When it comes to maintaining outdoor equipment for lawn care, it’s essential to be familiar with how each element functions within the whole system. Whether you’re dealing with a large cutting apparatus or a more compact device, having a clear understanding of the inner workings allows for better upkeep and more efficient operation.

By exploring the assembly of various sections, we can gain insight into how these machines achieve precise cutting and edging. Each mechanical piece has its specific role, contributing to the overall performance. Knowing how to identify and work with these individual elements can make a significant difference in prolonging the life of your equipment.

In this guide, we will break down the structure and look closely at each mechanical detail. This will give you a clearer view of how they function together to deliver reliable results, as well as how to address issues that may arise over time.

Swisher Trimmer Parts Overview

Maintaining outdoor equipment requires understanding the essential components that ensure smooth operation and longevity. By exploring the various elements that make up a well-functioning unit, users can perform effective upkeep, guaranteeing optimal performance across different tasks. Familiarity with key elements allows for quicker troubleshooting and more efficient maintenance.

Key Components

The structure of the unit includes several important parts that work together to provide consistent and reliable performance. These elements can be divided into different functional categories, each responsible for a specific role.

- Cutting mechanism: Includes blades or cutting lines that handle vegetation management efficiently.

- Drive system: Transmits power from the engine to the working tools, ensuring smooth operation.

- Protective casing: Shields both the user and the machinery from debris and potential damage during use.

- Power source: Whether gas or electric, this component powers the entire system.

The functionality and efficiency of any outdoor cutting equipment rely heavily on its key mechanisms. These essential elements work in unison to deliver precise cutting and optimal performance in various environments. Understanding the structure and the role of each component is crucial for maintenance and repairs.

Engine and Drive System

The engine serves as the powerhouse, converting fuel into the energy needed to rotate the cutting head. This drive system is responsible for transferring power to the blade, ensuring consistent and effective operation. Proper care and timely servicing of the engine are critical to maintaining long-term reliability.

Cutting Blade and Guard

The blade is the primary tool that handles the actual cutting, made from durable materials to withstand tough conditions. It is paired with a protective guard that shields the operator from debris while enhancing safety. Regular sharpening and proper adjustment of the blade ensure clean cuts and extended tool life.

Swisher Trimmer Cutting Mechanism

The cutting system operates with precision, ensuring efficient grass and vegetation control. The mechanism relies on a robust design that handles various terrains and plant densities, providing consistent performance in both light and heavy trimming tasks.

Blade assembly is engineered for durability, featuring sharp edges that maintain their effectiveness over time. These blades are capable of withstanding wear, reducing the need for frequent replacements. Their positioning allows for a smooth and even cut, minimizing strain on the device.

The rotation mechanism is driven by a powerful motor, which delivers enough force to the blades, enabling them to slice through thick foliage. This rotation is key to maintaining speed and precision, allowing for controlled operation even in challenging conditions. The entire cutting system is balanced to reduce vibrations, improving user comfort during extended use.

Engine Assembly and Its Role

The engine assembly plays a crucial part in powering and driving mechanical systems, ensuring efficient operation and performance. It combines various components that work together harmoniously to generate the necessary force and maintain functionality under diverse conditions.

Key elements of the engine assembly include:

- Cylinder Block – The main structure that houses pistons and supports other critical parts, providing the foundation for the engine’s operation.

- Pistons – These components move within the cylinder to convert energy from combustion into mechanical movement.

- Crankshaft – Connected to the pistons, it transforms their linear motion into rotational force, which is then transmitted to the rest of the system.

- Valves – Responsible for controlling the intake of air and fuel, as well as the expulsion of exhaust gases, ensuring proper combustion and efficiency.

- Blade Guard and Its Importance

The protective cover around the cutting element plays a crucial role in ensuring safe operation and durability. It helps to create a safer working environment by reducing potential risks associated with sharp blades. Additionally, it helps protect both the operator and surrounding objects from accidental contact with the cutting edge.

Another essential function of the guard is to extend the life of the cutting tool. By preventing debris from making direct contact with the blade, it reduces wear and tear, allowing for more consistent performance over time.

