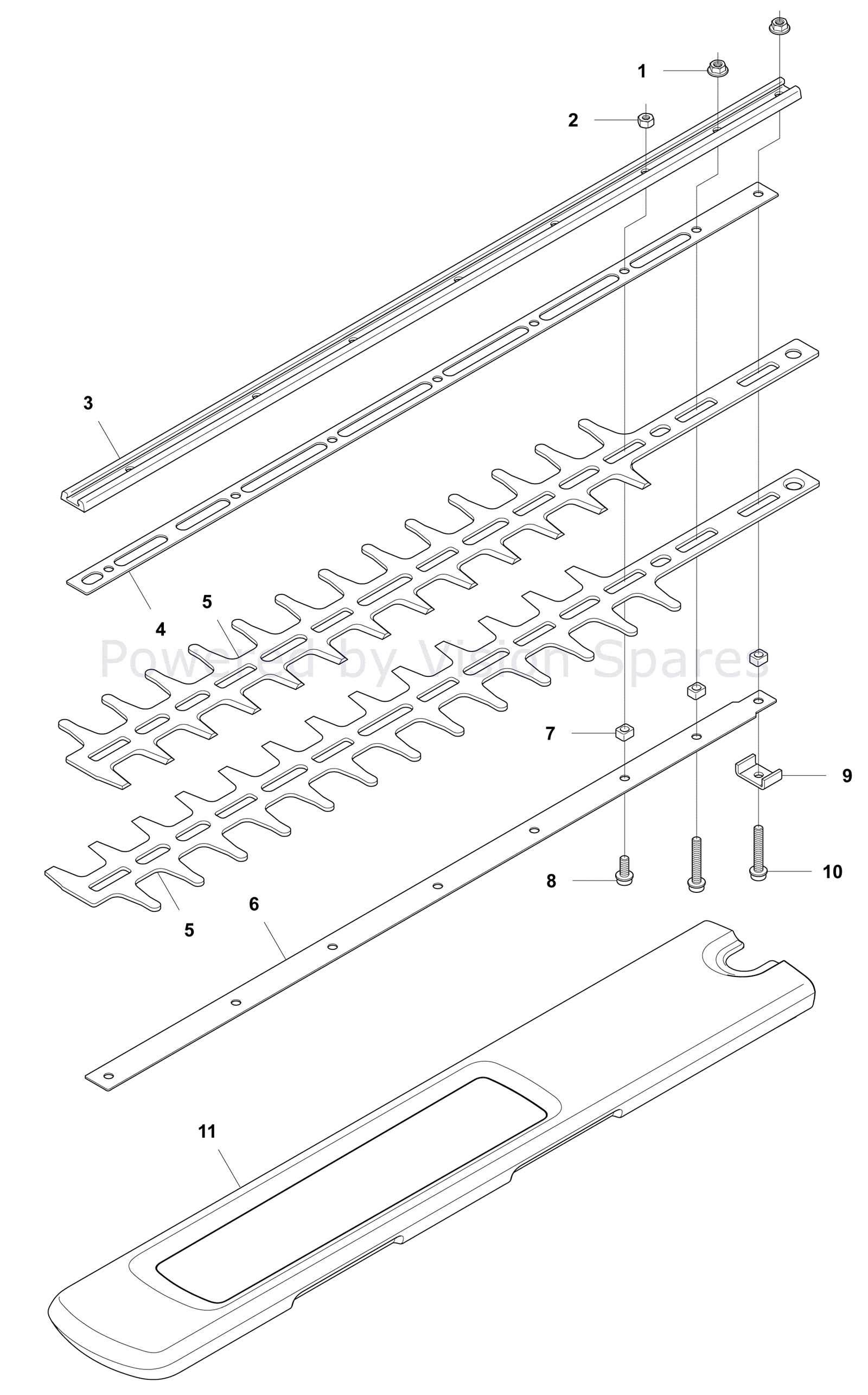

Understanding the Function of Cutting Blades

Cutting blades play a critical role in outdoor power equipment, ensuring smooth and efficient operation during vegetation management. Their sharp edges and strategic design make it possible to slice through various types of growth with ease. However, the effectiveness of these blades largely depends on understanding their structure and purpose. Key Features of Cutting BladesTo better appreciate their functionality, it’s important to consider the key elements that define cutting blades:

Proper Maintenance for LongevityRegular maintenance is essential for ensuring cutting blades remain sharp and effective over time. Blades should be inspected for Fuel System Parts and Their MaintenanceThe components that handle fuel delivery are essential for ensuring the proper operation of any machinery. Regular care and timely inspection of these elements help in preventing breakdowns and maintaining efficiency. Without attention to these key areas, the overall system can face issues that may disrupt performance. Key Elements in Fuel Delivery

Understanding the main elements responsible for fuel movement and distribution is important. Each component has its specific function, contributing to smooth operation. Regular check-ups and cleaning ensure that the machinery operates at its peak without unnecessary interruptions. Tips for MaintenanceMaintenance requires not just knowledge of the components but also careful handling. Cleaning, replacing worn-out parts, and checking connections are crucial steps. Timely interventions help prevent damage and prolong the lifespan of the system.

How to Replace the Trimmer Head EfficientlyReplacing the cutting head of your gardening tool is a straightforward process that can greatly enhance its performance. This task can be done quickly and without requiring professional assistance, allowing you to maintain your equipment with ease. Follow the steps outlined below to ensure a smooth and effective replacement. Preparation Steps

Replacement Process

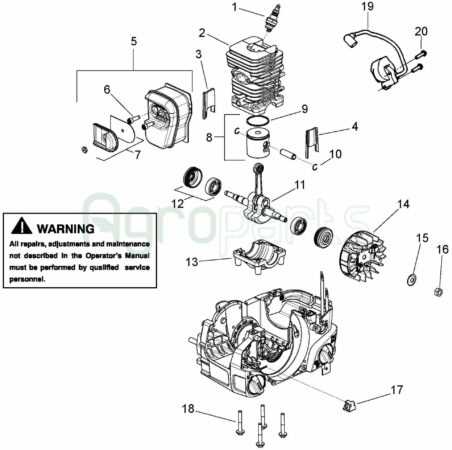

Regularly replacing the cutting head will not only improve your tool’s efficiency but also prolong its lifespan. Make this maintenance a part of your routine care to achieve optimal results in your gardening tasks. The Role of the Carburetor in Engine PerformanceThe carburetor serves as a crucial component in the overall efficiency and functionality of an internal combustion engine. Its primary responsibility is to mix air and fuel in the correct proportions to ensure optimal combustion. This balance is vital for maximizing power output and reducing emissions, making it a key player in engine performance. How the Carburetor FunctionsThe carburetor operates by utilizing several mechanisms to regulate the mixture of air and fuel. Here are the main functions:

Impact on Engine PerformanceThe effectiveness of the carburetor significantly influences engine performance. A well-calibrated carburetor contributes to:

Trimmer Line Types and Compatibility

Understanding the various types of cutting lines and their compatibility is essential for effective lawn care and maintenance. Selecting the right line can significantly enhance performance and ensure that your equipment operates efficiently. There are several types of cutting lines, each designed for specific tasks and conditions. For instance, some lines are round, providing a smooth cut for general trimming, while others are shaped like stars or squares, offering more aggressive cutting capabilities for tougher vegetation. Additionally, some lines are reinforced with materials like nylon or plastic for added durability. Compatibility is another crucial factor to consider. Not all lines are suitable for every piece of equipment, so it’s important to check the manufacturer’s recommendations. Ensuring that the selected line fits properly will not only improve cutting efficiency but also prolong the lifespan of your tools. Maintaining and Adjusting the Handlebar Assembly

Proper upkeep and adjustment of the handlebar assembly are crucial for optimal performance and user comfort during operation. Regular inspection and fine-tuning can significantly enhance maneuverability and control, allowing for a smoother experience. Inspection and CleaningBegin by checking the handlebar for any signs of wear or damage. Dirt and debris can accumulate, affecting functionality. A thorough cleaning with a damp cloth helps to maintain the integrity of the assembly. Pay attention to the grips, ensuring they remain secure and comfortable for prolonged use. Adjustment TechniquesAdjusting the handlebar height and angle is essential for ergonomics. This process typically involves loosening the adjustment knobs or screws, repositioning the handlebar to the desired height, and securely tightening the fasteners. Always ensure that the handlebar is aligned properly to prevent strain during operation.

|