Function Benefit Safety Prevents accidental injuries and protects nearby objects. Durability Minimizes blade wear from debris, extending tool life. Performance Maintains cutting Handle and Control Functions

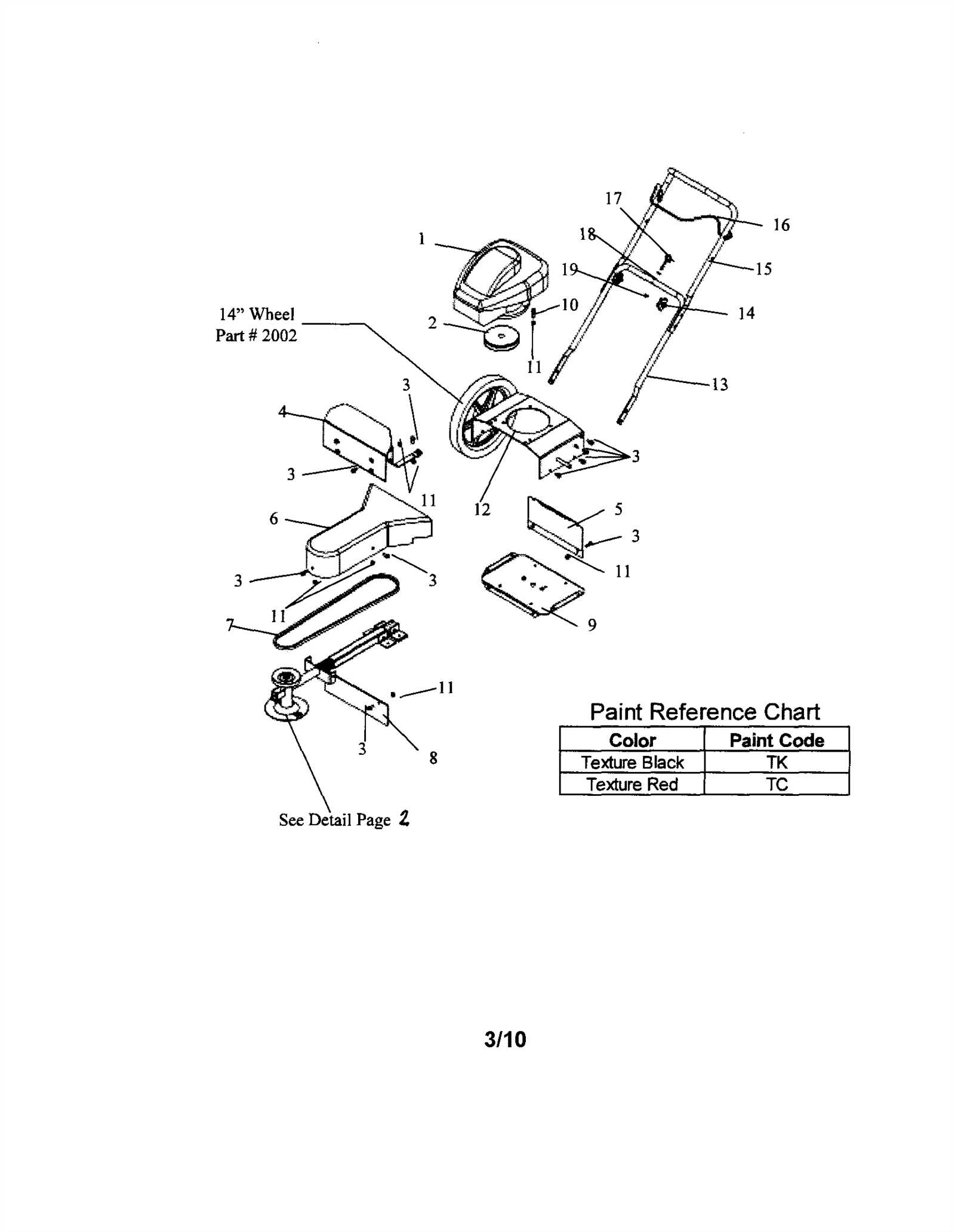

The functionality and efficiency of any outdoor power equipment heavily rely on the design and operation of its handle and control mechanisms. These components are essential for user interaction, allowing for precise maneuvering and management of the device during use. Understanding these elements is crucial for ensuring optimal performance and comfort while operating.

Ergonomic Design

Modern machinery often incorporates ergonomic principles in the construction of handles. This approach minimizes user fatigue and enhances control during extended usage. Comfortable grips allow for a secure hold, reducing the risk of slippage and improving overall handling. Features such as adjustable heights and angles can further enhance the user experience, accommodating various body types and preferences.

Control Mechanisms

The effectiveness of control systems directly influences operational ease. Controls are typically designed to be intuitive, enabling users to start, stop, and adjust the machine with minimal effort. Key features may include throttle control, safety switches, and locking mechanisms that enhance safety while providing quick access to essential functions. A well-designed control interface ensures that users can maintain focus on their tasks without distraction.

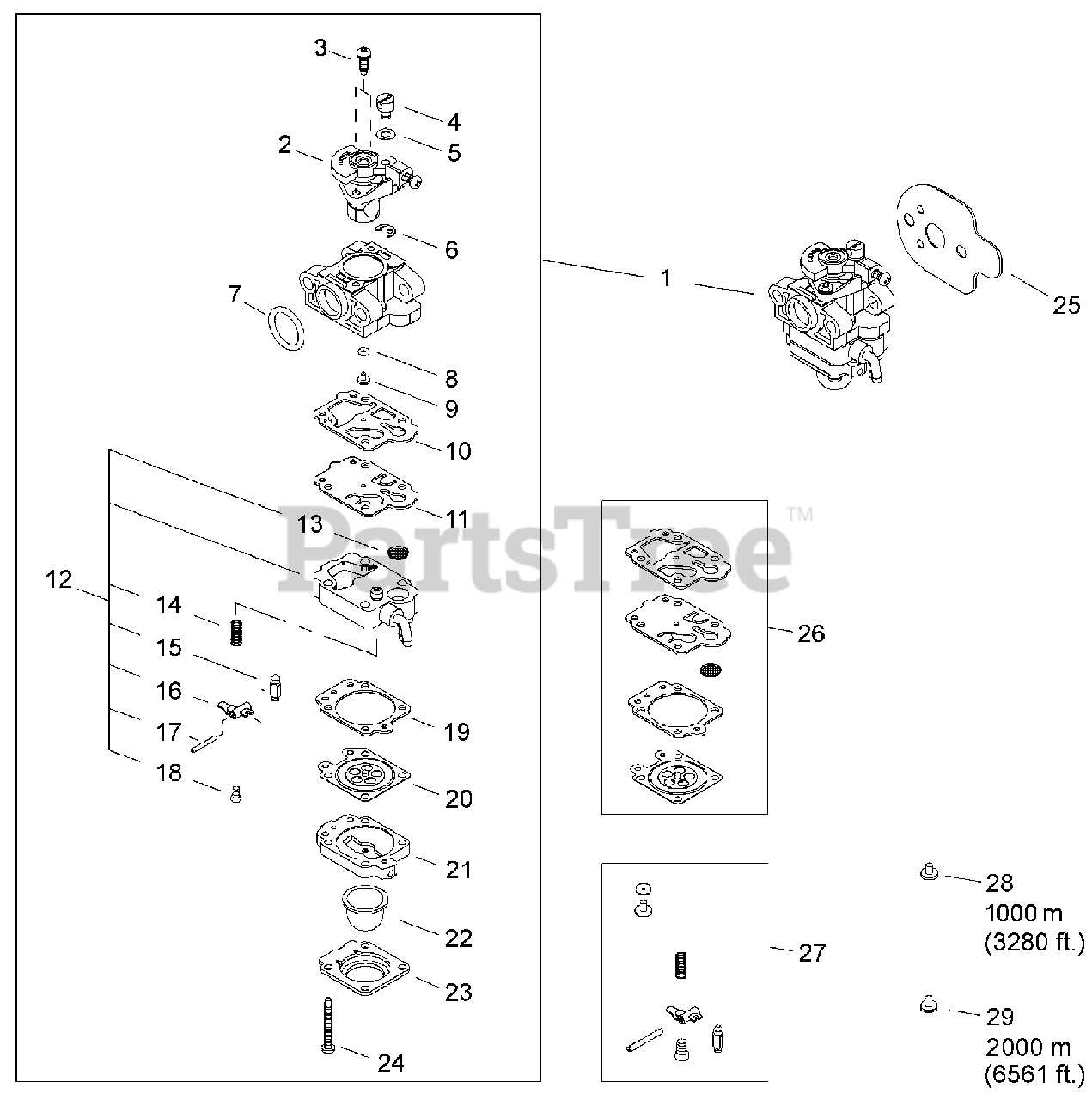

Fuel System Breakdown

The fuel system is a critical component of small engines, responsible for delivering the necessary energy for operation. Understanding its structure and functionality is essential for efficient maintenance and troubleshooting. This section delves into the various elements that make up the fuel system, highlighting their roles and how they interact to ensure optimal performance.

Components of the Fuel System

The fuel system comprises several key components, including the fuel tank, lines, filter, and carburetor. The fuel tank stores the gasoline, which is then transported through lines to the filter, where impurities are removed. The cleaned fuel is directed to the carburetor, where it mixes with air to create a combustible mixture that powers the engine.

Common Issues and Maintenance Tips

Regular inspection of the fuel system can prevent many operational problems. Common issues include clogged filters, damaged fuel lines, and carburetor malfunctions. Ensuring that the fuel is fresh and free from contaminants, along with periodically replacing the filter, can significantly enhance the system’s reliability and longevity.

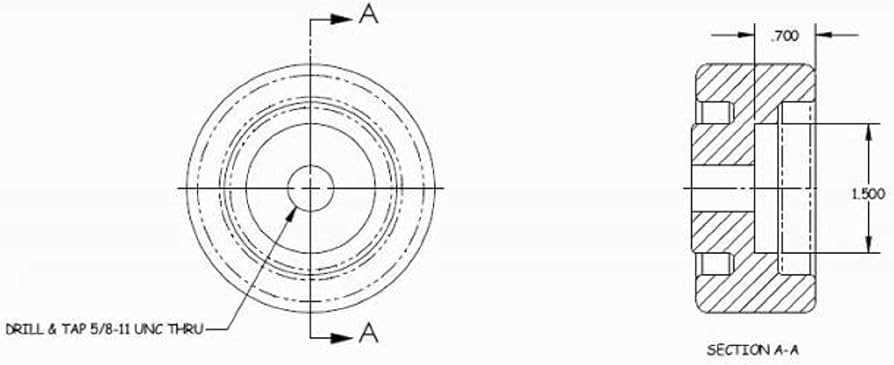

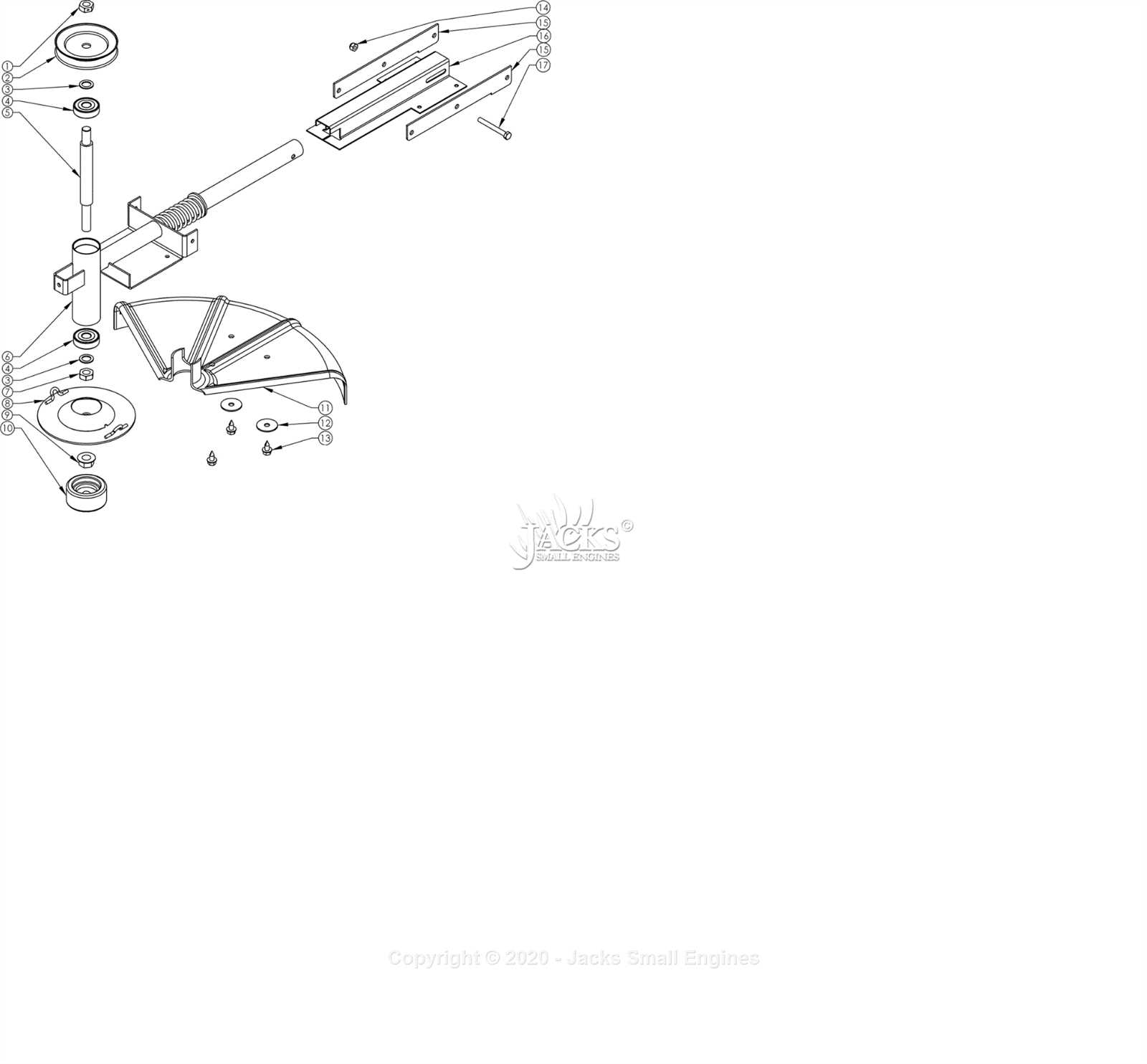

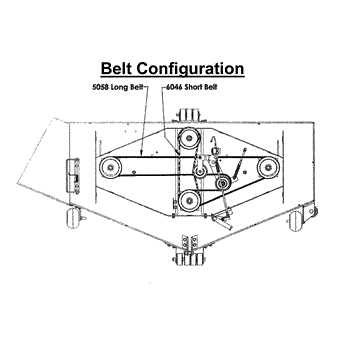

Swisher Trimmer Drive Belt Diagram

This section focuses on the essential components of the drive mechanism that transfers power to the cutting tool. Understanding how these elements interact is crucial for maintenance and repairs.

Drive Belt Overview

The drive belt is a vital component that facilitates the transfer of motion from the engine to the cutting mechanism. Its proper functioning ensures efficient operation and performance. Key features include:

- Material durability for extended use

- Correct tensioning to prevent slippage

- Appropriate alignment to minimize wear

Maintenance Tips

Regular inspection and maintenance of the drive belt are important for optimal functionality. Consider the following recommendations:

- Check for signs of wear and tear.

- Ensure proper tension is maintained.

- Replace the belt if fraying or cracking is observed.

Wheels and Their Impact on Mobility

The design and functionality of wheels play a crucial role in enhancing the ease of movement for various equipment. Their construction affects not only the efficiency of operation but also the overall experience of the user. Understanding how different wheel characteristics influence mobility is essential for optimizing performance.

Wheels come in various sizes and materials, each suited for specific environments and tasks. The diameter, tread pattern, and composition significantly impact traction and stability, making it vital to select the right wheels for the intended application.

Wheel Type Material Ideal Terrain Benefits Standard Wheels Rubber Paved surfaces Good traction and durability All-Terrain Wheels Polyurethane Grass, gravel Enhanced grip and shock absorption Swivel Wheels Plastic Indoor surfaces Easy maneuverability Heavy-Duty Wheels Metal Rough terrains Increased weight capacity and resistance Ultimately, the selection of wheels influences not only performance but also the safety and comfort of operation. By understanding the various options available, users can make informed choices that enhance mobility and efficiency in their tasks.

Throttle and Control Cable Details

The throttle and control cables play a crucial role in managing the performance and functionality of outdoor equipment. These components are responsible for transmitting signals from the operator to the machine, enabling precise control over speed and operation. Understanding their structure and function is essential for effective maintenance and troubleshooting.

Cable Types and Functions

There are primarily two types of cables utilized: throttle cables and control cables. Throttle cables regulate the engine speed by adjusting the flow of fuel or air, while control cables are used for various functions, such as engaging or disengaging mechanisms. Both types are designed to withstand harsh conditions and ensure reliable performance.

Maintenance Tips

Regular inspection of the cables for wear, fraying, or damage is vital for safe operation. Ensuring that the cables are properly lubricated and free from debris can prolong their lifespan. Additionally, any signs of malfunction should be addressed promptly to prevent further complications.

Protective Shields in Swisher Trimmers

Protective barriers play a crucial role in ensuring safety during outdoor maintenance activities. These components are designed to prevent debris and other hazardous materials from causing injury to the user. By effectively shielding vulnerable areas, they contribute to a safer working environment and enhance overall equipment functionality.

Typically constructed from durable materials, these barriers are strategically positioned to cover moving parts, safeguarding operators from potential contact. Their design often incorporates features that allow for optimal visibility while maintaining robust protection. Regular maintenance of these shields is essential to ensure their integrity and effectiveness over time.

Moreover, the presence of these safety elements not only enhances user confidence but also prolongs the lifespan of the equipment by minimizing wear and tear. It is advisable to consult the manufacturer’s guidelines for proper installation and maintenance practices, ensuring that the protective components remain functional and effective throughout their use.

Common Wearable Parts and Replacements

Regular maintenance is essential for optimal performance and longevity of outdoor equipment. Certain components are subject to wear over time, leading to diminished efficiency. Identifying and replacing these elements can significantly enhance functionality and reliability.

Cutting Blades

Cutting blades are among the most crucial components that experience significant wear. They are designed to endure tough conditions, but over time, they may become dull or damaged. Replacing these blades ensures a clean cut and prevents strain on the engine.

Air Filters

Air filters play a vital role in maintaining optimal airflow to the engine. Clogged or dirty filters can hinder performance, resulting in reduced power and efficiency. Regularly checking and replacing these filters can lead to improved air circulation and prolong the engine’s lifespan.

Lubrication Points and Maintenance Tips

Proper care and regular upkeep are essential for optimal performance and longevity of outdoor equipment. Ensuring that key components receive adequate lubrication not only minimizes wear and tear but also enhances functionality. This section outlines critical areas that require attention and provides helpful suggestions for maintaining equipment effectively.

Key lubrication points to consider include:

- Gearbox: Regularly apply a high-quality lubricant to prevent gear wear.

- Bearings: Inspect and grease bearings frequently to ensure smooth operation.

- Cables: Lubricate cables to reduce friction and prevent sticking.

- Chains: Use chain oil to maintain flexibility and prevent rust.

In addition to lubrication, here are some maintenance tips:

- Inspect Regularly: Frequently check for signs of wear, such as frayed cables or loose fittings.

- Clean Components: Remove debris and dirt from all parts to maintain efficiency and prevent damage.

- Replace Worn Parts: Address any worn or damaged components promptly to avoid further issues.

- Follow Manufacturer Guidelines: Adhere to the maintenance schedule provided by the manufacturer for best results.

By focusing on these lubrication points and maintenance practices, users can ensure their equipment operates smoothly and efficiently for years to come.